Novel flame-retardant high-strength heat-resistant magnesium alloy and preparation thereof

A magnesium alloy and high-strength technology, which is applied in the field of new flame-retardant, high-strength and heat-resistant magnesium alloys and their preparation, can solve the problems of single ignition point of the alloy, lack of flame retardant materials, strengthening and heat resistance, and limiting the application of magnesium alloys, and achieve performance improvement. , the effect of improving mechanical properties and improving ignition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

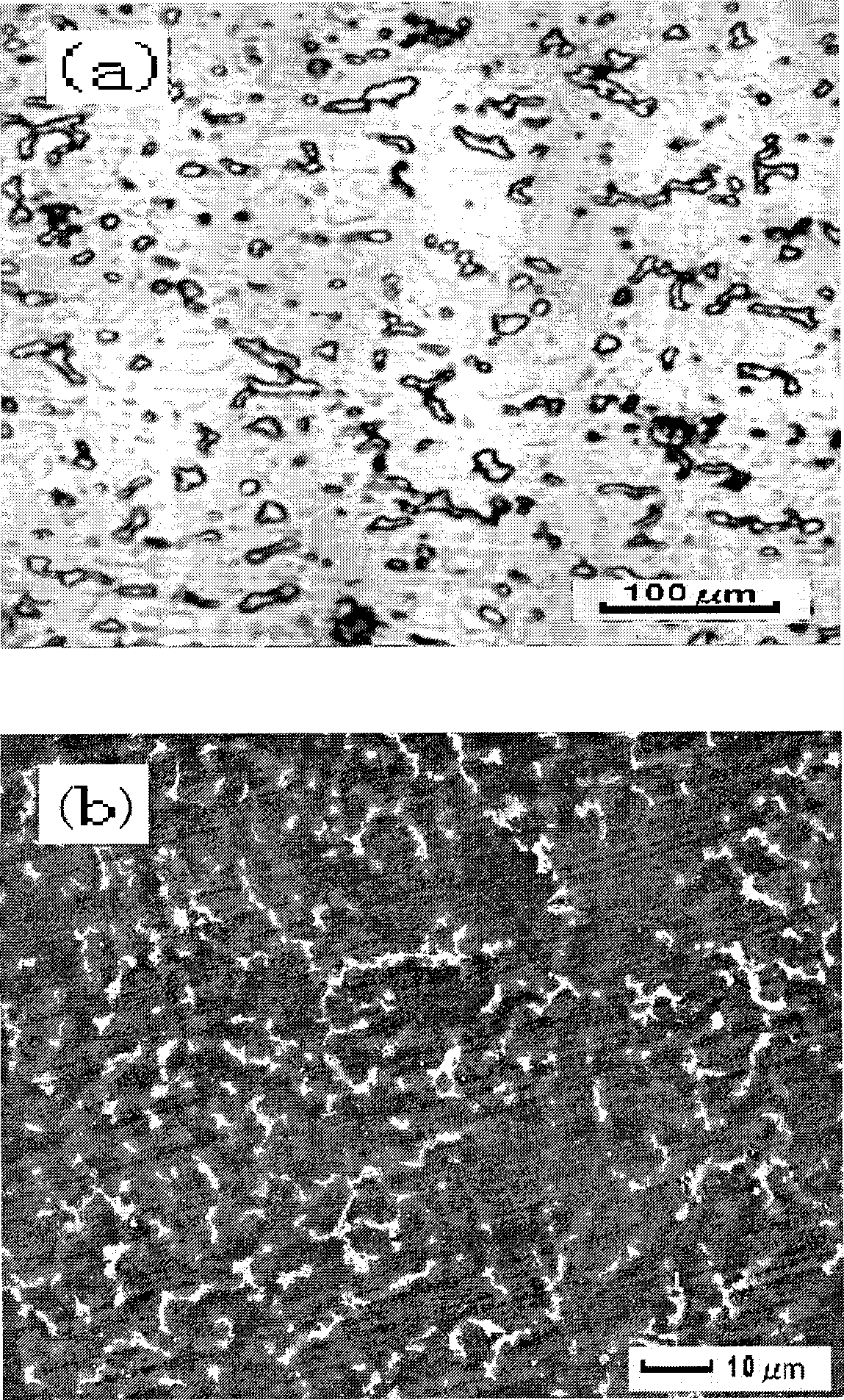

[0017] Preheat the smelting crucible to dark red, put 1Kg of AZ91D alloy and 270g of pure magnesium and other raw materials at 500℃, and pass in 99.2vol.% CO 2 +0.8vol.% SF 6 Mix the protective gas, and after the AZ91D alloy and pure magnesium (balance the excess Al caused by the addition of the master alloy) are melted, the temperature is increased to 740°C and the Al-50wt.%Ca master alloy 8g and Al- preheated to 200°C are added respectively. 26g of 10wt.% RE master alloy, 6g of Al-10wt.% Sr master alloy, and then cooled to 700°C for mechanical stirring, refining and slagging, standing for 10 minutes and then casting to obtain AZ91D+0.3wt.%Ca+0.2 wt.% RE+0.05wt.% Sr alloy. figure 1 The light microscope and scanning electron microscope photos of the alloy organization. Tests show that the alloy has an ignition point of 740°C, a hardness of HB 72, a room temperature tensile strength of 172MPa, a 150°C tensile strength of 159MPa, and a 250°C tensile strength of 136MPa.

Embodiment 2

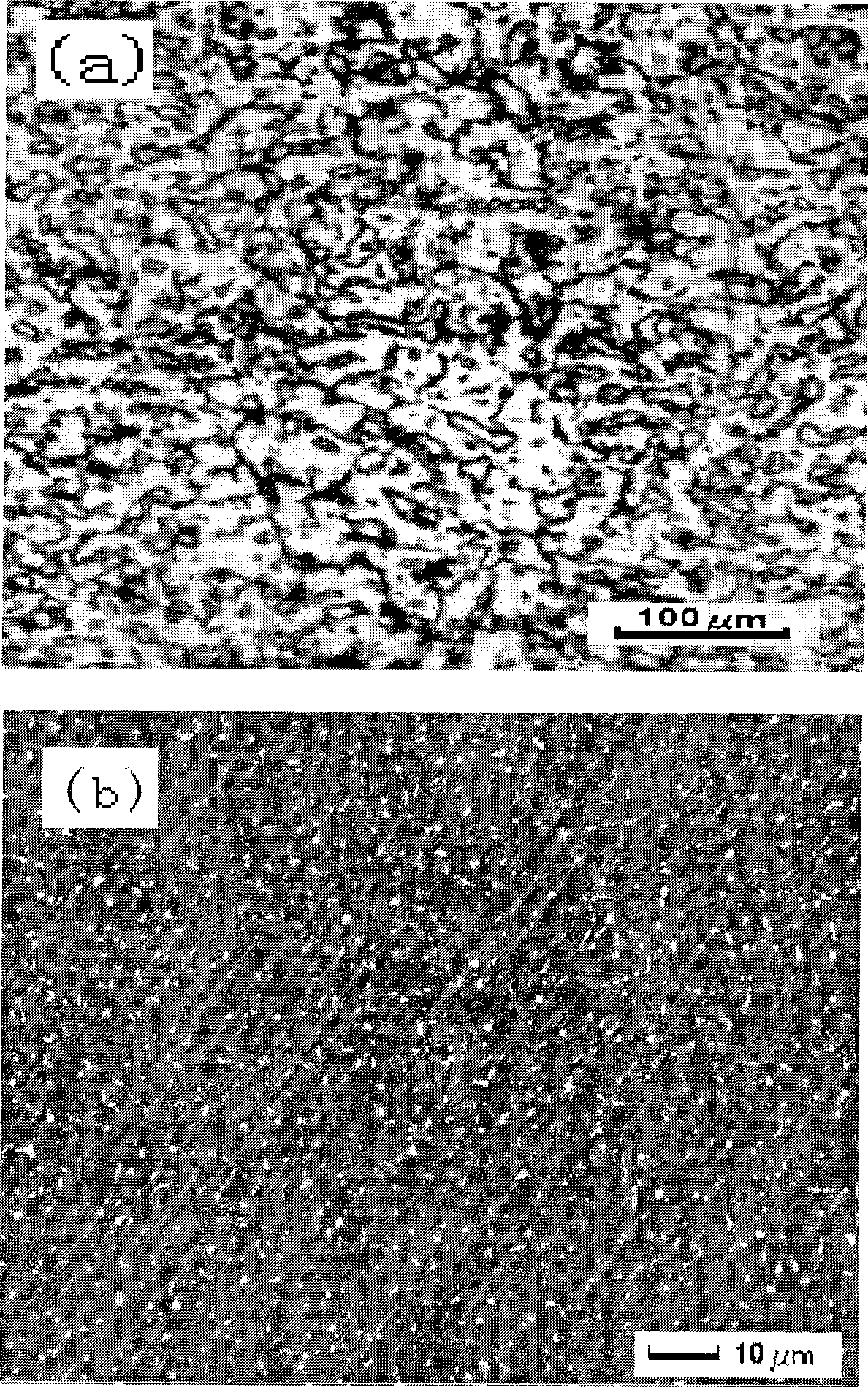

[0019] The specific test procedure is the same as that of specific example 1, in which 1Kg of AZ91D alloy and 800g of pure magnesium are first added, and the added master alloys are 38g of Al-50wt.%Ca master alloy, 95g of Al-20wt.%RE master alloy, and Al-10wt. .% Sr master alloy 19g. The AZ91D+1.0wt.%Ca+0.8wt.%RE+0.1wt.%Sr alloy was prepared. figure 2 The light microscope and scanning electron microscope photos of the alloy organization. Tests show that the alloy has a ignition point of 866°C, a hardness of HB86, a room temperature tensile strength of 211MPa, a 150°C tensile strength of 183MPa, and a 250°C tensile strength of 156MPa.

Embodiment 3

[0021] The specific test procedure is the same as that of specific example 1, in which 1Kg of AZ91D alloy and 400g of pure magnesium are first added, and the added master alloys are 15g of Al-50wt.%Ca master alloy, 37g of Al-20wt.%RE master alloy, and Al-10wt. .% Sr master alloy 23g. The AZ91D+0.5wt.%Ca+0.5wt.%RE+0.15wt.%Sr alloy was prepared. Tests show that the alloy has an ignition point of 786°C, a hardness of HB 90, a room temperature tensile strength of 212MPa, a 150°C tensile strength of 180MPa, and a 250°C tensile strength of 158MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com