Low-cost 63% IACS high-conductivity duralumin conductor and manufacturing method thereof

A technology with high conductivity and manufacturing method, applied in the direction of cable/conductor manufacturing, conductive materials, conductive materials, etc., can solve the problems of increased manufacturing costs, achieve the effect of improving conductivity and reducing grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

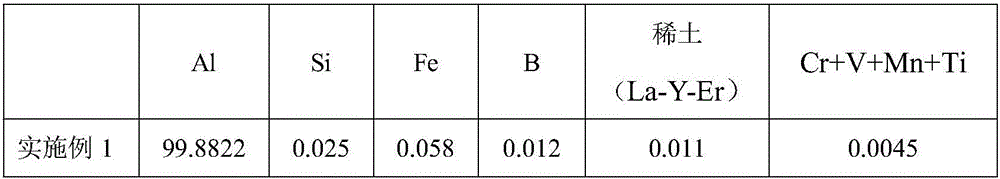

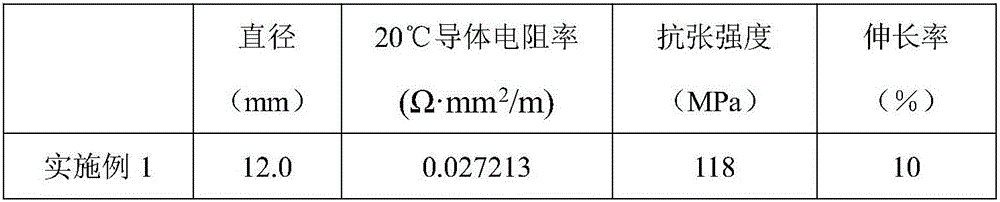

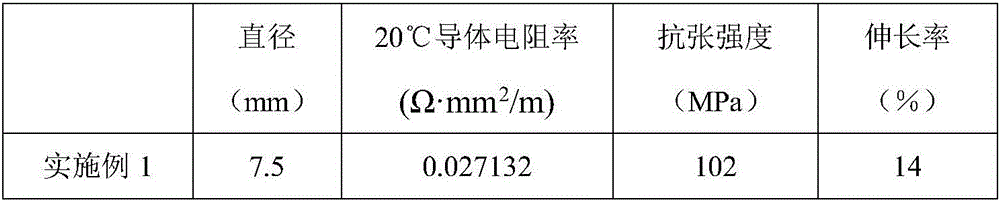

[0019] Detect the raw materials, select the brand as Al99.90 aluminum ingot 5T, take a sample for chemical analysis (see Table 1 for the composition), put it into the aluminum ingot smelting melt, and add 12kg of aluminum-boron alloy ingot with the brand of AlB8 in the holding furnace, the brand is AlY10 aluminum yttrium alloy ingot 12kg, brand AlLa10 aluminum lanthanum alloy ingot 15kg, brand AlEr10 aluminum erbium alloy ingot 12kg, through uniform stirring, refining and degassing, refining temperature 760 ~ 800 ° C, refining time 30 ~ 45 minutes, Remove slag, let it stand for 30-40 minutes, take samples for analysis, replenish materials in time according to the composition analysis results, and detect and control the content of each element (see Table 2); 500~520℃, rolled into a Φ12mm aluminum rod, the performance of the aluminum rod is shown in Table 3; the Φ12mm aluminum rod is extruded under high temperature and high pressure at 400~450℃ to obtain Φ7 .5 aluminum rod, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com