Preparation method of P-type zinc oxide micro/nano fibers

A micro-nano fiber, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problem that the P-N junction structure of semiconductor devices cannot be obtained, limit the development and application of zinc oxide-based optoelectronic devices, acceptor Low solid solubility of impurities, etc., to achieve the effect of environmental friendliness, low cost and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

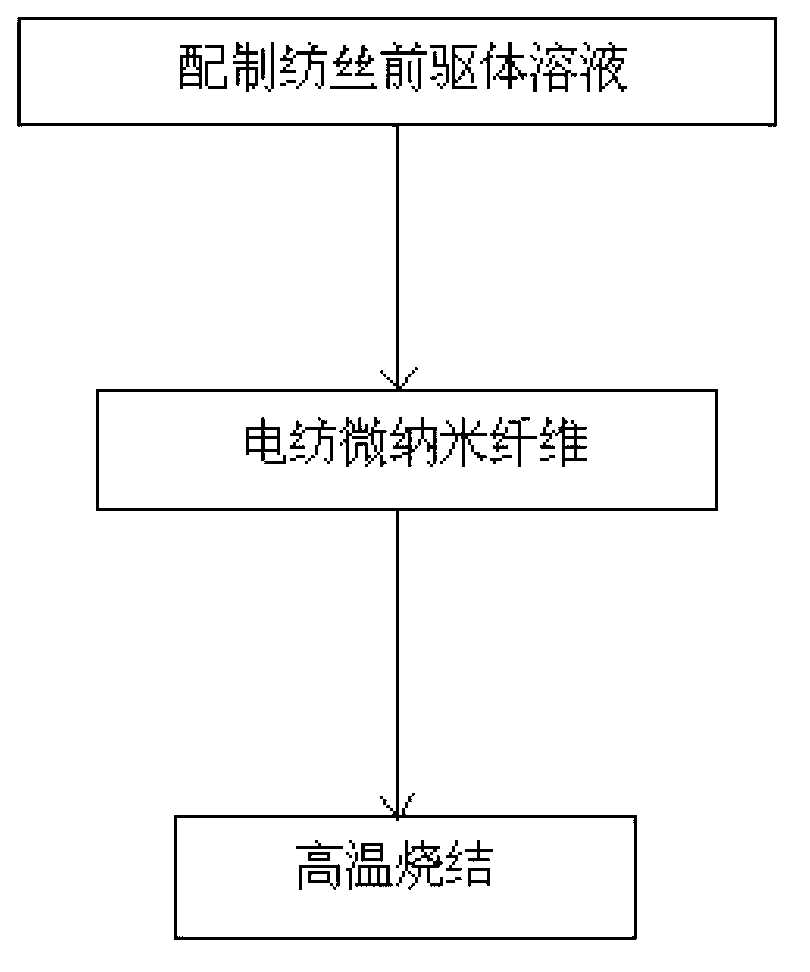

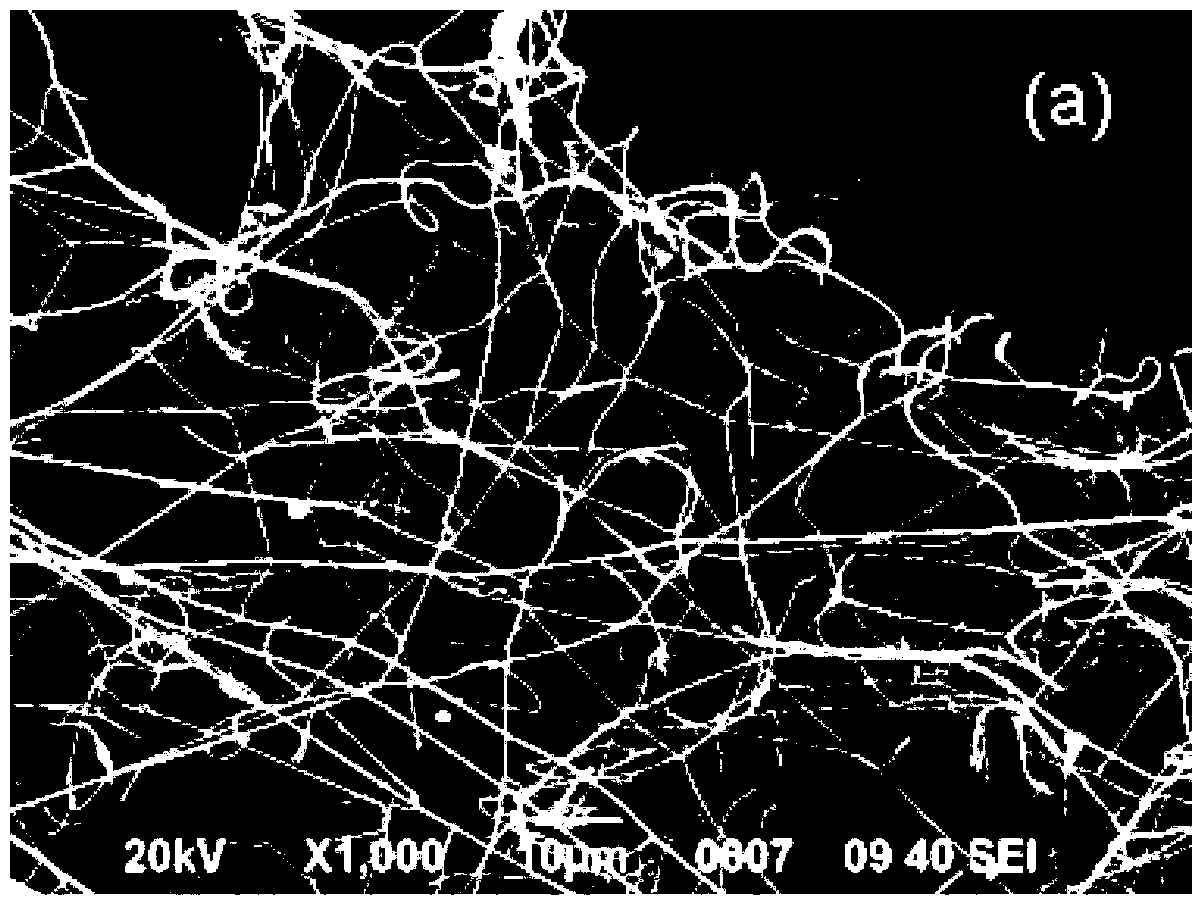

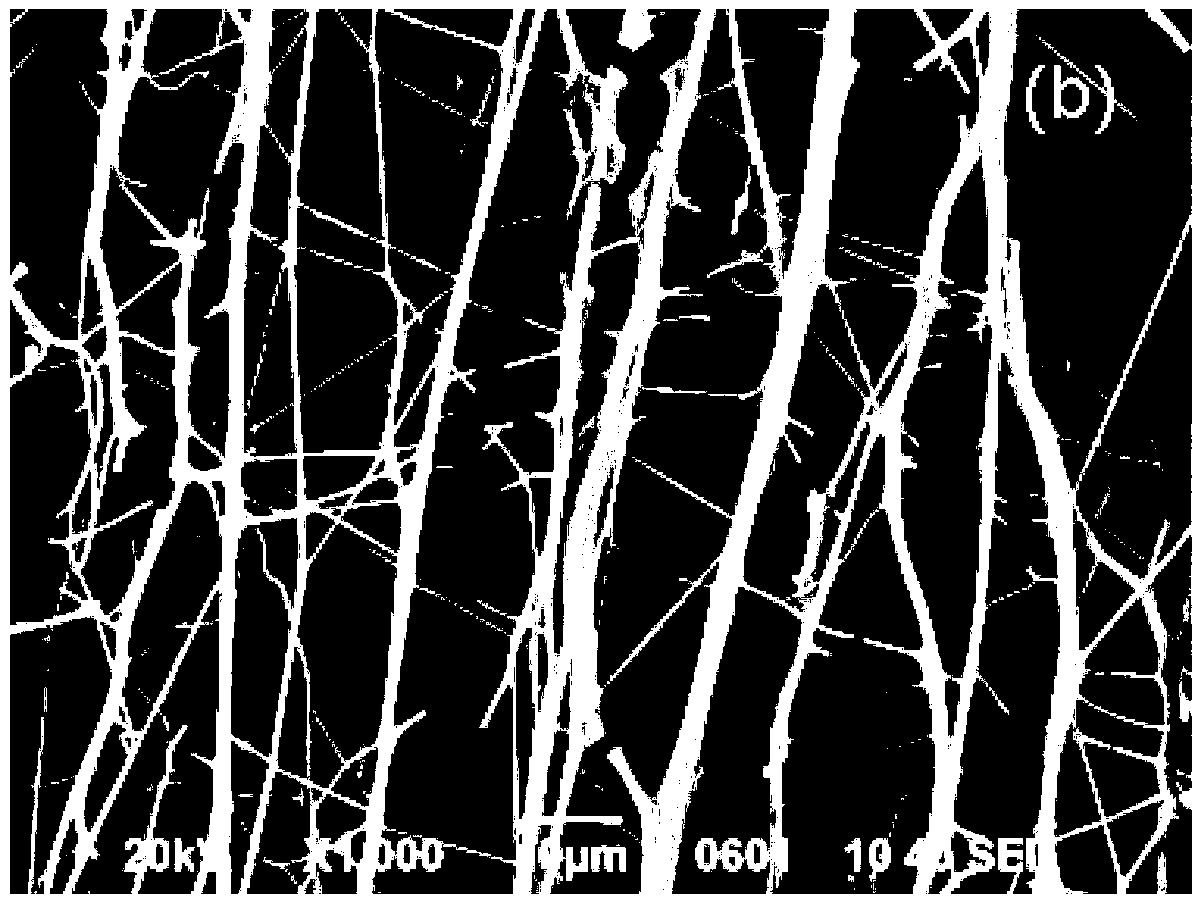

[0018] In this example, the electrospinning method can be used to dope different acceptor impurities to form a P-type zinc oxide semiconductor. The prepared zinc oxide micro-nanofibers have good P-type semiconductor characteristics. The specific steps include preparing a spinning precursor solution, electrospinning Three steps of micro-nano fiber and high temperature sintering:

[0019] (1) Preparation of spinning precursor solution: first select the preparation occasion where the ambient temperature is 15 °C and the humidity is 43% RH, and use an electronic balance to weigh 8.5 grams of anhydrous ethanol and 1.5 grams of polyvinylpyrrolidone (PVP, molecular weight 1.3 million) , mix and stir in the conical flask for 3 hours and then stand for 1 hour to obtain a homogeneous and transparent 15wt% PVP ethanol solution, and then use an electronic balance to weigh 1.0 grams of zinc acetate solid, 2.0 grams of absolute ethanol, 0.2 grams of distilled water and 0.2 grams of distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com