Al-Zn-Mg-Cu aluminum alloy deformation-solid solution heat treatment technology

A solution heat treatment, aluminum alloy technology, applied in the field of deformation heat treatment of metal materials, deformation heat treatment process, can solve the problems of intensified recrystallization, unfavorable alloy strength, plasticity and fracture toughness, etc., to achieve convenient operation, plasticity and fracture toughness improvement , The effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

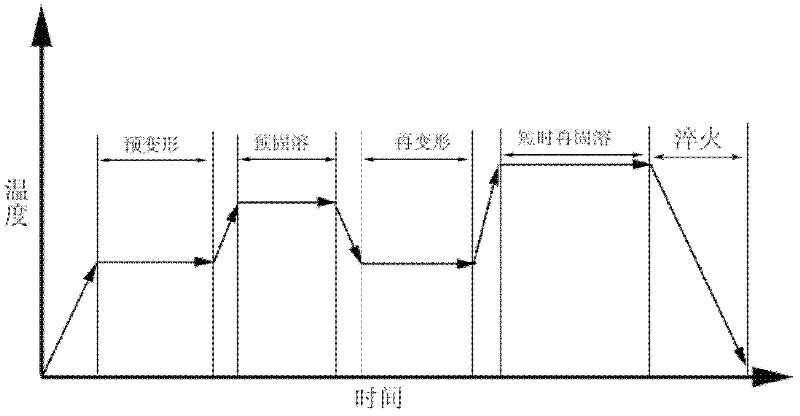

[0025] Embodiment 1-11 adopts the homogenized Al-7.5Zn-1.6Mg-1.5Cu-0.13Zr (mass fraction) aluminum alloy cast slab, adopts as attached figure 1 Deformation-solution heat treatment is carried out in the process flow shown, and the deformation amount, pre-solution and short-term re-solution conditions are specifically shown in Examples 1-11, and the aging treatment is carried out through a two-stage aging system (110°C / 6h+160°C / 10h ); Embodiment 12 adopts Al-6.5Zn-2.4Mg-2.2Cu-0.15Zr according to attached figure 1 The shown technological process carries out deformation, solution heat treatment, and deformation, solution and aging process are the same as embodiment 1; Embodiment 13 adopts Al-5.6Zn-2.5Mg-1.6Cu-0.23Cr, according to the attached figure 1 Deformation and solution heat treatment are carried out in the process flow shown, and the deformation, solution and aging processes are the same as in Example 1; the chemical composition of the alloy in Comparative Example 1 is the ...

Embodiment 2

[0030] The sample was pre-deformed by 10% at 400°C; then pre-solutionized at 440°C for 30 minutes; then deformed by 60% at 400°C; water-quenched at 470°C for 10 minutes; and finally double-stage aging.

Embodiment 3

[0032] The sample was pre-deformed by 95% at 400°C; then pre-solutionized at 440°C for 30 minutes; re-deformed by 60% at 400°C; water-quenched at 470°C for 10 minutes; and finally double-stage aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com