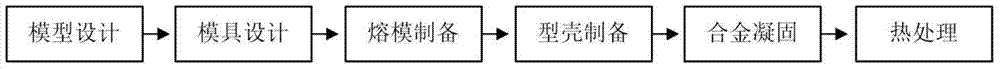

Method for determining shrinking percentages of investment pattern precision casting mold

A technology for mold shrinkage and determination method, which is applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of difficult casting accuracy, simple roughness, etc., to achieve the effect of improving accuracy, saving workload, and enriching the accuracy of design details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] step one:

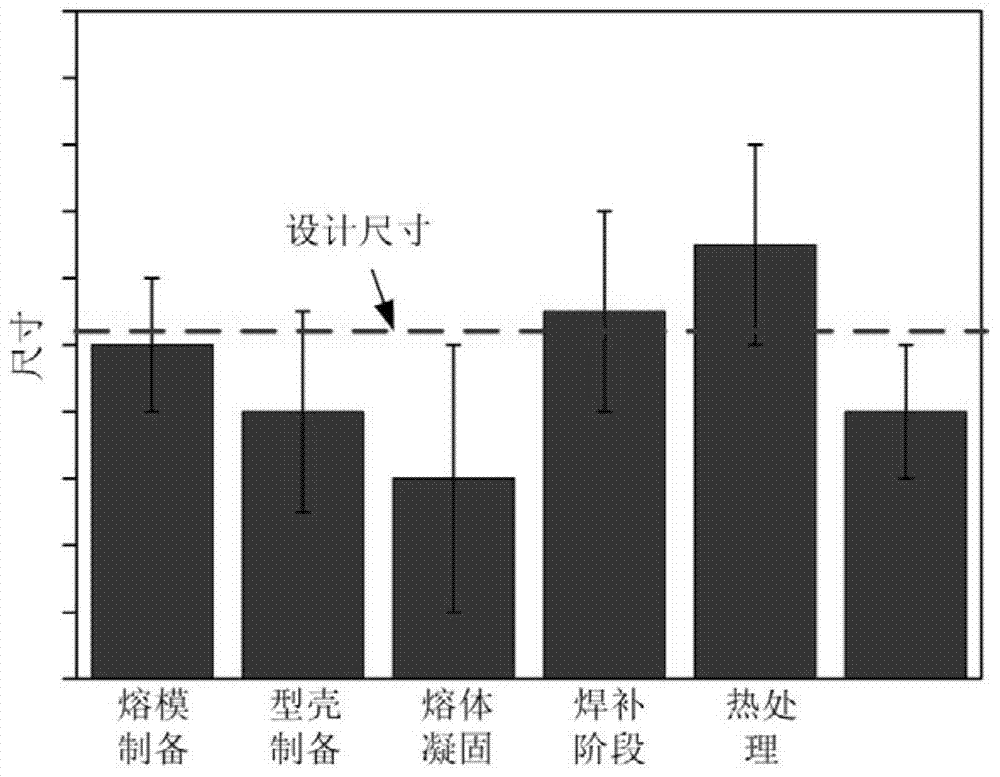

[0024] Moldflow was used to establish the model of the oblique support plate of the aero-engine casing, and the deformation cloud image of the investment mold preparation stage was analyzed and obtained. The simulated size of the flange outer diameter on the outer ring of the wax mold is 1002mm.

[0025] Step two:

[0026] ABAQUS is used to build a model for the casing preparation stage of the casing, the wax pattern cloud diagram deformed in the previous step is used as the input of this model to obtain the cavity deformation cloud diagram of the casing, and the outer diameter of the flange on the outer ring is measured to be 1005mm.

[0027] Step 3: Use ProCAST to establish a model for the alloy solidification stage of the casing. The inner cavity of the deformed shell in the previous step is used as the input of this model to obtain a cloud image of the deformed casting. The outer diameter of the flange on the outer ring is measured to be 998mm.

[0028] Step 4: U...

Embodiment 2

[0031] Step 1: Use Moldflow to establish the engine turbine model, analyze and obtain the deformation during the investment mold preparation stage. The measured maximum diameter of the wax mold is 257mm.

[0032] Step 2: Use ABAQUS to build a model for the turbine shell preparation stage, and use the wax pattern cloud image deformed in the previous step as the input of this model to obtain the shell cavity deformation cloud image. The measured maximum diameter is 259.2mm.

[0033] Step 3: Use ProCAST to establish a model for the solidification stage of the turbine alloy, and use the deformed shell cavity in the previous step as the input of this model to obtain a cloud image of the deformed casting. The measured maximum diameter is 260mm.

[0034] Step 4: Apply MSE.Marc to build a model for the heat treatment stage of the turbine, use the castings after solidification and deformation in the previous step as the input of this model, and obtain the cloud map of the castings after heat ...

Embodiment 3

[0037] Step 1: Use Moldflow to build a gas turbine triple blade model, and analyze and obtain the deformation during the investment mold preparation stage. Obtain the deformation profile of the blade wax mold after shrinking.

[0038] Step 2: Use ABAQUS to build a model for the preparation stage of the shell of the blade, and use the deformed wax pattern cloud image of the previous step as the input of this model to obtain the deformation cloud image of the shell cavity.

[0039] Step 3: Use ProCAST to build a model for the alloy solidification stage of the blade, and use the deformed shell cavity in the previous step as the input of this model to obtain a cloud image of the deformed casting.

[0040] Step 4: Use MSE.Marc to establish a model for the heat treatment stage of the blade, and use the castings after solidification and deformation in the previous step as the input of this model to obtain the cloud map of the castings after heat treatment.

[0041] Step 5: Cut the deformed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com