Positioning method and positioning tool for embedded part of T-beam sidewalk

A technology for positioning tooling and positioning methods, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of embedded part position deviation, embedded part offset, and poor position accuracy of embedded parts, so as to reduce internal stress and improve Installation efficiency, effect of reducing correction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

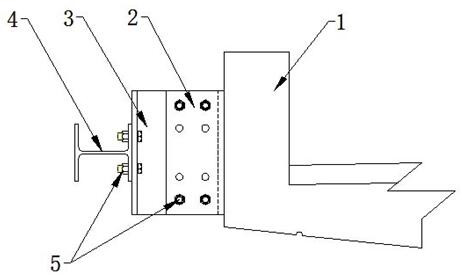

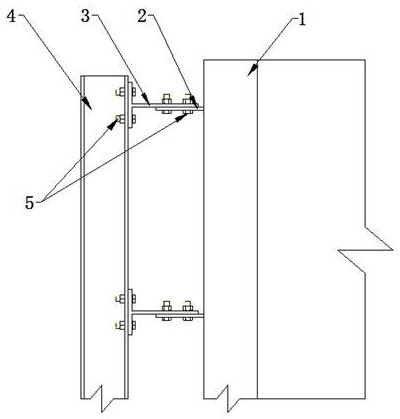

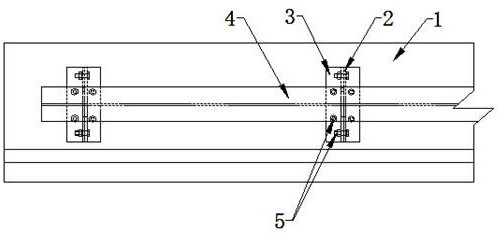

[0034] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0035] The existing positioning method of the embedded part 2 is to fix the embedded part 2 on the prefabricated template. When the T-beam prefabricated formwork is assembled, it will cause errors in the position of the embedded part 2; when the concrete is vibrated, the deformation of the T-beam prefabricated formwork will also cause the position of the embedded part 2 to deviate from the predetermined position; at the same time, due to the pushing of the concrete, It will also cause the embedded part 2 to shift. As a result, the positioning accuracy of the embedded part 2 is poor and deviates from the predetermined position. As a result, when the sidewalk is installed, the embedded part 2 needs to be corrected, and it needs to be matched or even installed on site. After installation, the sidewalk has structural internal stress, low installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com