Wire mesh cover automatic production equipment

An automatic production, wire mesh technology, applied in the direction of online network, household appliances, other household appliances, etc., can solve the problems of performance reliability, poor integrity, large overall space occupation, etc., to overcome the messy layout, high feeding efficiency, The effect of preventing wire entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

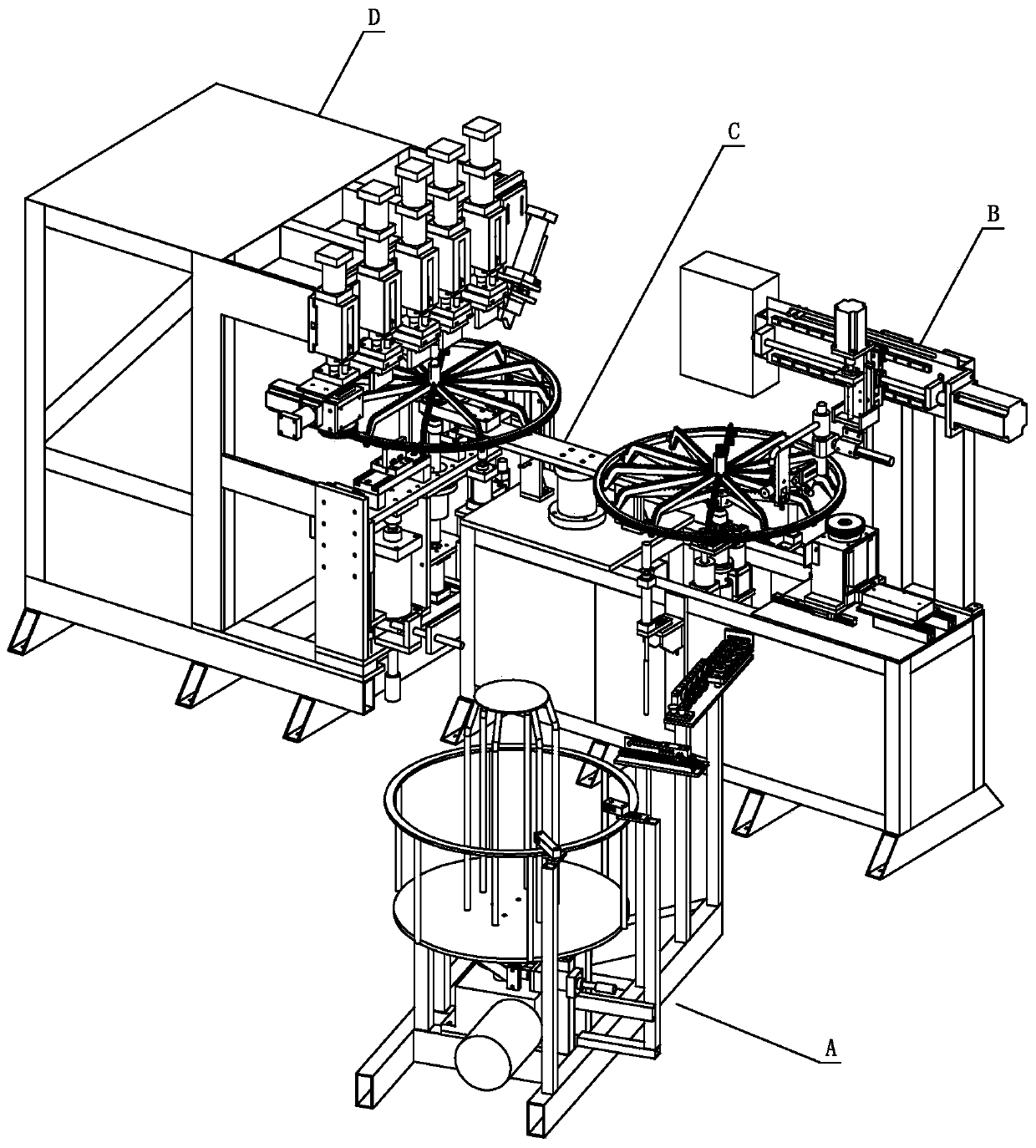

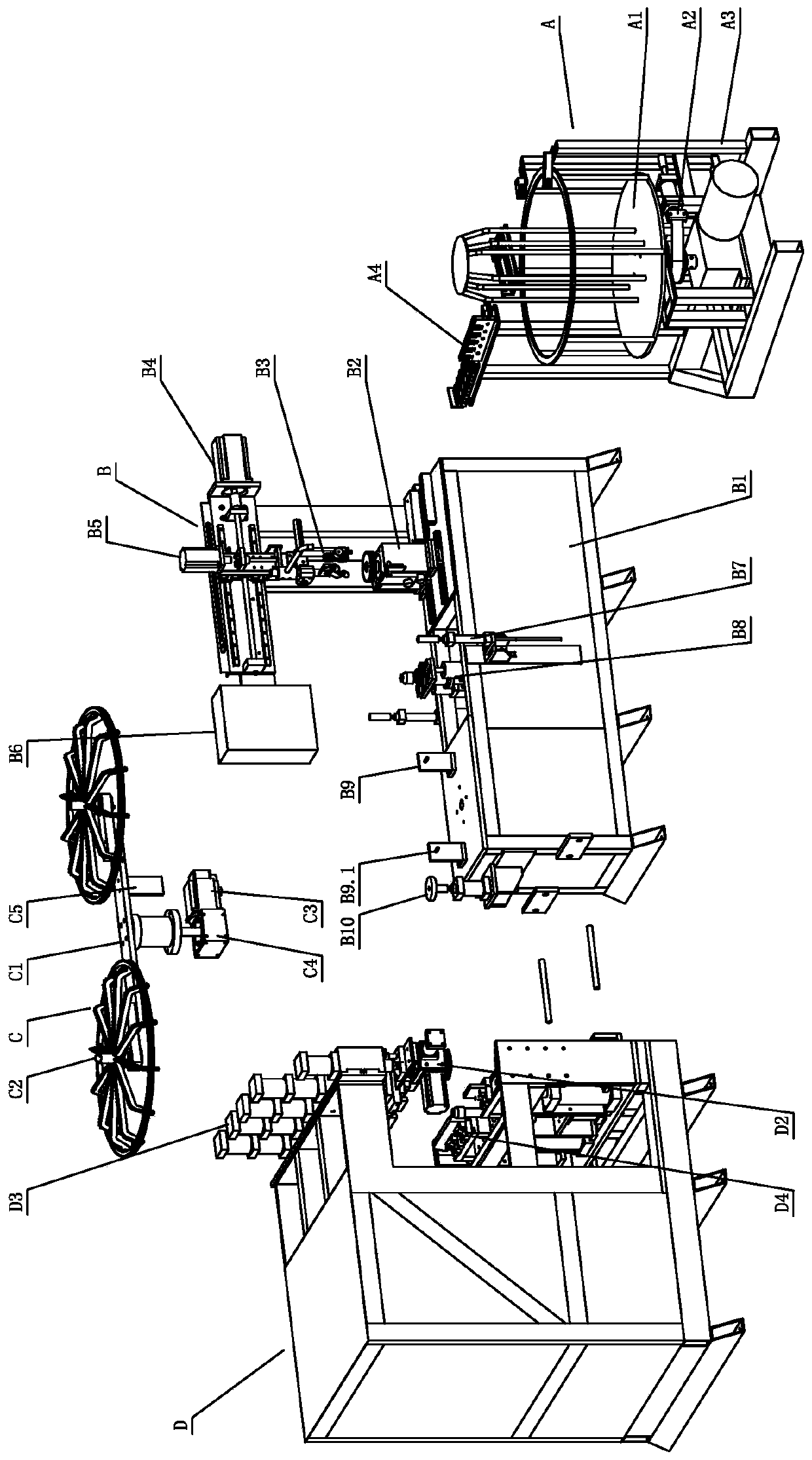

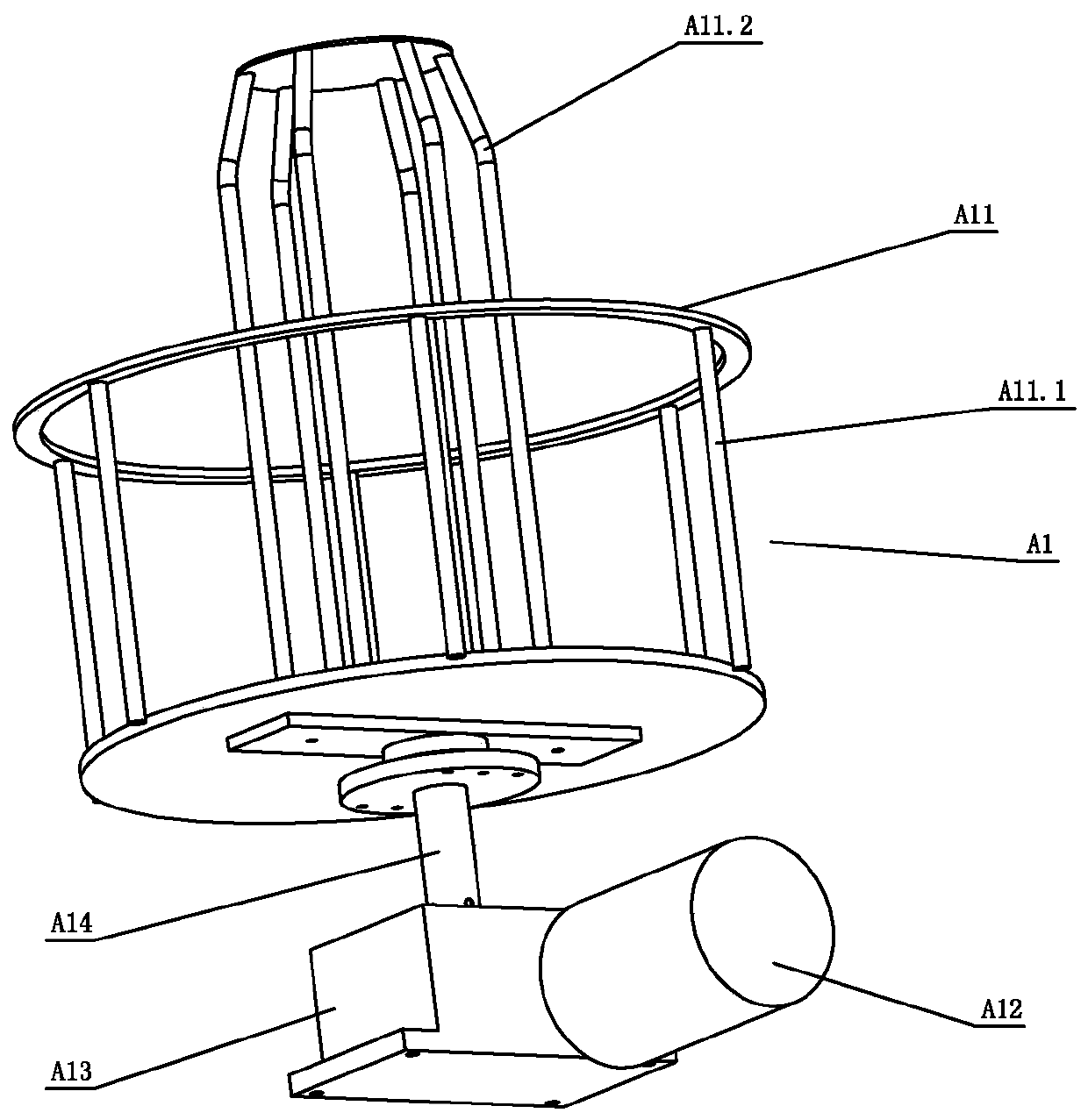

[0040] see Figure 1 - Figure 1 9. The processing object of this wire mesh cover automatic production equipment is a circular wire mesh cover. Its work is to arrange the metal wire E on the warp skeleton in an involute spiral manner, and then weld the metal wire E to the warp skeleton. The metal wire E is a steel wire; specifically, the automatic production equipment for the wire mesh cover includes a wire feeding system A, a wire arrangement system B, a station switching system C and a welding system D, and the station switching system C is located between the wire arrangement system B and the welding system. Between the systems D, the warp skeleton is alternately switched between stations; the station switching system C is set on the cable arrangement base B1 of the cable arrangement system B, and the cable arrangement system B and the welding system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com