The stents should satisfy to numerous requirement, some of which are in a certain contradiction to each other, which hinders a search for optimal solutions.

In addition to that, there exists many other additional requirements, among which it is necessary to point out an undesirability of using expensive technologies and materials for stent manufacturing, which increase the cost of an operation and is an obstacle for a

mass application of endoprosthetics.

But it complicates the course of operation and considerably increases expenditures for it; that is why this way has not found a wide application.

In many cases an additional difficulty is also caused by the necessity of using a small

diameter catheter during a delivery and installation of the stent.

An additional problem arises while designing small

diameter stents due to the necessity of using a small

diameter wire for their manufacturing, which requires providing for a necessary rigidity.

Thus, in order to overcome the above difficulties, it is necessary to develop such stents which, on the one hand, should create a same for deformed vessels, bile ducts, ducts and other tubular organs, and, on the other hand, would repeat the form of their bents without a rough straightening of organs being prostheticated, which can cause a

distortion of their

normal functioning.

However, geometrical dimensions of the cells will also change with that, which spoils a homogeneity of its reaction to the installation of the stent in a zone of a prostheticated organ contact with the stent, which can be the reason of post-operational complications.

In addition to that, an availability of a big number of rigid connection nodes of cells which render an undesirable local action upon a vessel for which a

prosthesis is made, can be the reason of complications.

The above rigid nodes also decrease the stent transformation possibilities, which limits the sphere of its application.

By that, this design does not have a high adaptability to a (streamlined) manufacturing.

This stent is distinguished by a better transformability compared to the preceding analogue; however it also does not allow to provide for a homogeneity of a reaction of an organ for which a

prosthesis is made in the place of the stent installation.

Besides, it also does not solve problems, related to the installation of the stent in bent sections of organs for which a

prosthesis is being made.

However, it also does not completely eliminate all the drawbacks inherent to the preceding analogue.

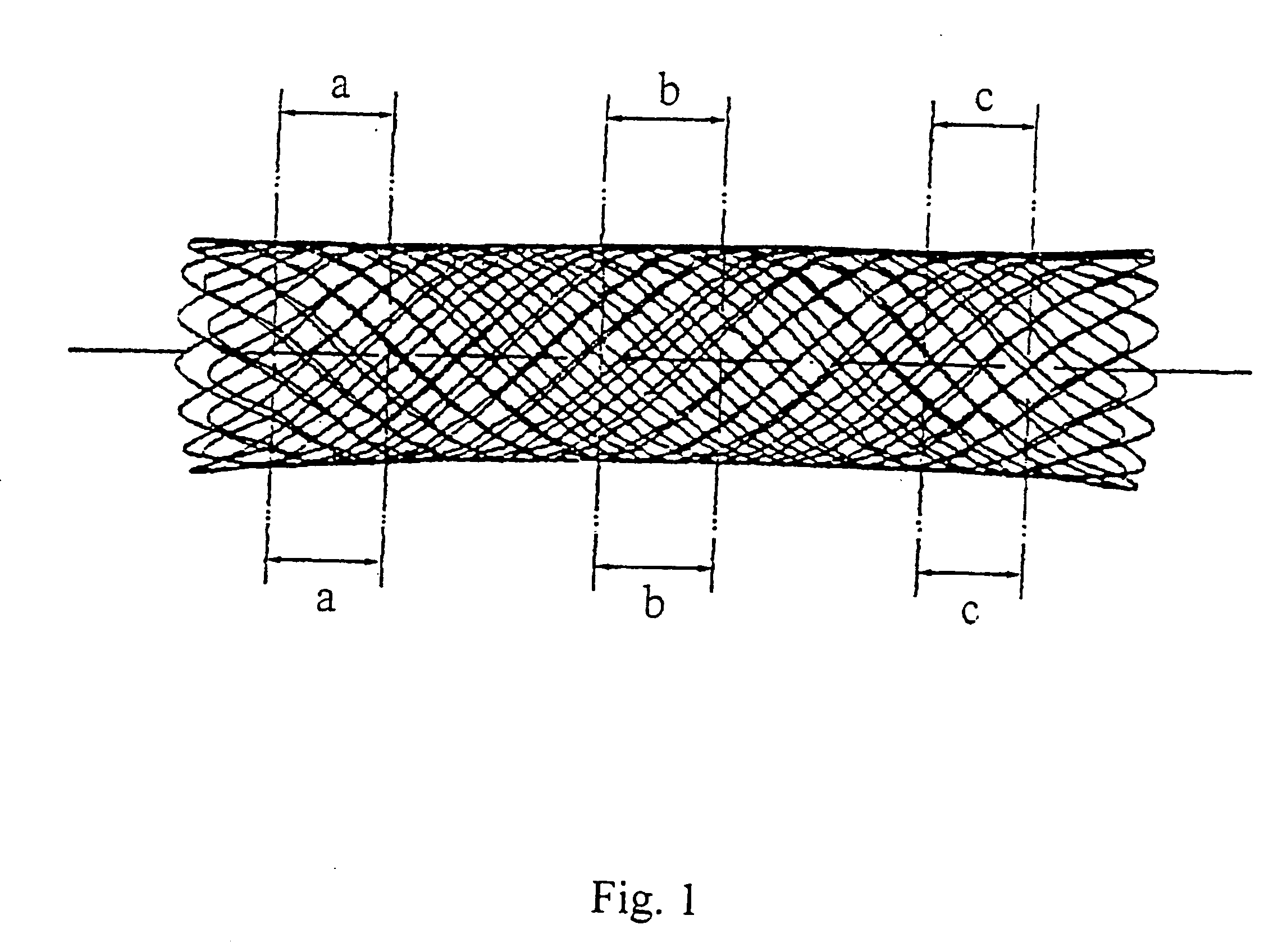

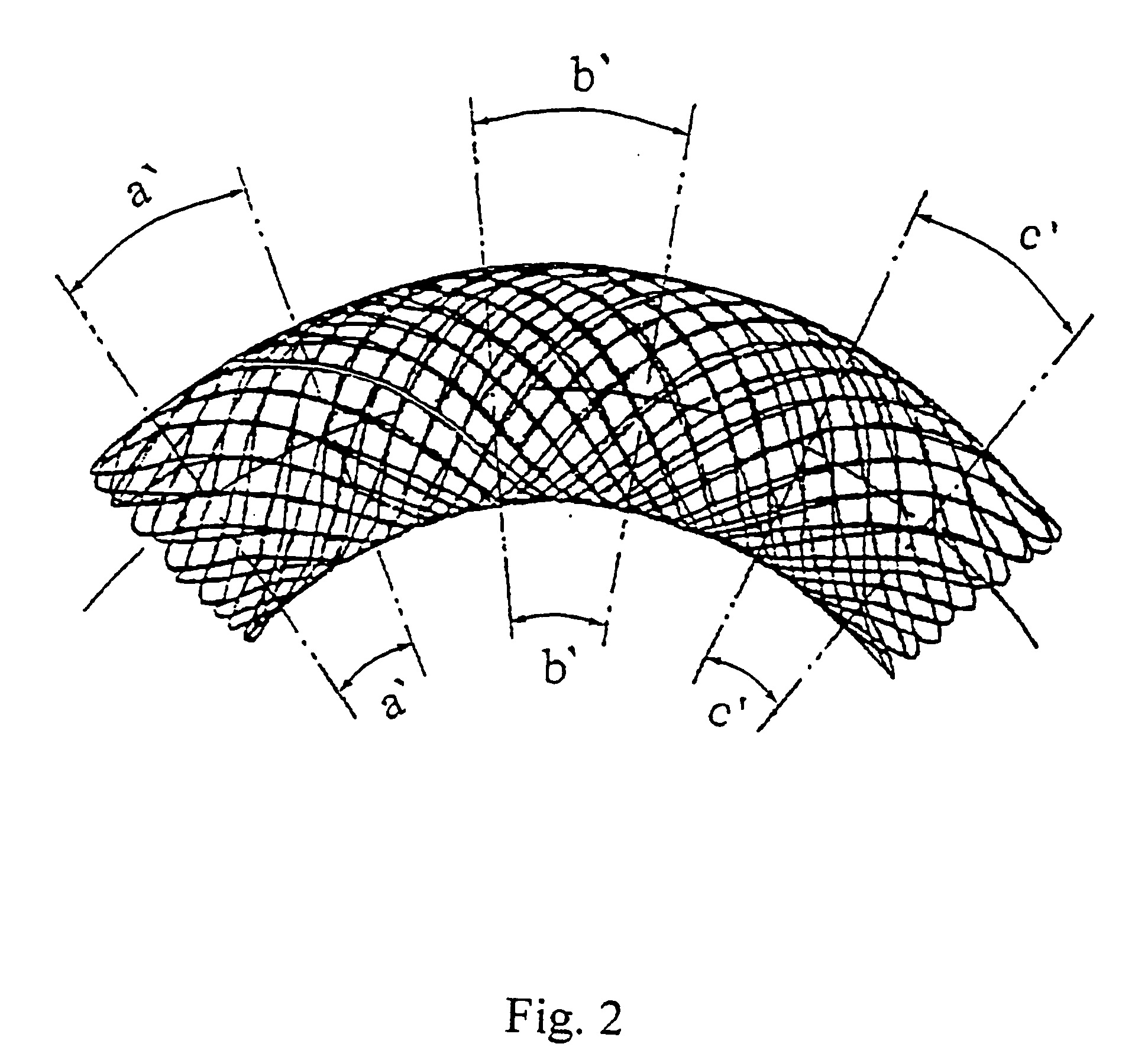

Besides, in such design of the stent, the “density” of a spiral pattern will be different at convex and concave sections of the stent, which will cause a non-homogeneity of the reaction of an organ for which a prosthesis is made in the zone of the stent installation.

It should be also pointed out that common drawbacks of spring stents, requiring, where it is needed, a uniform pressure upon a vessel wall, a small

pitch of a spring, deteriorating an

ion exchange, but not providing for enough uniformity of pressure, are inherent to the above design.

However different dimensionss and the form of cells of rigid segments and of the connector do not permit to provide for a homogeneity of a reaction of an organ for which a prosthesis is made in the zone of the stent installation.

The stent also have restrictions in part of its transformation, which interferes with the use of the stent in narrow vessels, and requires a rather complex

manufacturing technology.

By that, it is, however, impossible to achieve the changing of the stent rigidity at its separate sections, as it will be the same along all length of the stent.

Besides, the proposed

stent design will experience difficulties in transformation because of the presence of relatively rigid element in the frame—a circular row of cells, which will hardly allow to use it in prostheticated organs with small diameters.

At the same time this technology requires a relatively big labour input and is not meant for manufacturing the so-called “self-opening” stents.

It also does not provide for the manufacturing of stents, which separate sections have different elasticity, as well as for manufacturing of stents having a curvilinear form in the operating condition.

The above method is characterised by a greater adaptability to manufacture than the method of patent U.S. Pat. No. 5,443,498, however it also does not provide for the manufacturing of stents, separate sections of which can have different elasticity, as well as for the manufacturing of stents with a curvilinear form.

Besides, the presence of a great number of twists reduces the stent transformability and its biological compatibility with an organ being prostheticated.

However, when changing the stent elasticity at its separate sections by proposed means, invariability and homogeneity of

cell dimensions is not provided which can become the reason of spoiling a function of a prostheticated organ due to the danger of

thrombus formation, appearance of

stenosis and other post-operational complications.

This method requires a lesser labour input compared to other analogous methods, but it also does not allow to manufacture stems, the elastic properties of which could be changed at any se=don of the stent, preserving geometrical dimensions of stent cells; it does not provide a sufficient stent rigidity at its end sections and improved transformability, and also does not eliminate the danger of causing traumas to a prostheticated organ when its has a curvilinear form and a small internal diameter.

Besides, the technology of the stent manufacturing remains rather complicated.

When an elasticity along the whole length of the stent is equal, its geometrical compatibility with bent sections of prostheticated organs will be achieved only at the expense of the elasticity of the stent and bent sections will be subjected to greater loads than rectilinear ones because of the action of additional elastic forces, which can be the reason of post-operational complications.

Login to View More

Login to View More  Login to View More

Login to View More