Hoist for elevator

A traction machine and elevator technology, which is applied to elevators, electric components, electromechanical devices, etc. in buildings, can solve the problems of low cooling, more components, cooling, etc., and achieve the effect of efficient cooling and less structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

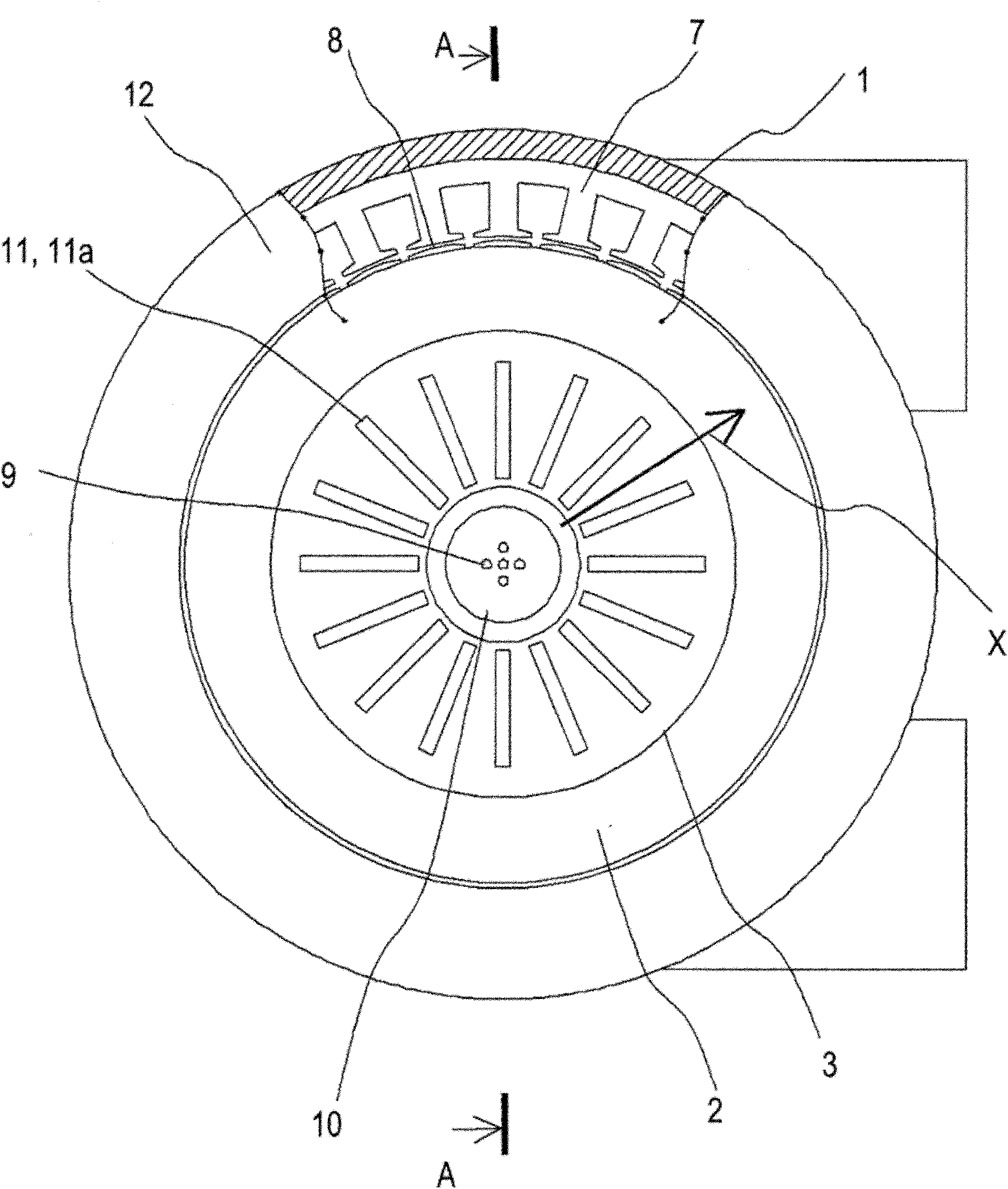

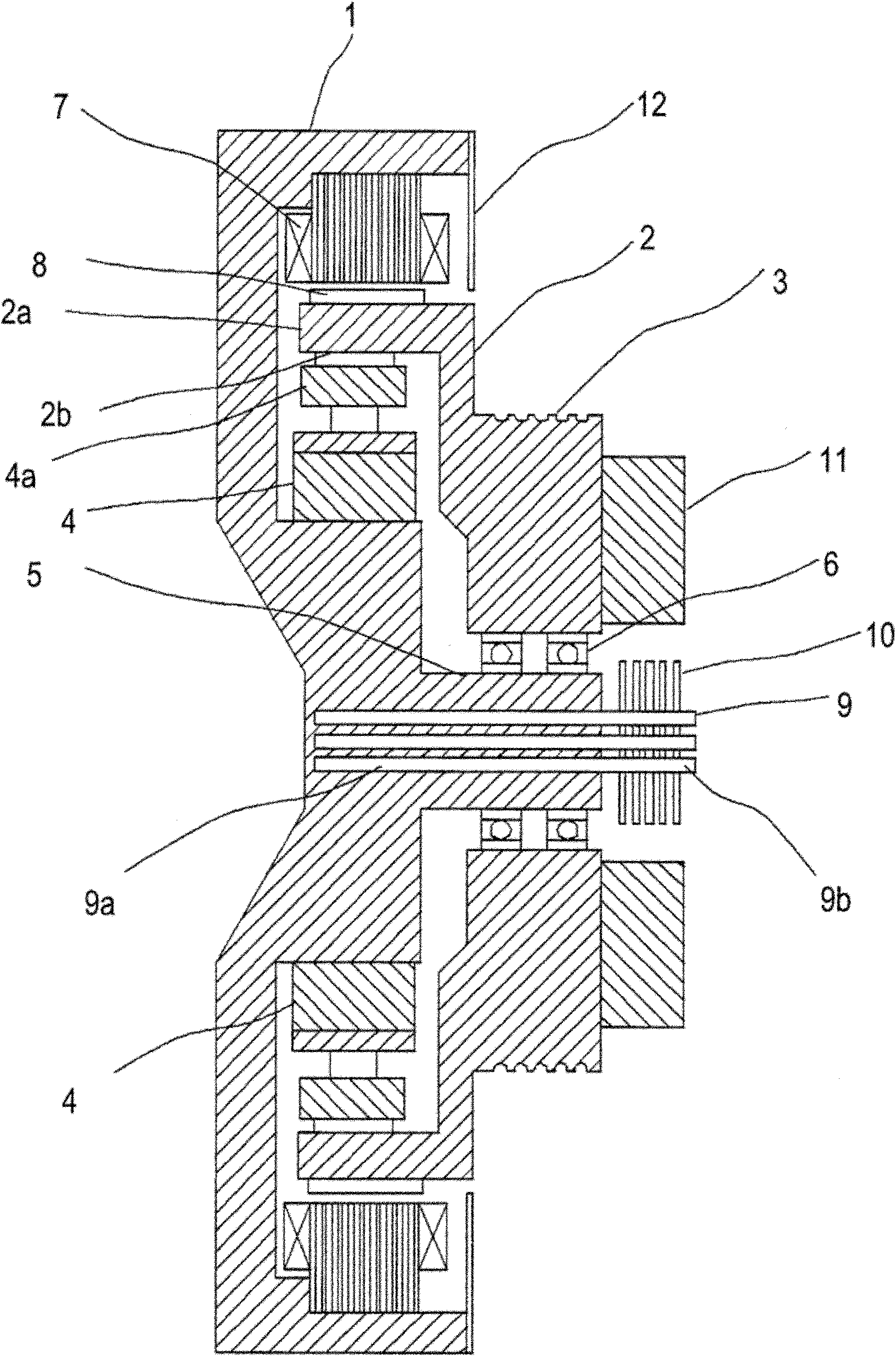

[0025] figure 1 It is a front view of the hoisting machine used in the first embodiment of the present invention. figure 2 Is showing figure 1 Figure of the A-A section.

[0026] In the figure, the hoisting machine includes a fixed frame 1, a rotating body 2, a driving sheave 3, and a brake 4 that brakes the rotation of the rotating body 2. The fixed frame 1 has a bowl shape with one side open, and a spindle 5 is erected at the center of the fixed frame 1. The rotating body 2 is in the shape of a bowl with one side open, and the opening end surface 2 a is arranged inside the fixed frame 1 so as to face the bottom surface of the fixed frame 1. In addition, the rotating body 2 is rotatably supported by the main shaft 5 via a bearing 6. In addition, a stator 7 is attached to the inner peripheral surface of the fixed frame 1. In addition, the field magnet 8 and the stator 7 are mounted on the outer periphery of the rotating body 2 so as to face each other. The stator 7 and the f...

no. 2 approach

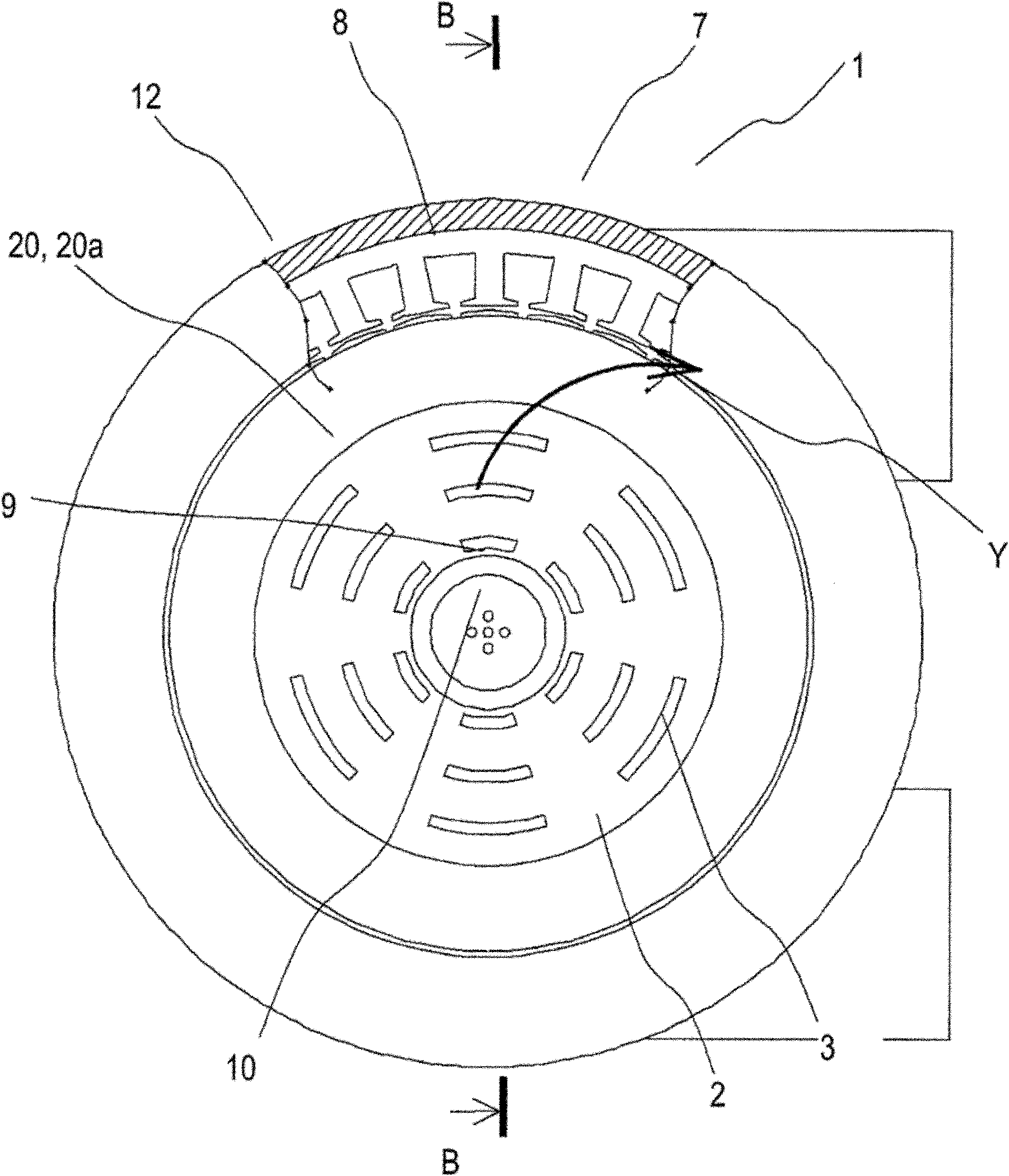

[0036] image 3 It is a front view of the hoisting machine used in the second embodiment of the present invention. Figure 4 Is showing image 3 Figure of the B-B section.

[0037] Compared with the first embodiment, the traction machine in the second embodiment changes the cooling fins provided on the rotating body 2.

[0038] On the side surface of the driving sheave 3, the cooling fin 20 is arranged around the heat dissipation fin 10. The cooling fin 20 is composed of a plurality of arc-shaped plates 20a. The arc-shaped plate 20a is in the shape of an arc concentric with the rotating body 2, and the arc-shaped plate 20a is spaced apart in the rotation direction and the radial direction. Configure it. In addition, the arc-shaped plate 20 a is formed as an arc corresponding to the same central angle of the rotation center of the rotating body 2. In addition, the arc-shaped plates 20a adjacent to each other in the rotation direction are arranged on concentric circles. Other poin...

no. 3 approach

[0050] Figure 7 It is a front view of the hoisting machine used in the third embodiment of the present invention. Compared with the second embodiment, the traction machine of the third embodiment changes the cooling fins provided on the rotating body 2.

[0051] On the side surface of the driving sheave 3, cooling fins 25 are arranged around the heat dissipation fins 10. The cooling fins 25 are composed of a plurality of arc-shaped plates 25a, and the arc-shaped plates 25a have an arc shape concentric with the rotating body 2 and are arranged at intervals in the rotation direction and the radial direction. In addition, the arc-shaped plate 25 a is formed as an arc corresponding to the same central angle of the rotation center of the rotating body 2. In addition, arc-shaped plates 25a adjacent to each other in the rotation direction are arranged on circles with different radii centered on the rotation center. The other points are the same as the second embodiment, and detailed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com