Low-impact non-pyrotechnic separation device

A separation device, non-pyrotechnical technology, which is applied to the docking device of space navigation aircraft, transportation and packaging, space navigation equipment, etc., can solve the problems of malfunction, damage to surrounding parts, inconvenient storage, etc., and achieves small and effective separation impact. Separation, reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

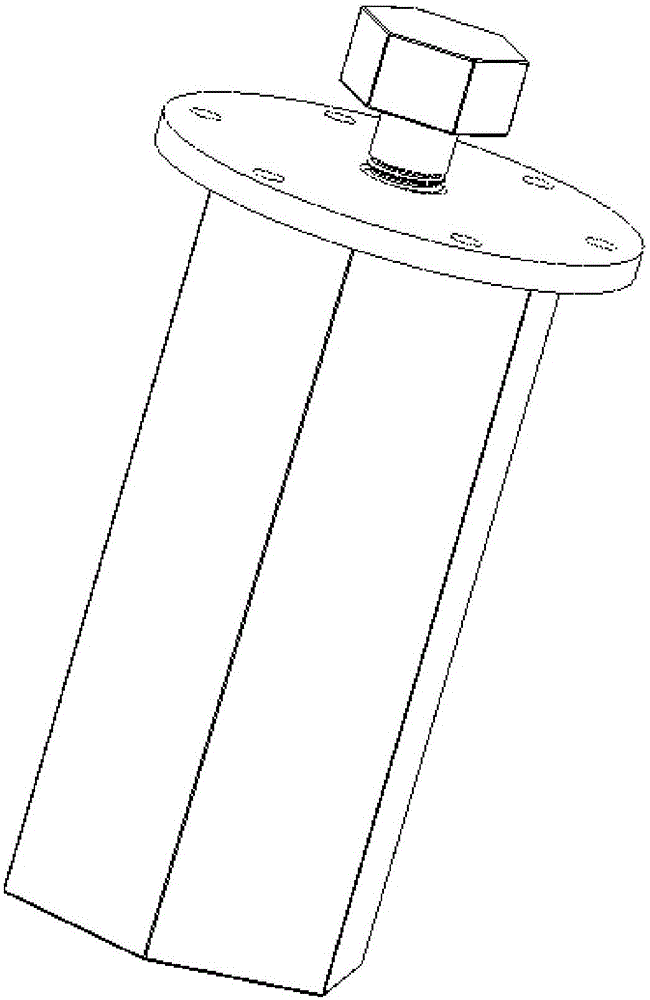

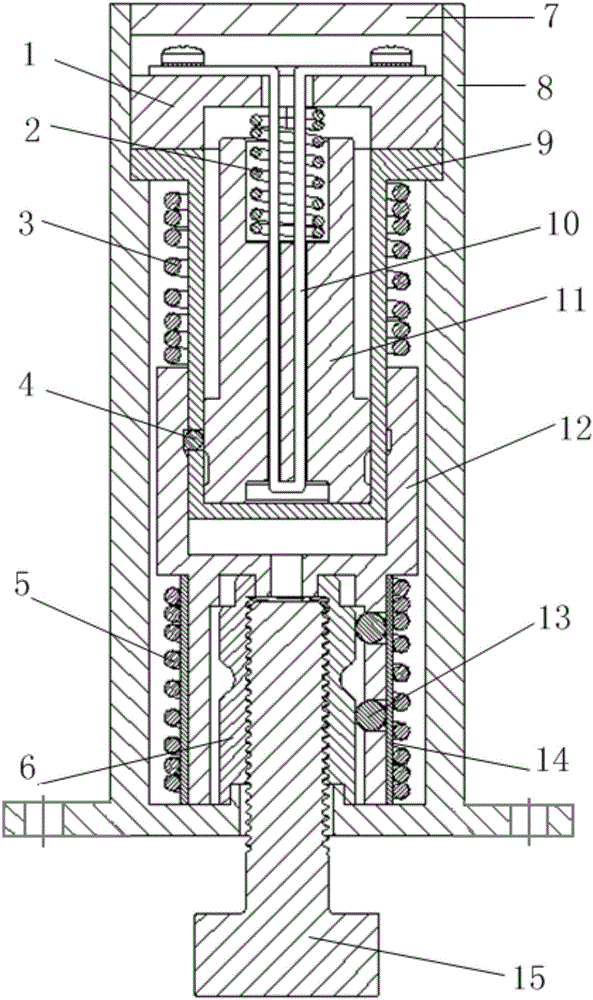

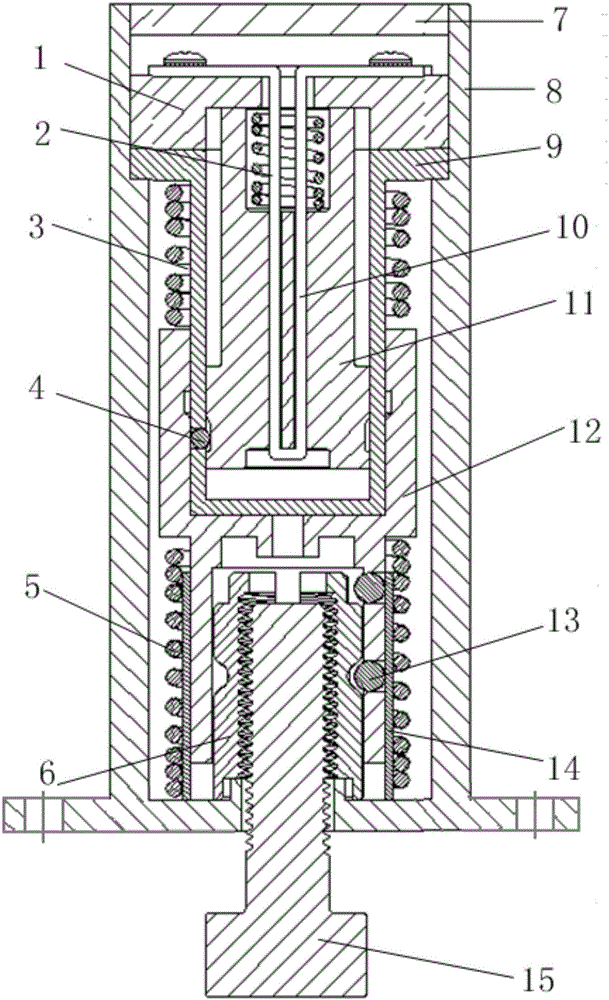

[0019] Such as Figure 1 ~ Figure 2 As shown, the present invention provides a low-impact non-pyrotechnic separation device, which is composed of a shape memory alloy wire 10, a trigger block 11, a split nut 6, a locking sleeve 12, a compression spring 5, a safety spring 2, Buffer spring 3, ball 13, ball retaining ring 14, steel ball 4, shell 8, end cover 7, upper bracket 1, lower bracket 2, the structural composition diagram is as follows figure 2 shown.

[0020] The end of the housing 8 close to the bolt 15 is a flange mounting surface, before the bolt 15 is connected with the non-pyrotechnic separation device, the non-pyrotechnic separation device can be fixed at the place to be installed; the upper bracket 1 is located in the housing 8 and installed on the lower On the bracket 9, a cavity is formed between the upper bracket 1 and the lower bracket 9, and the trigger block 11 is installed in the cavity; after the shape memory alloy wire 10 is folded in half, the folded en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com