Multi-point stress vibrating-punching combined compacting method

A vibrating method, multi-point technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of no theoretical system for treatment design and construction, treatment effect and high efficiency limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] (1) Carry out detailed and comprehensive investigation and analysis first, grasp the load standards and design requirements of the proposed site and roads and other above-ground facilities, and clarify the grade standard of the proposed site reinforcement treatment (including the design requirements). At the same time, be familiar with the engineering geological survey data of the proposed site and the technical conditions for the formation of the dredged sand layer, recognize the characteristics of the soil properties, grasp the treatment depth and treatment range, and formulate appropriate control standards for intensity.

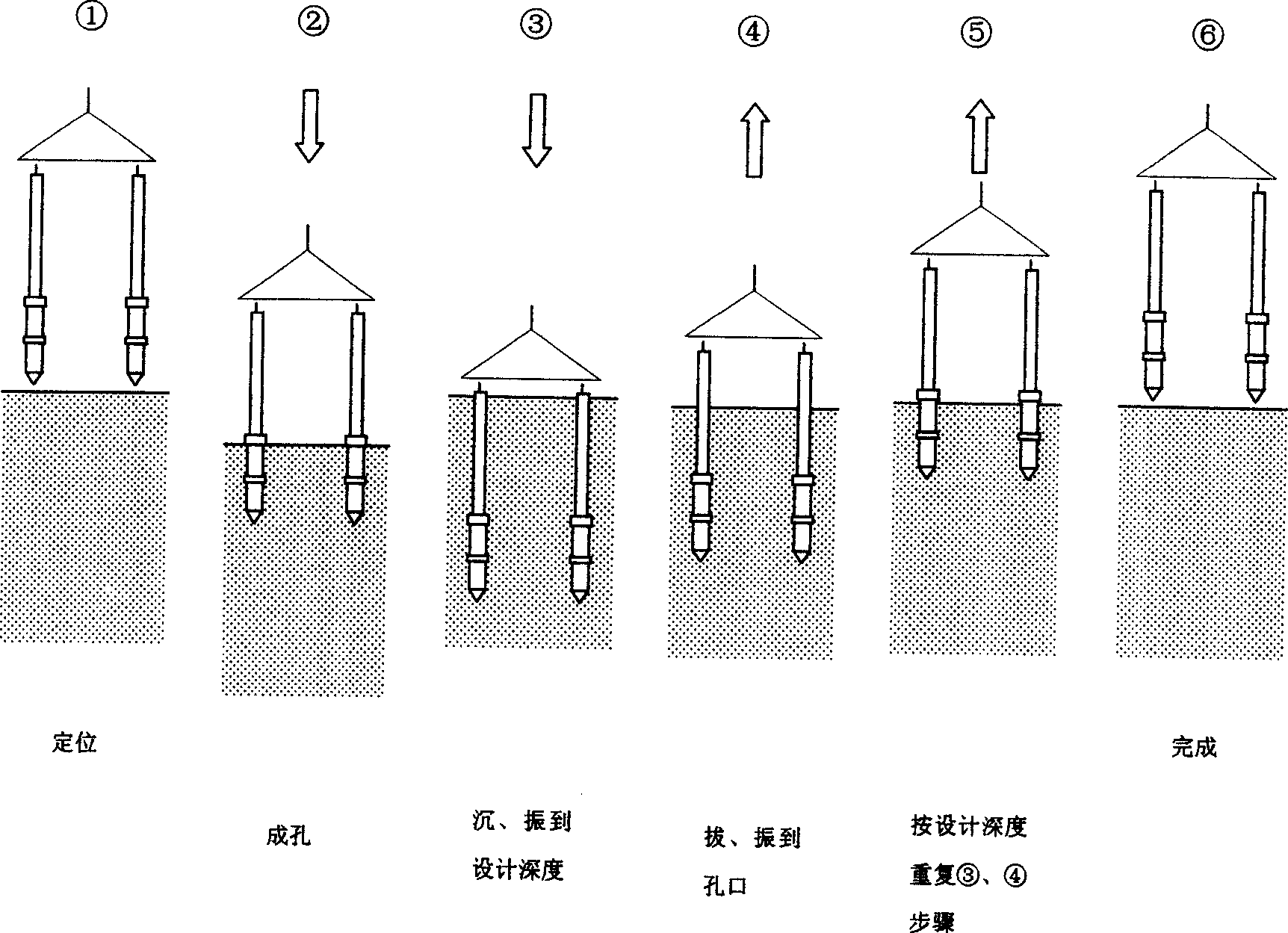

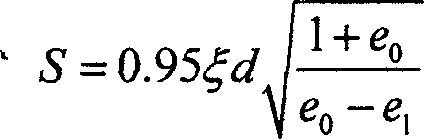

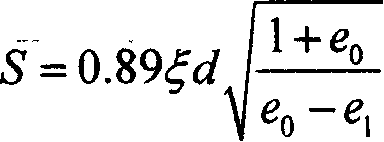

[0054] (2) The present invention utilizes the matching and kneading of the two methods of joint vibratory impact method and vibration rolling compaction method of multi-point stress vibration: the reinforced soil skeleton is applied to the technical effect of force, that is, the loose sandy soil skeleton exert force. The force application is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com