High-strength steel having high impact energy absorption power and method for mfg. same

A technology of high-strength steel plates and steel plates, applied in the field of high-strength hot-rolled steel plates and high-strength cooled steel plates, can solve problems such as unclear

Inactive Publication Date: 2000-01-12

NIPPON STEEL CORP

View PDF2 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

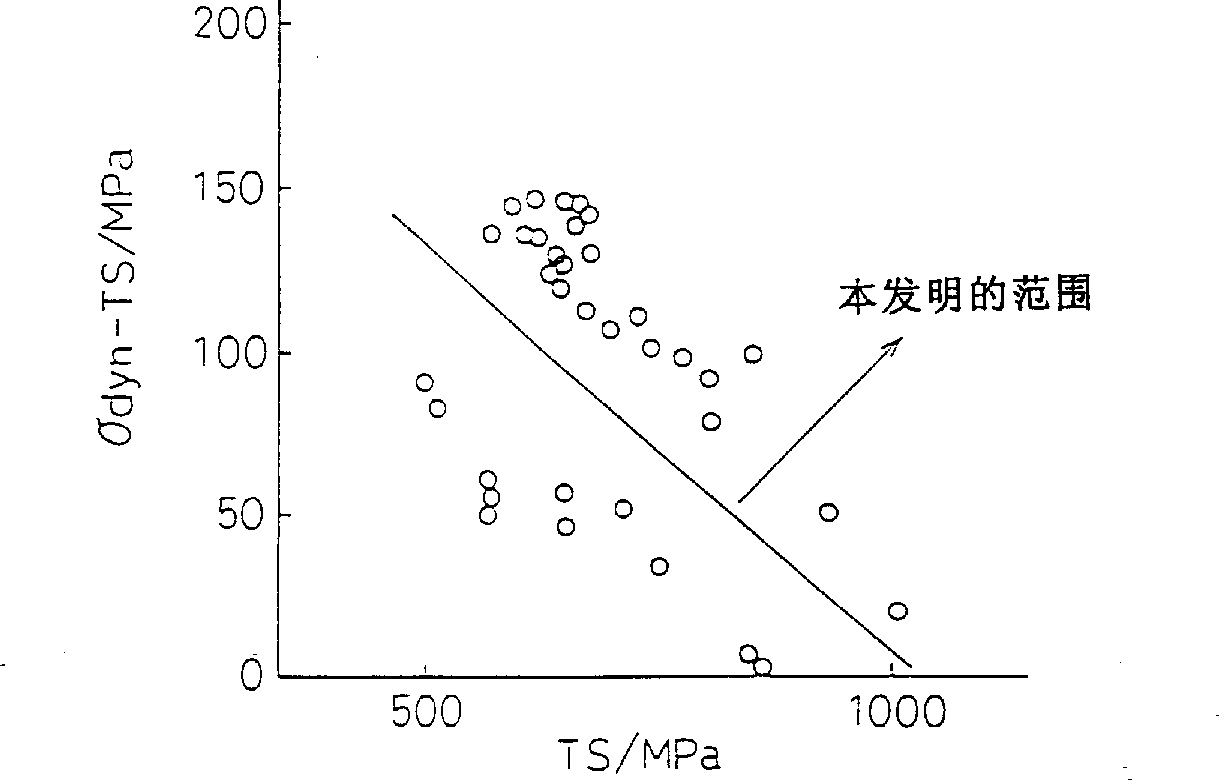

[0005] Furthermore, Japanese Patent Unexamined Publication No. Hei 7-18372 provides a method for producing a high-strength steel sheet containing retained austenite having excellent impact resistance, for a method of increasing the yield stress by a higher deformation rate so that Methods by which impact absorption can be improved are disclosed; however, it has not been demonstrated which aspects of retained austenite other than the amount of retained austenite should be controlled in order to improve impact absorption

[0006] Therefore, although the understanding of the dynamic deformation properties of component materials that affect impact energy absorption during a vehicle crash is improving, what properties should be maximized in order to obtain more excellent impact energy absorption properties for automobiles? The steel of the components and the criteria for material selection are still not very clear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0093] steel number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

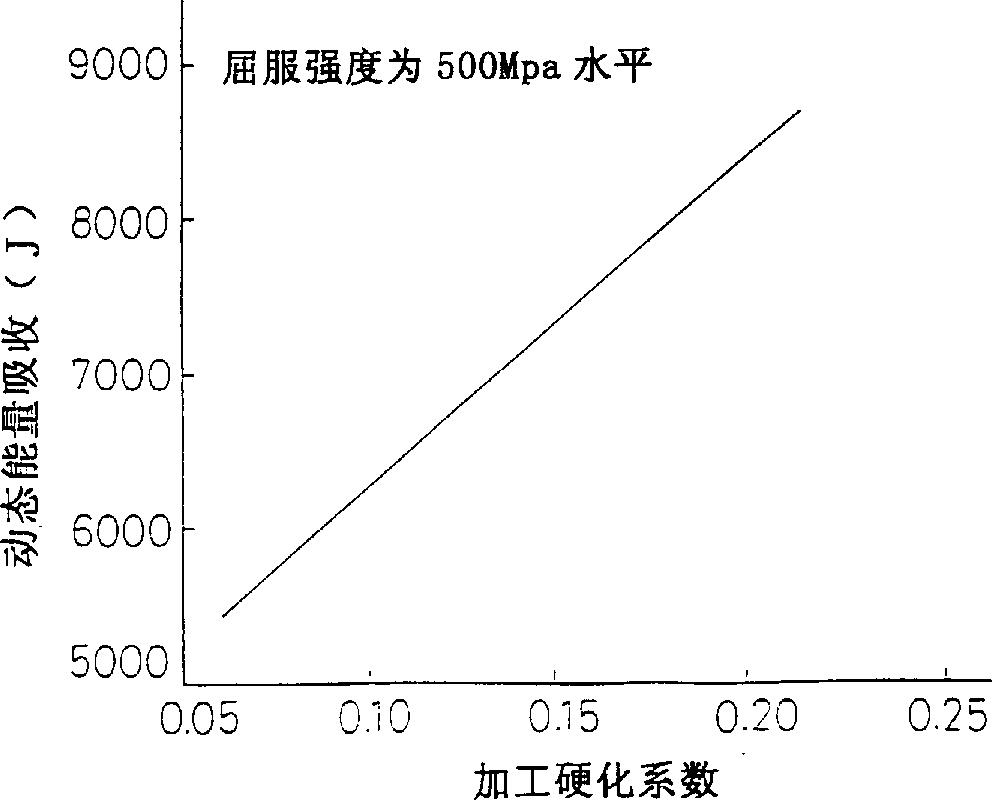

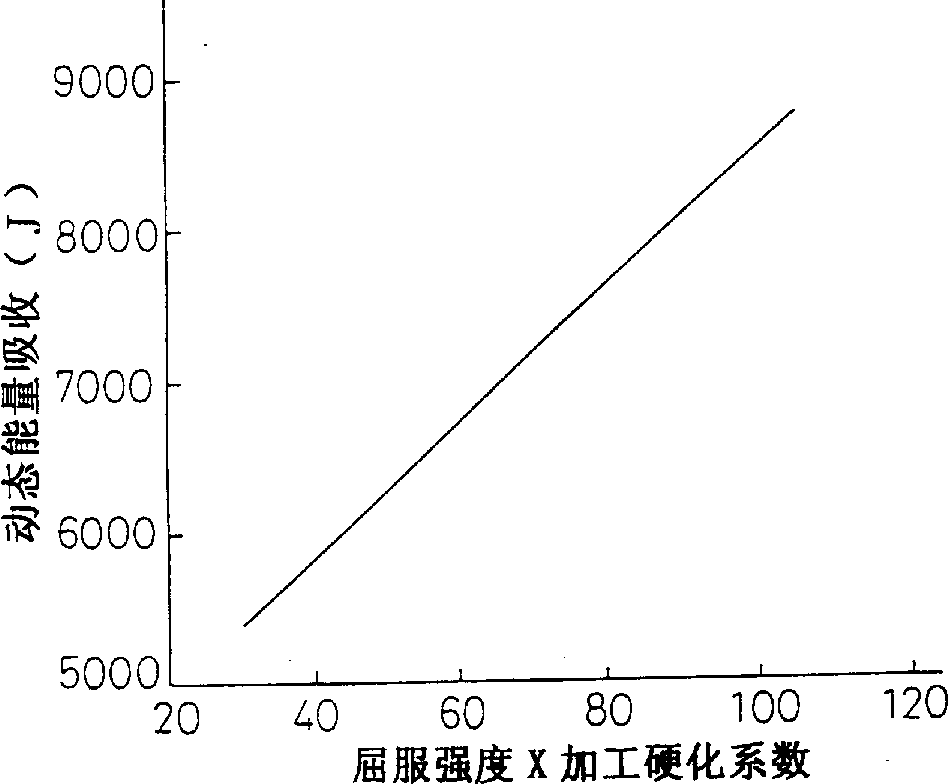

A high-strength steel sheet to be formed and worked into parts for absorbing striking energy occurring at a collision, for example, front-side members, which exhibits a high absorbing power against striking energy; and a process for the production thereof. The sheet is a high-strength steel sheet exhibiting high dynamic deformation resistance and excellent workability and is characterized in that the microstructure of the finally obtained sheet is a composite one comprising ferrite and / or bainite with either of them being present as the main phase and containing as the third phase another phase containing residual austenite at a volume fraction of 3 to 50 %, that the difference between the quasi-static deformation strength observed when the sheet is subjected to pre-deformation of equivalent strain exceeding 0 % and up to 10 % and then deformed at a strain rate of 5 x 10[-4] to 5 x 10[-3] (1 / s) and the dynamic deformation strength (sigma d) observed when the sheet is subjected to the above pre-deformation and then deformed at a strain rate of 5 x 10[2] to 5 x 10[3] (1 / s), i.e., sigma d, is 60 MPa or above, and that the work hardening exponent at a strain of 1 to 5 % is 0.080 or above.

Description

technical field [0001] The present invention relates to a high-strength hot-rolled steel sheet and a high-strength cooled steel sheet having high yield stress during dynamic deformation, which can be used as automotive components and the like to ensure passenger safety by effectively absorbing impact energy at the time of collision. The invention also relates to a method of producing such a steel sheet. Background technique [0002] In recent years, the protection of occupants from automobile crashes has been recognized as an extremely important aspect of automobiles, and there is an increasing desire for suitable materials with excellent resistance to high-speed deformation. For example, by using such a material as a front-end component of a car, when the material is crushed, the energy of a frontal collision can be absorbed, thereby mitigating the impact on the occupants. [0003] Because each part of the car is deformed at a strain rate of about 10 3 (1 / sec), therefore,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/00C21D8/02

CPCC21D2211/008C21D8/0273C21D8/0226C21D8/02C21D8/0236C21D2211/005C21D2211/001C21D2211/002C22C38/00

Inventor 河野治高桥雄三胁田淳一间渊秀里高桥学上西朗弘冈本力栗山幸久佐久间康治

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com