Design method for marine propeller made of carbon fiber composite material

A technology of marine propellers and composite materials, which is applied in the direction of rotating propellers, calculations, and rotary propellers, and can solve problems such as imperfect propeller design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

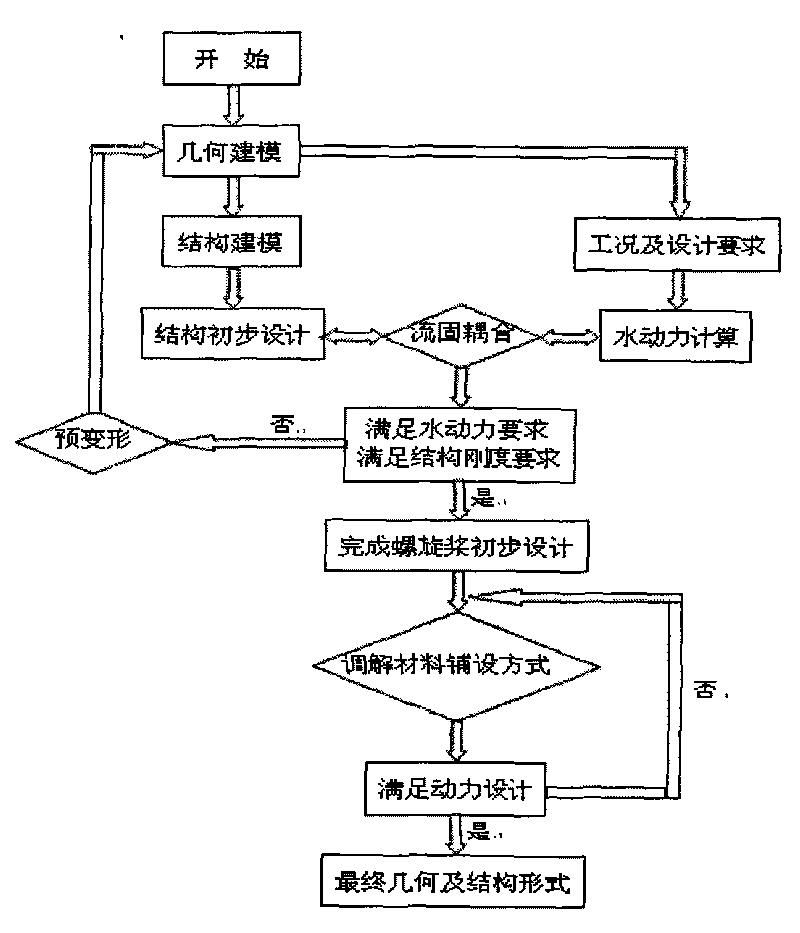

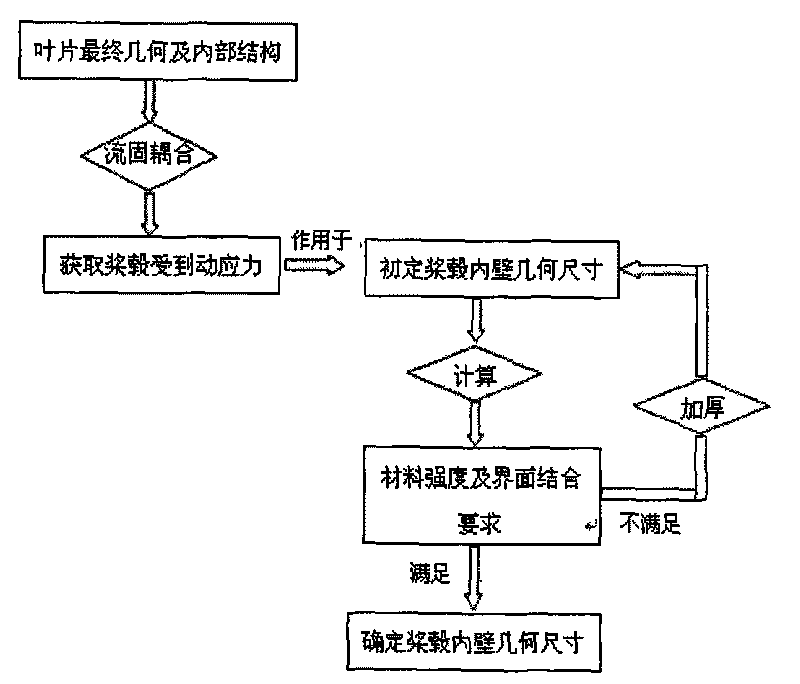

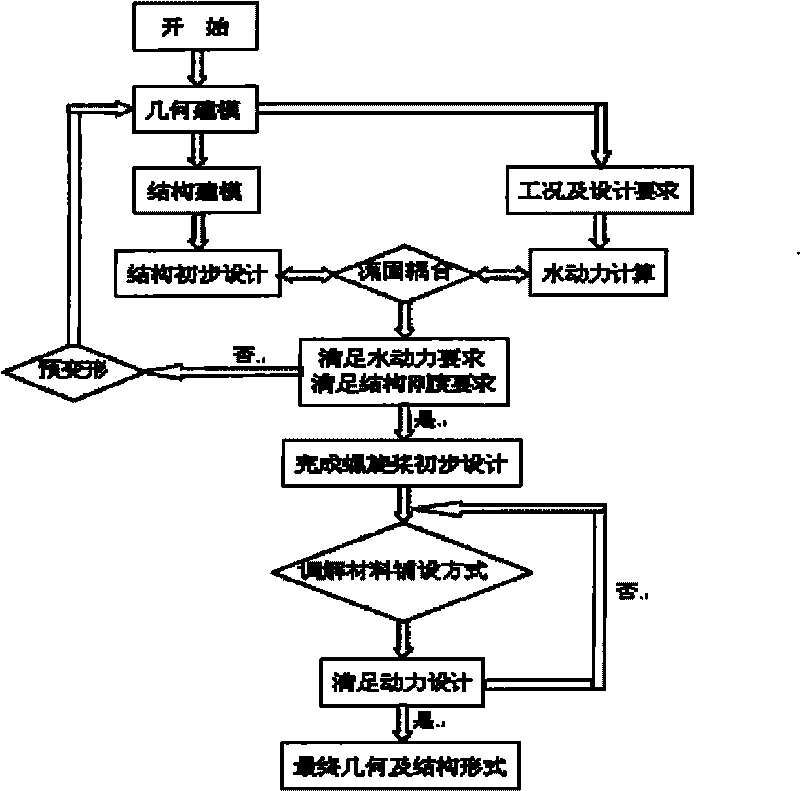

[0028] Specific implementation mode one: as Figure 1~2 As shown, the design method of the carbon fiber composite material marine propeller of the present embodiment is realized by the following steps:

[0029] Step 1: Composite unidirectional carbon fiber or twill carbon fiber cloth with epoxy resin to make a standard specimen of carbon fiber composite material, and complete the test on a tensile testing machine according to GB 3354-82 to obtain the elastic constant and Poisson's ratio performance parameters, Among them, the elastic constant is EX=1.1e11Pa, EY=EZ=8.97e9Pa, Poisson's ratio is 0.34, and the shear modulus is 3.9e9Pa;

[0030] Step 2: According to the geometric value of the MAU-type metal propeller, use the three-dimensional solid configuration software UG to construct the geometric model of the carbon fiber composite propeller;

[0031] Step 3: Import the geometric model of the carbon fiber composite propeller into the finite element software ANSYS, select the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com