Non-contact capacitance induction touch panel

A capacitive sensing, non-contact technology, applied in the input/output process of electrical digital data processing, instruments, data processing, etc., can solve the problem that keyboard or key-type operation cannot be satisfied, does not have continuous handwriting and multi-point input, resistance The touch screen is easy to age and other problems, so as to achieve the effect of flexible size design, strong specificity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

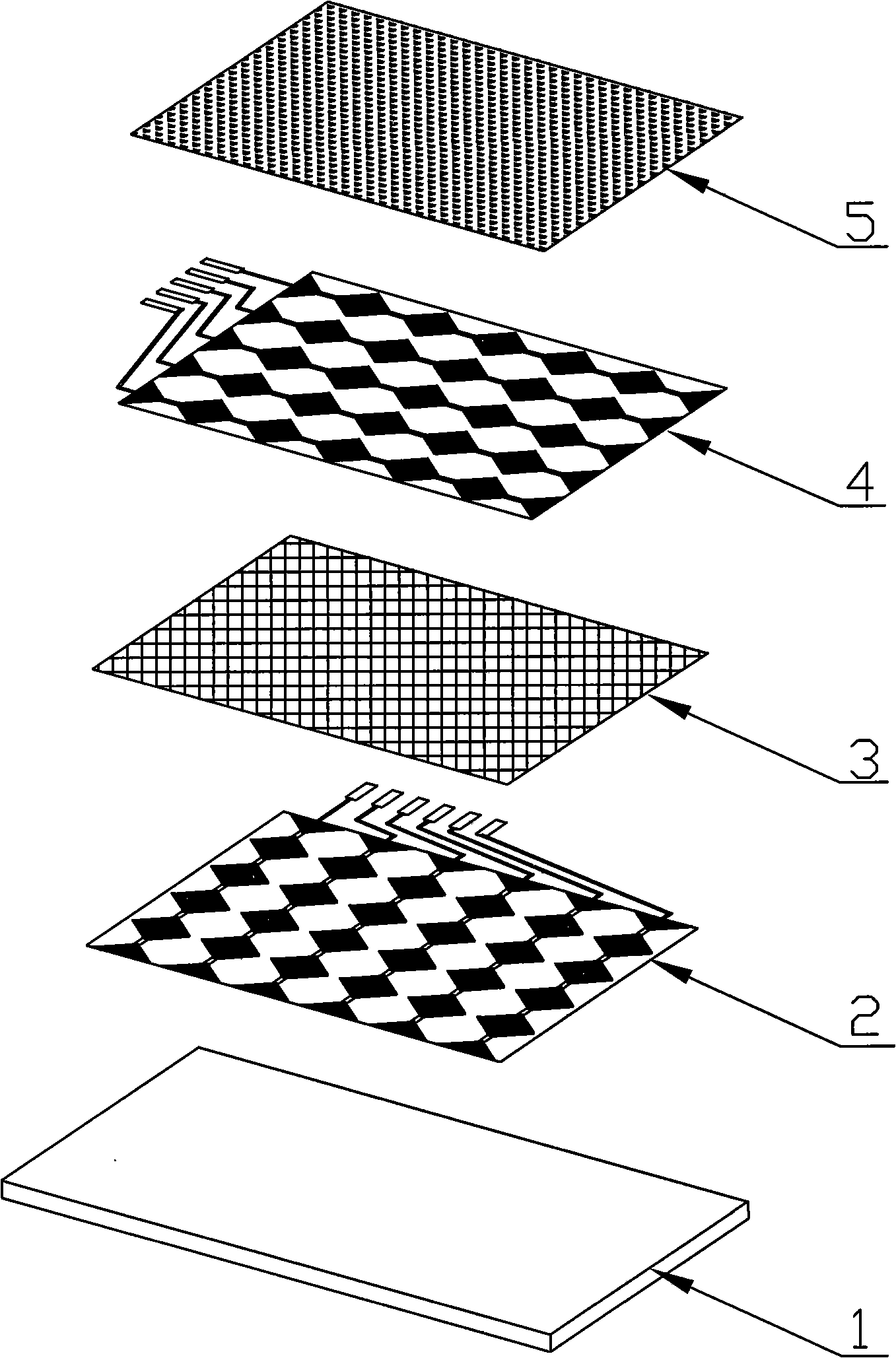

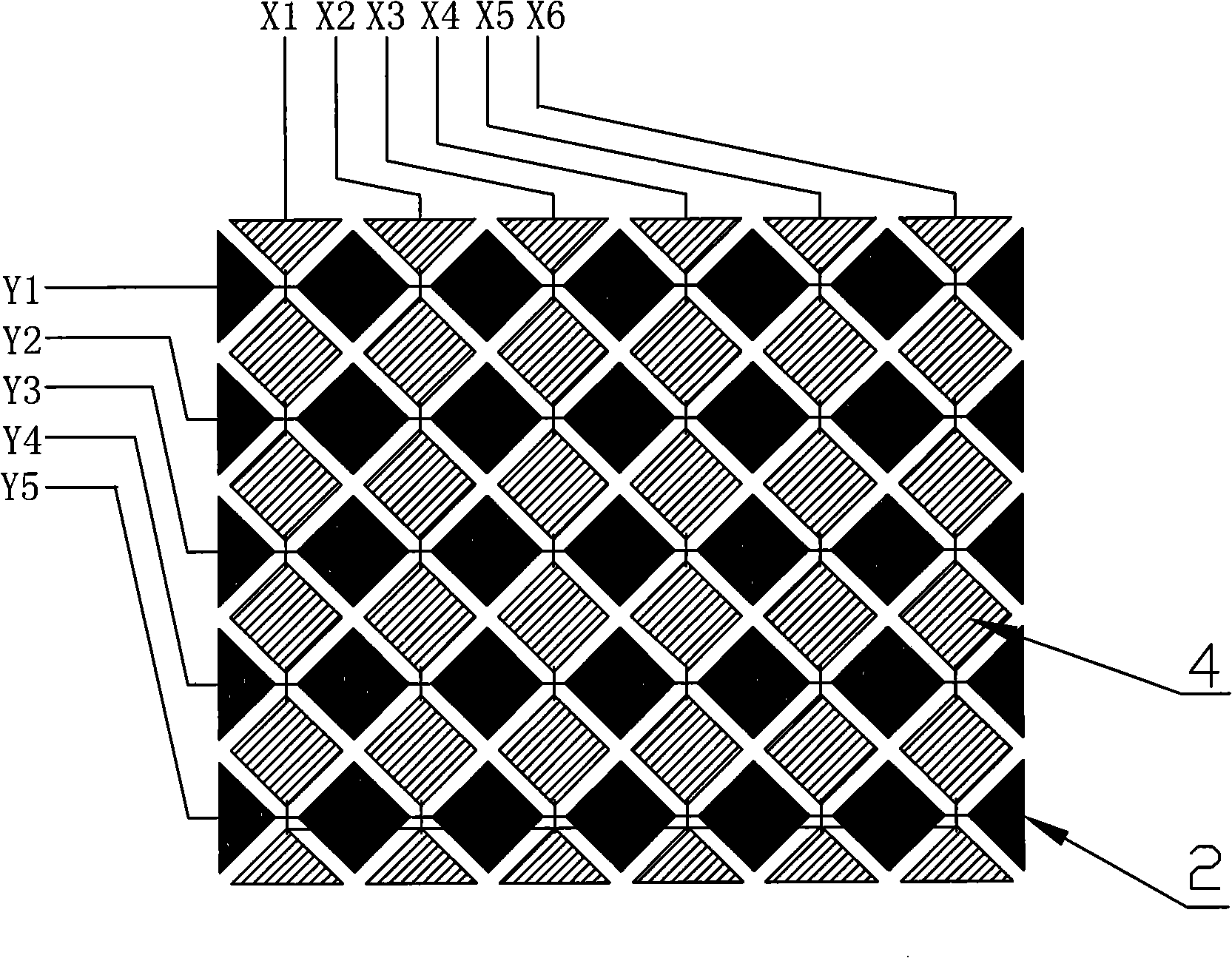

[0015] refer to figure 1 , figure 2 , a non-contact capacitive sensing touch screen, comprising a substrate glass 1, one surface of the substrate glass 1 is coated with a horizontally connected mesh Y-direction ITO electrode matrix 2, the Y-direction ITO electrode matrix is coated with an insulating layer 3, and the insulating layer 3 is coated with There is a matrix of X-direction ITO electrodes 4 that is roughly complementary in shape to the blank part of the grid-shaped Y-direction ITO electrode 2 matrix, and is vertically connected. The leads of the Y-direction ITO electrode 2 matrix and the X-direction ITO electrode 4 matrix extend to the edge of the substrate glass 1 .

[0016] As a further improvement of the present invention, the X-direction ITO electrode 4 matrix is coated with a protective film 5, which can be coated with high hardness and corrosion-resistant materials in special cases to adapt to different application environments. The insulating layer 3 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com