Hydraulic support and surrounding rock coupling three-dimensional dynamic design method

A hydraulic support, three-dimensional dynamic technology, applied in pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of support design pertinence, poor adaptability, etc., to improve adaptability, reduce failure rate, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

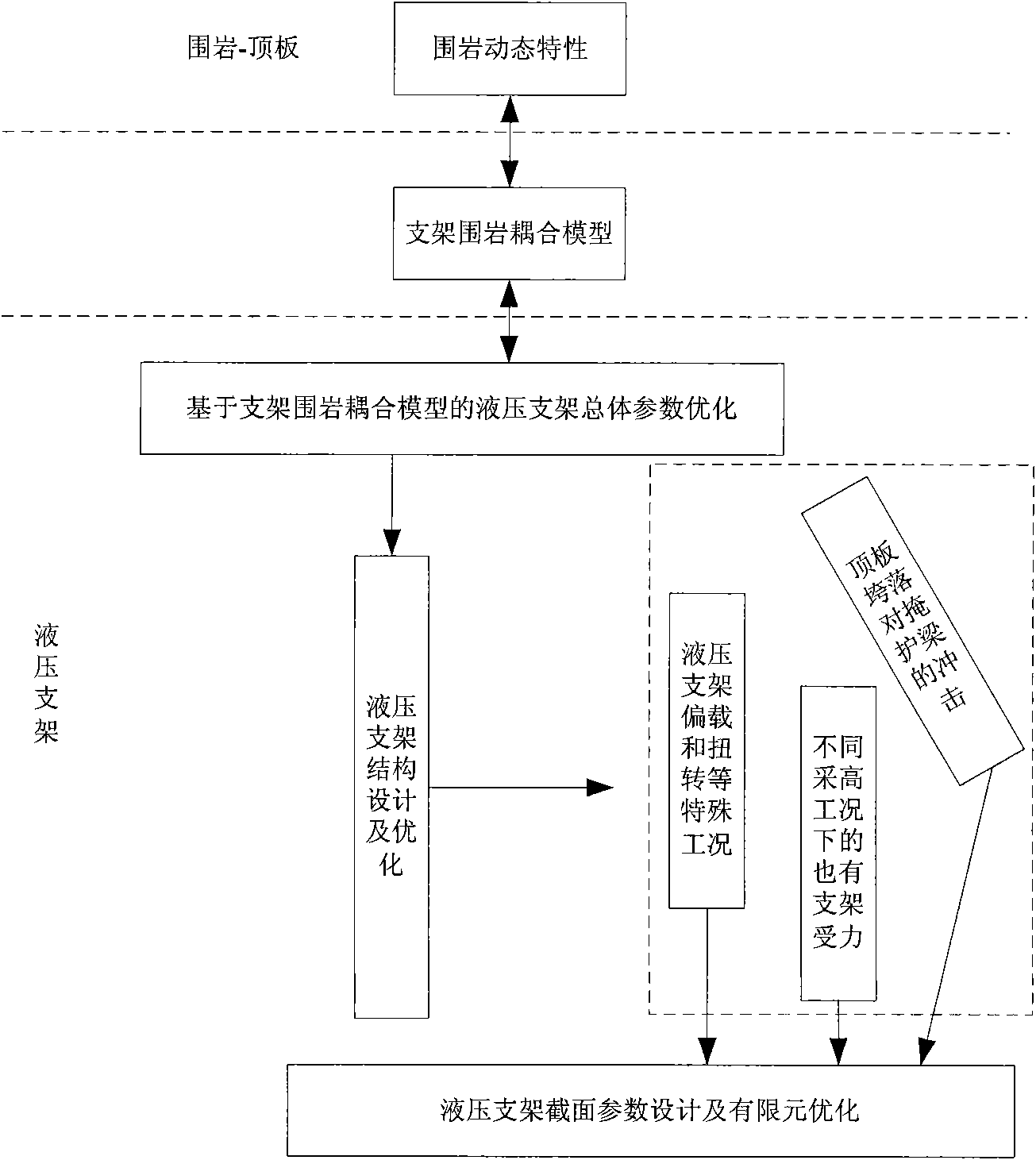

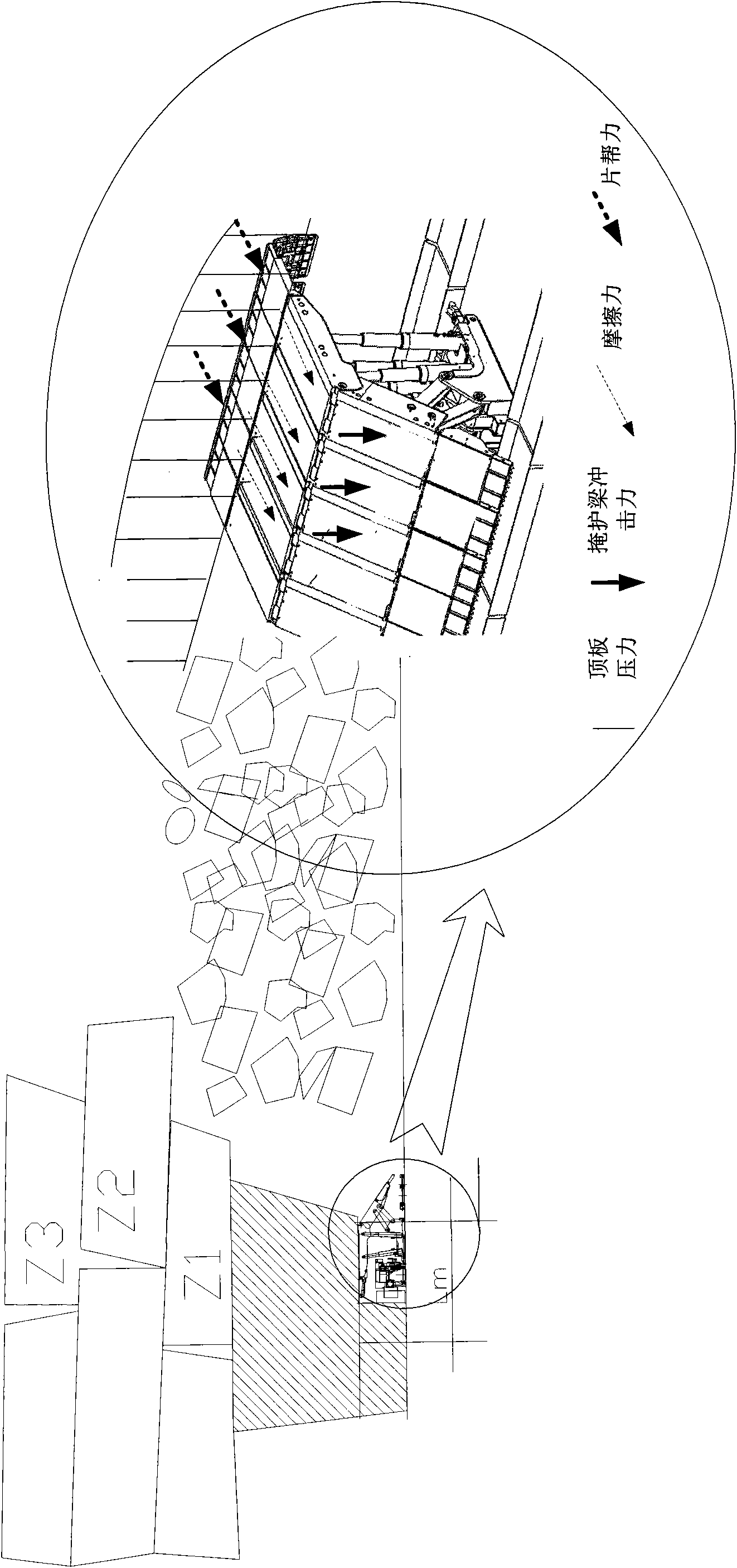

[0031] in accordance with figure 1 As shown in the hydraulic support surrounding rock coupling design process, in the discrete element analysis software, the large mining height fully mechanized caving mining support surrounding rock relationship coupling model is established. Simulate that as the working face advances, the surrounding rock gradually presents the top coal separation layer, the first top coal caving, the top coal secondary caving, the top coal caving three times, the direct top coal caving, the direct top coal caving, the direct top second The migration state of the roof (coal) such as secondary caving, and with the advancement of the working face, the various processes are cyclical and overlap each other, and jointly act on the support of the working face.

[0032] Among them, the geological characteristics and caving characteristics of the roof and top coal can be corrected and adjusted by inputting the coal seam geological conditions of a specific mining are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com