Pull rod press machine with power arranged at lower portion

A technology of presses and tie rods, applied in presses, stamping machines, manufacturing tools, etc., can solve the problems of poor mechanical properties of presses, ineffective hydraulic cylinder speed-up, large overall size of presses, etc., to meet the requirements of strength and Rigidity requirements, superior comprehensive performance, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

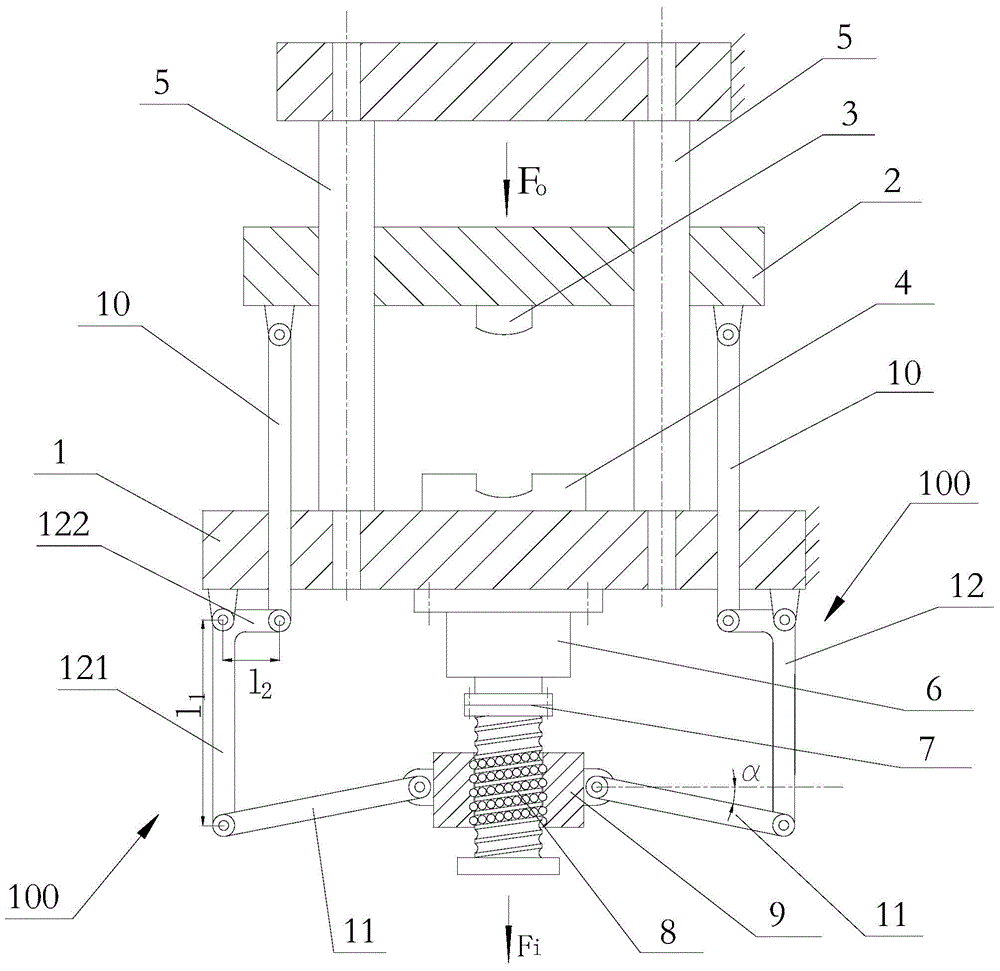

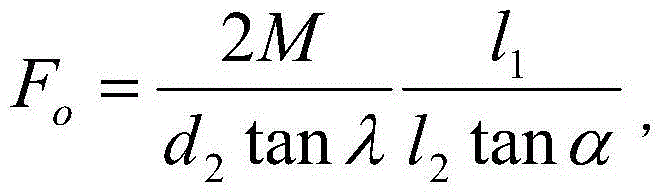

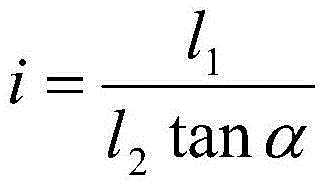

[0019] see figure 1 The shown press includes a workbench 1 fixedly arranged on the frame, an upper mold assembly 2 that is vertically lifted and lowered on the frame and positioned above the workbench 1, and the upper mold assembly 2 includes an upper and lower The sliding seat 2 that is lifted and lowered on the frame, the upper mold 3 that is fixedly arranged under the sliding seat 2, the lower mold 4 that matches the upper mold 3 is fixedly arranged on the workbench 1, and the upper mold 4 is installed on the workbench 1. There are a plurality of vertically extending guide posts 5 to provide guidance for the sliding seat 2 to slide up and down.

[0020] The press also includes a motor 6 fixedly installed under the workbench 1 , a lead screw 8 connected to the output shaft of the motor 6 , and a nut 9 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com