Container loading and unloading and transferring device and using method thereof

It is a container and reverse shipping technology, which is applied in the direction of loading/unloading, transportation and packaging, conveyor objects, etc. It can solve the problems that the container can not be loaded along the railway flat side, and the structure is not simple enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

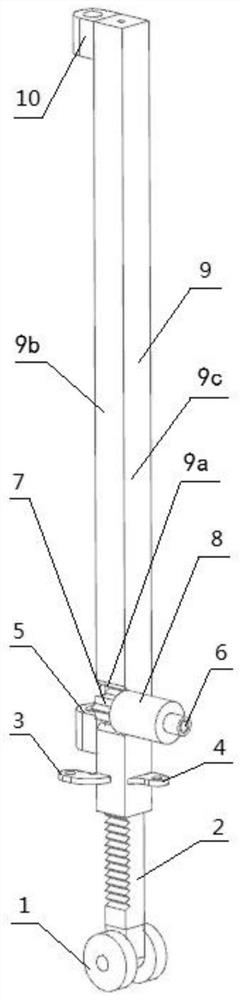

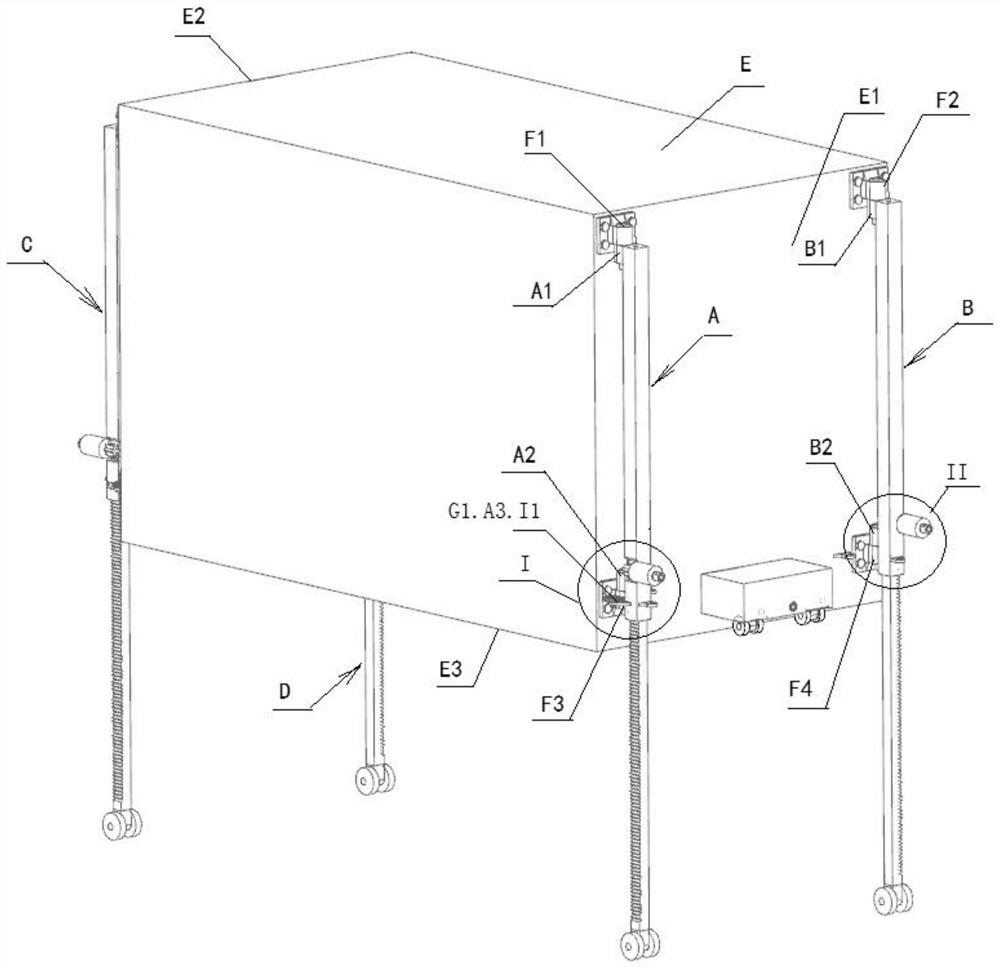

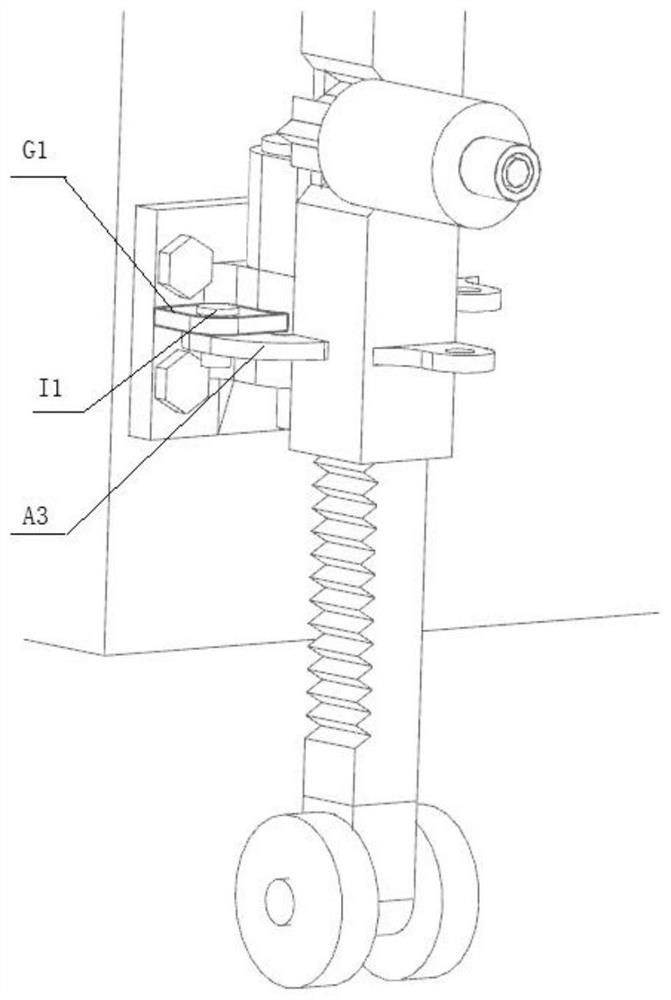

[0100] see Figure 2 to Figure 7 , in order to cooperate with the use of containers, this embodiment adopts four sets of lifting and reversing modules, and the four groups of lifting and reversing modules are divided into front left lifting and reversing module A, front right lifting and reversing module B, rear left lifting and reversing module C, and rear right lifting and reversing module D . The front left lifting and reversing module A and the front right lifting and reversing module B are located outside the front wall E1 of the container E, and the rear left lifting and reversing module C and the rear right lifting and reversing module D are located outside the rear wall E2 of the container E.

[0101] For this reason, the above-mentioned front left lifting and reversing module A, front right lifting and reversing module B, rear left lifting and reversing module C, and rear right lifting and reversing module D are connected with the front case wall E1 and the rear case ...

Embodiment 2

[0143] see Figure 9 to Figure 14 , The difference between this embodiment and Embodiment 1 is: this embodiment also includes four container lateral fixed travel lock lugs, four lateral travel latches.

[0144] The four container lateral fixed travel lugs are divided into the front lower left container lateral fixed travel lug H1, the front lower right container lateral fixed travel lock lug H2, the rear lower left container lateral fixed travel lock lug H3, and the rear lower right container lateral fixed travel lock lug H4.

[0145] The front left lower container horizontally fixed travel lock ear H1 is fixed on the front wall E1 of the container E near the position of the left front lower latch seat F3 and is located on the other side of the left front lower latch seat F3.

[0146] The front right lower container horizontally fixed travel lock lug H2 is fixed on the front wall E1 of the container E near the position of the right front lower latch seat F4 and is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com