Nylon bristlelike monofilament fabric for cleaning, and cleaning tools formed by the same

A cleaning tool, nylon technology, applied in the field of tools, can solve the problems of poor toughness and resistance to alternating stress, unsatisfactory material selection, cleaning surface damage, etc., to achieve low cost, optimized raw material composition, and efficient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

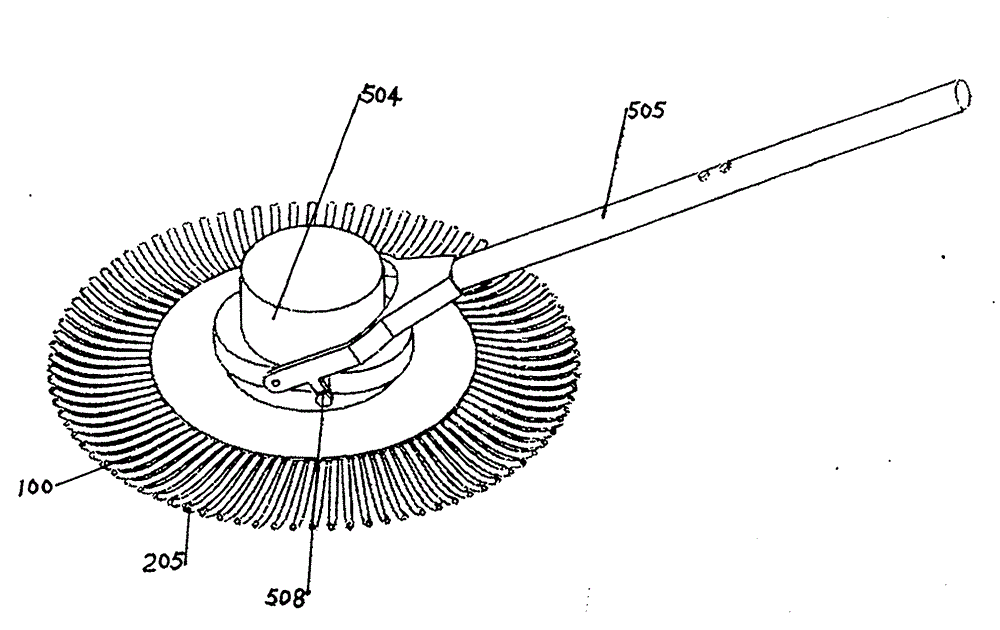

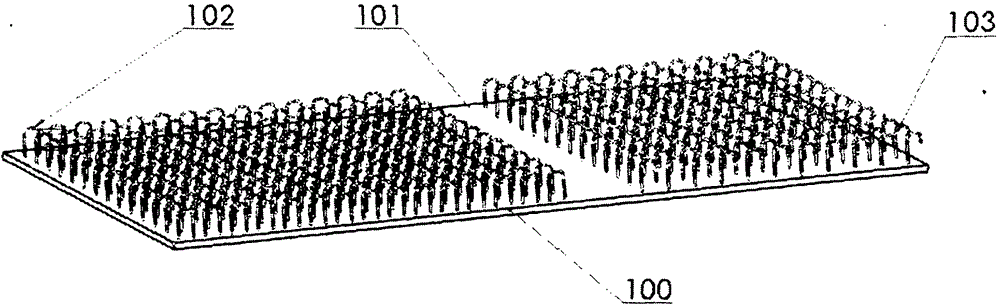

[0060] figure 1 It is the structural outline drawing of nylon bristle fabric.

[0061] figure 1 Indicates that the nylon bristle fabric 100 is adopted to form a cloth base 101 woven from nylon fibers or nylon bristles and a nylon bristle loop group 102 or a nylon bristle hair hook group 103 woven on one surface of the cloth base as a working part. constitute. The nylon bristle loop group 102 and the nylon bristle hair hook group 103 are stiff.

[0062] figure 2 Is the cross-sectional schematic diagram of nylon bristle.

[0063] figure 2 A non-circular bristle cross-section is shown in , wherein the nylon bristle cross-section 104 has a better brushing cleaning effect than the circular cross-section, and the non-circular bristle cross-section is approximately defined by an enveloping circle 105 The bristle cross-sectional dimension.

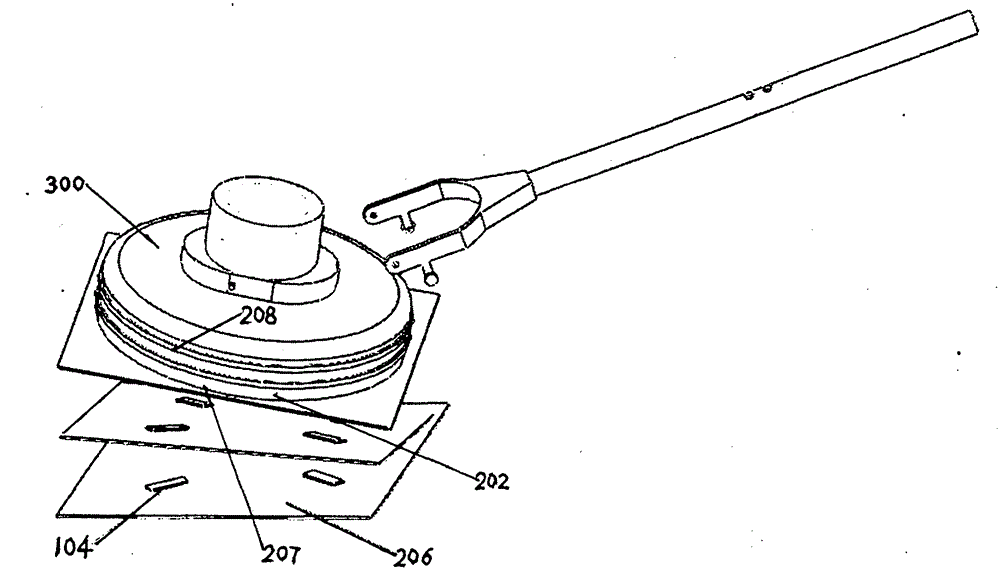

[0064] image 3 It is the structural outline drawing of back-to-back connection of nylon bristle fabrics.

[0065] image 3 The nylon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com