Degradable magnesium alloy femoral internal fixation screw and preparation method thereof

A technology for fixing screws and magnesium alloys, which is applied in the fields of biodegradable femoral internal fixation implantation devices, bone screws, and orthopedic internal fixation devices. Cost, structure size optimization, effect of improving stress concentration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

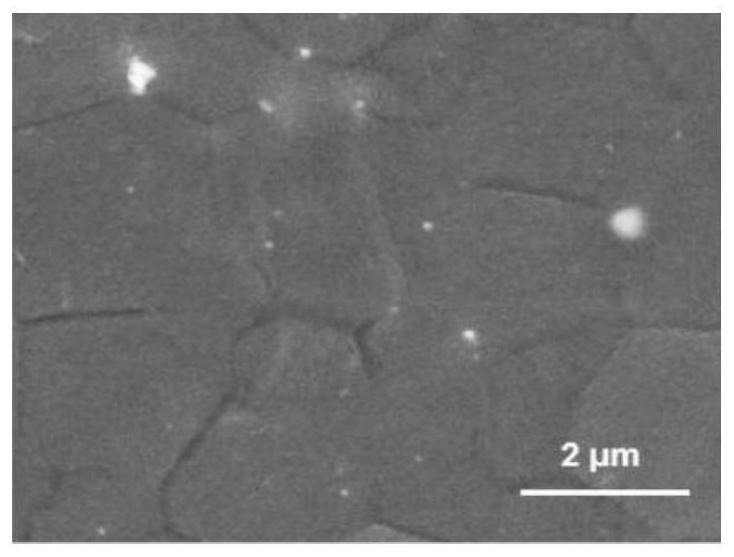

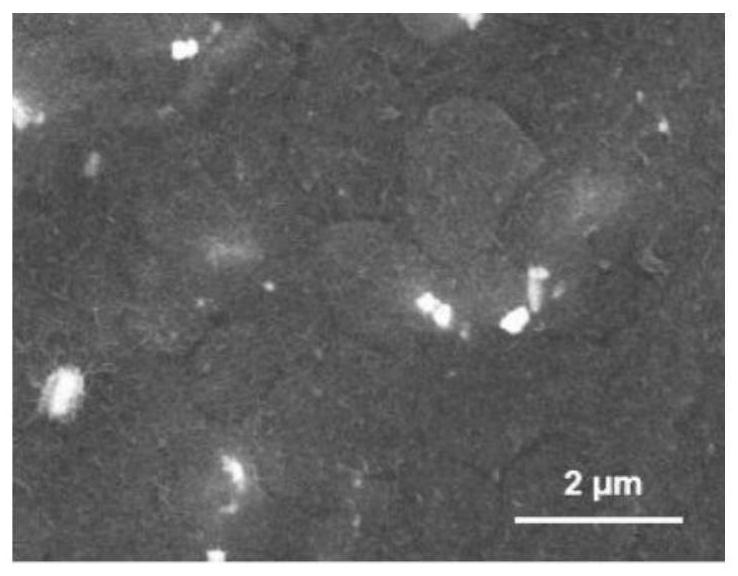

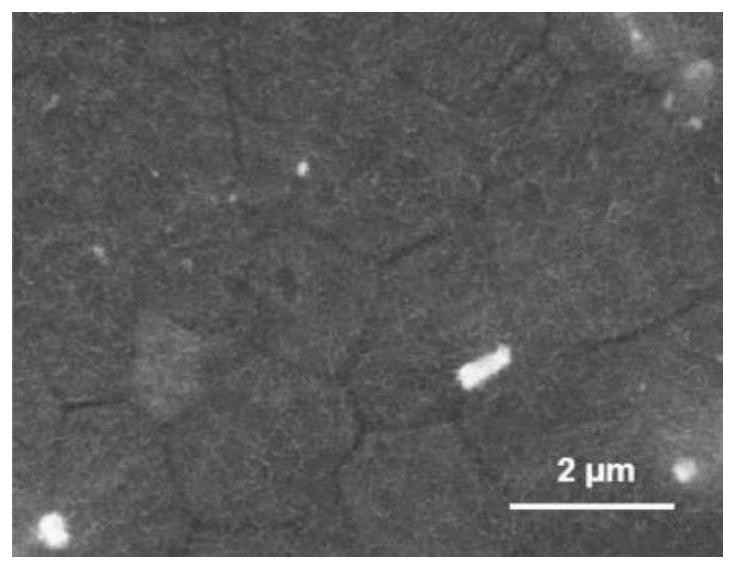

Image

Examples

Embodiment 1

[0031] The magnesium alloy in this embodiment is composed of the following components in mass percentage: Zn 2.0%, Ca 0.19%, Mn 0.3%, and the balance is Mg and unavoidable impurities.

[0032] The preparation method is as follows:

[0033] Material selection: use pure magnesium ingot with a purity greater than 99.99% as the magnesium raw material, use zinc particles with a purity greater than 99.9% as the zinc raw material, and use a magnesium-calcium master alloy with a mass fraction of 25% as the calcium raw material with a mass fraction of 10%. The magnesium-manganese master alloy is used as the manganese raw material.

[0034] Smelting: Pickling and drying the raw materials used for the aforementioned magnesium alloys, putting them into a graphite crucible, introducing a protective gas (SF6:N2=0.4%:99.6%), and keeping the smelting process under a protective atmosphere. After the magnesium ingot and intermediate alloy are melted, use a hand-held electric drill to stir the ...

Embodiment 2

[0038] The magnesium alloy in this embodiment is composed of the following components in mass percentage: Zn 2.3%, Ca 0.2%, Mn 0.5%, and the balance is Mg and unavoidable impurities. The preparation method is the same as in Example 1.

Embodiment 3

[0040] The magnesium alloy in this embodiment is composed of the following components in mass percentage: Zn 2.5%, Ca 0.2%, Mn 0.7%, and the balance is Mg and unavoidable impurities. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com