A single-chamber double-thrust solid rocket motor and rocket

A solid rocket, dual-thrust technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as dynamic pressure balance changes, flight mission failures, and control system burdens, so as to reduce the speed of pressure changes and improve Structural integrity, effect of reducing design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

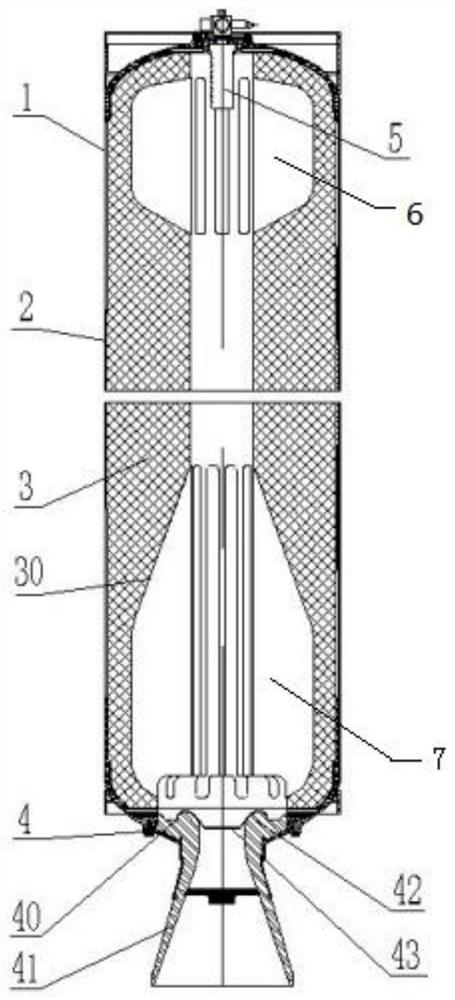

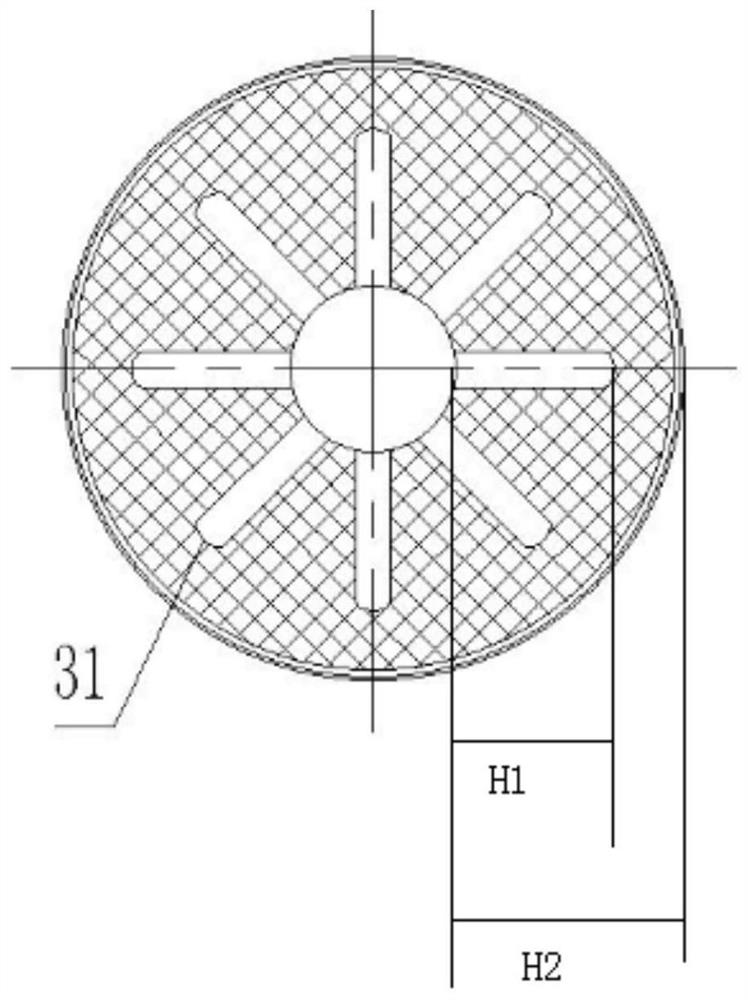

[0024] Please refer to Figure 1 to Figure 2 The schematic diagram of the structure of the single-chamber dual-thrust solid rocket motor provided in Example 1 of the present application, the rocket motor includes a combustion chamber casing 1, an insulating layer 2 attached to the inner surface of the combustion chamber casing 1, and a The propellant grain 3 inside, the igniter 5 arranged at one end of the combustion chamber casing 1 and the nozzle assembly 4 arranged at the other end of the combustion chamber casing 1;

[0025] The propellant grain 3 is provided with an inner hole that runs through both ends thereof; the propellant grain 3 is uniformly provided with a radially extending front wing groove 6 at one end of the inner hole close to the igniter 5 . One end of the inner hole close to the nozzle assembly 4 is evenly provided with radially extending empennage grooves 7;

[0026] In this embodiment, the combustion chamber casing 1 is the structural frame of the engine,...

Embodiment 2

[0038] This embodiment provides a rocket, on which the single-chamber dual-thrust solid rocket motor described in Embodiment 1 is installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com