Dual thrust bearing for a turbocharger

A thrust bearing and double thrust technology, applied in the direction of rotating bearings, bearings, turbine/propulsion device lubrication, etc., can solve problems such as time-consuming repair or replacement, damage to the bearing mounting surface, and expensive central housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

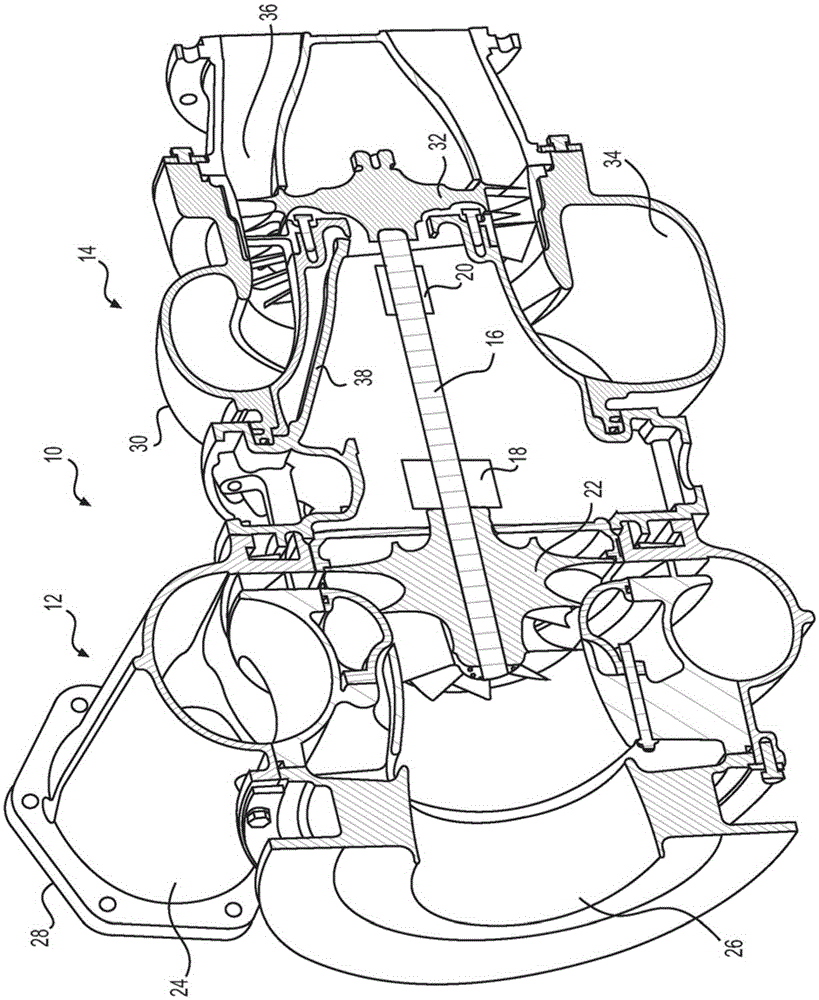

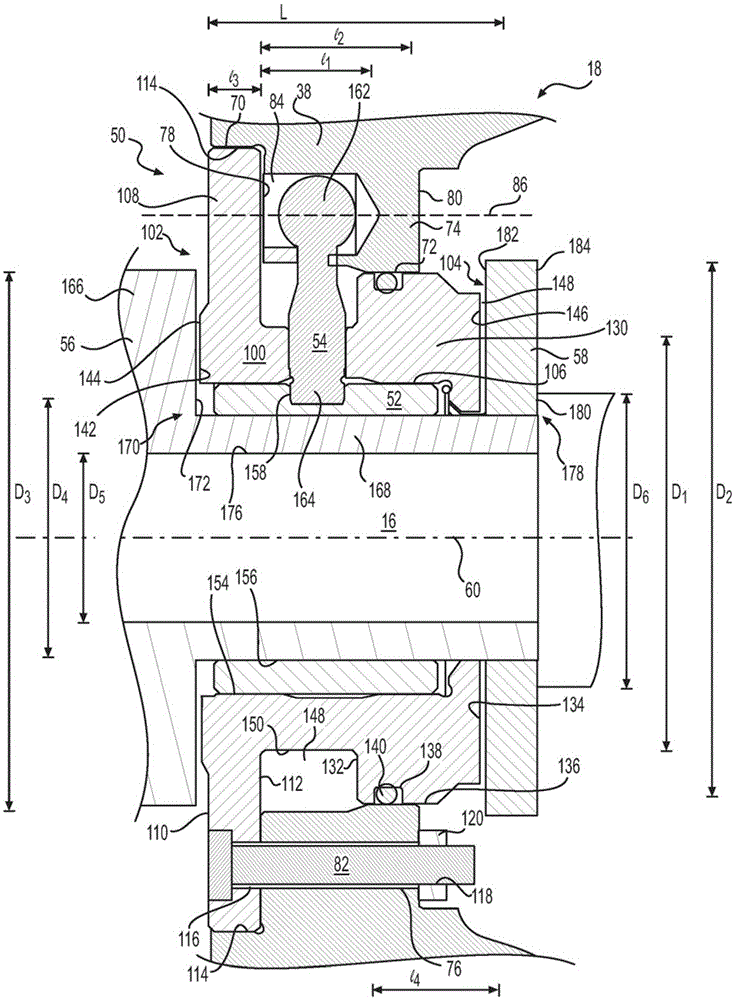

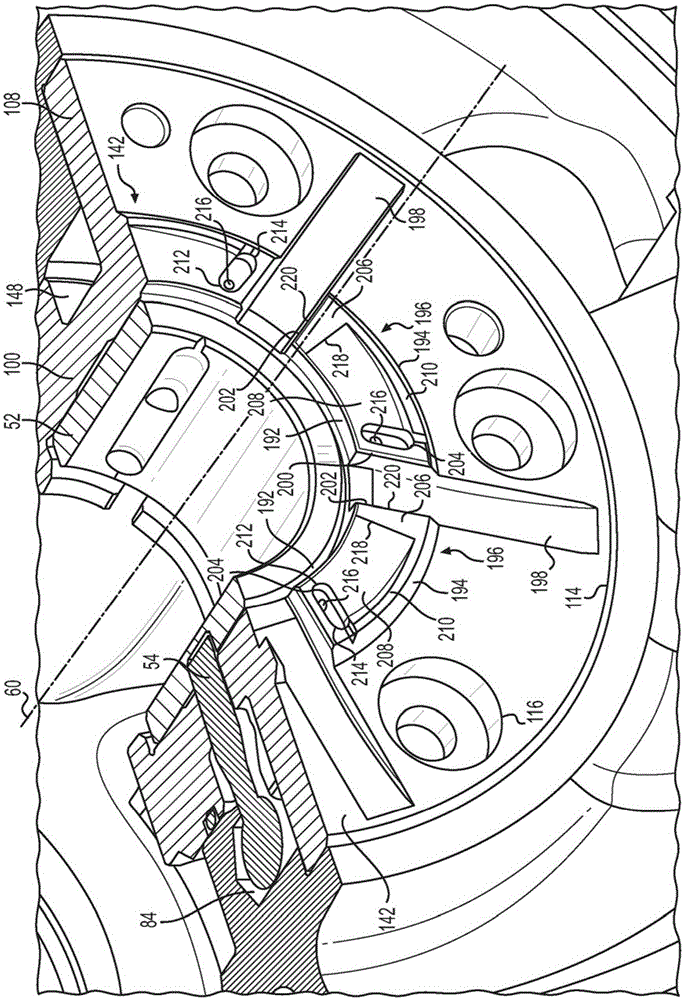

[0017] figure 1 An exemplary embodiment of a turbocharger 10 is shown. Turbocharger 10 may be used with an engine (not shown) of a machine performing some type of operation related to an industry such as railroading, shipping, power generation, mining, construction, agriculture, or another industry known in the art. Such as figure 1 As shown, turbocharger 10 may include a compressor stage 12 and a turbine stage 14 . Shaft 16 may extend between compressor stage 12 and turbine stage 14 . Shaft 16 may be supported by one or more bearing assemblies 18 and / or bearings 20 . Compressor stage 12 may embody a fixed geometry compressor wheel 22 connected to shaft 16 and configured to compress air received from the environment to a predetermined pressure level prior to entering the engine for combustion. Air may enter compressor housing 24 via compressor inlet 26 and exit compressor housing 24 via compressor outlet 28 . As the air moves through compressor stages 12 , compressor whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com