Longitudinal driving device for numerical control lathe

A driving device, CNC lathe technology, applied in feeding devices, metal processing mechanical parts, metal processing equipment and other directions, can solve the problems of affecting processing accuracy, wire nut damage, falling deformation, etc., to improve processing accuracy, easy to replace parts, Resolving the effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

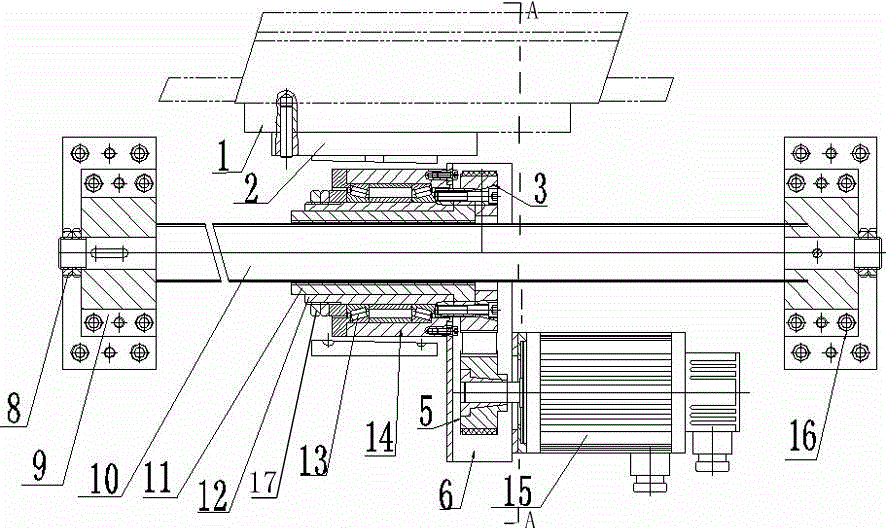

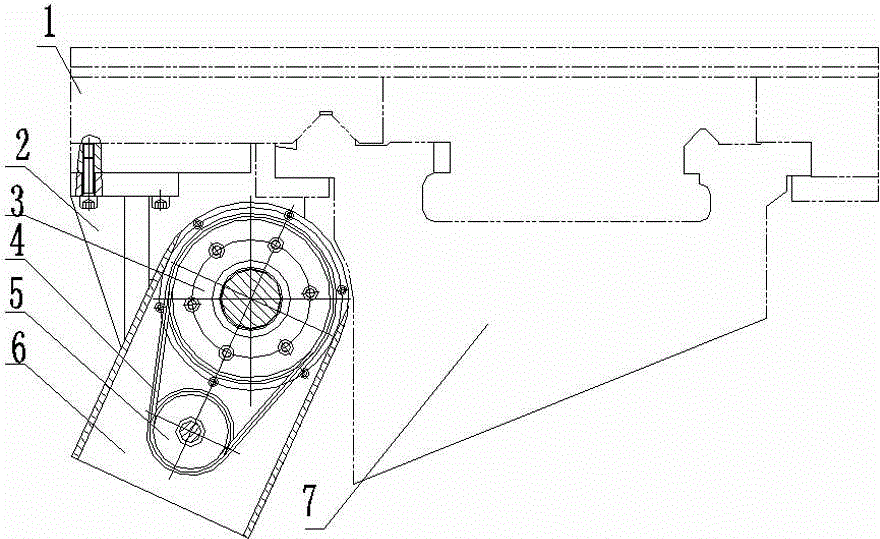

[0015] The present invention as figure 1 , 2 shown

[0016] Including the lathe bed 7, the lathe bed 7 is provided with a large supporting plate 1, and a ball screw 10 is arranged under the lathe bed 7, and one end of the ball screw 10 is fixed on its tail end 16, and the other end passes through the fixed support. Seat 9 is fastened with nut-8; ball screw 10 is screwed with nut 11, and transition sleeve 12 is arranged outside nut 11, and double thrust bearing 13 is arranged outside transition sleeve 12, and double thrust bearing 13 is provided with bearing Seat 14; one end of transition sleeve 12 and screw nut 11 is fixed with pulley 1 3 by bolts, and the other end of transition sleeve 12 is provided with nut 2 17 to fix double thrust bearing 13 in bearing housing 14; Connecting bracket 2 is arranged, and bearing block 14 is fixed in connecting bracket 2; Connecting bracket 2 is also provided with motor bracket 6, is horizontally provided with servo motor 15 on motor bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com