Dual-thrust toothed belt type lifter with spring-strip buffering gear and self-adaptive sliding block

A lifter and self-adaptive technology, applied in the direction of door/window accessories, buildings, wing leaf control mechanisms, etc., to achieve the effects of prolonging service life, reducing frictional resistance, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

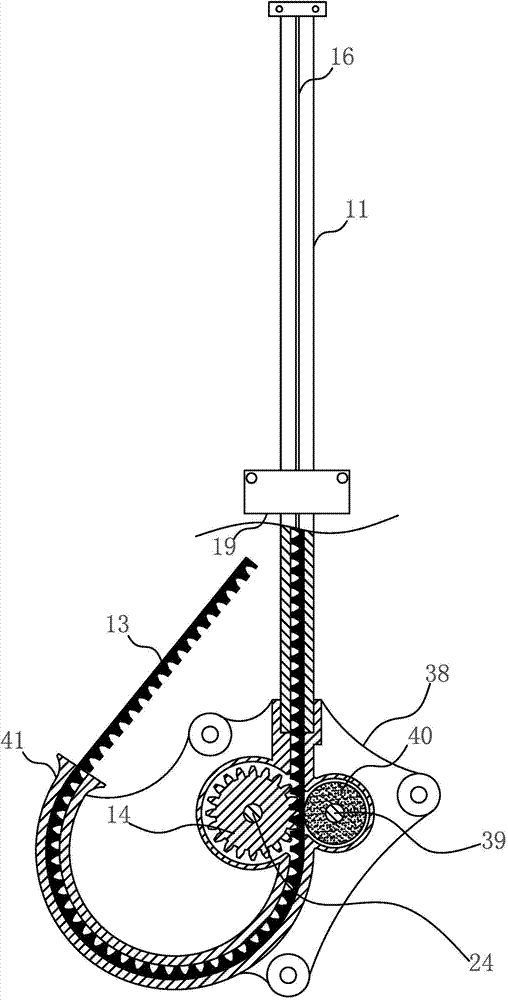

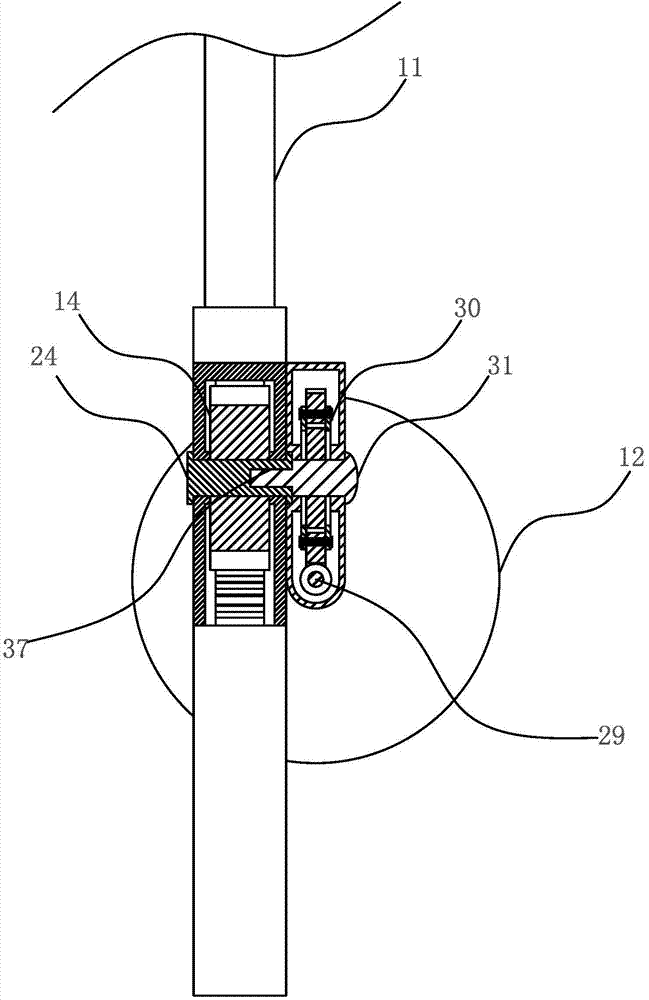

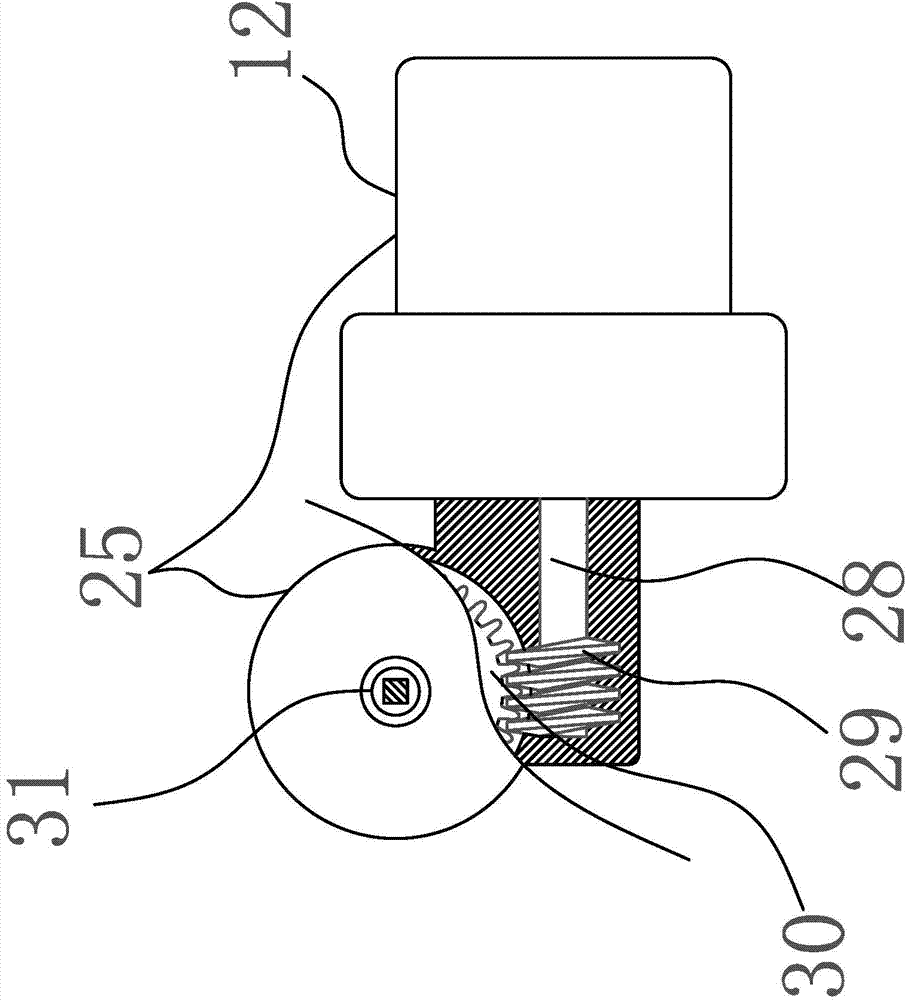

[0024] Figure 1-Figure 12 In the embodiment, a self-adaptive slide block lifter of a double-push toothed belt type shrapnel buffer gear includes a drive mechanism (25), a lifter bracket (11) and a lifter base (38), and is characterized in that: the lifter bracket ( 11) It is a rectangular strip-shaped pipe body, a slit is longitudinally arranged on the side wall of the pipe body to form a slide rail (16), and a rectangular toothed belt guide groove (47) is formed on the inner wall of the pipe body of the lifter support (11), and the toothed belt The guide groove (47) is provided with a toothed belt (13) that can twitch up and down and has toughness, and the toothed belt drive gear (13) and the lower end of the lifter support (11) are located on the lifter base (38). 14) are meshed with each other, and the back side of the toothed belt at the meshing place is provided with a pressing wheel (40) that compresses and pushes the toothed belt (13). The upper end of the toothed belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com