Double-thrust-rod fixing seat based on 8.1-meter full-bearing city bus

A technology for urban passenger cars and fixed seats, which is applied to vehicle springs, vehicle components, and cantilevers mounted on pivots, etc., can solve the problem of increasing processing difficulty and manufacturing cost, not meeting the lightweight design requirements, and increasing vehicle manufacturing. Cost and other issues, to achieve the effect of simple welding composition, light weight, and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

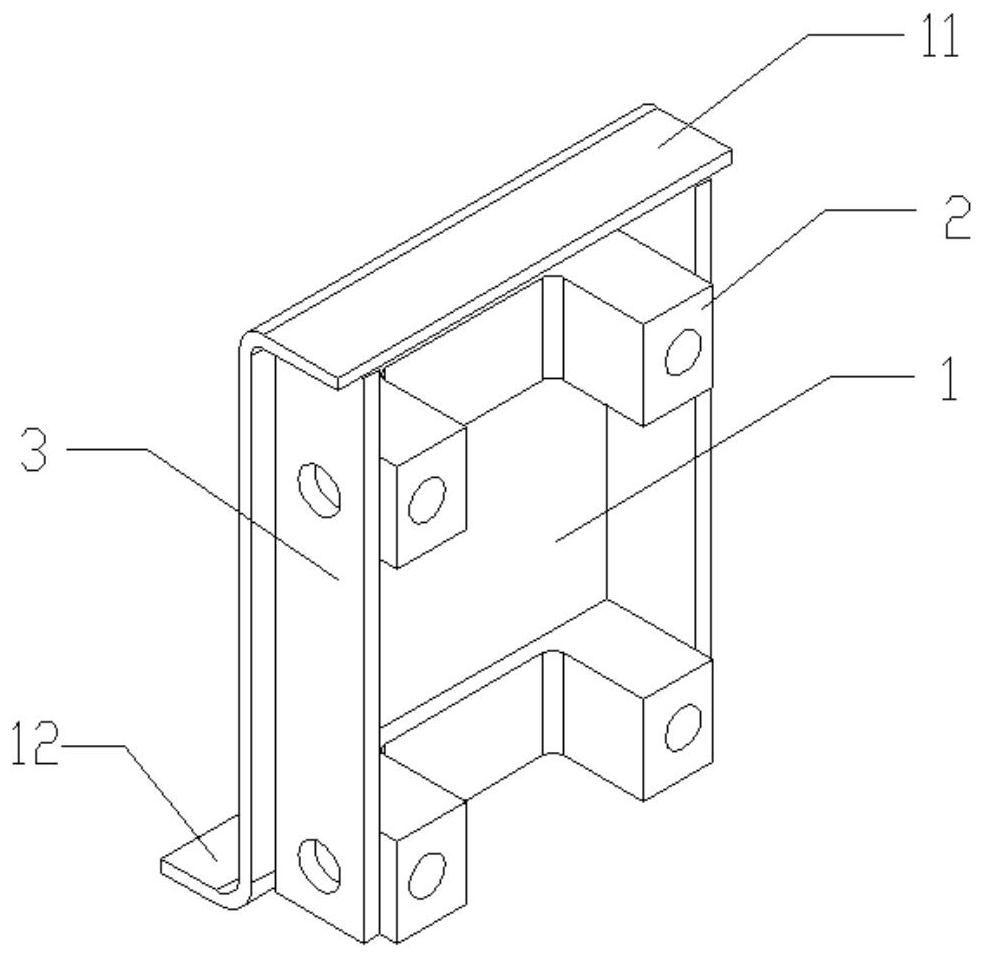

[0024] In the following, the present invention will be further explained in conjunction with the accompanying drawings, so that those skilled in the art can better understand.

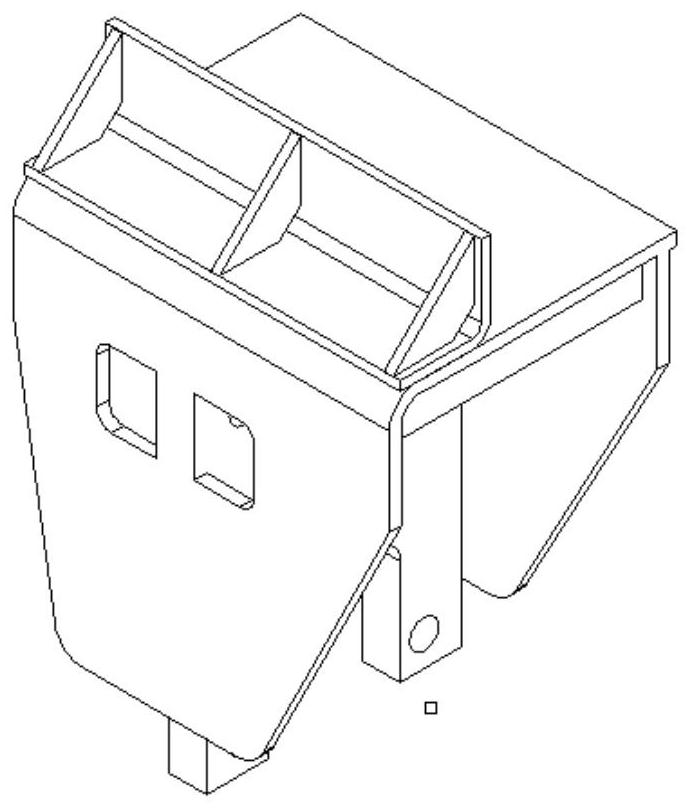

[0025] see figure 2 , a double thrust rod fixing seat based on an 8.1-meter full load-bearing city bus, welded on the frame rectangular tube, used to install the double thrust rods, to ensure the stability of the double thrust rods, including the bottom plate of the fixing seat 1, the fixing seat body 2 and the left and right stiffening plate risers 3.

[0026] A first side plate 11 and a second side plate 12 are arranged on the base plate 1 of the fixing base, the first side plate 11 is arranged on the top of the base plate 1 of the fixing base perpendicular to the base plate 1 of the fixing base, and the second side plate 12 is perpendicular to the base plate of the fixing base 1 The fixed seat bottom plate 1 is arranged at the bottom end of the fixed seat bottom plate 1, and is located on the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com