Energy storage flywheel with minimum power magnetic bearing and motor/generator

A technology of magnetic bearings and generators, applied in bearings, shafts and bearings, controlling mechanical energy, etc., can solve the problems of cost reduction and vitality, and achieve the effects of reducing connectors and current drives, high power density, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

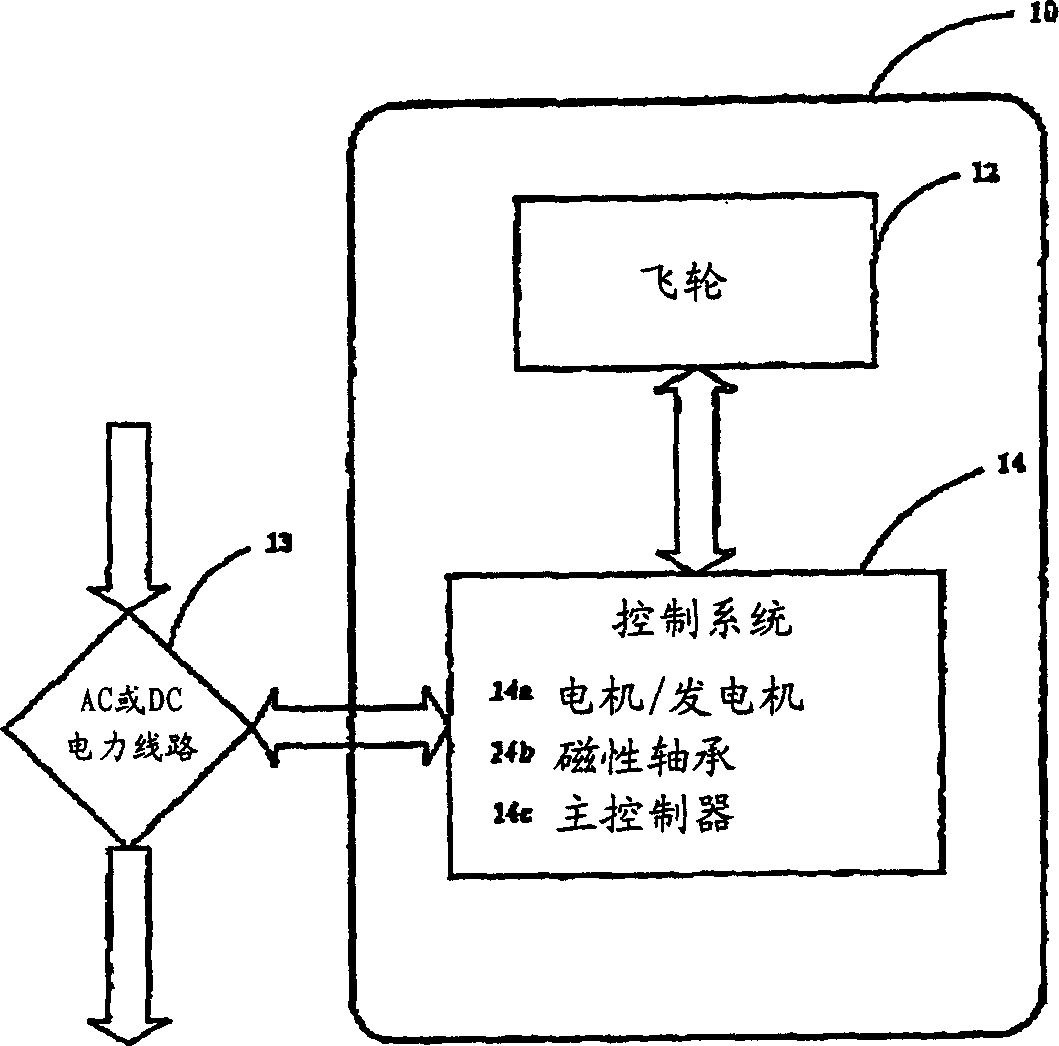

[0019] figure 1 is a block diagram of the system 10 of the present invention. The flywheel assembly 12 is connected to a control system 14 . The control system includes motor / generator power electronics 14a, magnetic bearing controller 14b and master controller 14c. These components can input electrical power from a power line 13 to the flywheel assembly 12 or output electrical power from the flywheel assembly 12 to the power line 13 . Flywheel 12 converts input power from electrical energy to mechanical potential energy. On output, the flywheel 12 converts mechanical energy into electrical energy and supplies it to the control system 14 . The motor / generator power electronics 14a regulates the input and output power to match the power line 13, converting AC to DC or vice versa to match the flywheel voltage to the power line 13 voltage. The magnetic bearing controller 14b monitors the shaft position and uses the magnetic bearing to make adjustments to maintain the motor / ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com