Improved scroll-type fluid displacement apparatus with fully compliant floating scrolls

A fluid displacement and scroll technology, which is applied to the components of pumping devices for elastic fluids, sealing devices of piston pumps, and combination of rotary piston/oscillating piston pumps for elastic fluids, etc. It can solve the problem of manufacturing technology. Complex, high cost, limited service life and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

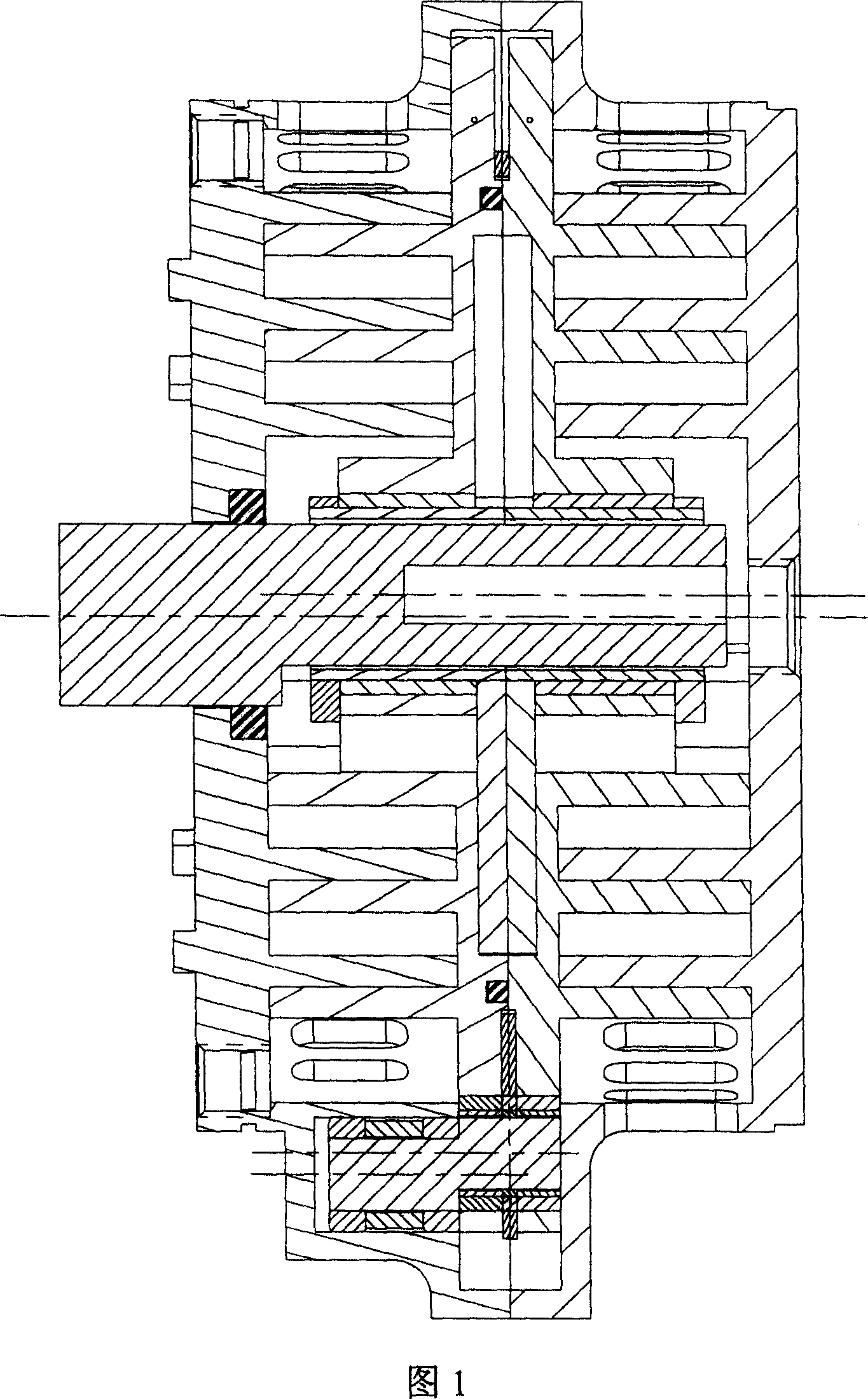

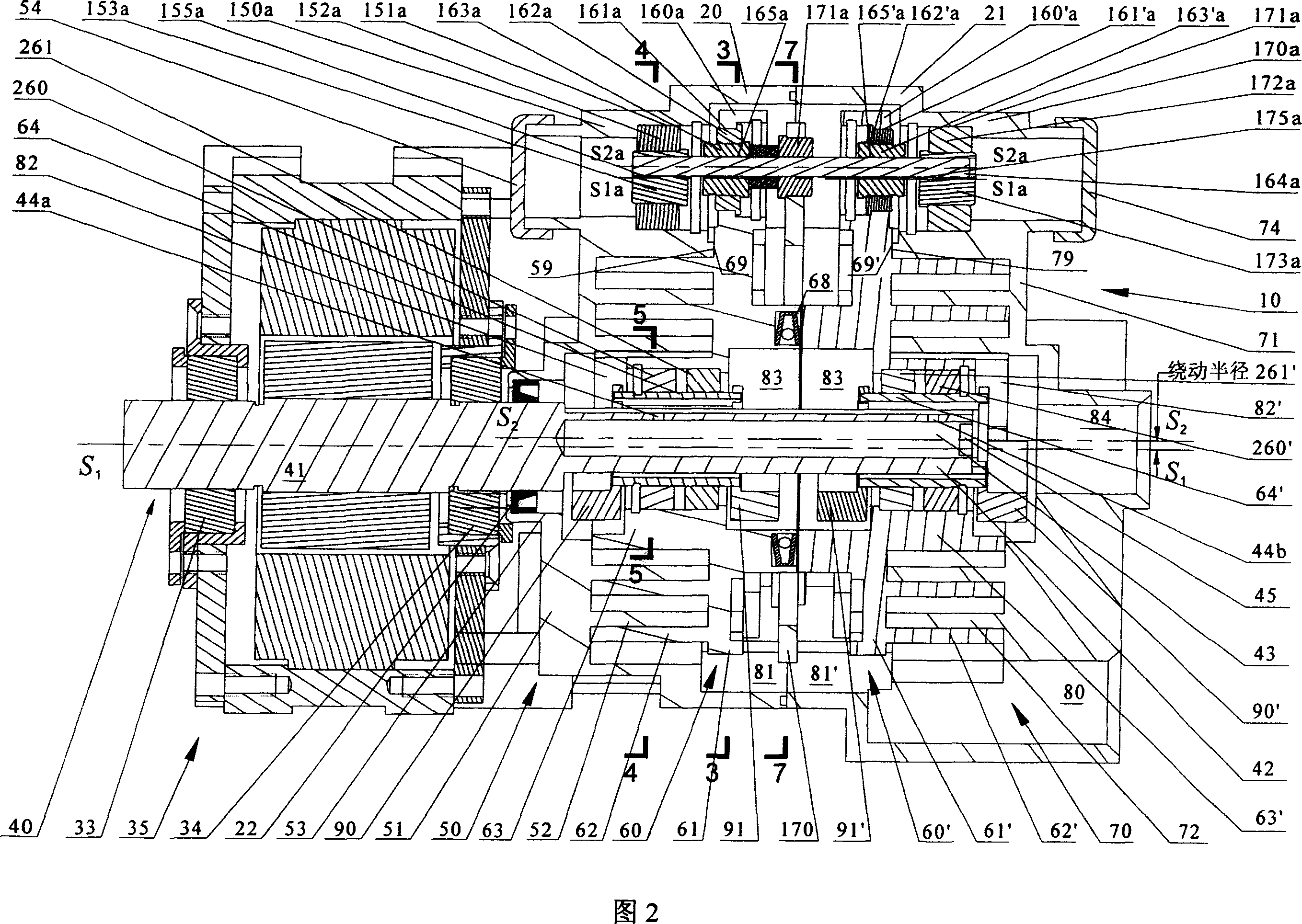

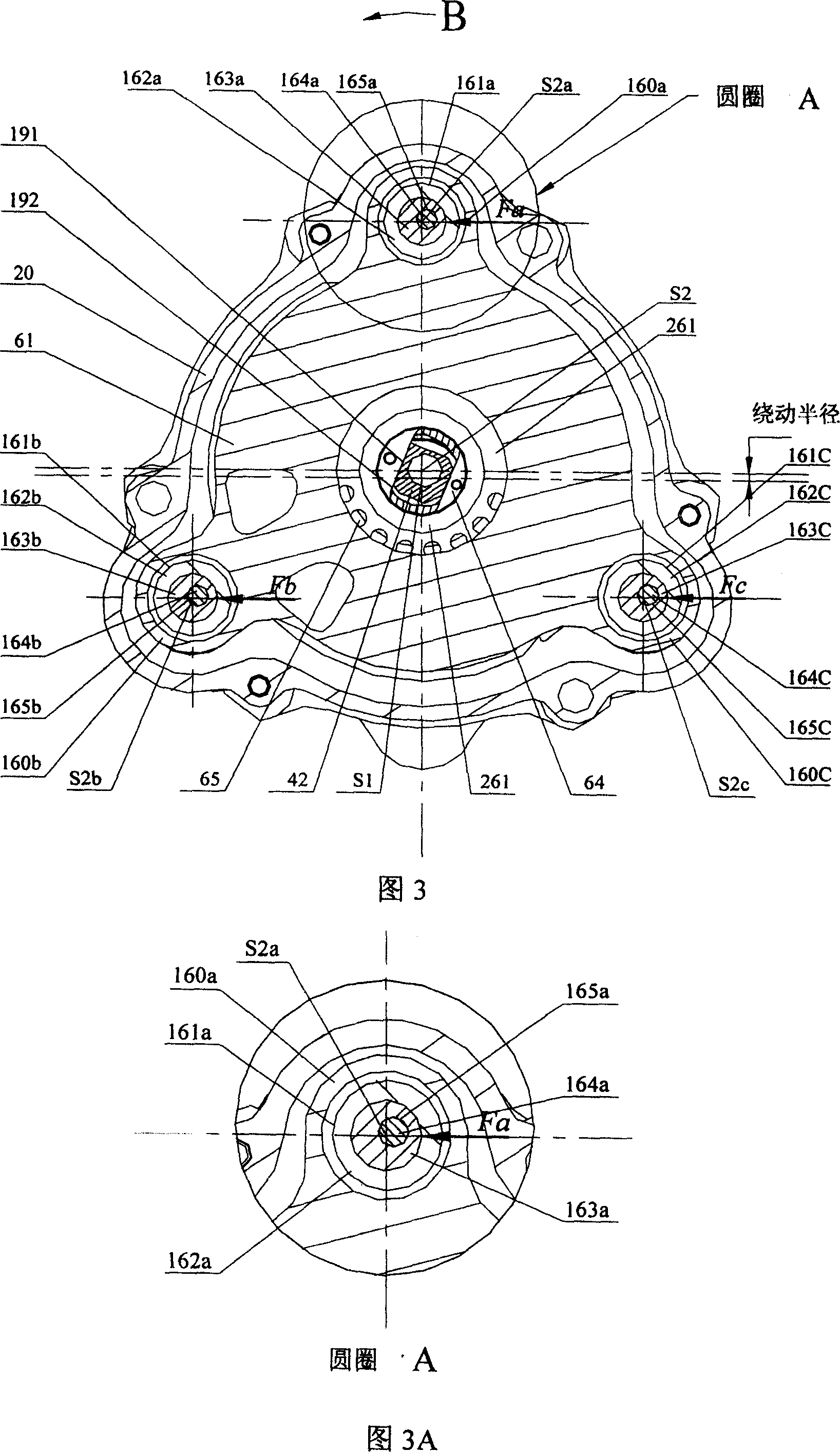

[0032] Referring to Figure 2, it depicts an omnidirectionally compliant suspended twin scroll air compressor with a CSPS mechanism. The compressor 10 includes a front casing 20 and a rear casing 21 . The central drive crankshaft 40 consists of a central shaft 41 and a crankpin 42 . The central shaft 41 is supported by the crankshaft bearings 33 and 34 and driven by the motor 35 to rotate about the axis S1-S1. The shaft seal 22 seals the high pressure gas in the central plenum 82 from the surrounding environment. The axial hole 43 is located in the middle of the crankpin 42, and is used to balance the centrifugal force generated by the crankpin 42 when the central crankshaft 40 rotates around the axis S1-S1. The axial hole 43 can also store lubricating grease. These greases can be gradually released through the small holes 44a and 44b to respectively lubricate the driving surface 191 of the crank pin 42 and the driven sliding surfaces 192 and 192' of the central driving join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com