Double-thrust self-balancing uniform-load structure bearing for high-speed rotor

A high-speed rotor, self-balancing technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of increased linear speed and limited lifting space, and achieve the effect of optimizing the structure size and wide application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

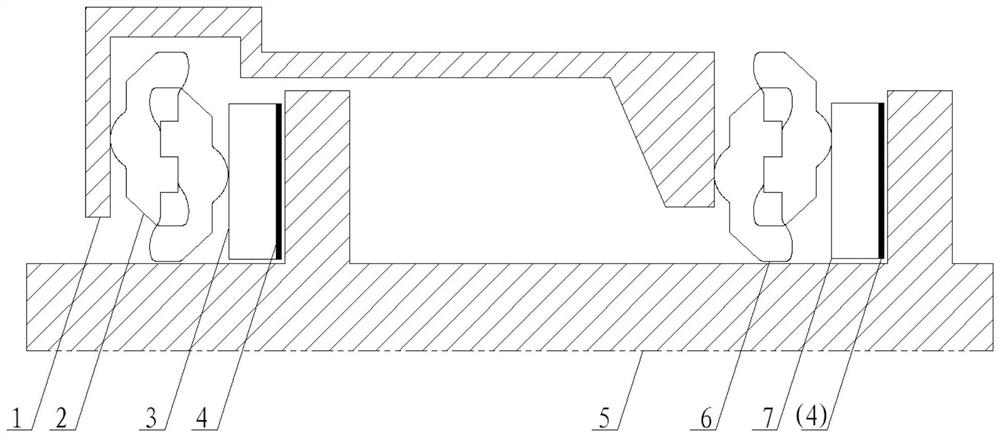

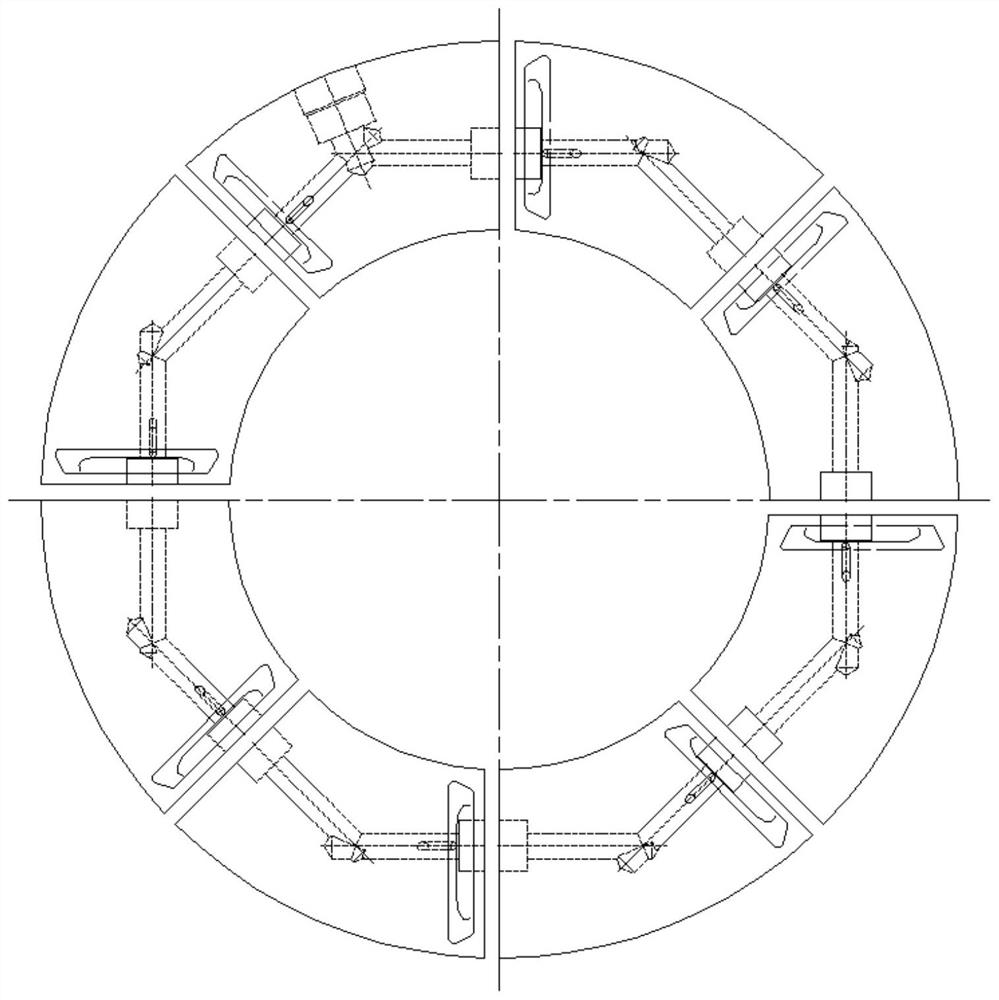

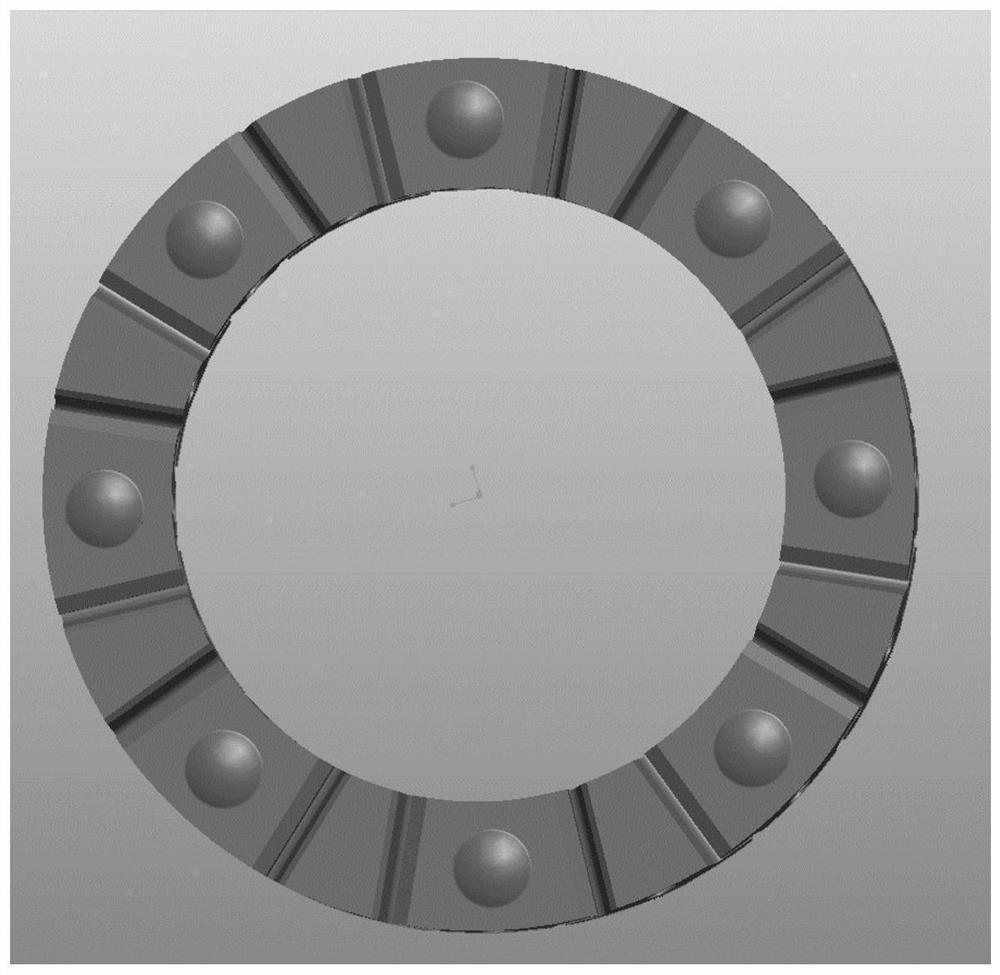

[0014] The technical solution adopted in the present invention is: a double-thrust self-balancing load-sharing structural bearing for high-speed rotors, including feedback components, front balance weights, front thrust pads, bearing copper alloy, rotor, rear balance weights, and rear thrust pads Piece. The copper alloy surface of the bearing is plated with silver, and the space between the silver plated layer and the rotor has a self-lubricating function at the moment of starting, and after operation, an oil film is formed through lubricating oil to bear the axial load thrust. The axial thrust transmitted to the rotor from the outside is at the moment of starting, and the force on the front and rear thrust pads depends on the gap between the rotor and the rotor during installation. However, after operation, the front and rear thrust tiles can be evenly stressed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com