Process for making double-magnetic-repulsion gas safety valve of motor

A gas safety valve and manufacturing process technology, applied in the valve operation/release device, lift valve, valve details, etc., can solve the problems of people's life and property safety threats, large swing of the end cover, and short valve opening stroke, etc. Eliminate potential safety hazards, reduce pressure loss, and increase the effect of displacement height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

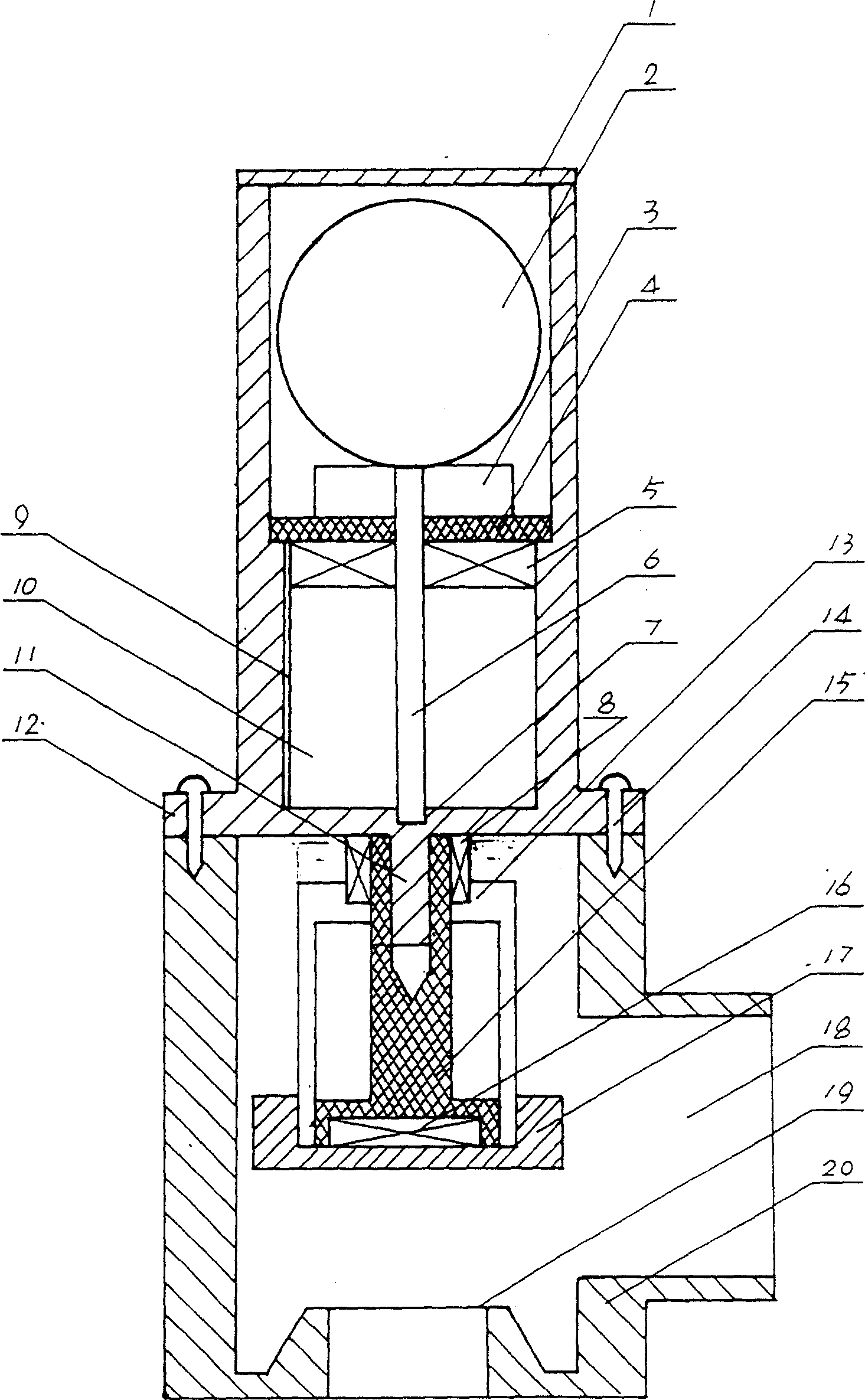

[0008] A manufacturing process of a gas safety valve with double magnetic push by a motor mainly includes the following steps:

[0009] a. There is a micro DC motor in the motor box of the valve, and a threaded drive shaft with a main magnet is connected through the gear box and the positioning plate; b. The corresponding position of the motor box and the main magnet is provided with the main magnet. c. Provide a system connector to connect and fix the motor box with the valve body; d. Provide secondary magnetic steel displacement guide rails through the connecting bolts under the system connector, and the bottom of the secondary magnetic steel displacement guide rails Equipped with anti-thrust magnets; e. A "U"-shaped adapter with auxiliary magnets is provided outside, and the bottom end of the "U"-shaped adapter is covered with a valve end cover; the main and auxiliary magnets are opposite to each other. The faces of the secondary magnets are of the same polarity, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com