Patents

Literature

82results about How to "Small bend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

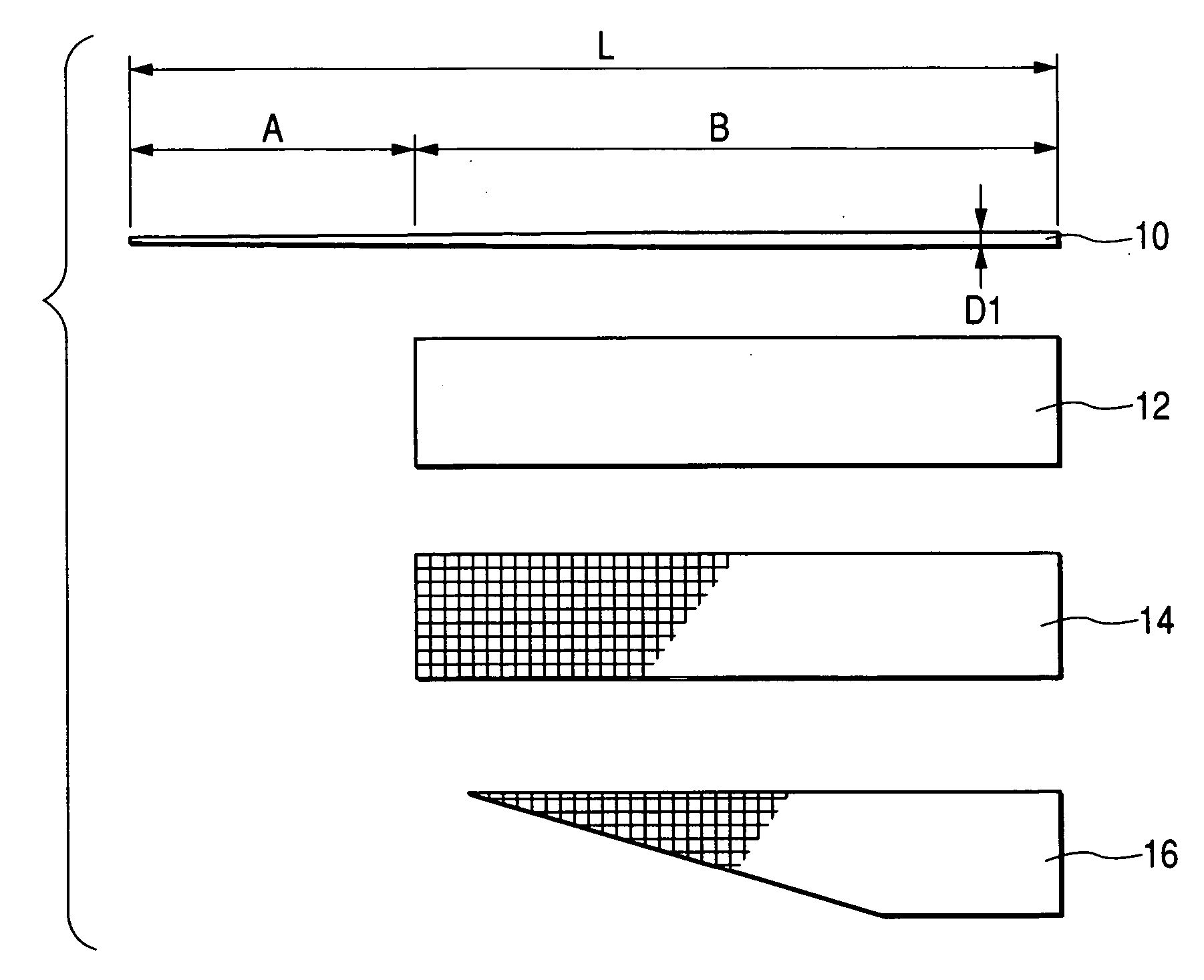

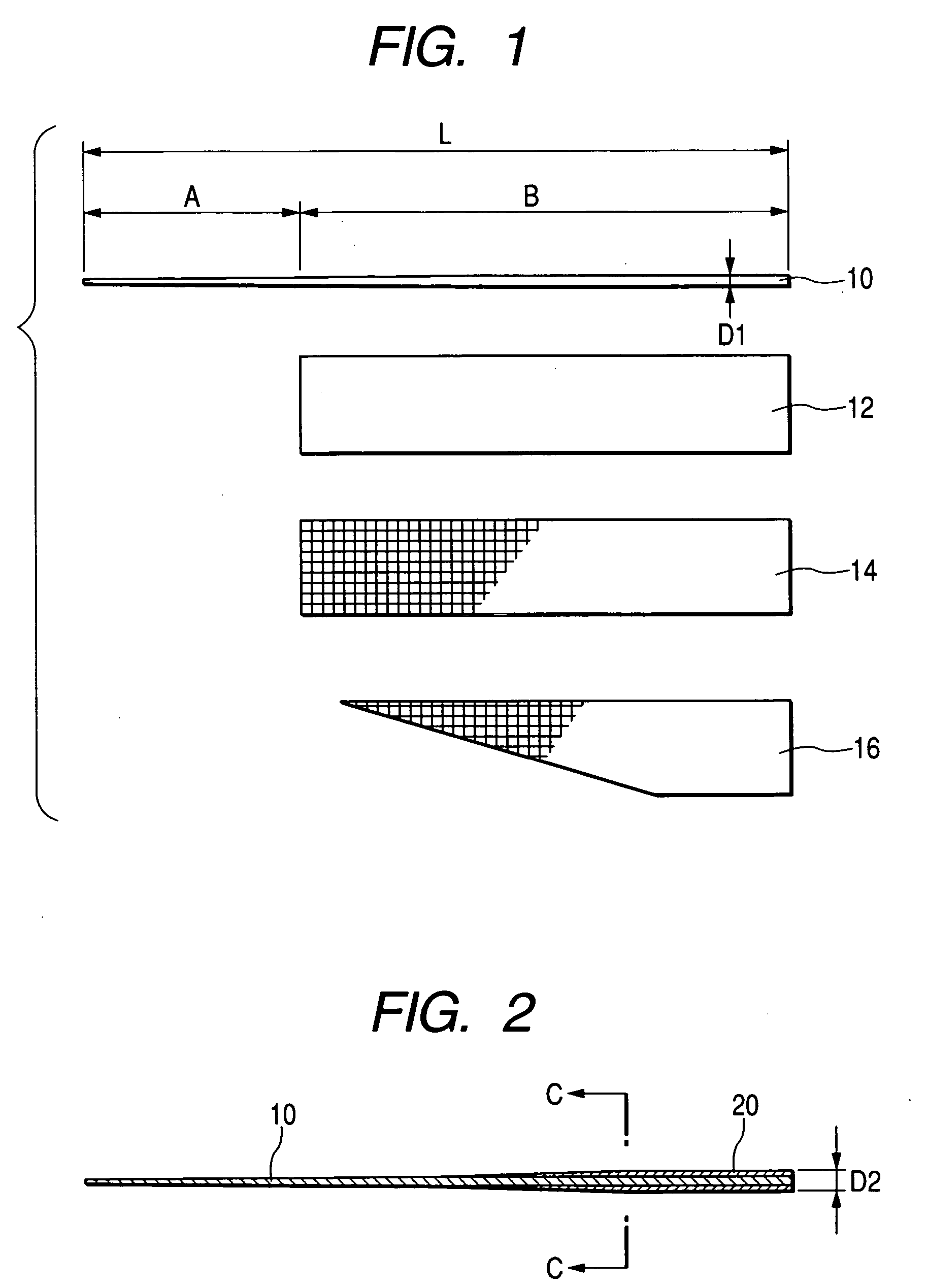

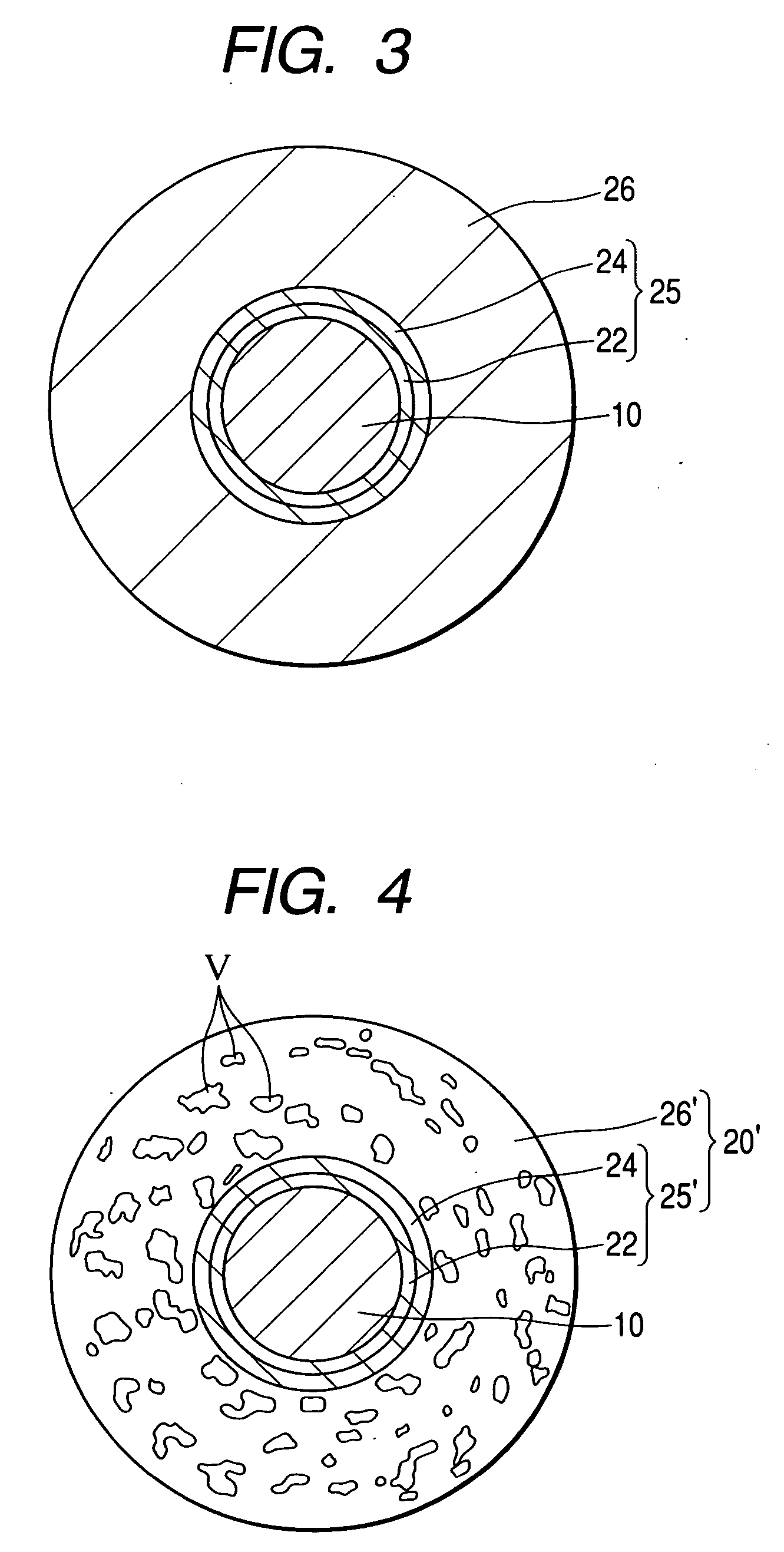

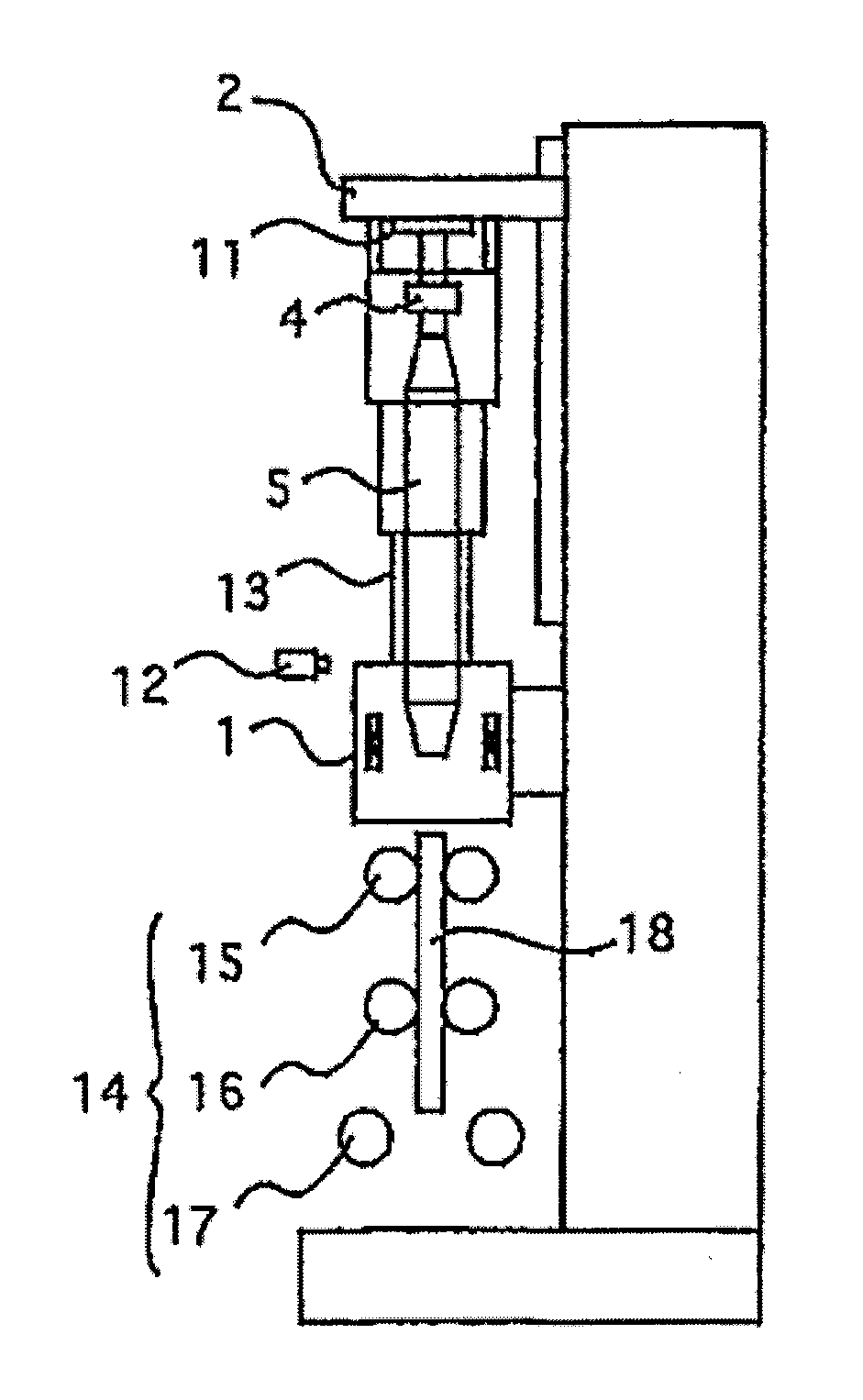

Process for Producing Glass Strip, Glass Strip and Glass Substrate

InactiveUS20070271957A1Improve flatnessReduce adhesionSynthetic resin layered productsGlass reforming apparatusInternal pressureSurface roughness

A manufacturing method of a glass strip, the method including a heating and drawing process of heating and softening a glass plate preform (1), drawing the glass plate preform to have a desired thickness and forming a glass strip (11), wherein at the heating and drawing process the glass plate preform (1) is drawn so that an internal pressure of a heating furnace (3) is kept positive relative to an atmospheric pressure and so that gas flows introduced to both surfaces of the glass plate preform (1) respectively are equal to each other within the heating furnace (3). It is possible to improve a surface roughness and obtain a desired surface roughness.

Owner:FURUKAWA ELECTRIC CO LTD

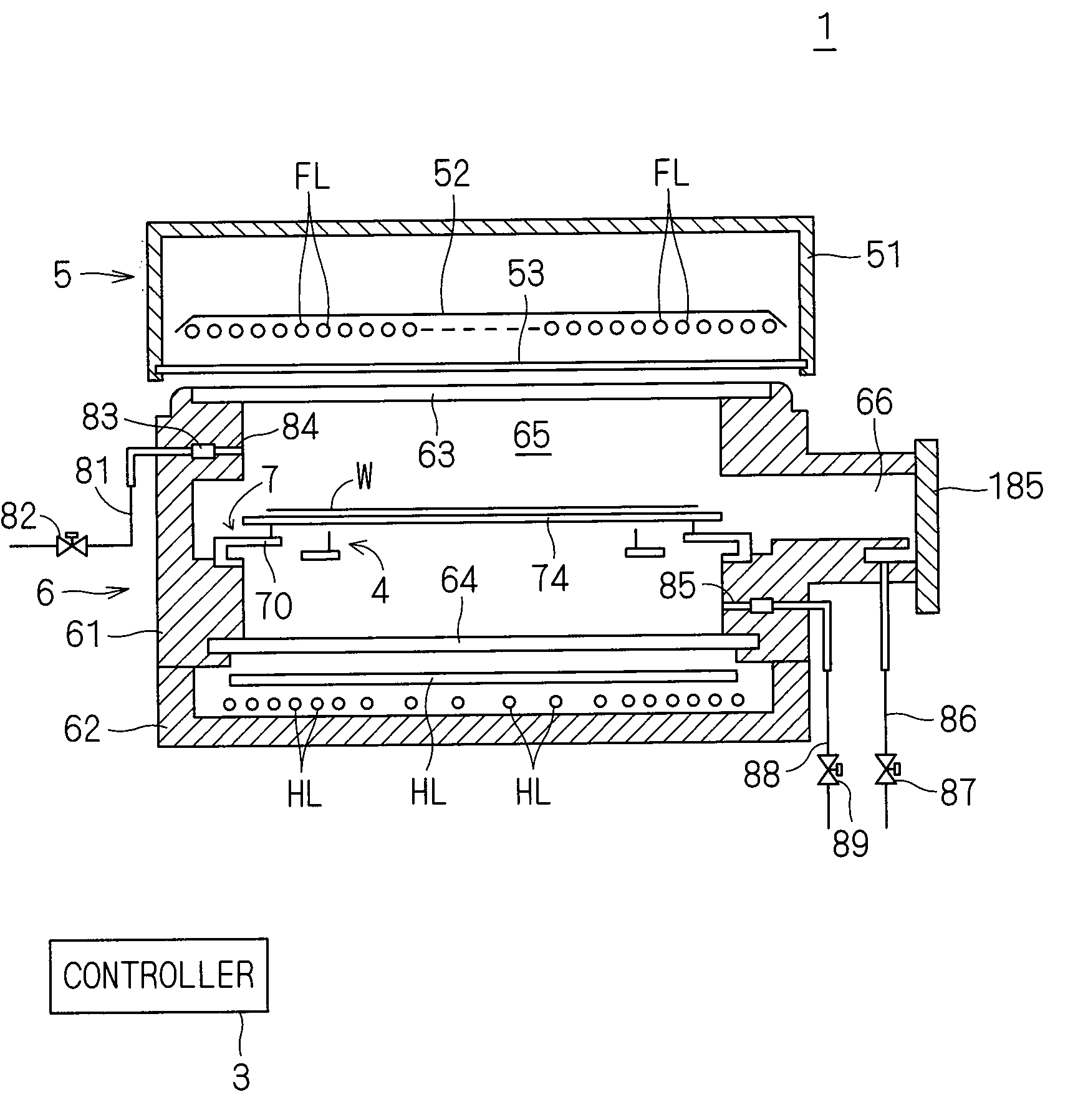

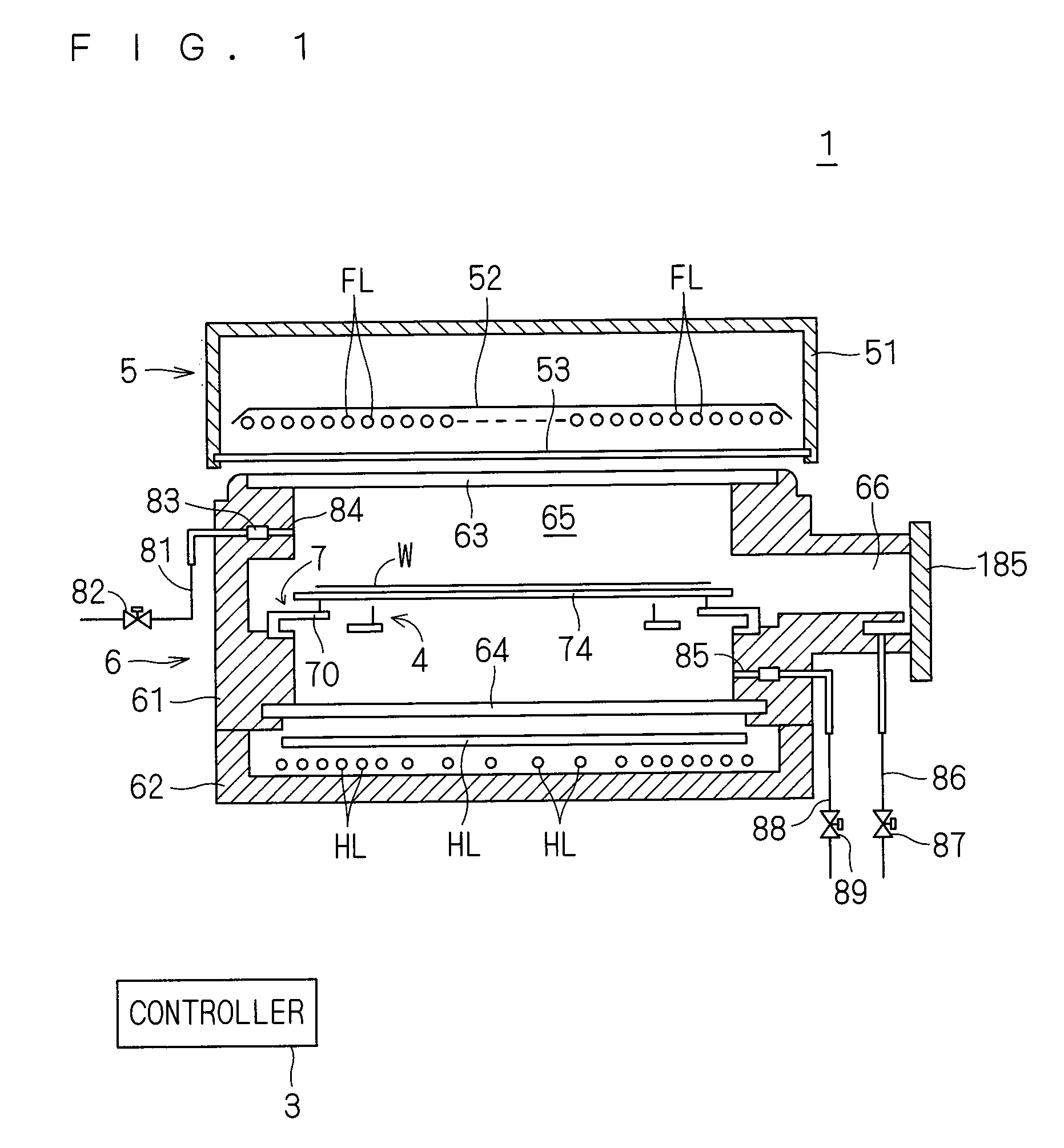

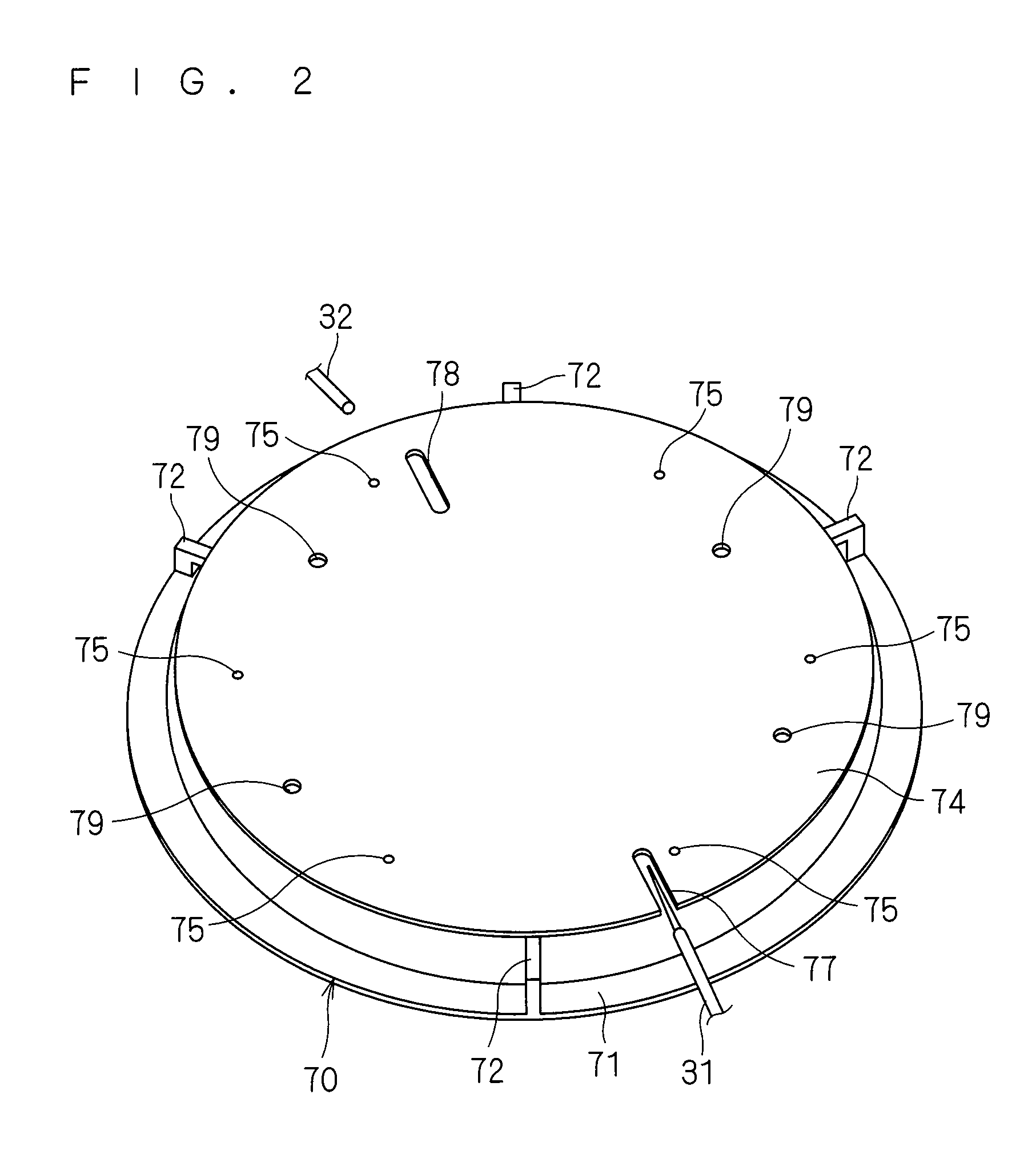

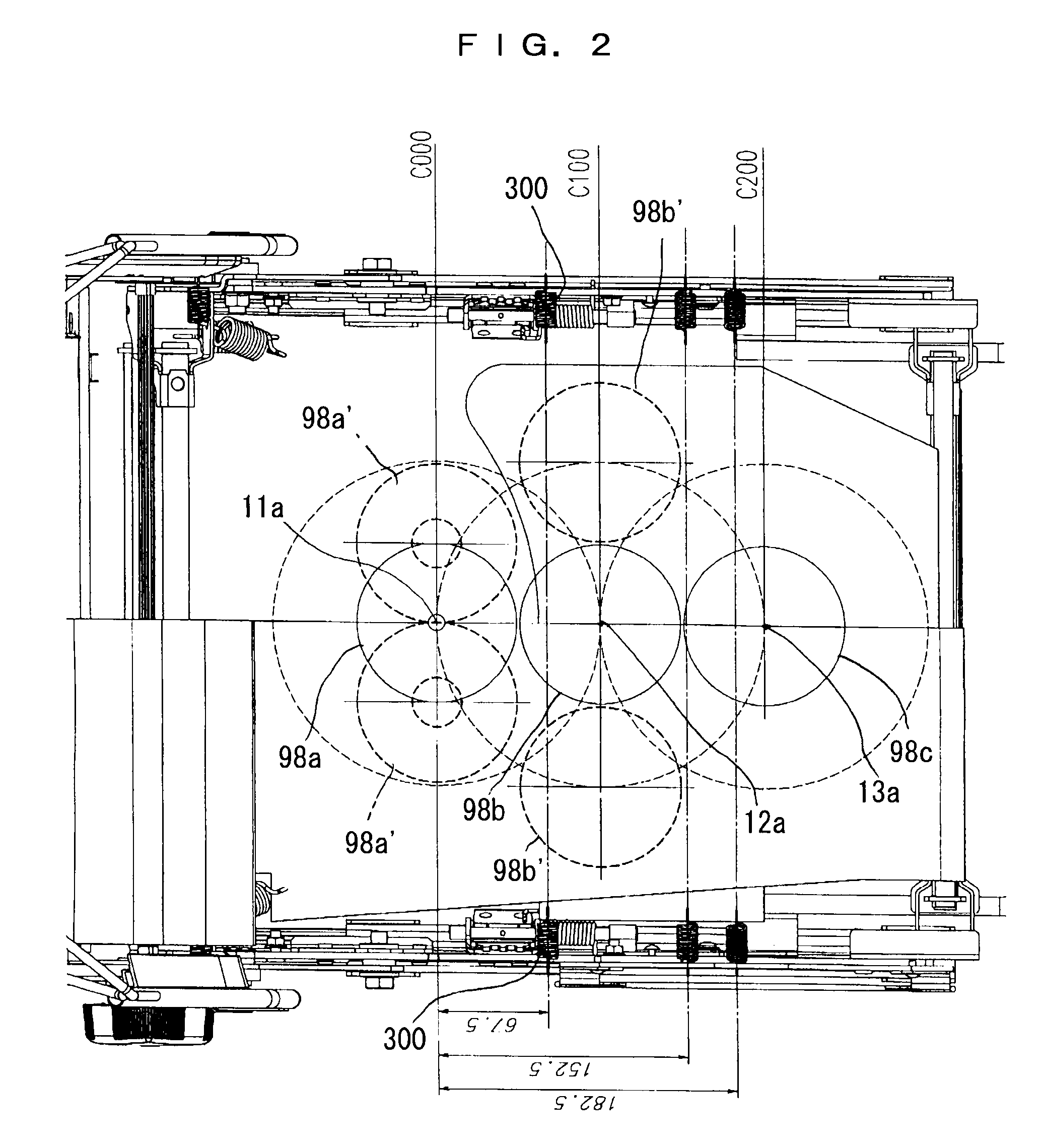

Heat treatment apparatus for heating substrate by exposing substrate to flash light

InactiveUS20090175605A1Suppresses temperature changesPrevent treatment failureSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingElectrical resistance and conductanceSusceptor

A semiconductor wafer to be treated is placed in a horizontal position on a holding plate held by a susceptor. Six bumps are mounted upright on the upper surface of the holding plate. The semiconductor wafer is supported by the six bumps in point contacting relationship, and is held at a distance ranging from 0.5 mm to 3 mm from the upper surface of the holding plate. Light is directed from halogen lamps onto the semiconductor wafer held by the holding plate to preheat the substrate until the temperature of the semiconductor wafer is increased up to a predetermined temperature. Thereafter, flash light is directed from flash lamps onto the semiconductor wafer. A thin gas layer lying between the back surface of the semiconductor wafer and the upper surface of the holding plate acts as a resistance to suppress the motion of the semiconductor wafer, thereby preventing a crack in the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

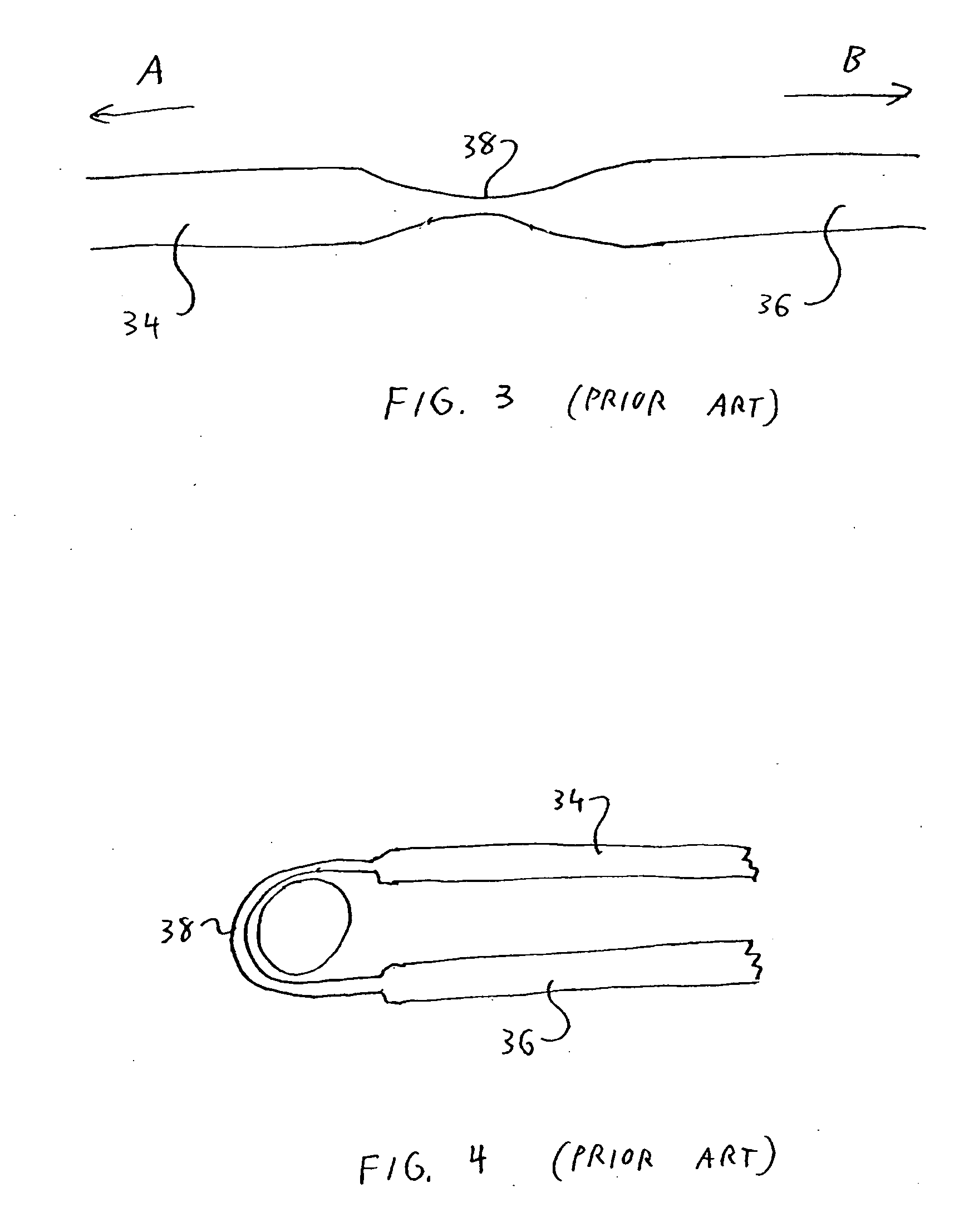

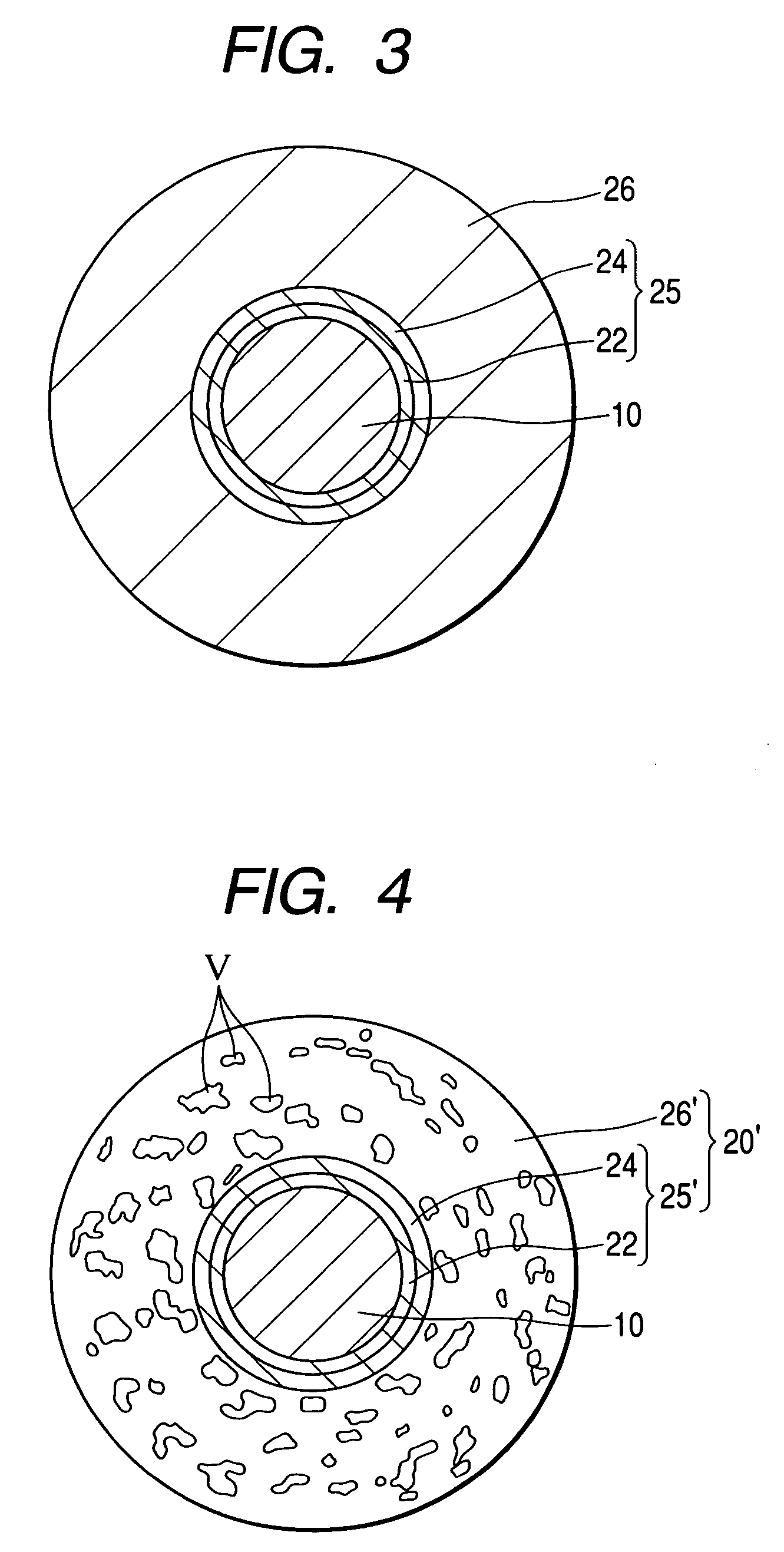

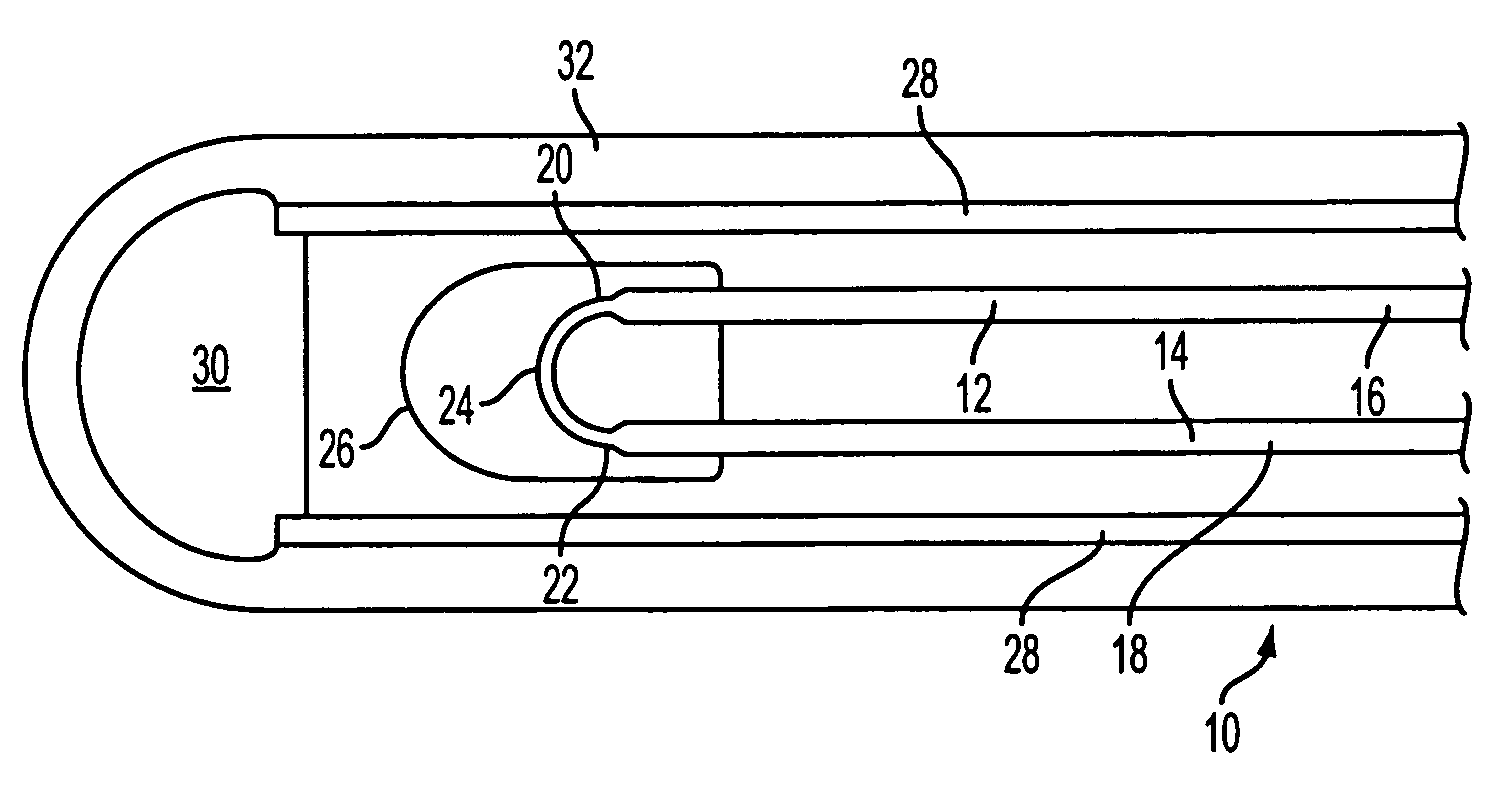

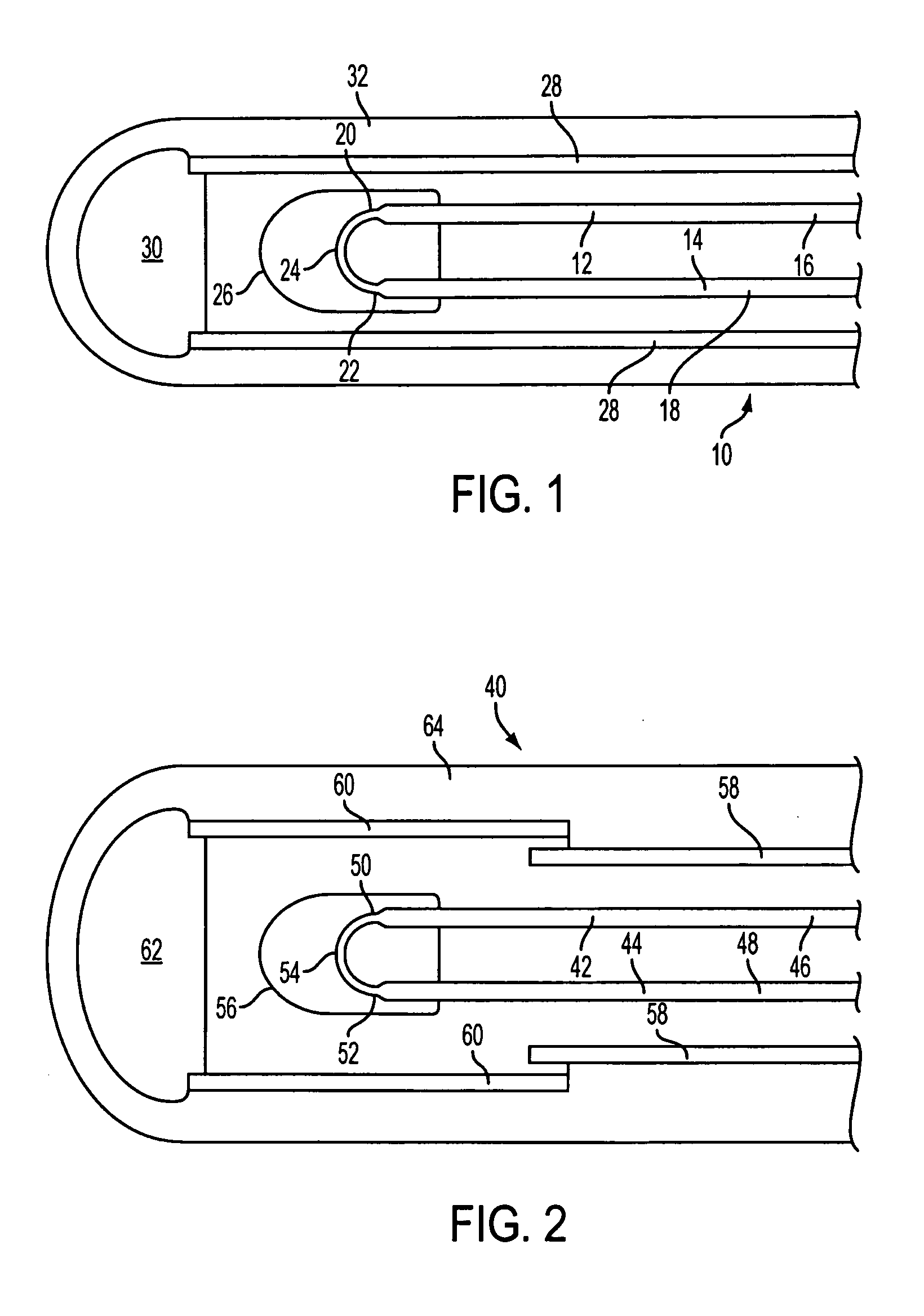

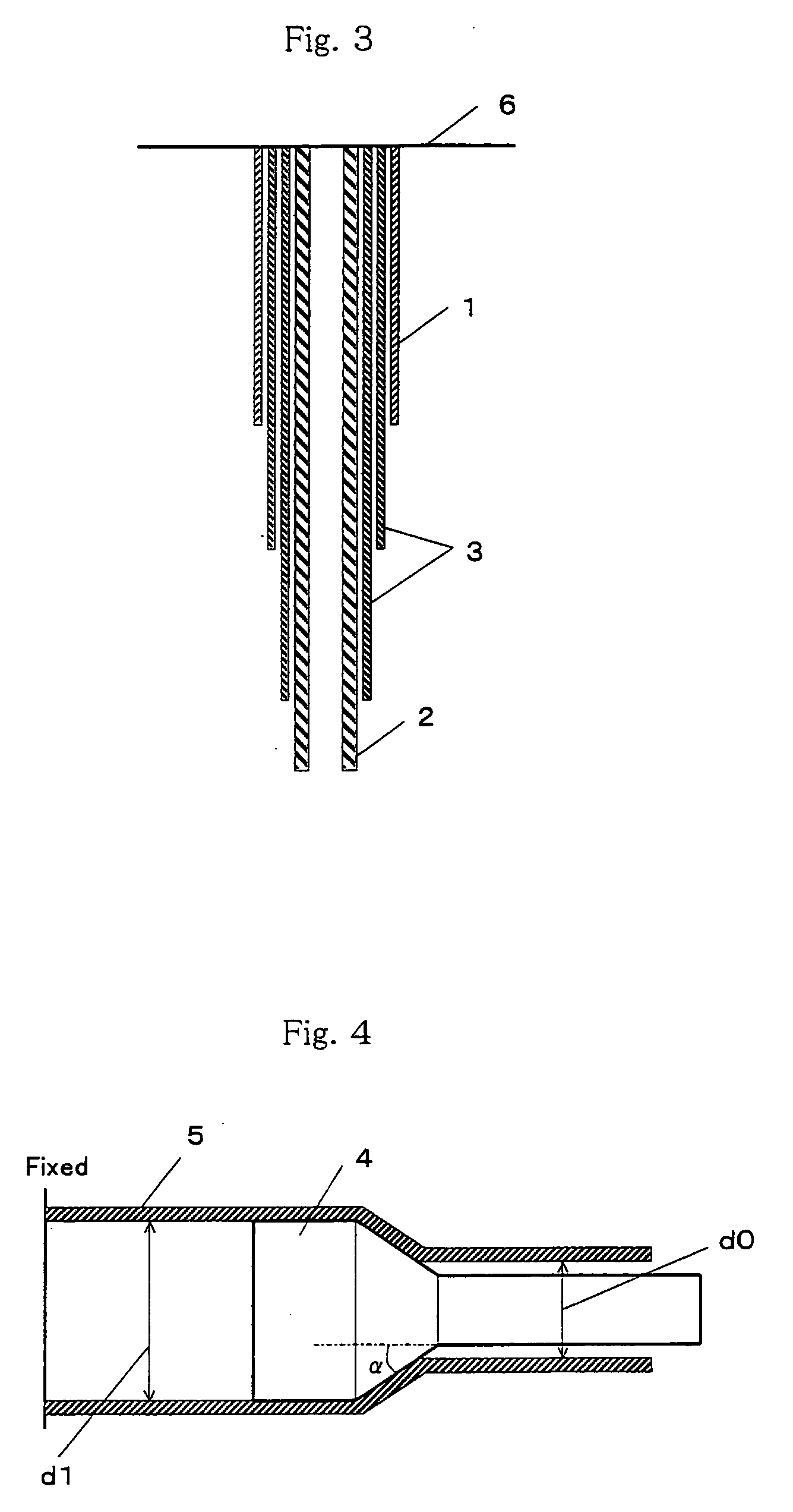

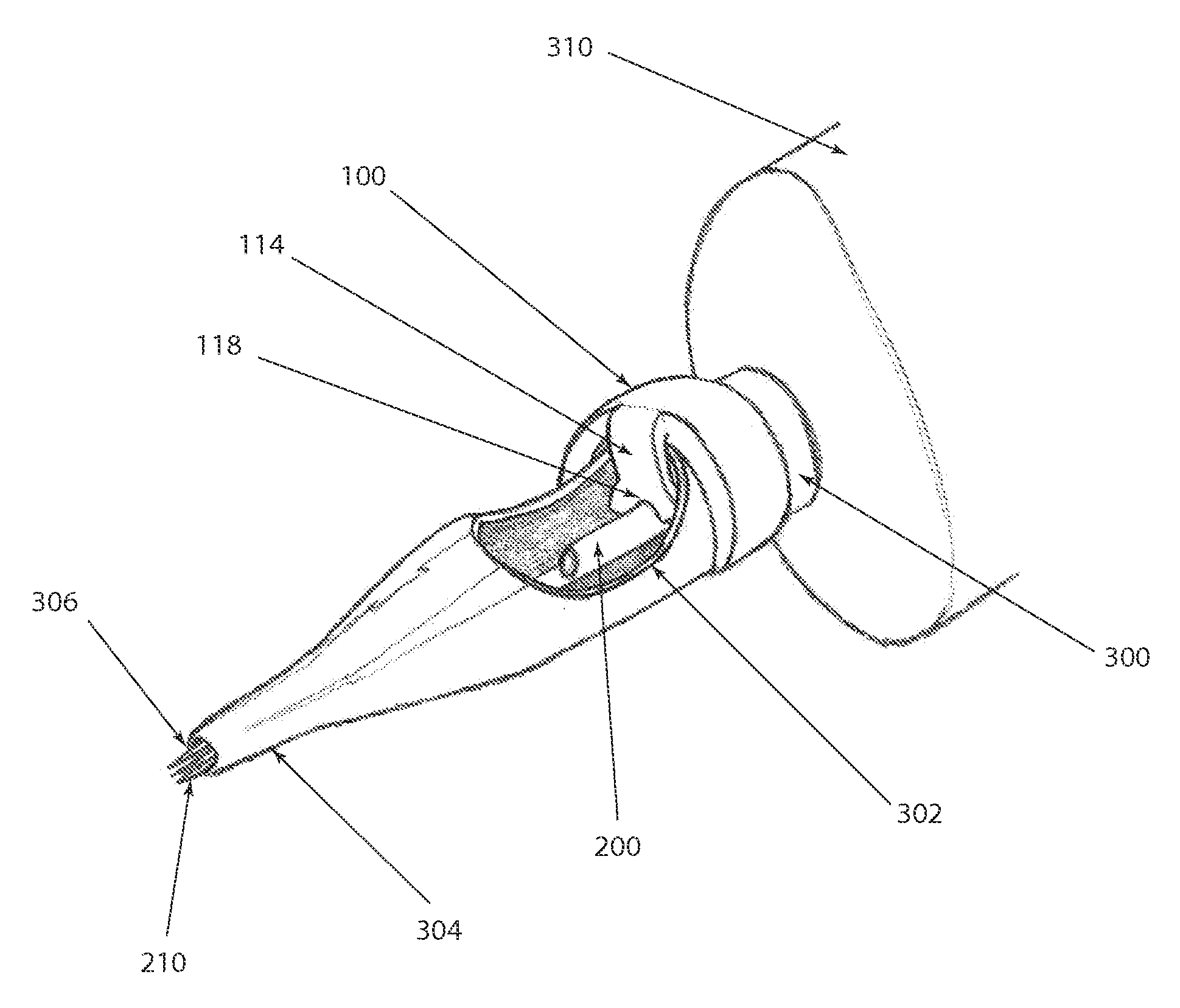

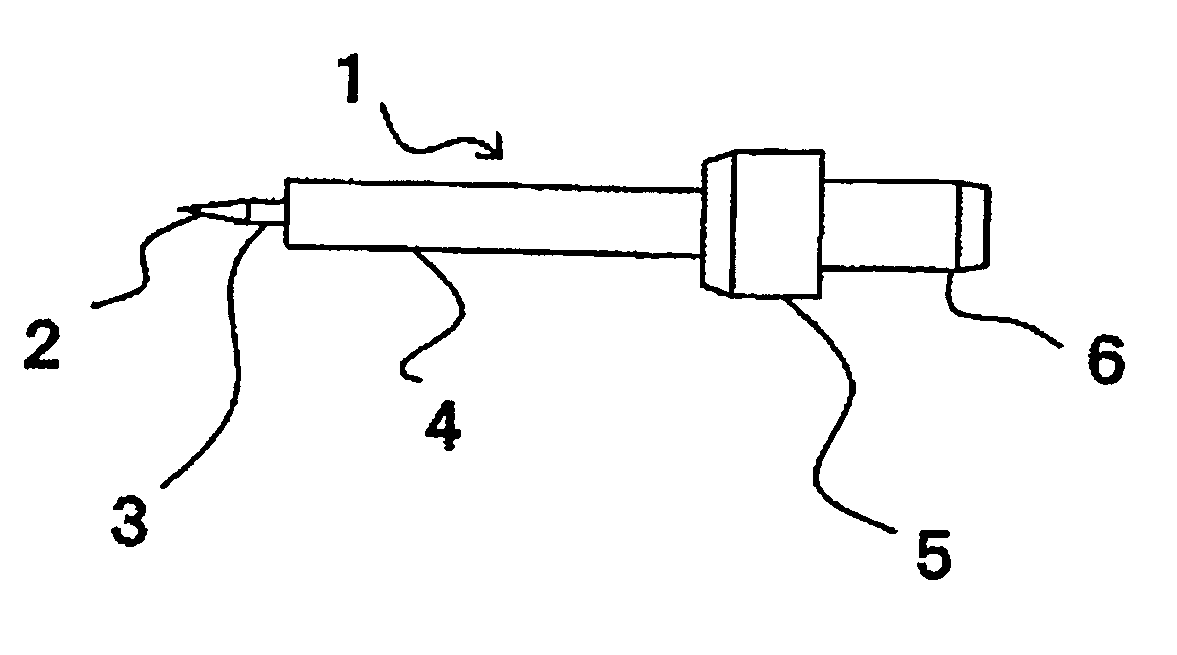

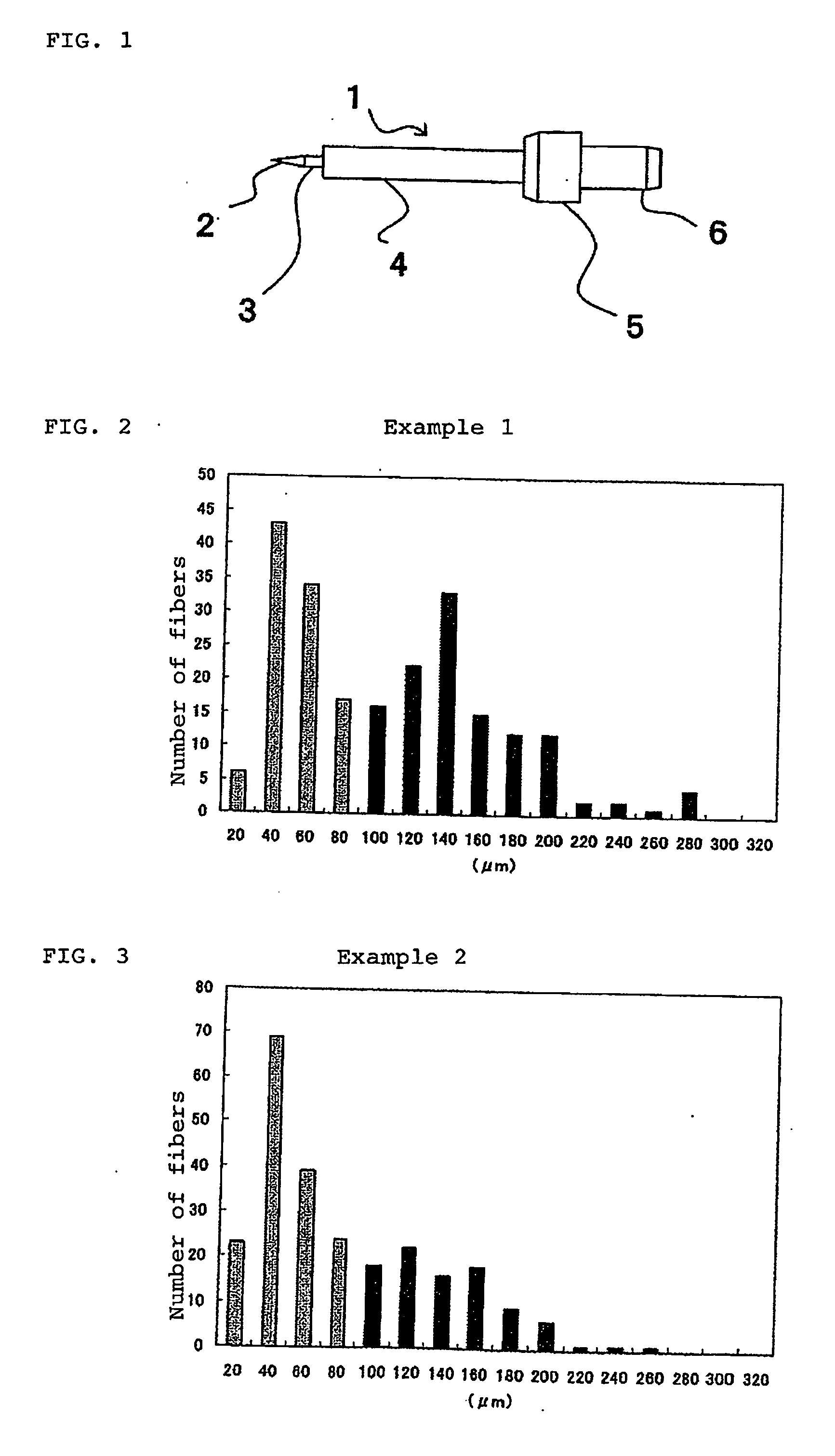

Fiber optic cable with miniature bend incorporated

ActiveUS20060104578A1Easy to optimizeSmall diameterConstructionsFibre mechanical structuresFiberControl line

A fiber optic cable includes a miniature bend at one end, connecting a pair of optical fibers forming an originating light path with a return light path. The use of the miniature bend to connect to the originating and return light paths results in an end portion of the cable having a sufficiently small diameter to permit the cable to be blown into otherwise inaccessible locations, for example, the control line of an oil well.

Owner:AFL COMM LLC

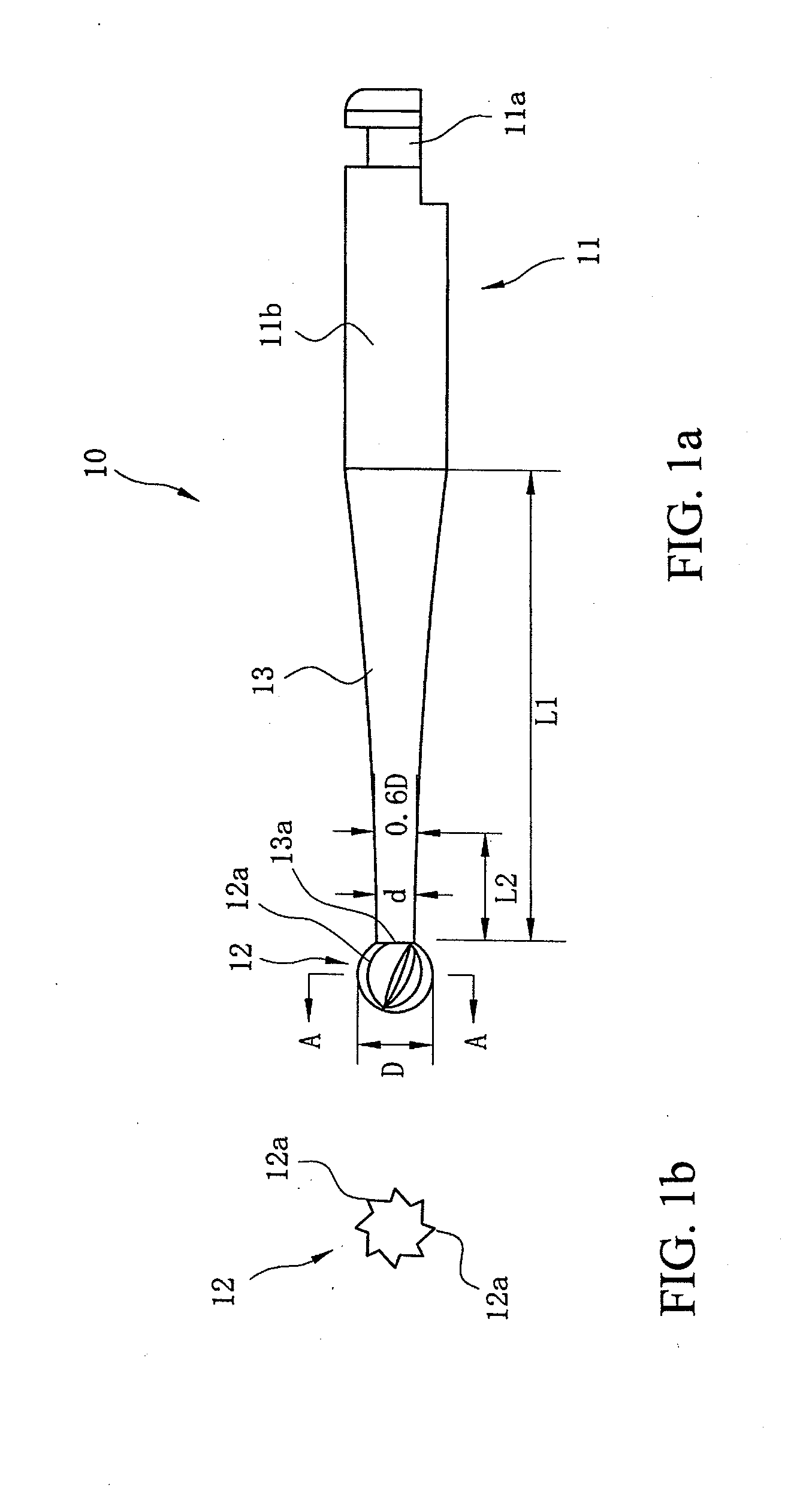

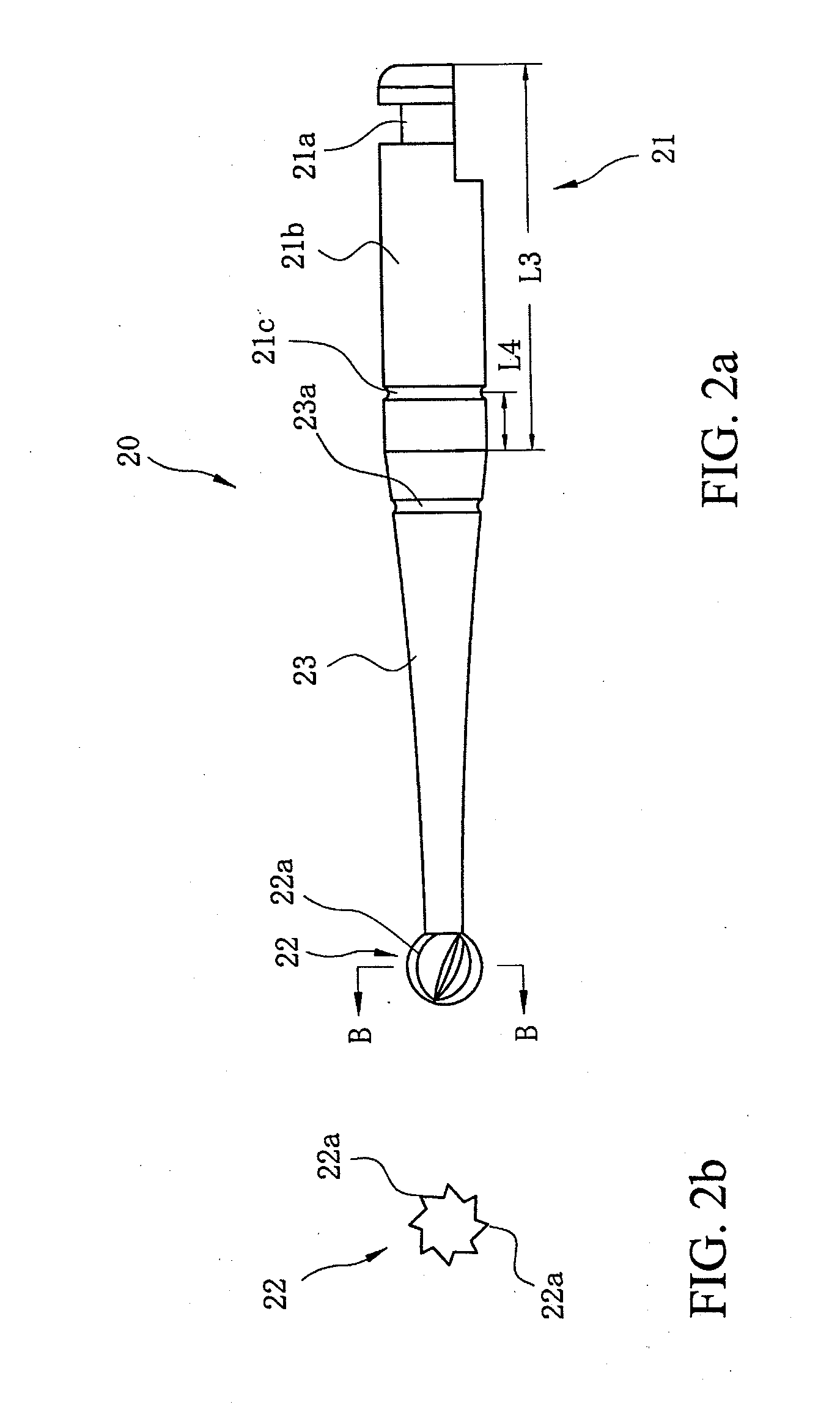

Tip rod

Where a super-elastic alloy is used as a core material, boundary separation can be prevented on substantial deflection. The super-elastic alloy is used as the core material, an outside layer made with fiber-reinforced resin is provided outside except the tip part region of said core material, and a resin-rich layer greater in resin ratio than said outside layer is provided between said outside layer and the core material so as to be adjacent to the core material.

Owner:DAIWA SEIKO CORPORATION

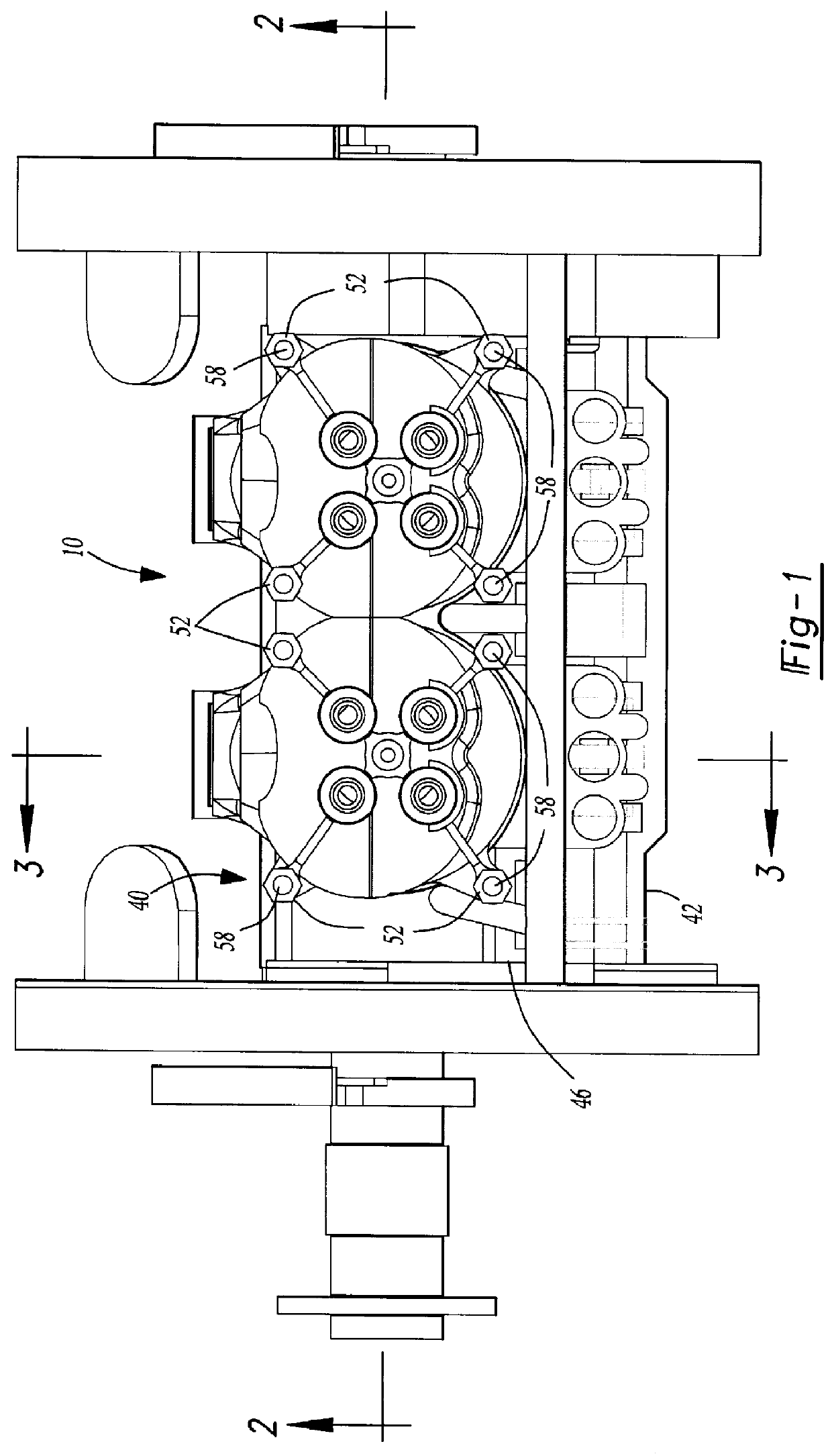

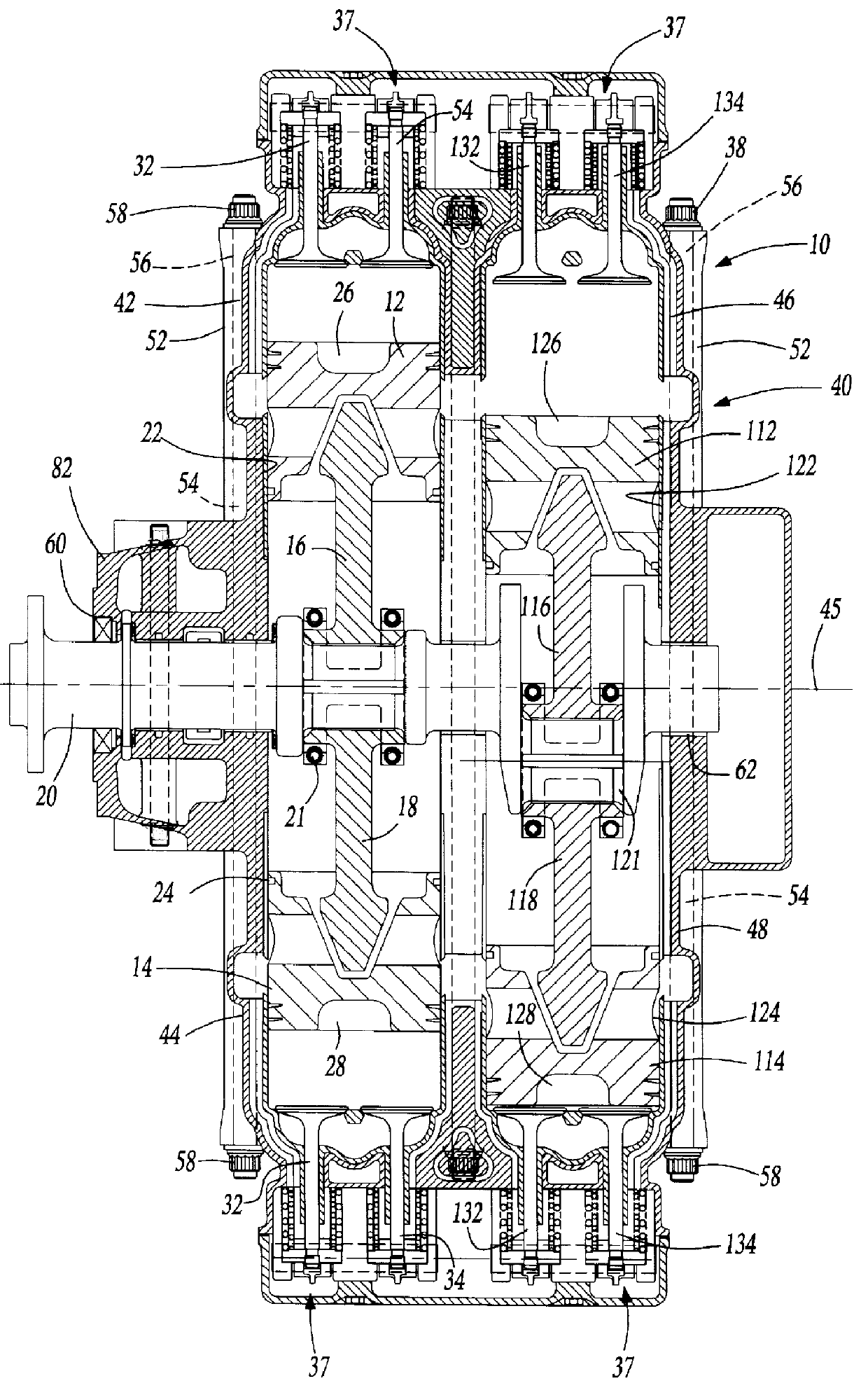

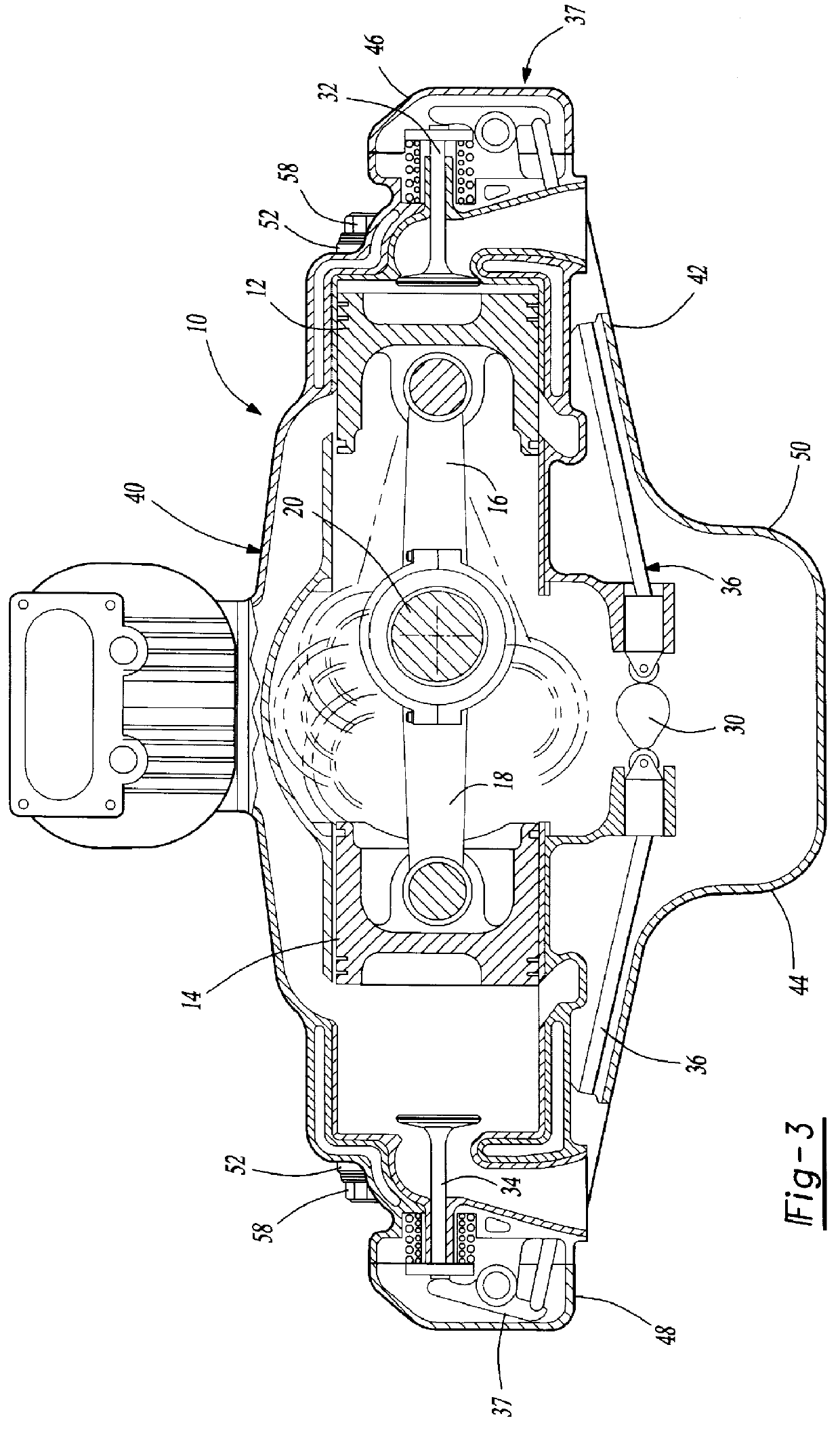

Engine construction

InactiveUS6073595AEasy to useSmall bendCasingsSealing arrangements for enginesMain bearingEngineering

An in-line opposed cylinder engine constructed of a pair of half blocks which when combined form a pair of spaced cylinder heads and an intermediate crankcase and in which the cylinder heads and the intermediate crankcase are tied together by a plurality of spaced elongated through bolts which extend through the cylinder heads and through the half blocks. Each cylinder head is integral with the remainder of the half block and is preferably of a composite construction with a core of steel or the like which forms the cylinder bore, the firing deck, the exhaust ports and the valve guide as well as the main bearing supports. A matrix structure of lighter material such as aluminum is cast around the core and forms the induction air passages to the intake ports, the coolant passages, oil passages, and the main bearing bosses.

Owner:CONTINENTAL MOTORS

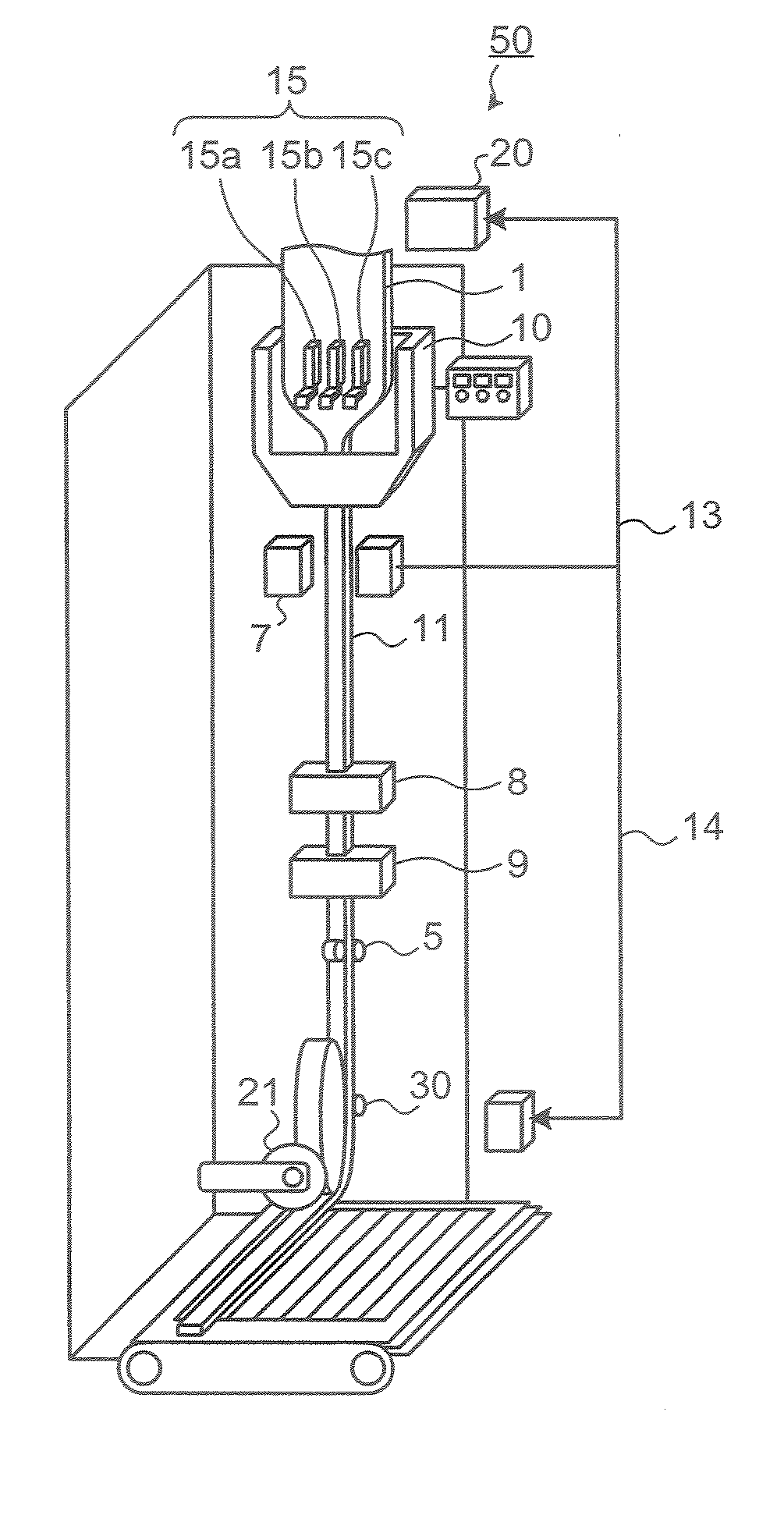

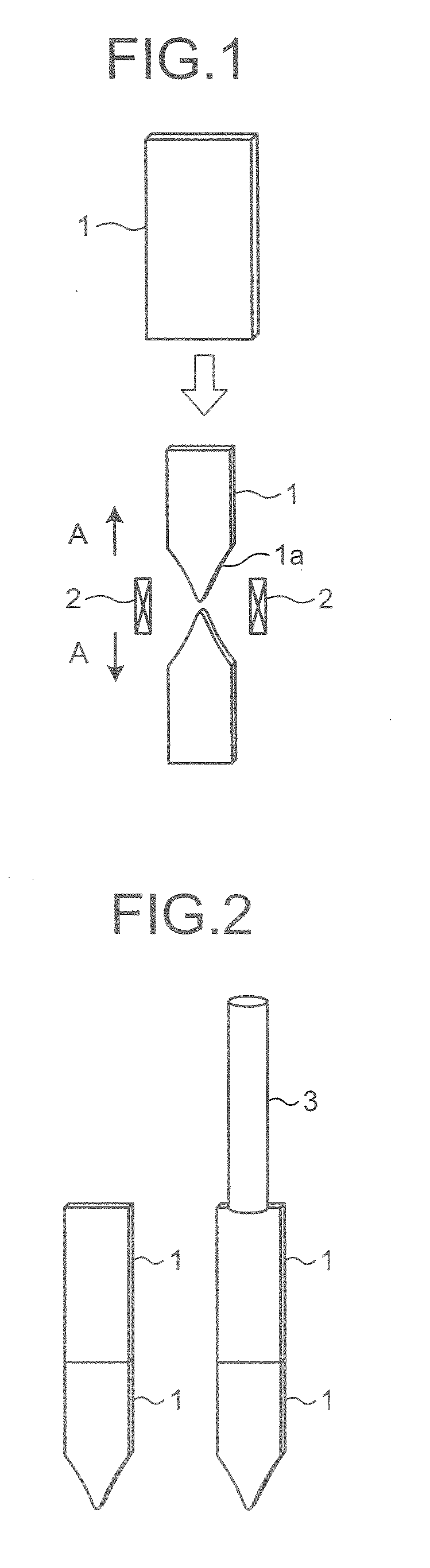

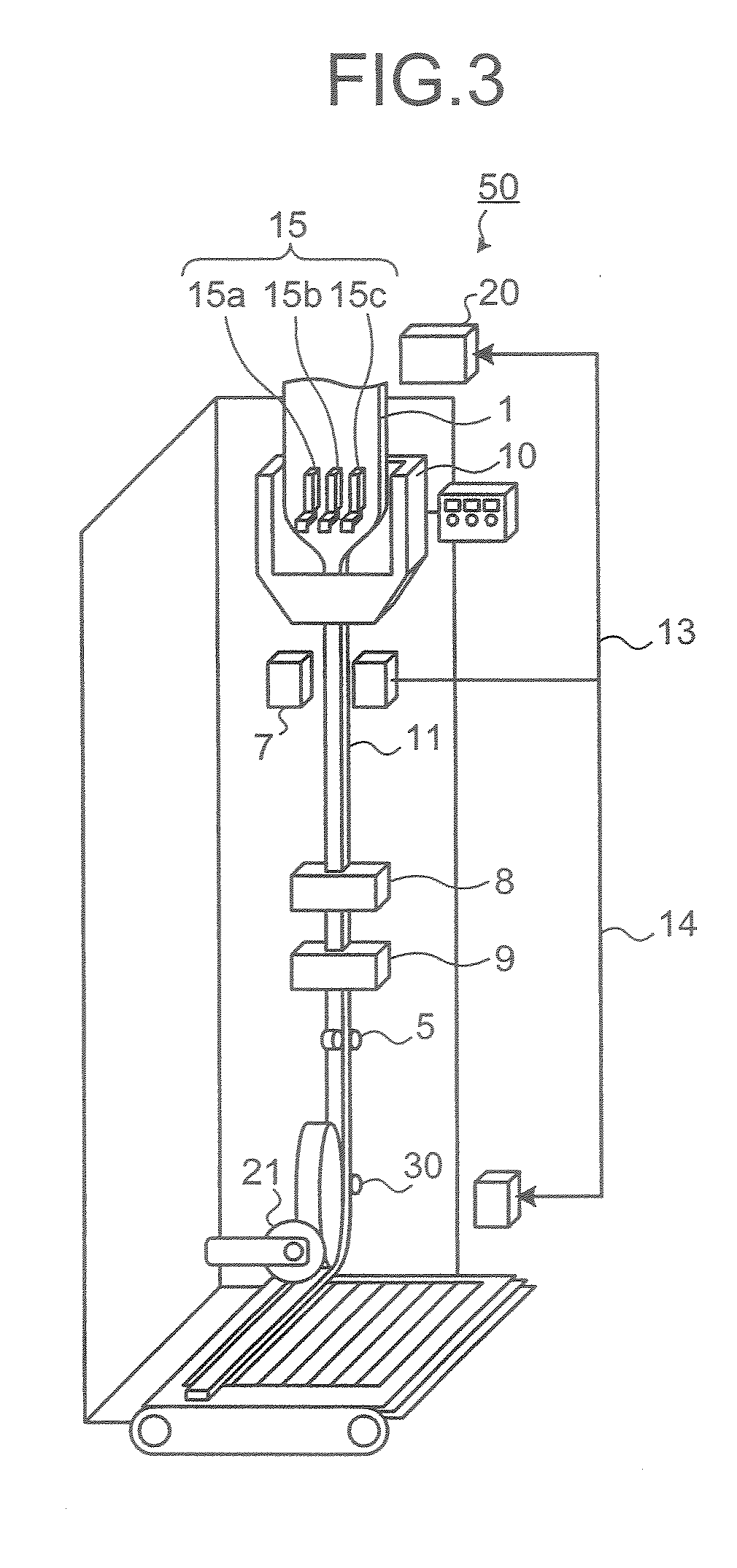

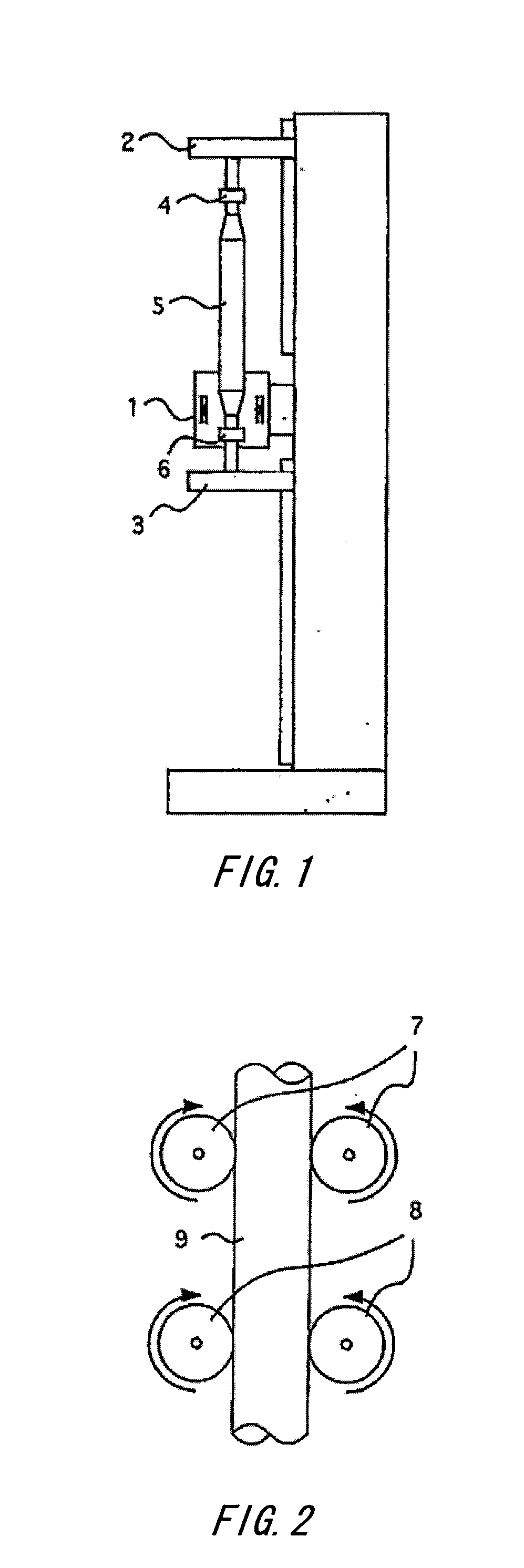

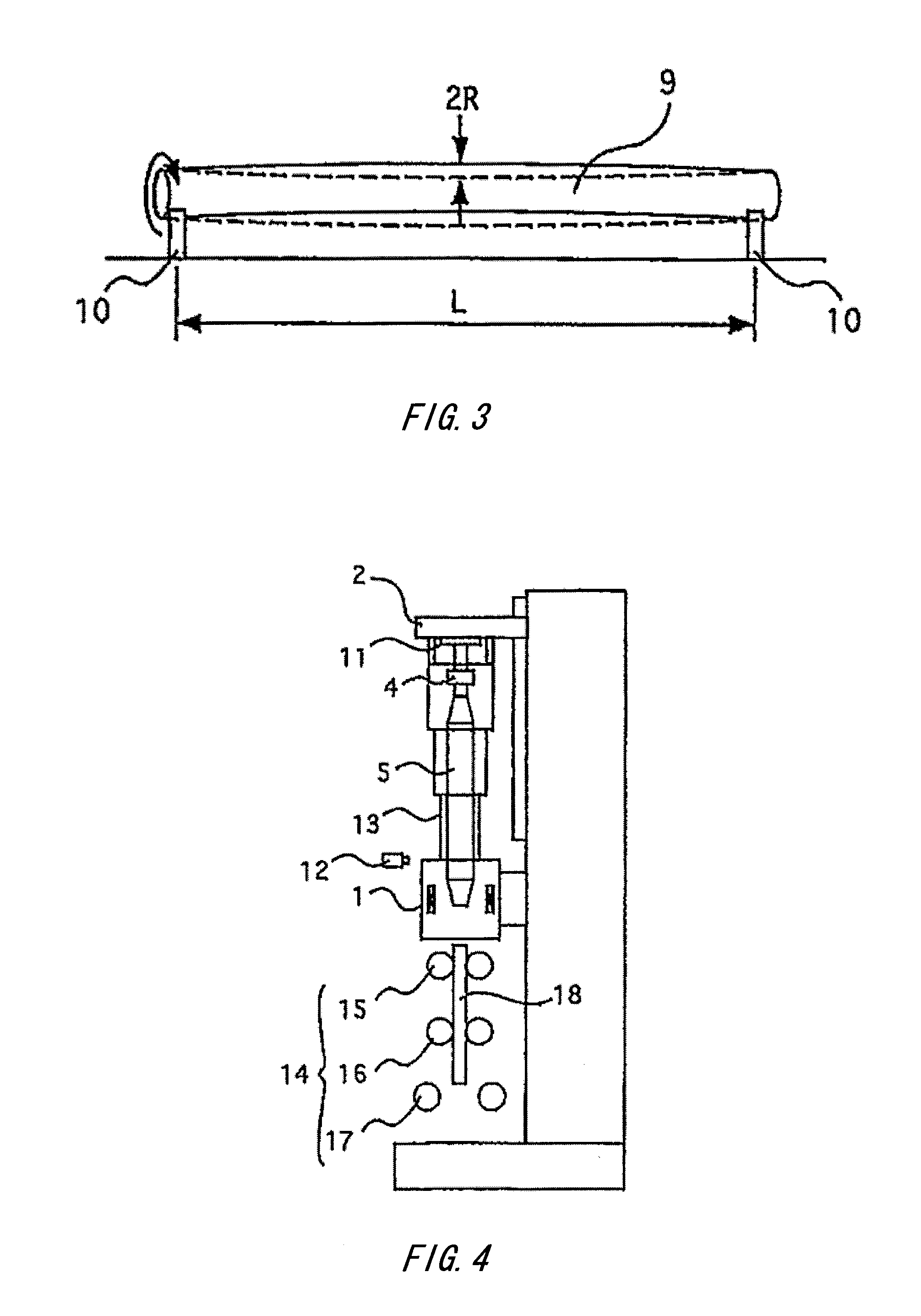

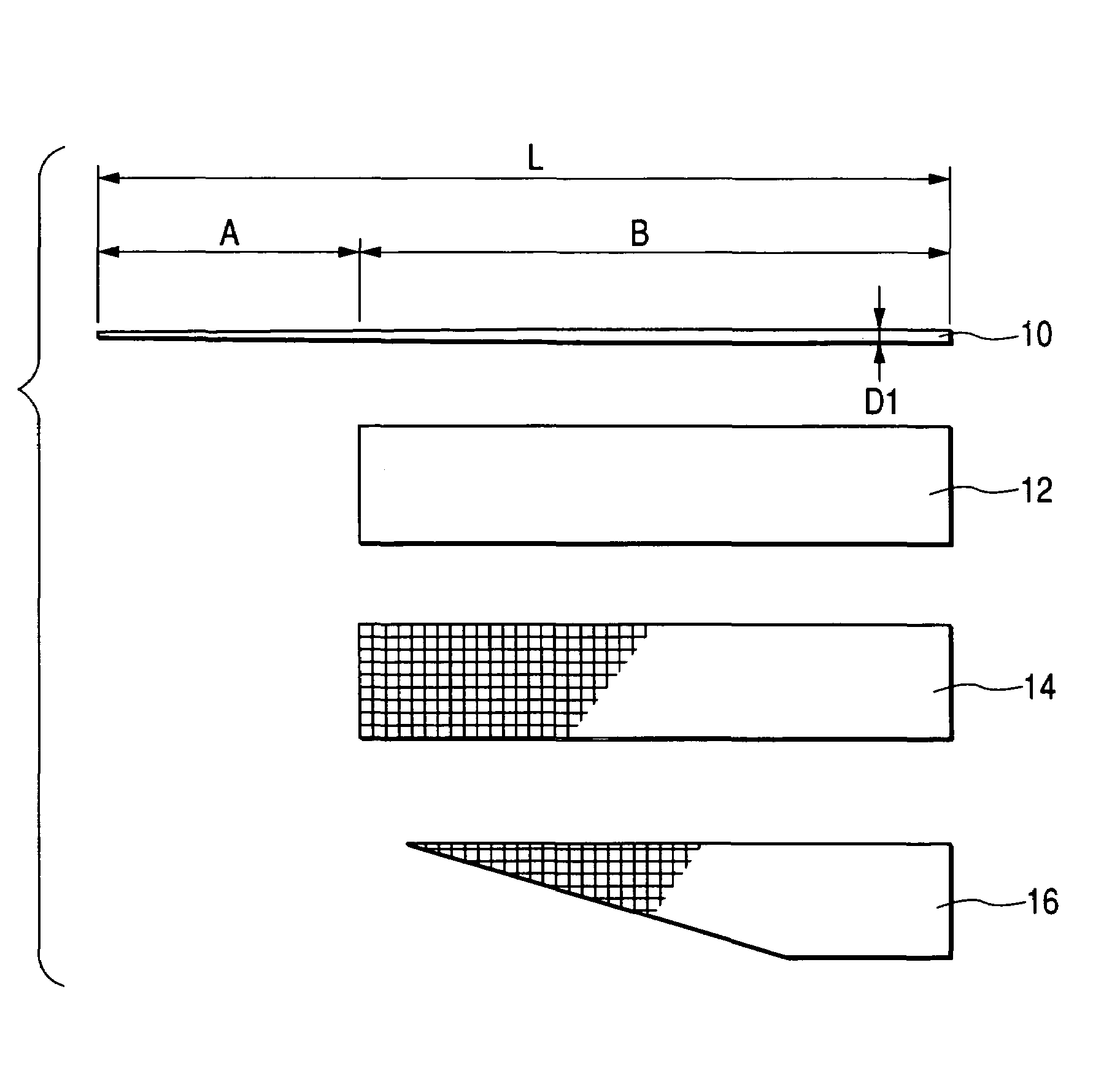

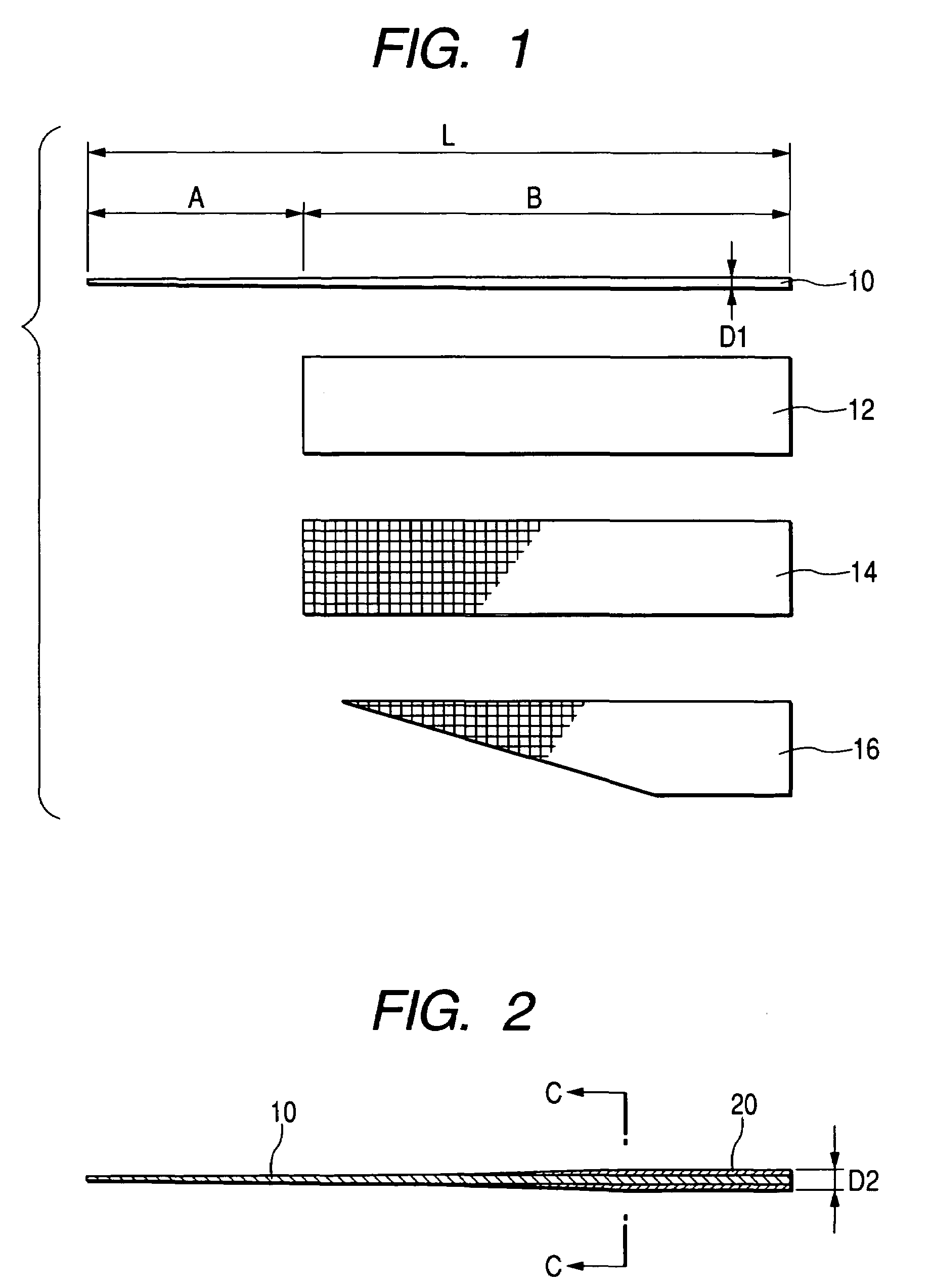

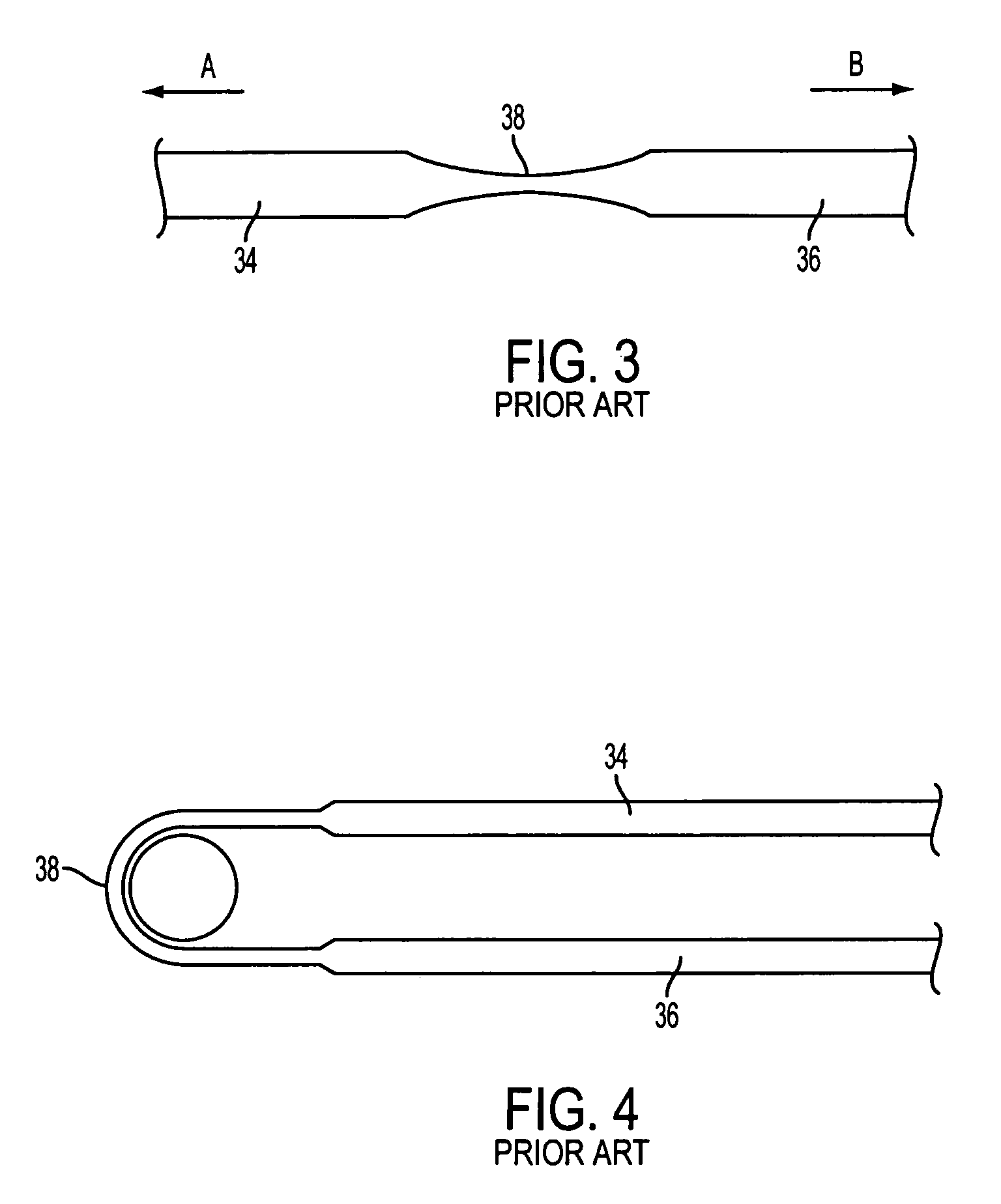

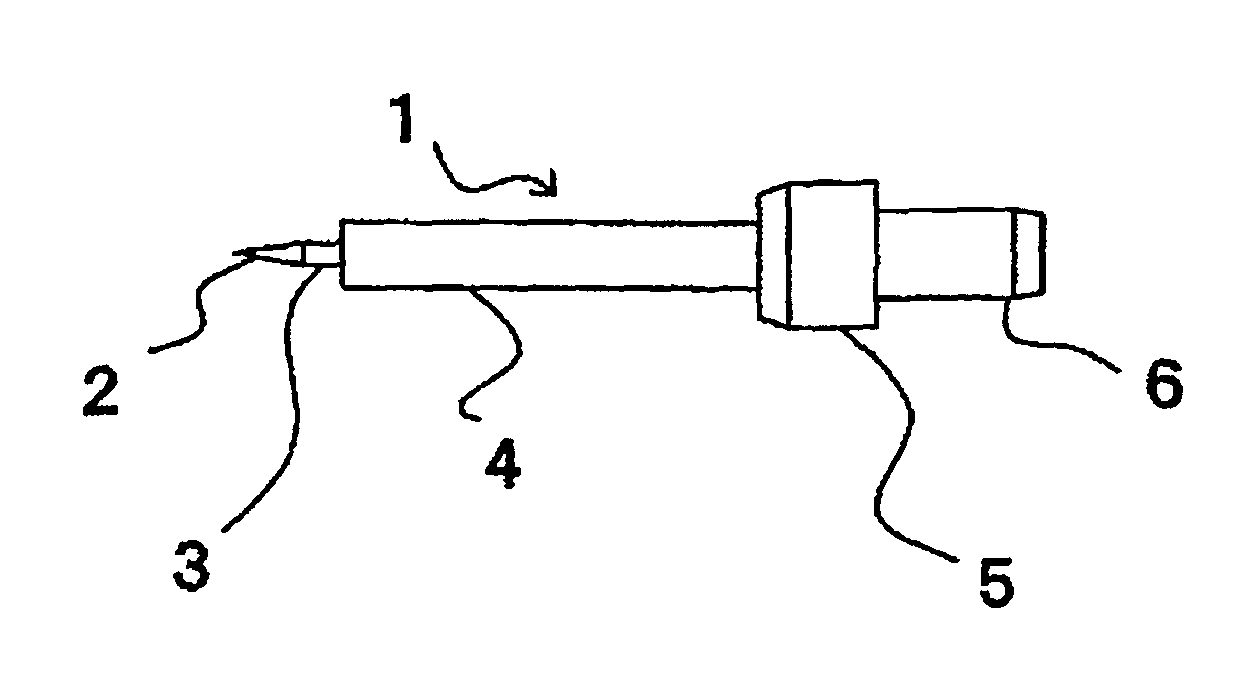

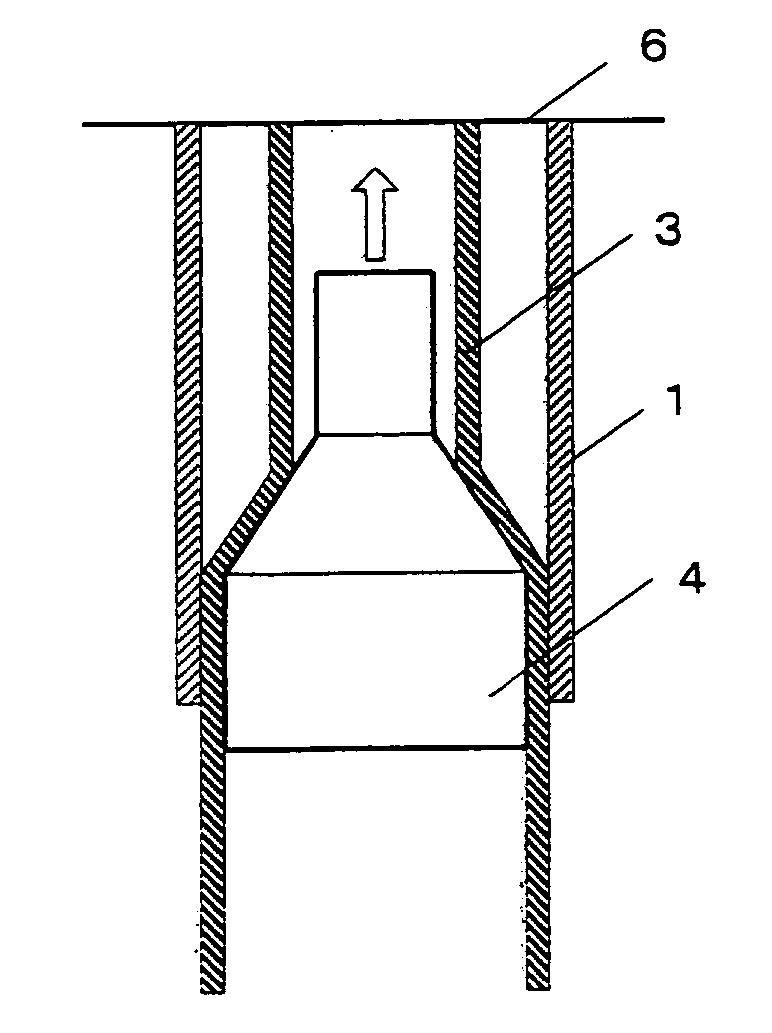

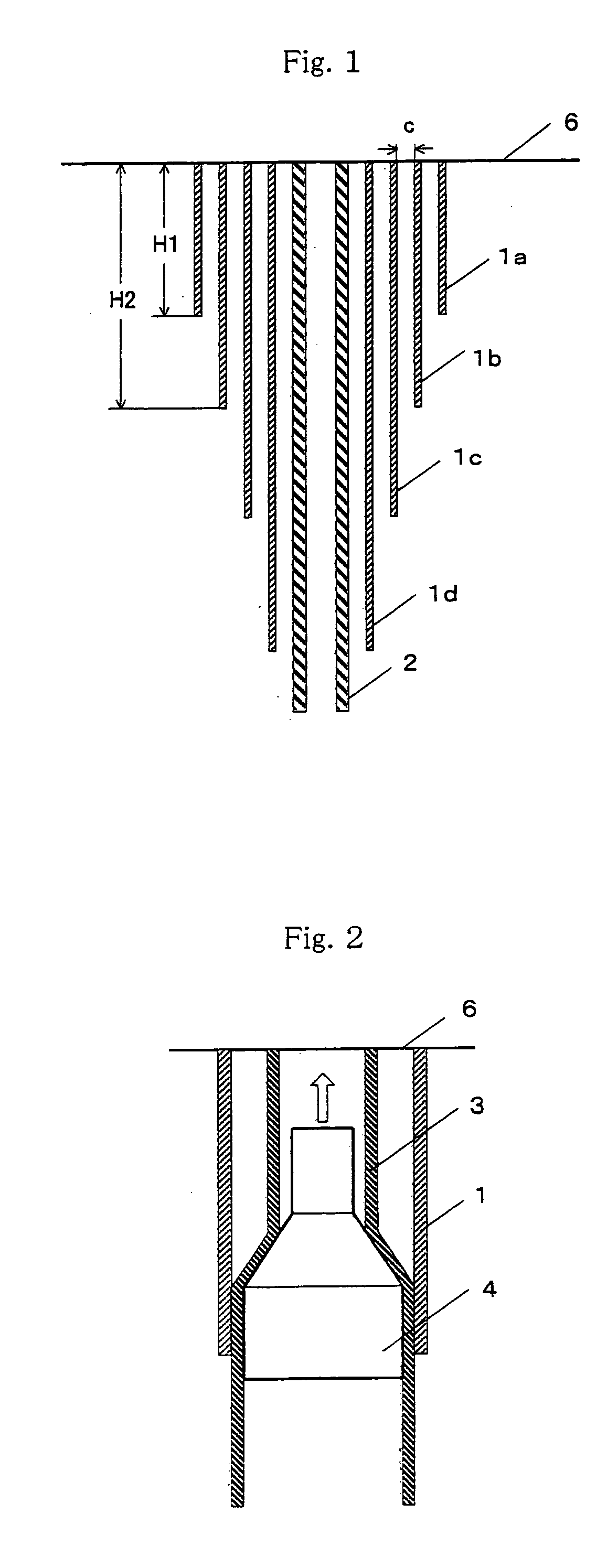

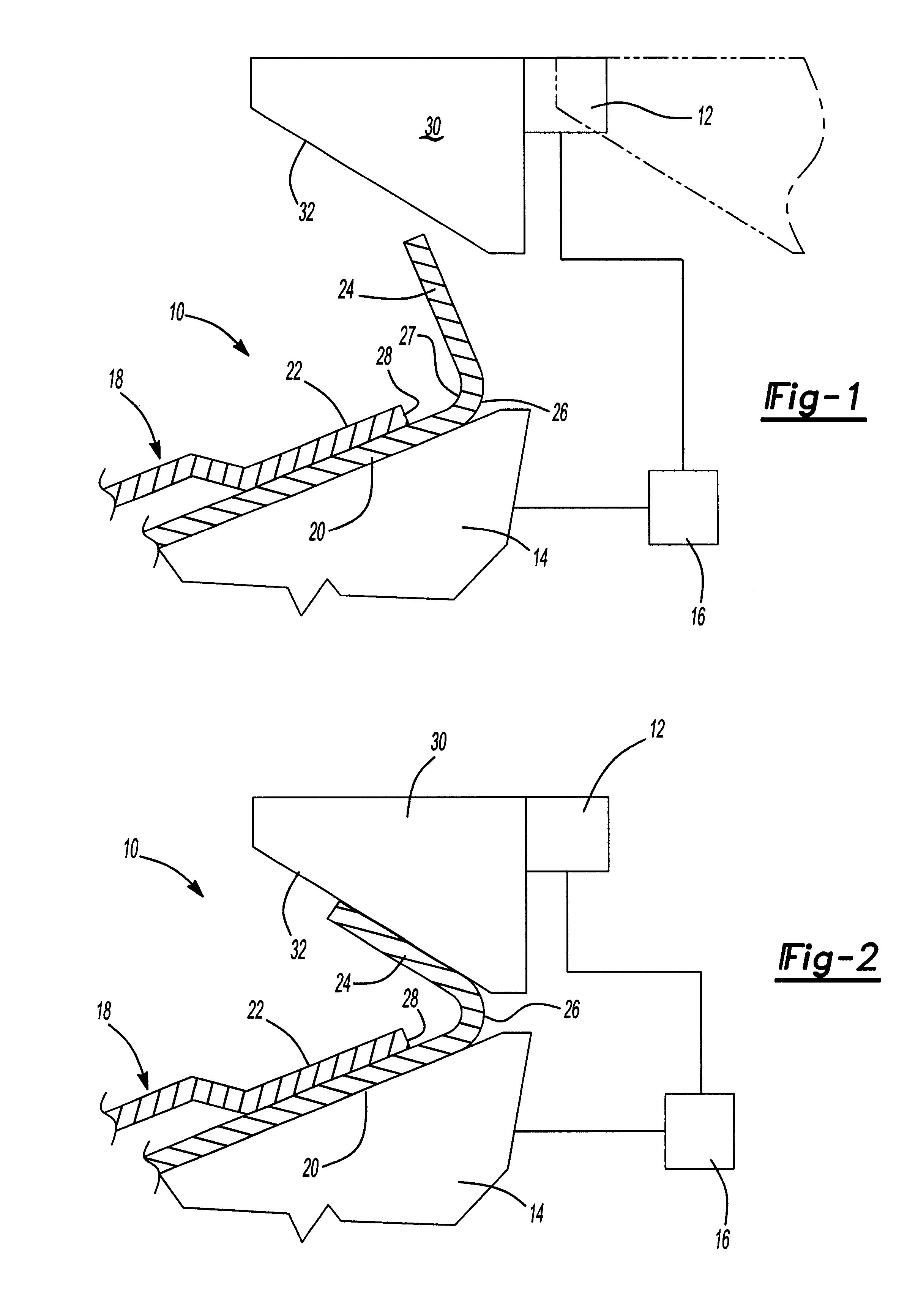

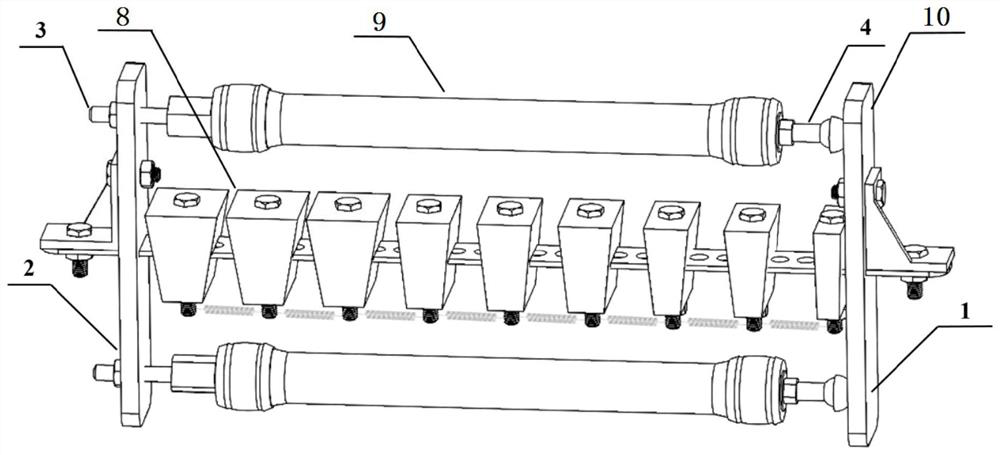

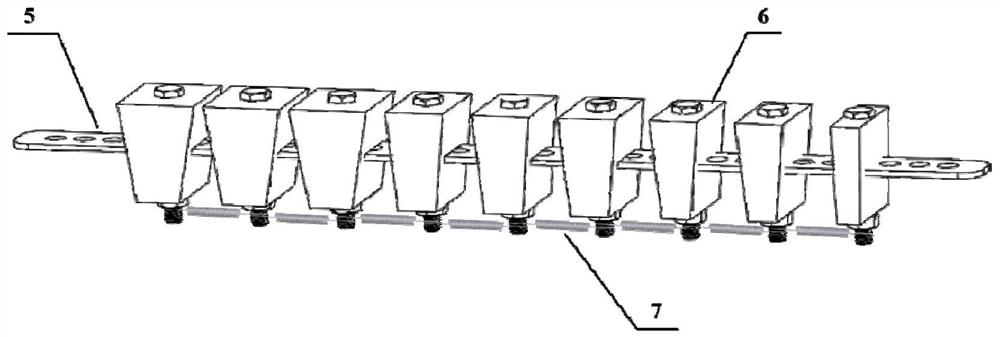

Elongating method and apparatus for glass base material

ActiveUS20120222452A1Easy to getSmall bendCoupling light guidesGlass reforming apparatusHeating furnaceMaterials science

A method of elongating a glass base material to obtain a glass rod having a smaller diameter, using a glass base material elongating apparatus including a feeder at least for the glass base material, a heating furnace, and an elongating mechanism of the glass base material below the heating furnace, is such that a horizontal plane position measuring unit of the glass base material is provided inside or near the heating furnace, the feeder has a glass base material horizontal plane position adjusting unit, and the elongating mechanism has three or more sets of elongating rollers capable of switching between grasping and releasing for keeping the position of the glass rod in the horizontal plane to be constant, and the glass base material is elongated with the position thereof in the horizontal plane kept as targeted by controlling the glass base material horizontal plane position adjusting unit.

Owner:SHIN ETSU CHEM IND CO LTD

Tip rod

Where a super-elastic alloy is used as a core material, boundary separation can be prevented on substantial deflection. The super-elastic alloy is used as the core material, an outside layer made with fiber-reinforced resin is provided outside except the tip part region of the core material, and a resin-rich layer greater in resin ratio than the outside layer is provided between the outside layer and the core material so as to be adjacent to the core material.

Owner:DAIWA SEIKO CORPORATION

Fiber optic cable with miniature bend incorporated

ActiveUS7269320B2Easy to optimizeSmall diameterConstructionsFibre mechanical structuresFiberControl line

Owner:AFL COMM LLC

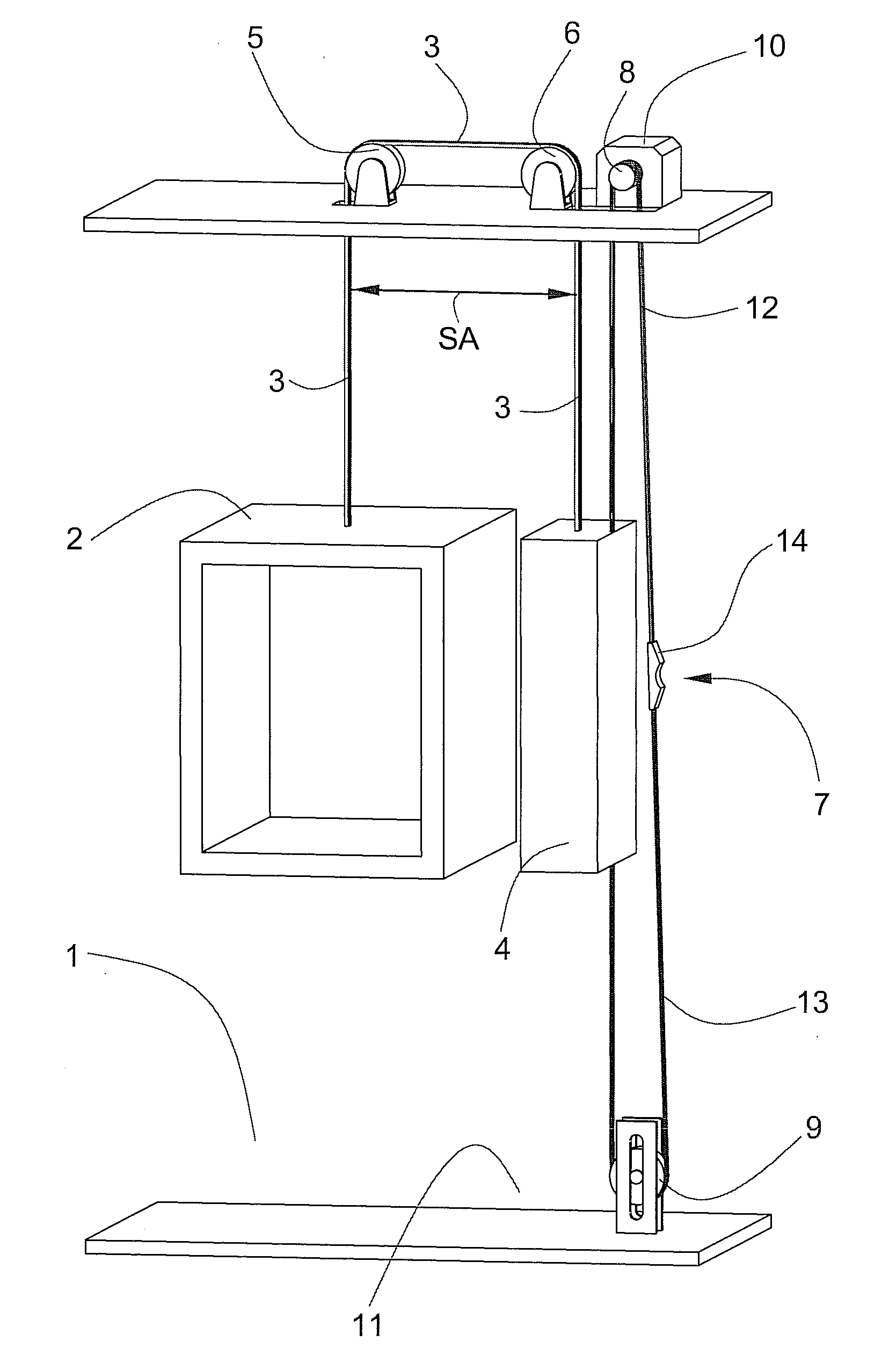

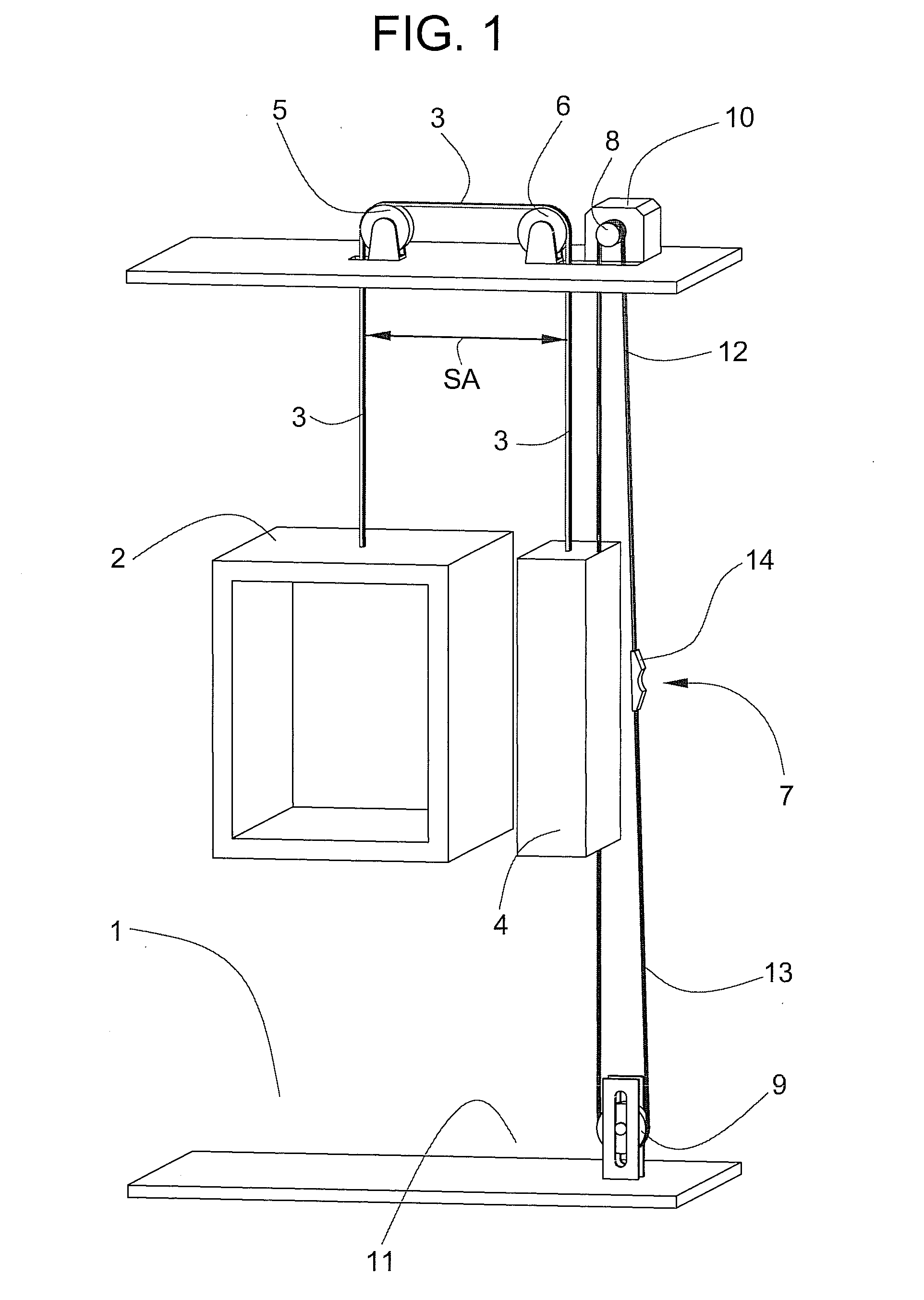

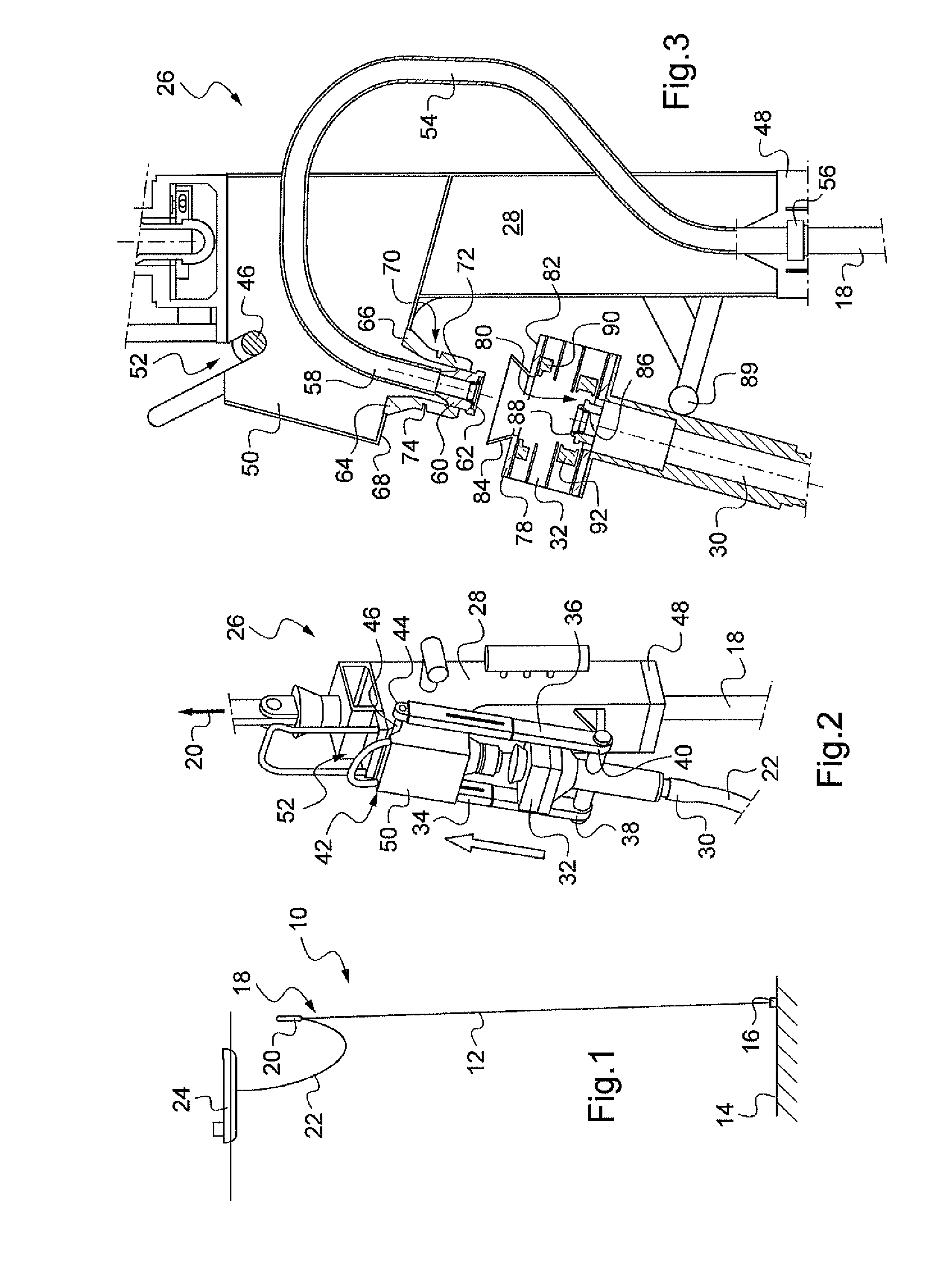

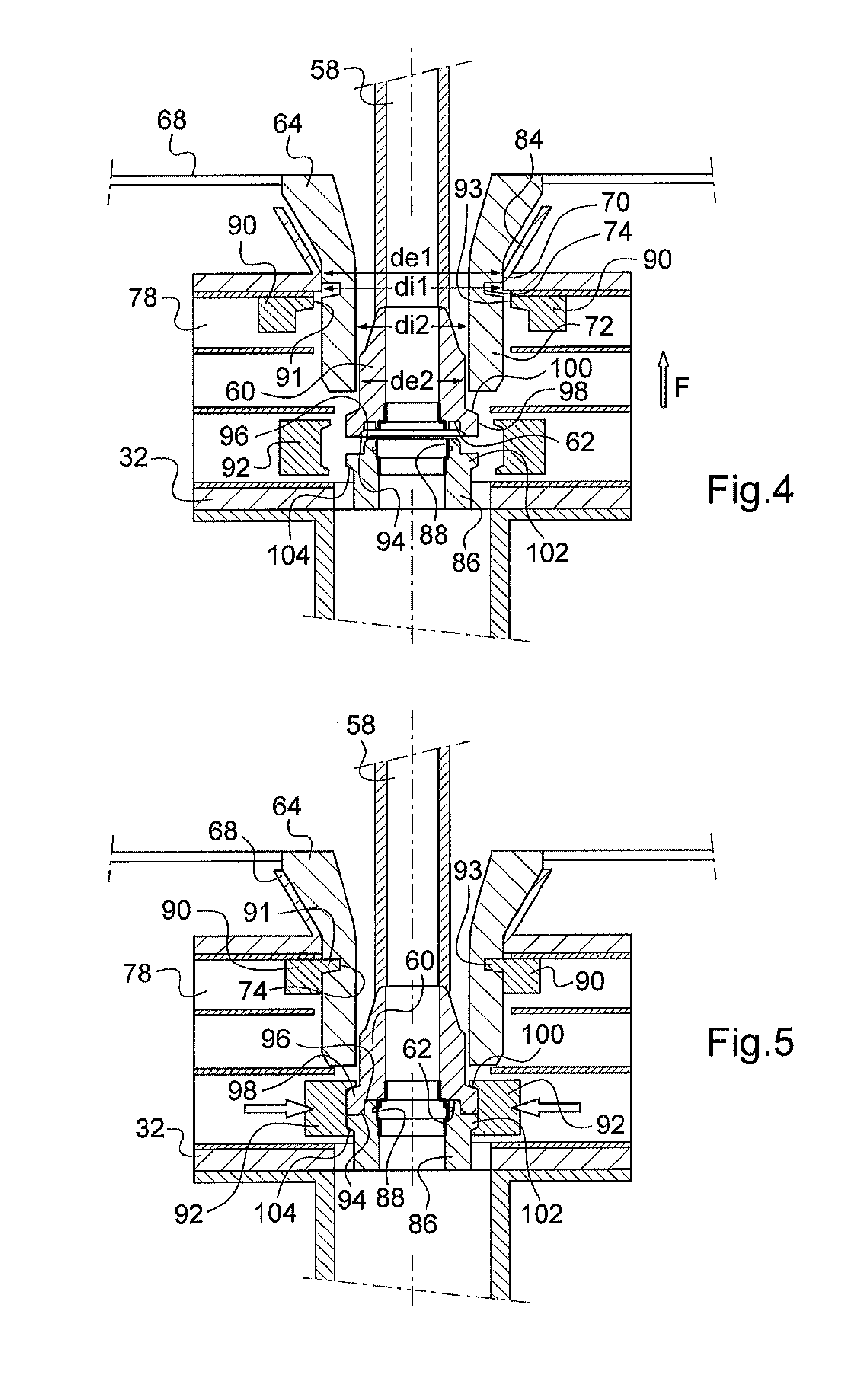

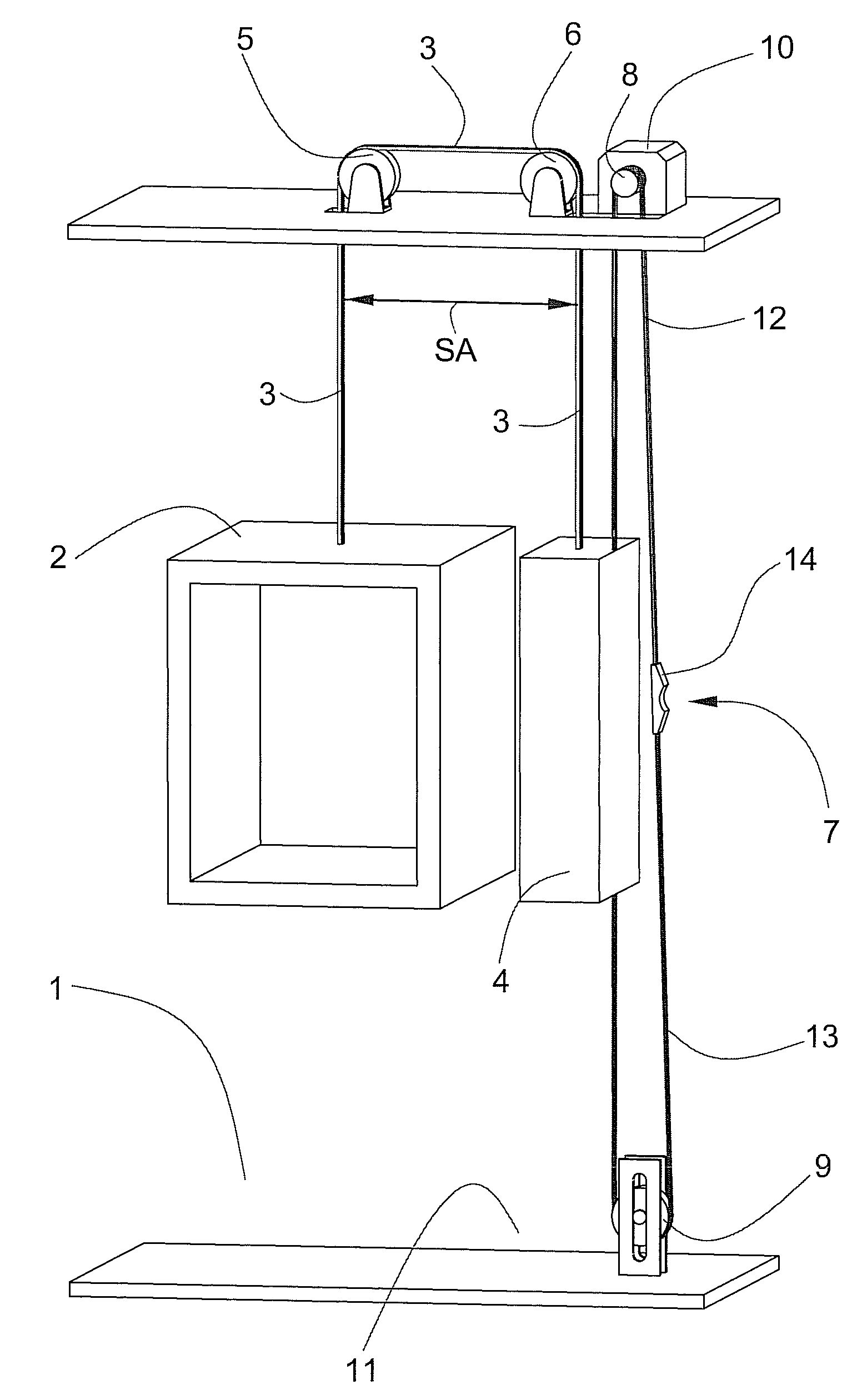

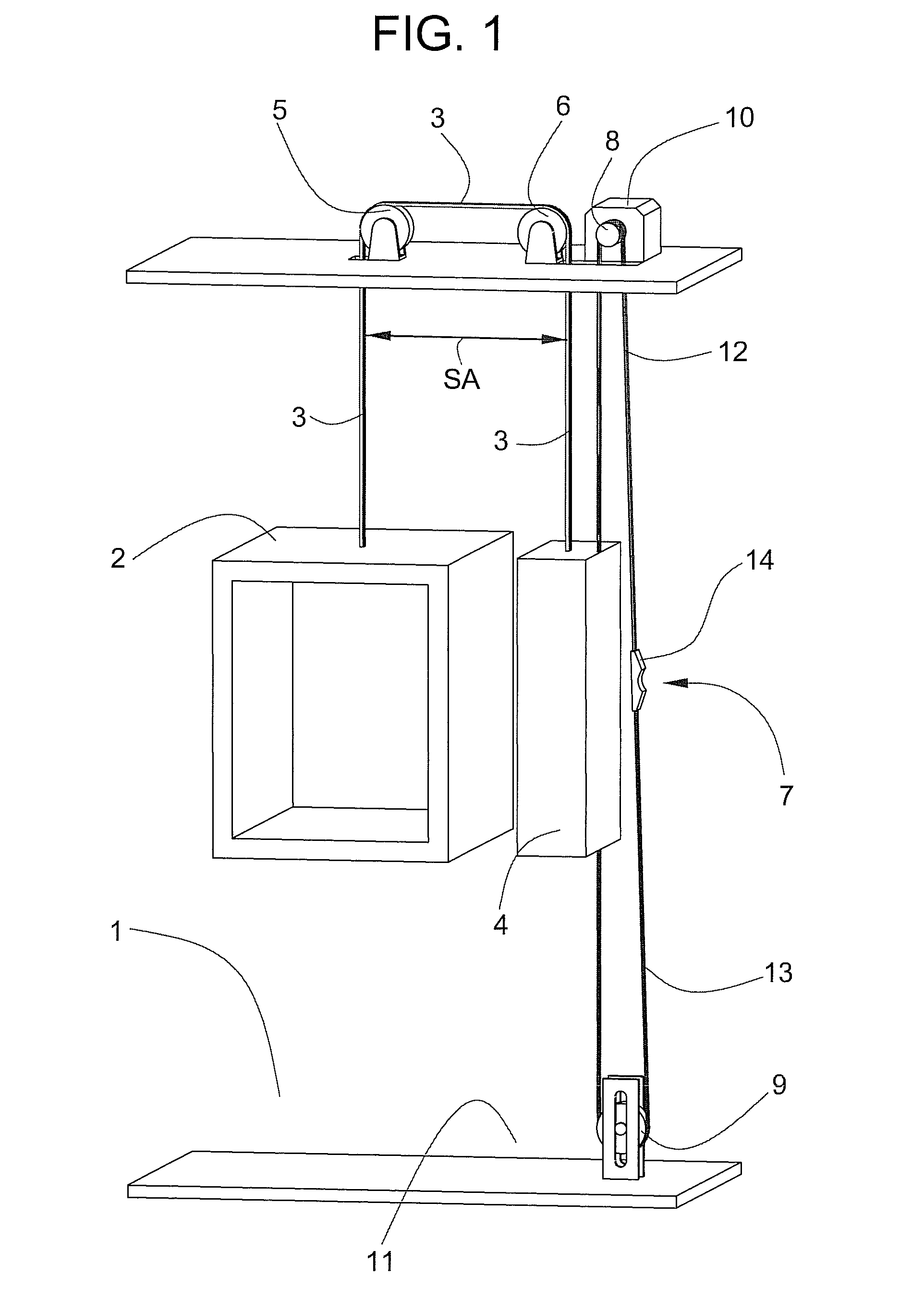

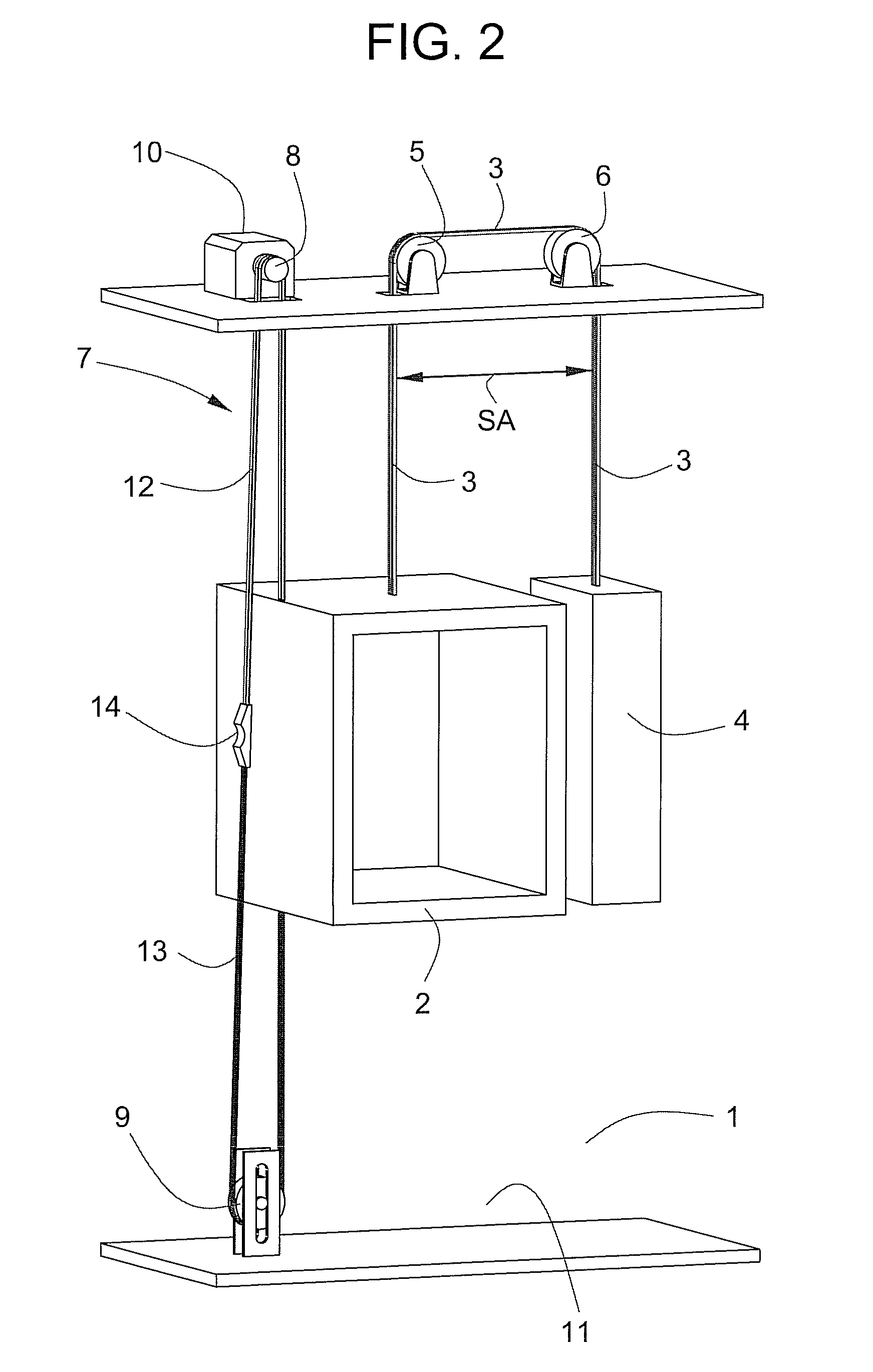

Lift with support means and drive means

A lift has a lift cage movable in a lift shaft and is connected with a counterweight by means of at least one support means. The lift cage or counterweight moves by means of at least one drive means separate from the support means. One end of the drive means engages the upper end of the counterweight, is guided by way of a drive pulley and by way of a deflecting roller, and engages at its other end with the lower end of the counterweight. A drive unit drives the drive pulley. The drive means consists of a drive part and a tension part of different characteristics, wherein the drive and tension parts are connected by means of a drive means connection.

Owner:INVENTIO AG

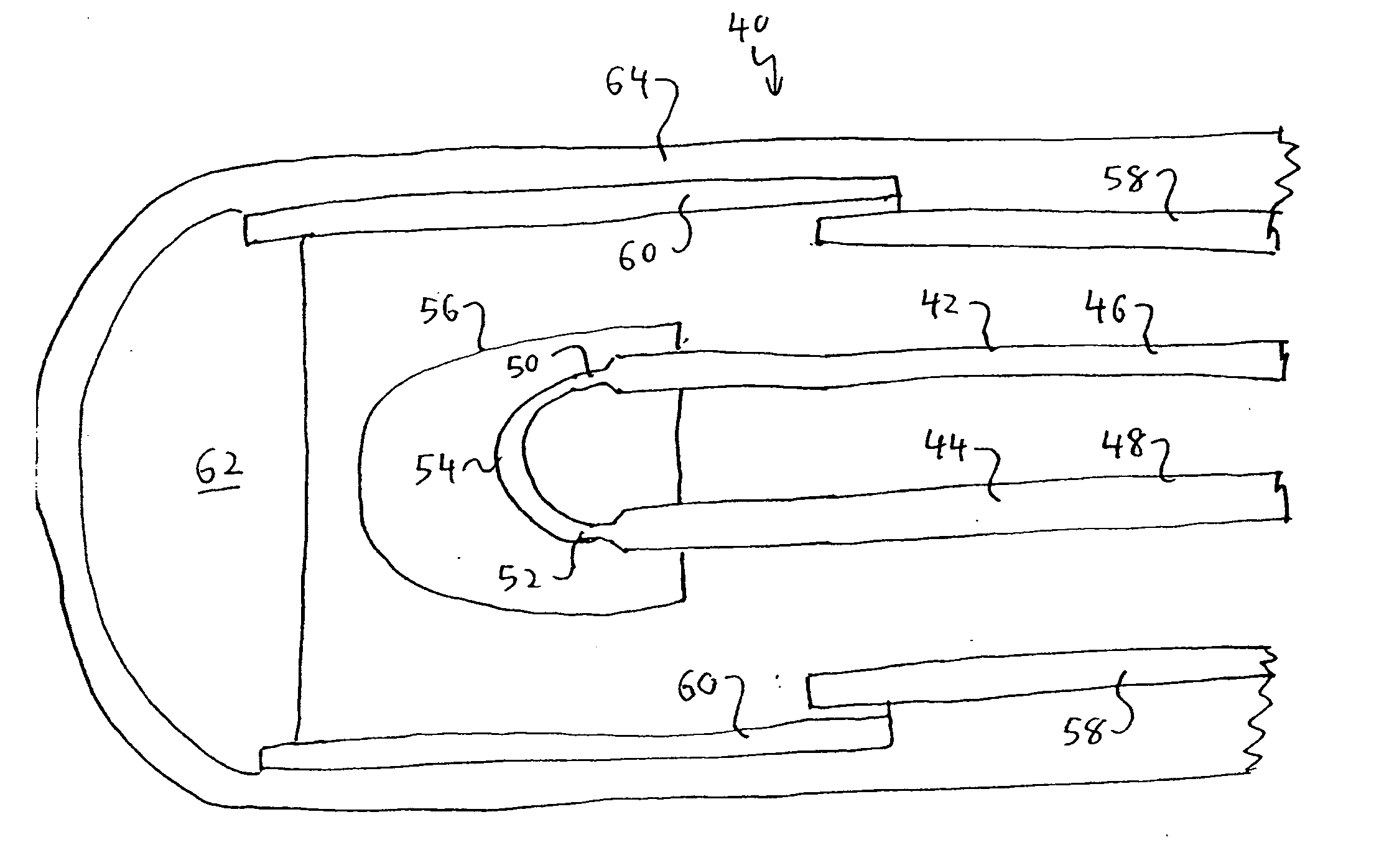

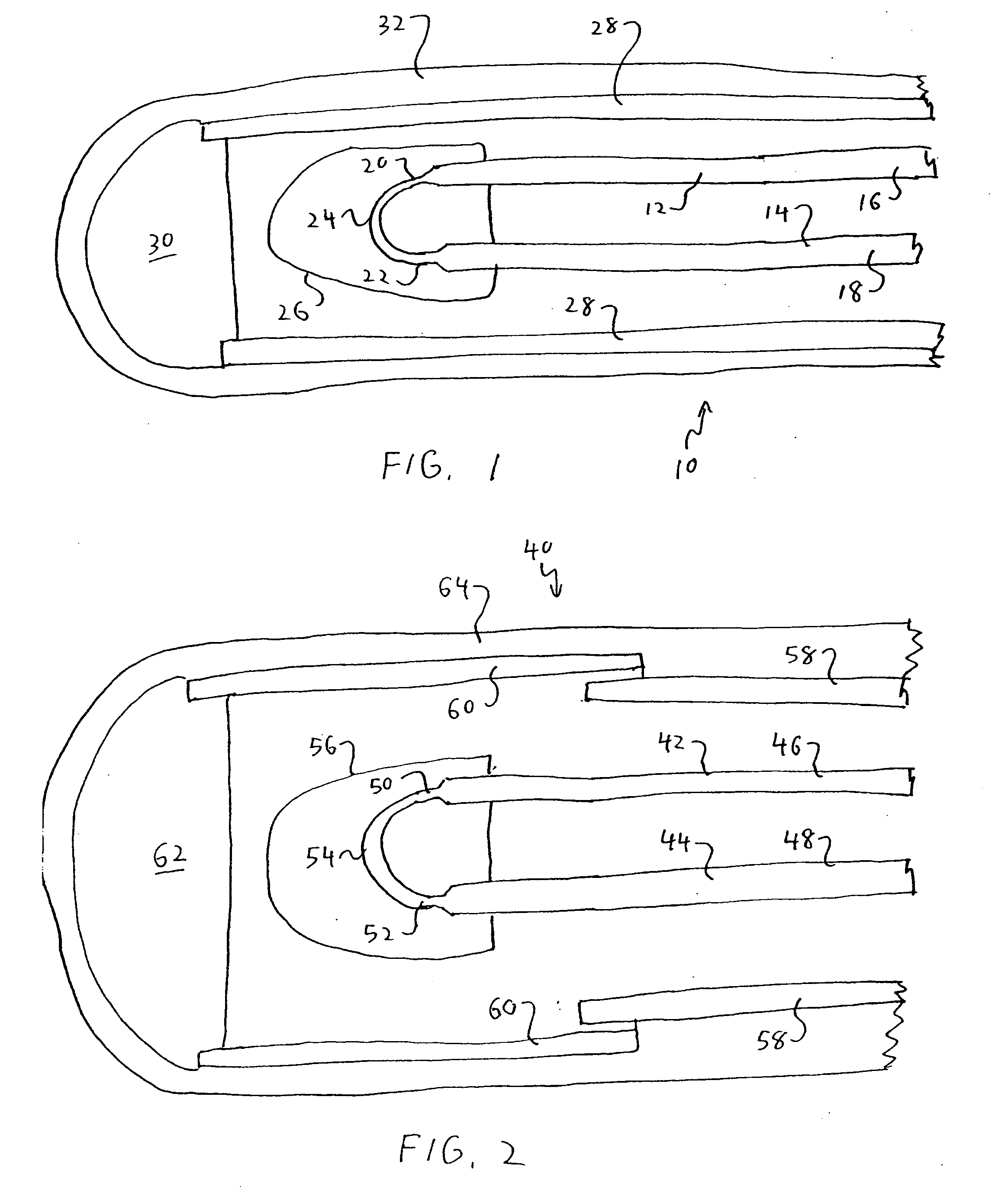

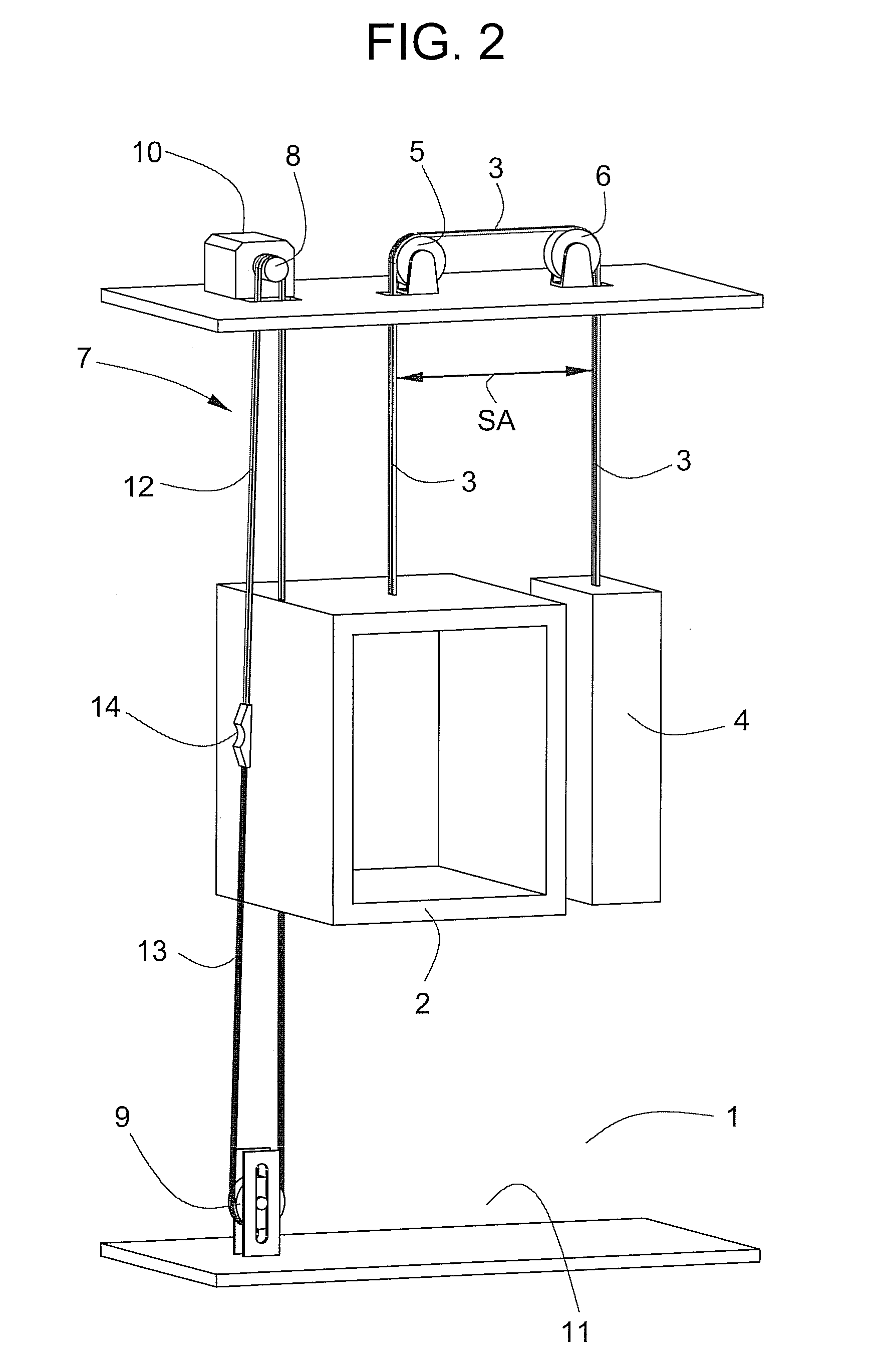

Underwater connection installation

ActiveUS8418766B2Small bendImprove accuracyPipe laying and repairDrilling rodsHydrogen compoundsEngineering

An underwater connection installation (26) and a laying method for connecting a riser and a flexible pipe (22) that are intended for carrying hydrocarbons. A post (28) is attached to a float (20) to suspend the riser (12) below the surface. The post (28) supports a gooseneck shape pipe (54) that has a bent-over outlet free end (58) ending in a first coupling (60). A coupling end piece (32) mounted on the flexible pipe (22) includes a second coupling (86). The coupling end piece (32) and the post (28) define mechanical guides including complementary frustoconical rings (64, 84). The driving of the coupling end piece (32) and of the bent-over free end (58) toward each other causes the frustoconical rings (64, 84) to engage one another to bring about coaxial alignment of the couplings (60, 86).

Owner:TECH FRANCE SA

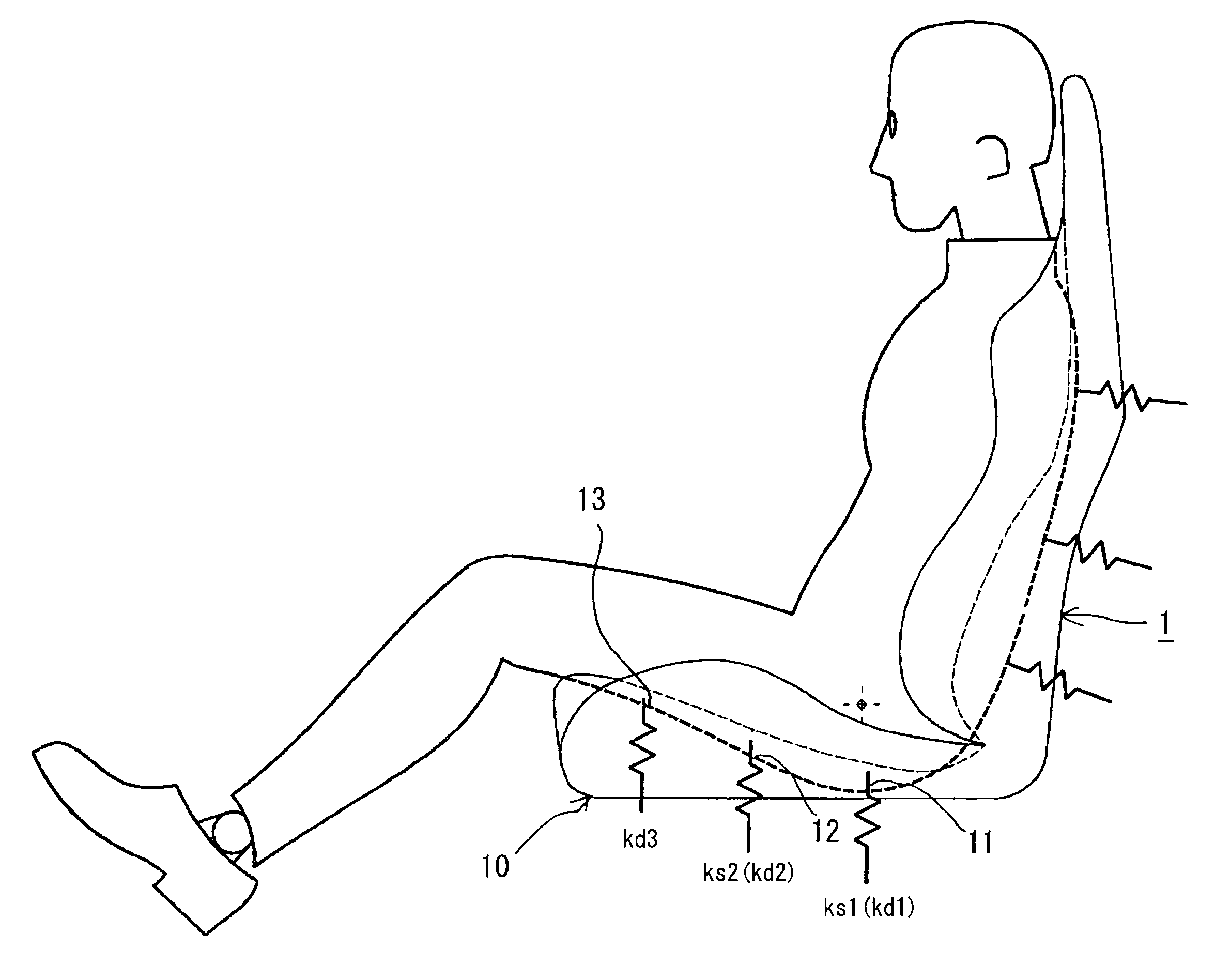

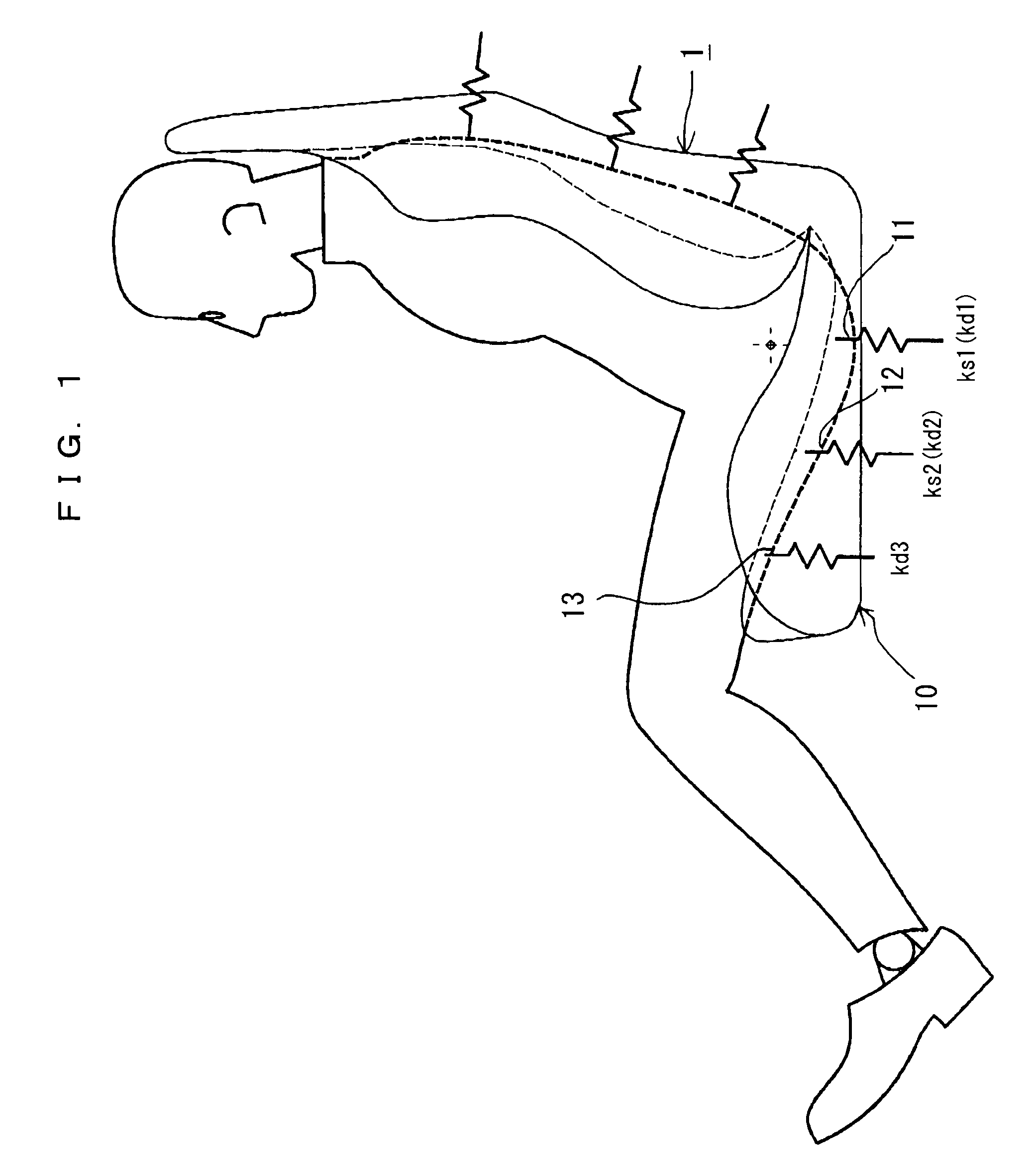

Vehicle seat and vehicle seat evaluation method

ActiveUS20090051206A1Improve linearityDifference in easiness of transmitting vibrationStoolsFurniture partsHuman bodyIschial tuberosity

A vehicle seat allowing to improve a vibration absorption characteristic, securing a stable seating posture, having high vehicle operability, and allowing to alleviate fatigue due to long time seating. In a seat cushion of a vehicle seat, a first human body support portion having a center at a position corresponding to a substantially center between the pair of ischial tuberosities of a human body, and a second human body support portion corresponding to the vicinities of femoral bases of a human body and having a center at a position located forward at a horizontal distance of 100 mm along a longitudinally center line of the seat cushion from the first human body support portion are regarded respectively as spring elements, and static spring constants and dynamic spring constants thereof are set to a predetermined relationship. Thus, stability and vibration absorbency during static seating are improved.

Owner:DELTA TOOLING CO LTD

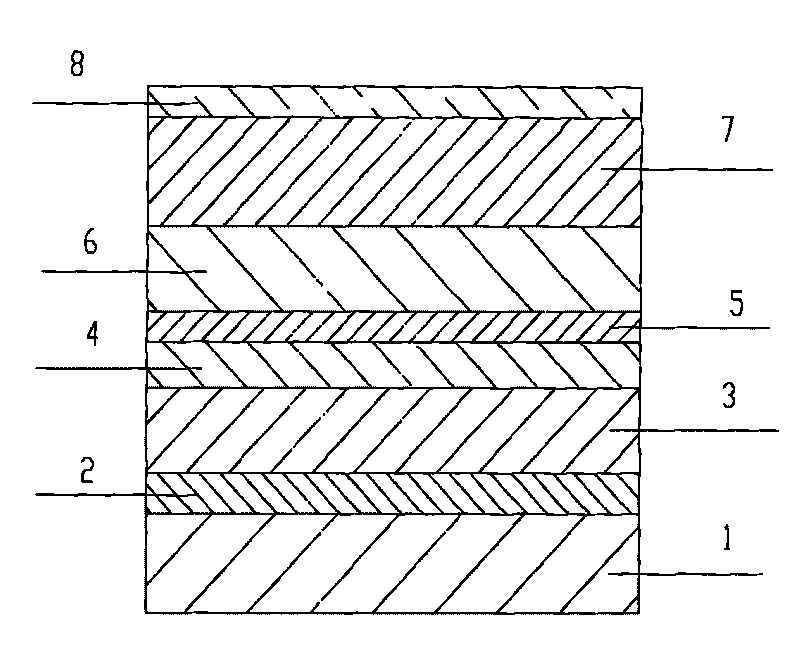

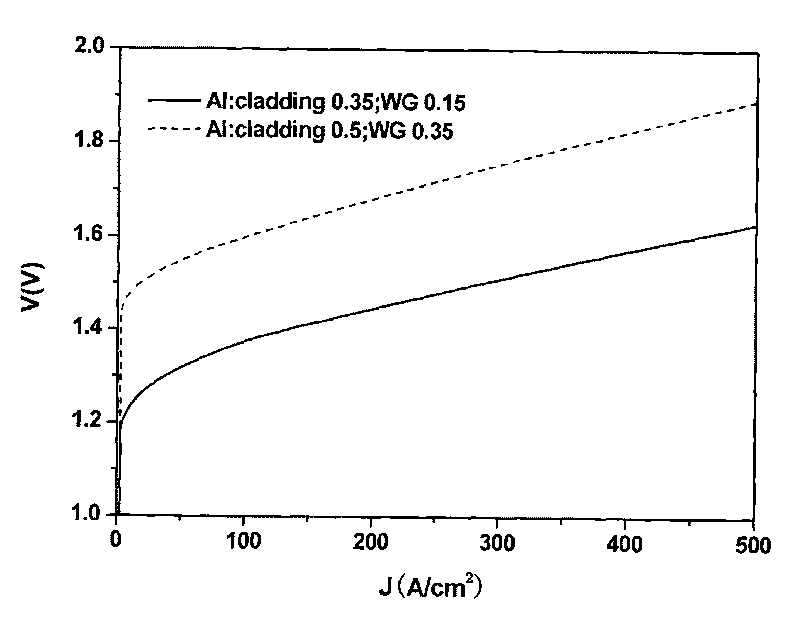

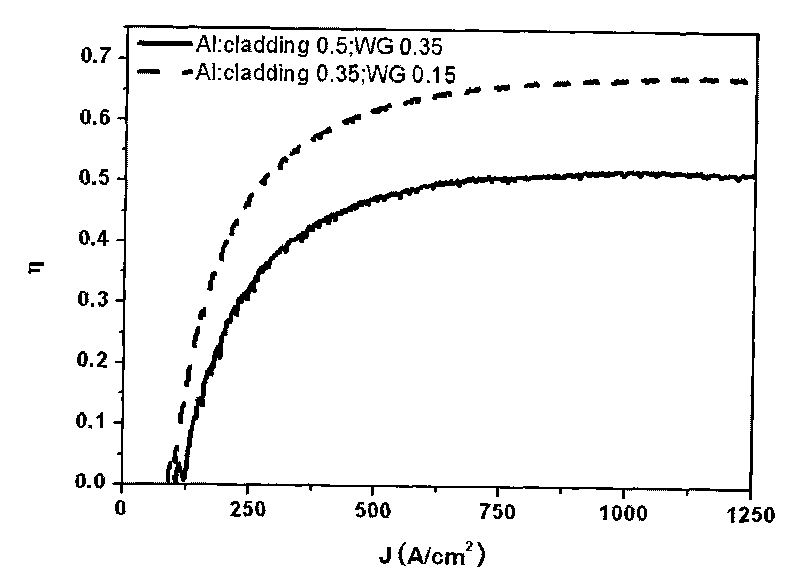

Quantum well epitaxy structure of semiconductor laser in 940 nm-1000 nm wave band

InactiveCN101764355ASmall energy levelSmall bendLaser detailsSemiconductor lasersQuantum wellElectrode Contact

The invention discloses a quantum well epitaxy structure of a semiconductor laser, in particular to a quantum well epitaxy structure of a high-efficiency semiconductor laser in a 940 nm-1000 nm wave band. The quantum well epitaxy structure comprises a substrate, a buffer layer, a lower limiting layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, an upper limiting layer and an electrode contact layer, wherein the buffer layer, the lower limiting layer, the lower waveguide layer, the quantum well layer, the upper waveguide layer, the upper limiting layer and the electrode contact layer are sequentially deposited on the substrate; the upper waveguide layer and the lower waveguide layer are AlxGaAs, and x is equal to 0.13-0.2; and the upper limiting layer and the lower limiting layer are AlyGaAs, and y is equal to 0.3-0.39. The quantum well epitaxy structure solves the problems of high working voltage and low photoelectric conversion efficiency of the semiconductor laser by optimizing the Al content of the waveguide layers and the limiting layers of the quantum well epitaxy structure, and achieves the purposes of reducing the working voltage and enhancing the photoelectric conversion efficiency.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

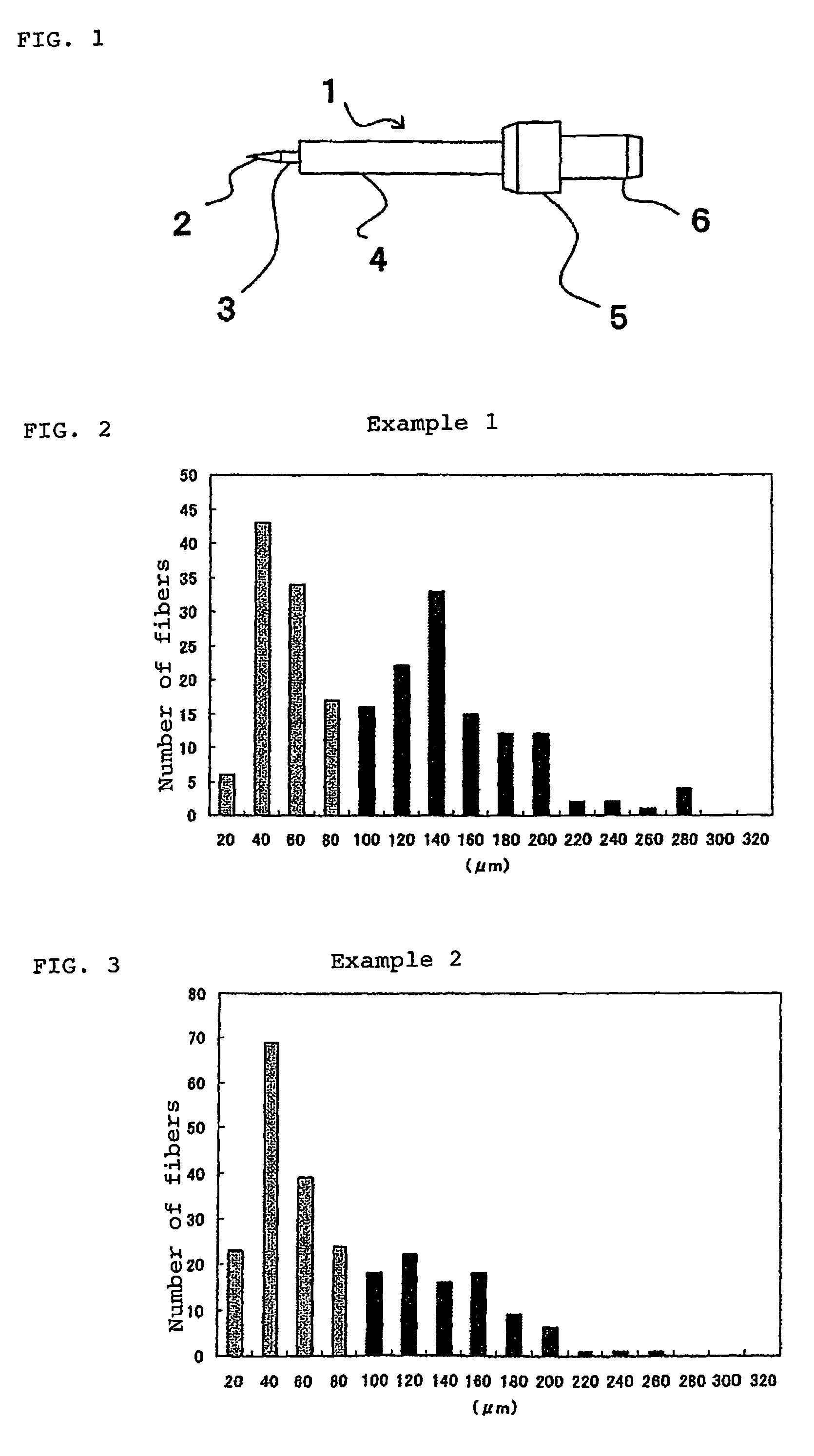

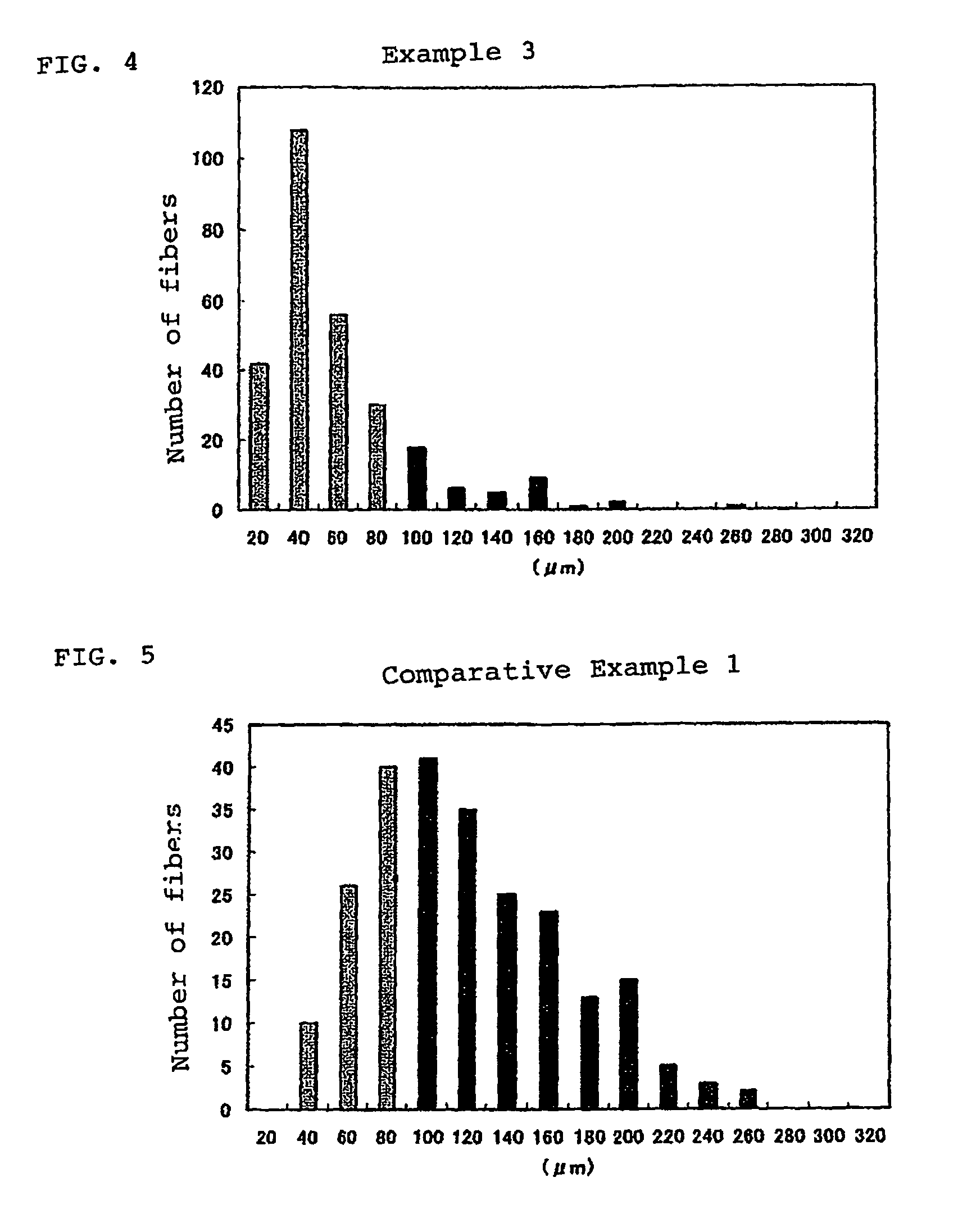

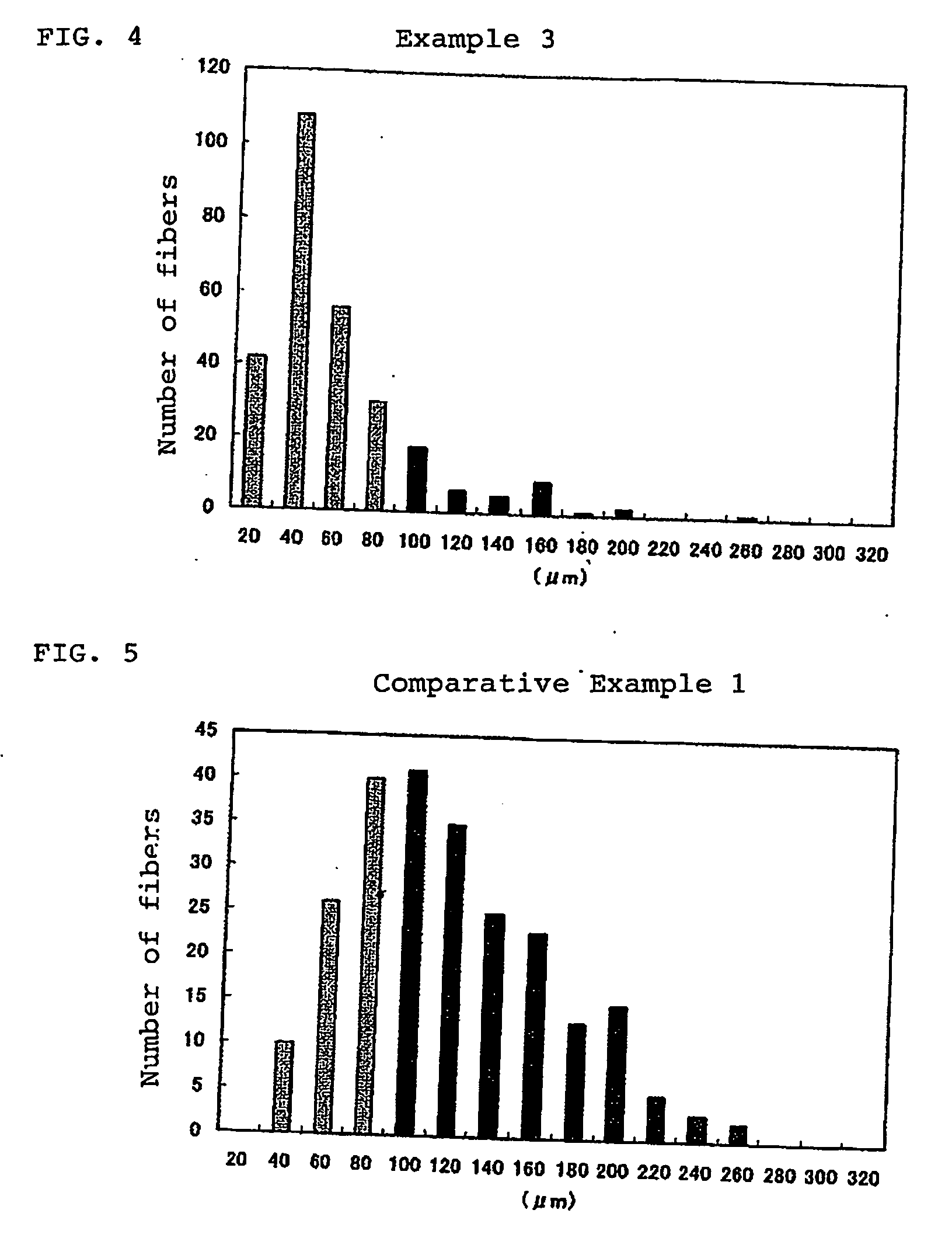

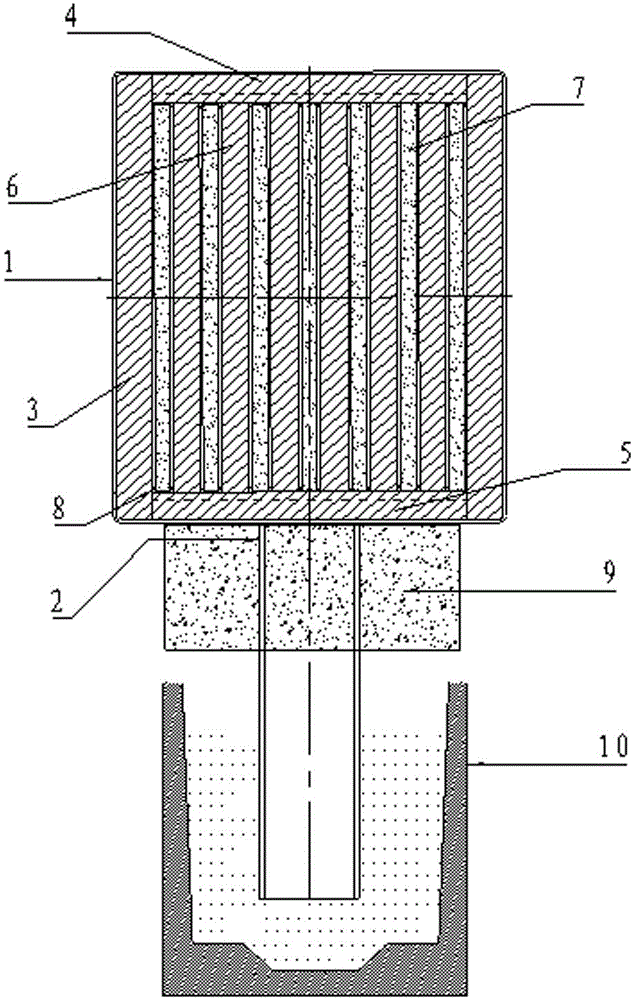

Synthetic resin needles and synthetic resin composition for needles

A medical needle is made of a synthetic resin which is reinforced, including the point part of the needle, to reduce deformation during puncture, even when the needle is produced by injection molding. The needle is made of a synthetic resin composition which includes synthetic resin and reinforcing fiber having a length of 80 μm or below and reinforcing fiber having a length exceeding 80 μm. The number ratio of the former fiber to the whole fiber component is 40% to 90%. A synthetic resin composition for needles includes a synthetic resin and a reinforcing fiber component, wherein the composition is prepared by adding at least two kinds of fibers, namely a fiber having a mean length of 1 mm to 10 mm and a fiber having a mean length of 10 μm to 100 μm to the synthetic resin and kneading the obtained mixture.

Owner:TERUMO KK

Steel pipe for embedding-expanding, and method of embedding-expanding oil well steel pipe

InactiveUS20040035576A1Reduce collapse strengthRoundnessDrilling rodsWork manipulationUltimate tensile strengthOil well

(1) A steel pipe that is expanded radially in a state wherein it was inserted in a well such as an oil well, characterized in that the non-uniform wall thickness ratio E0 (%) before expanding satisfies the following expression {circle over (1. E0<=30 / (1+0.018alpha) {circle over (1 Wherein alpha is the pipe expansion ratio (%) calculated by the following expression {circle over (2. alpha=[(inner diameter of the pipe after expanding-inner diameter of the pipe before expanding) / inner diameter of the pipe before expanding]x100 {circle over (2 (2) A steel pipe that should be expanded radially in a state wherein it is inserted in a well, such as an oil well, characterized in that the eccentric non-uniform wall thickness ratio is 10% or less. When the embedding-expanding method is performed with use of the steel pipe of (1) or (2), lowering of collapse strength of the expanded steel pipe is prevented and bending thereof can be decreased.

Owner:NIPPON STEEL CORP

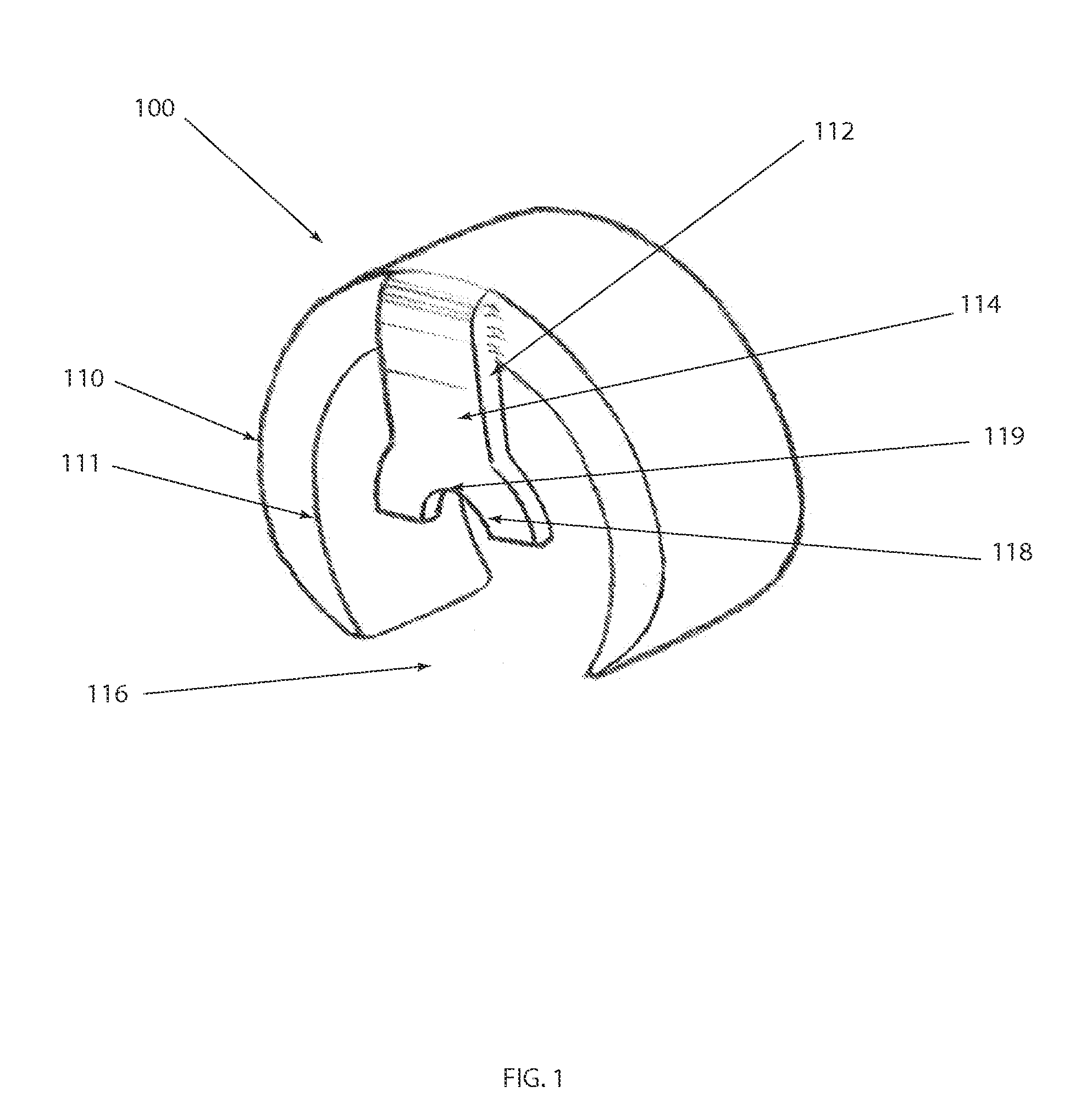

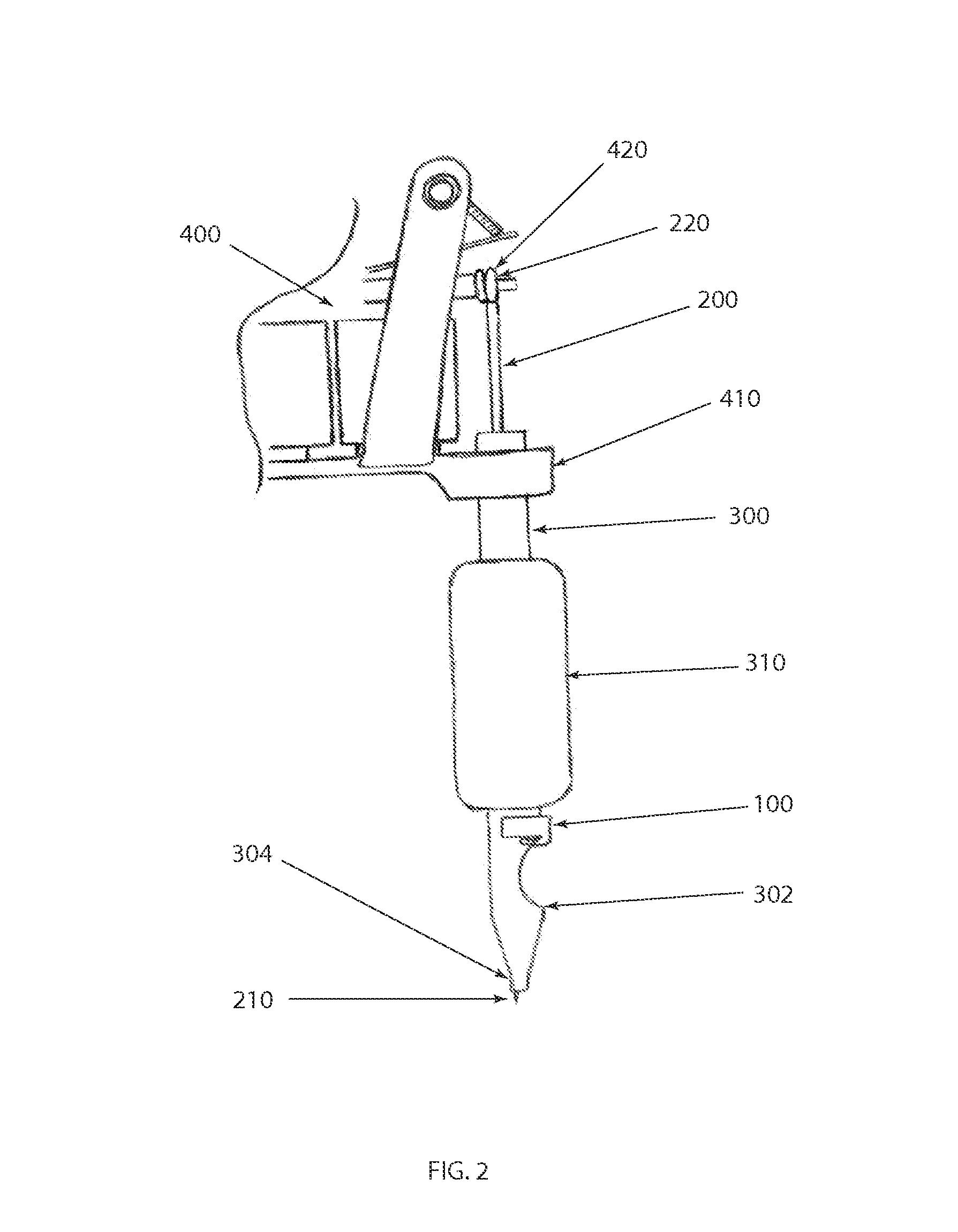

Tattoo needle stabilization device and method of use

InactiveUS9050445B2Avoid excessive wearStay in shapeMetal-working apparatusMedical devicesTattoo needleBiomedical engineering

Owner:KLEBS DAVID +1

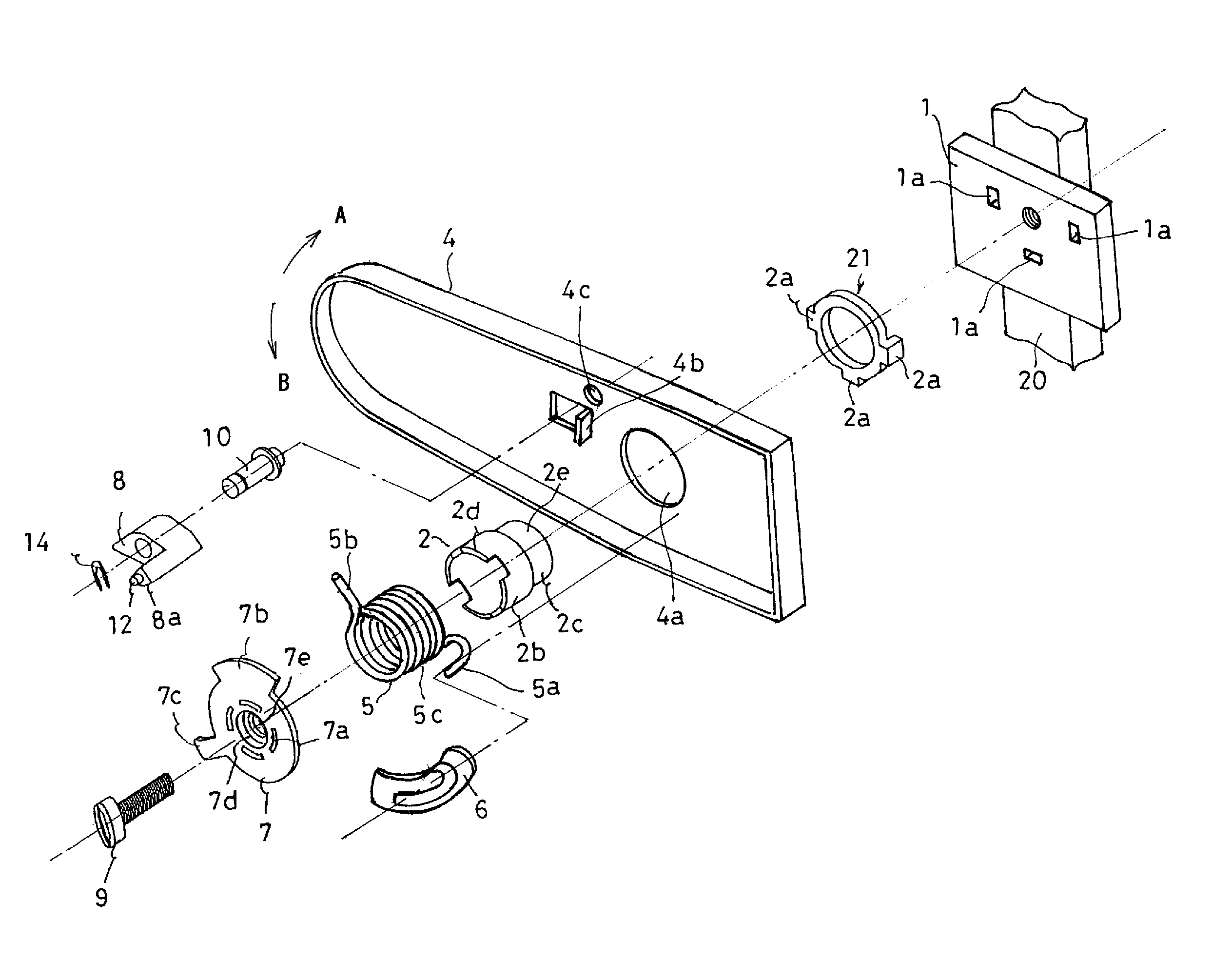

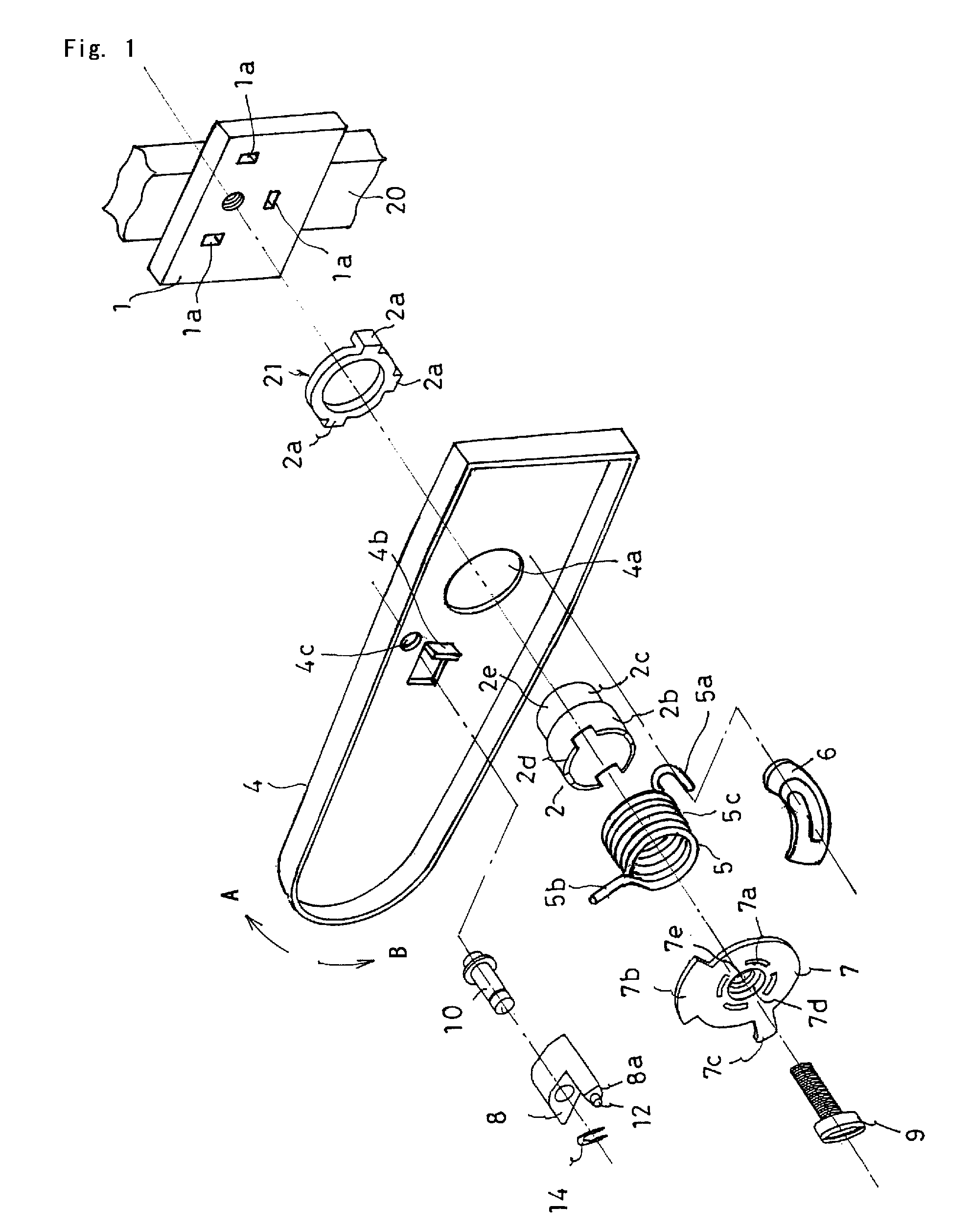

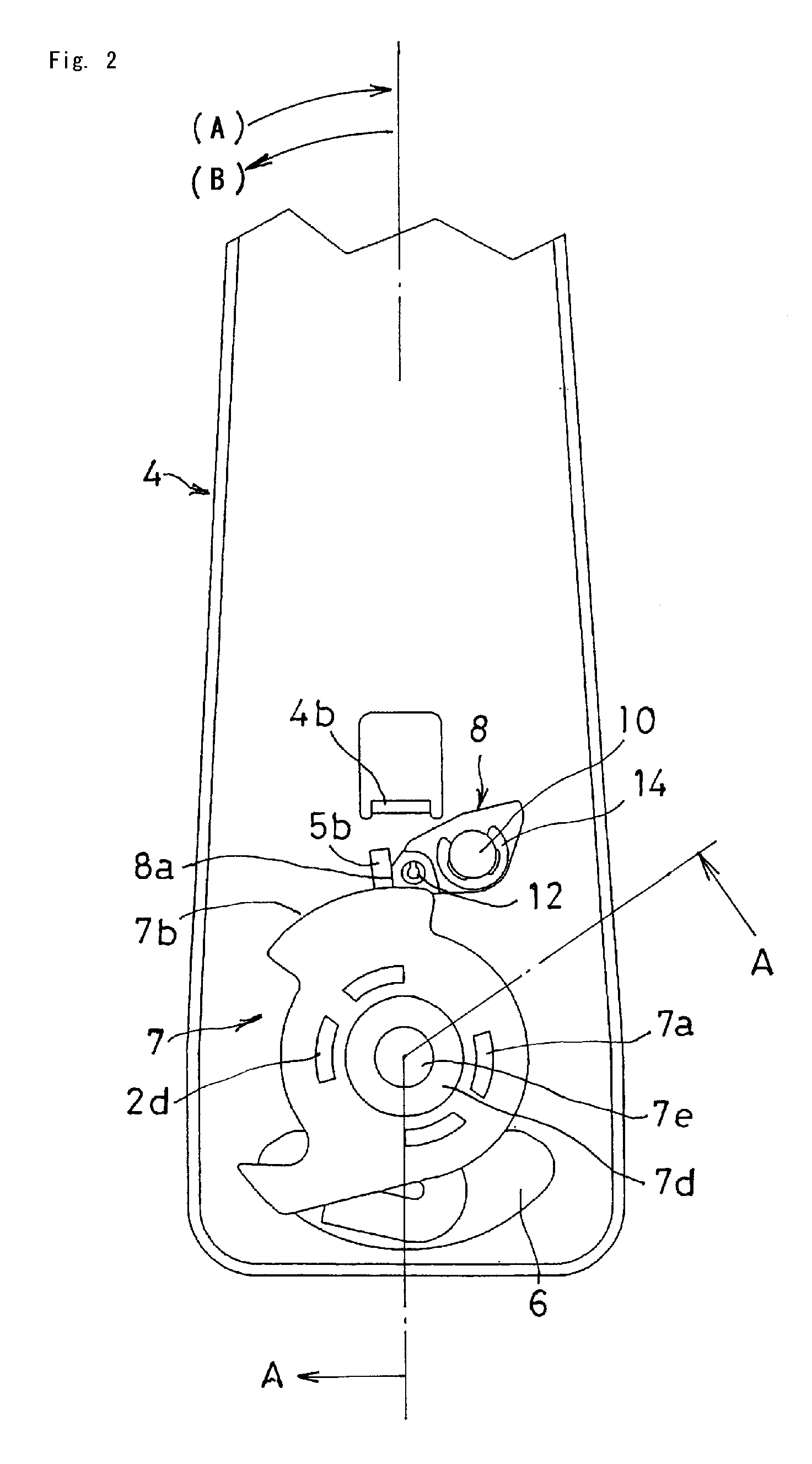

Armrest

InactiveUS8177301B2Prevention of deformation and breakageComfortable to useArm restsStoolsCoil springEngineering

An armrest, has a stationary shaft rotatably supporting an armrest body against a seat frame. The stationary shaft is inserted, so as to have fastening tolerance, inside a coil lock spring and to have a stationary-side hook and a free-side hook. A diameter of the coil lock spring is reduced or enlarged according to a normal or a reverse rotation, respectively, of the armrest body, so as to prevent or permit, respectively, the rotation of the armrest body. One of the inside diameter of the lock spring and the outside diameter of the stationary shaft is tapered in said shaft's axial direction.

Owner:NHK SPRING CO LTD

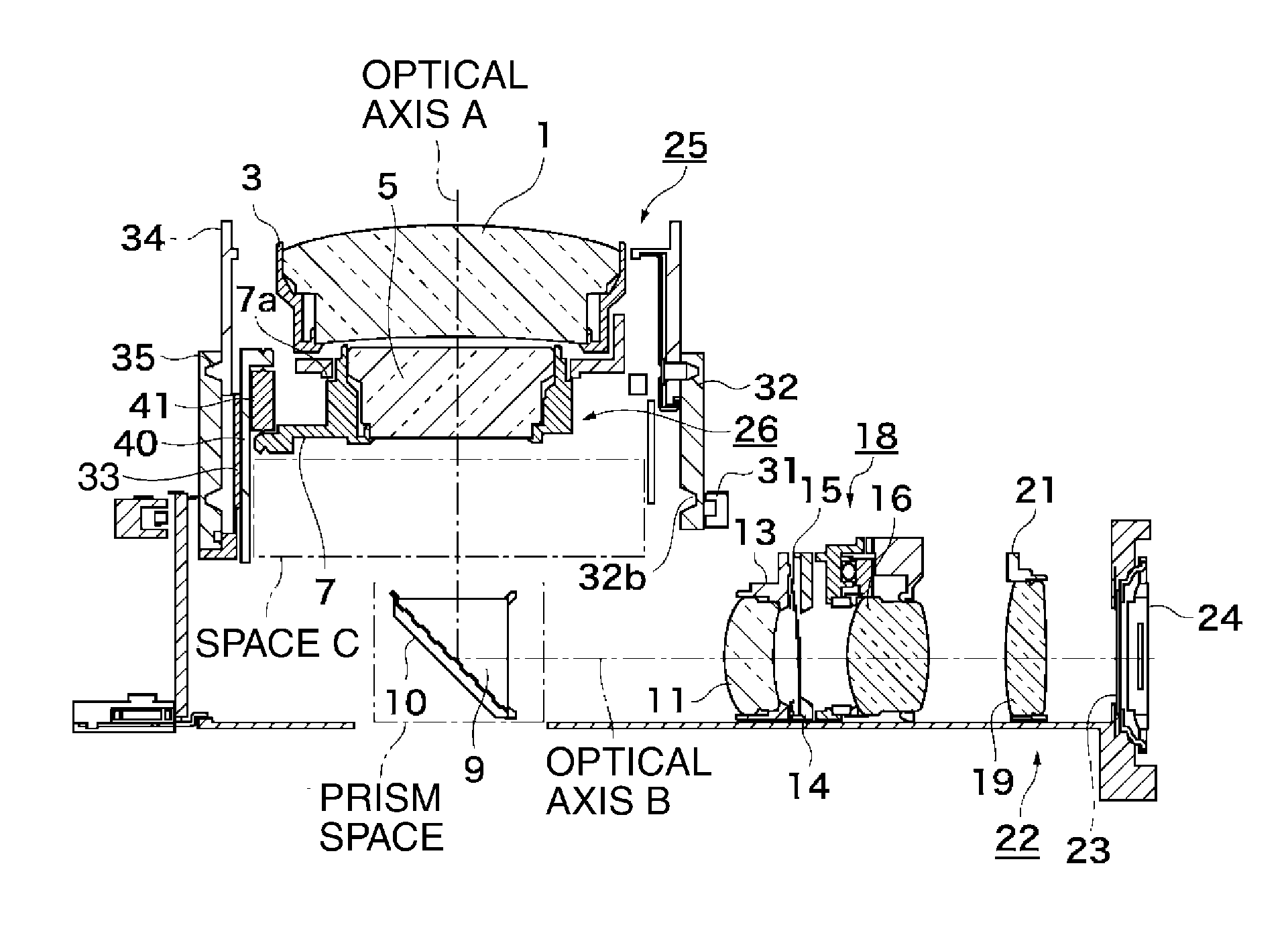

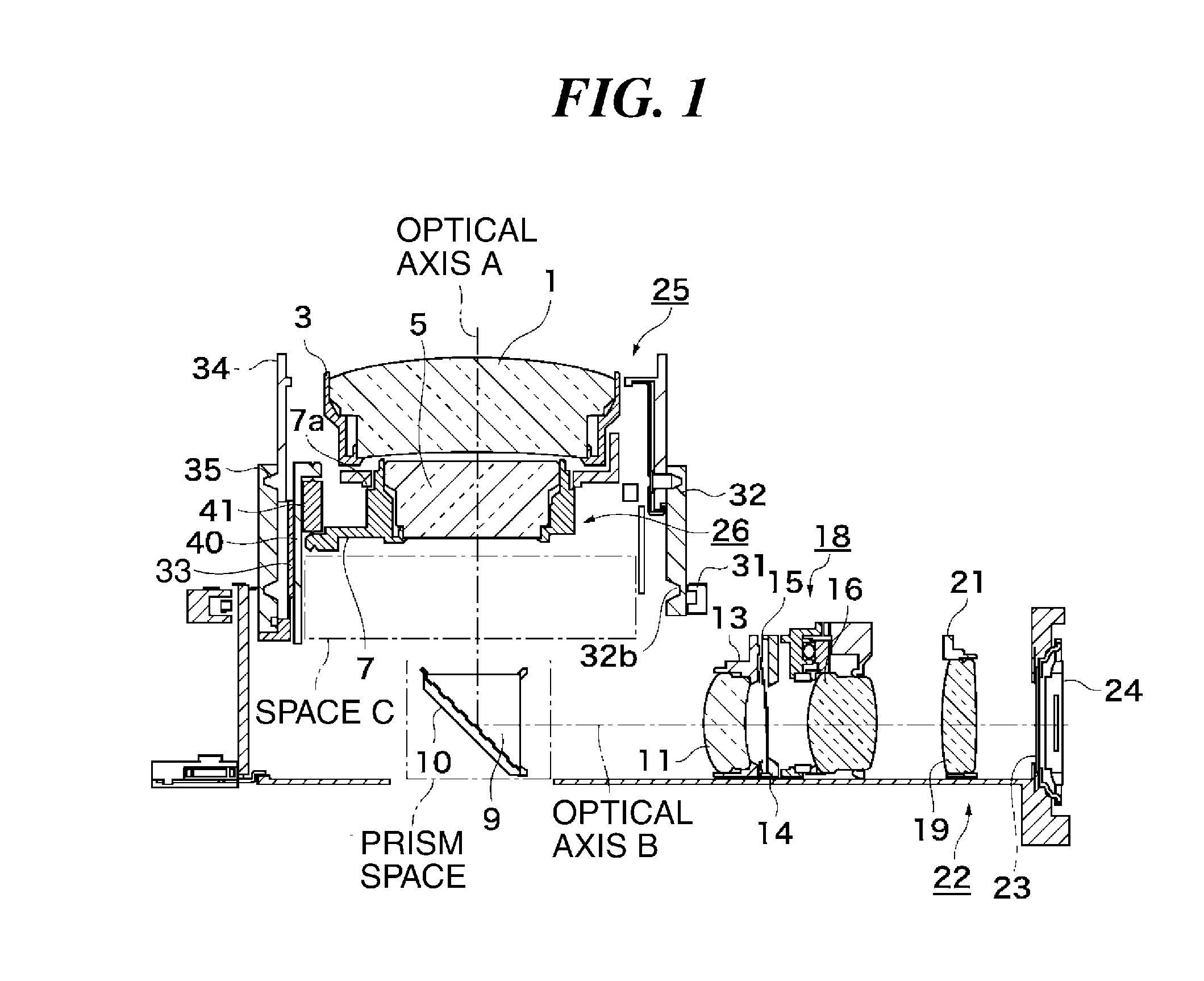

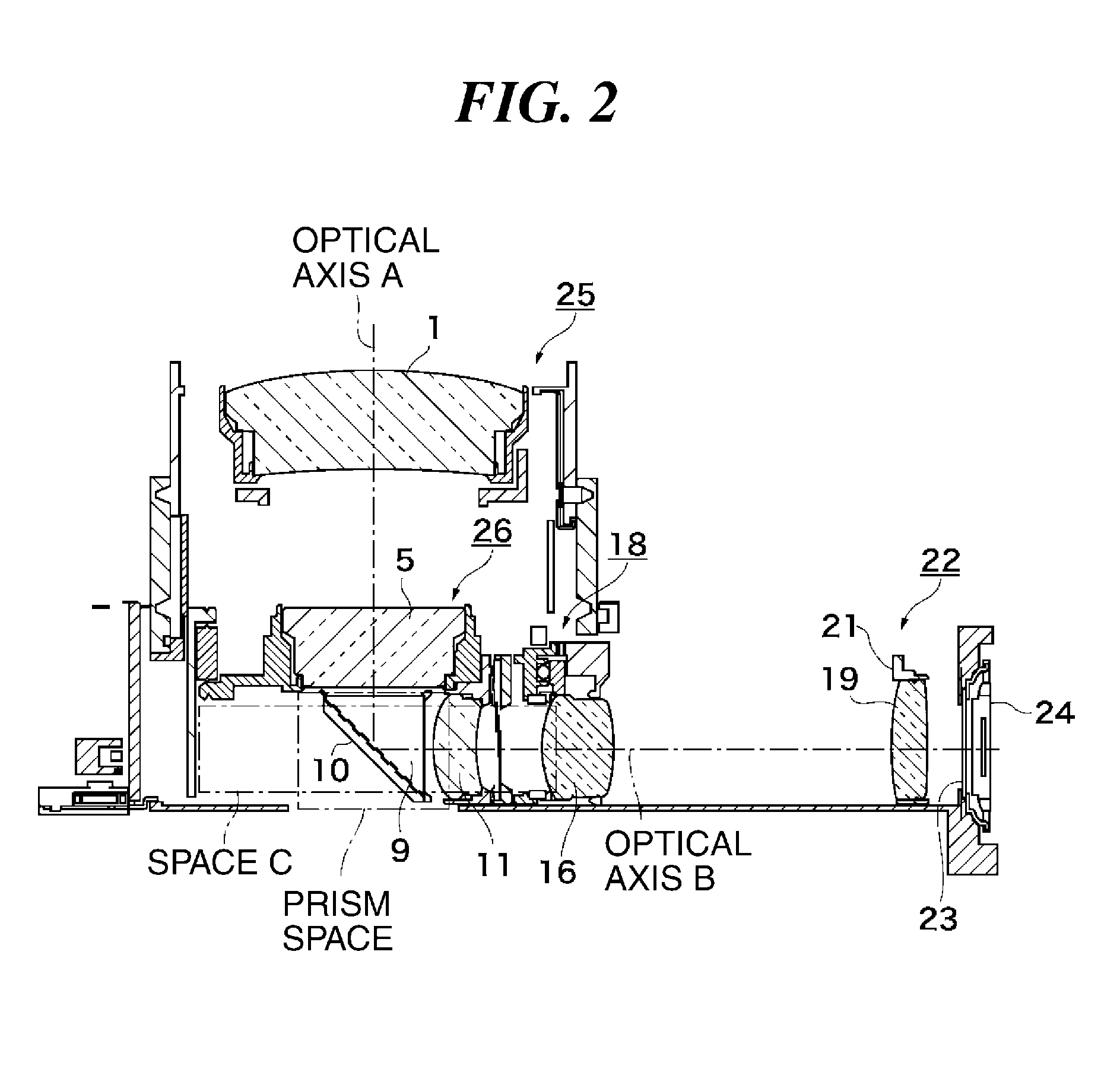

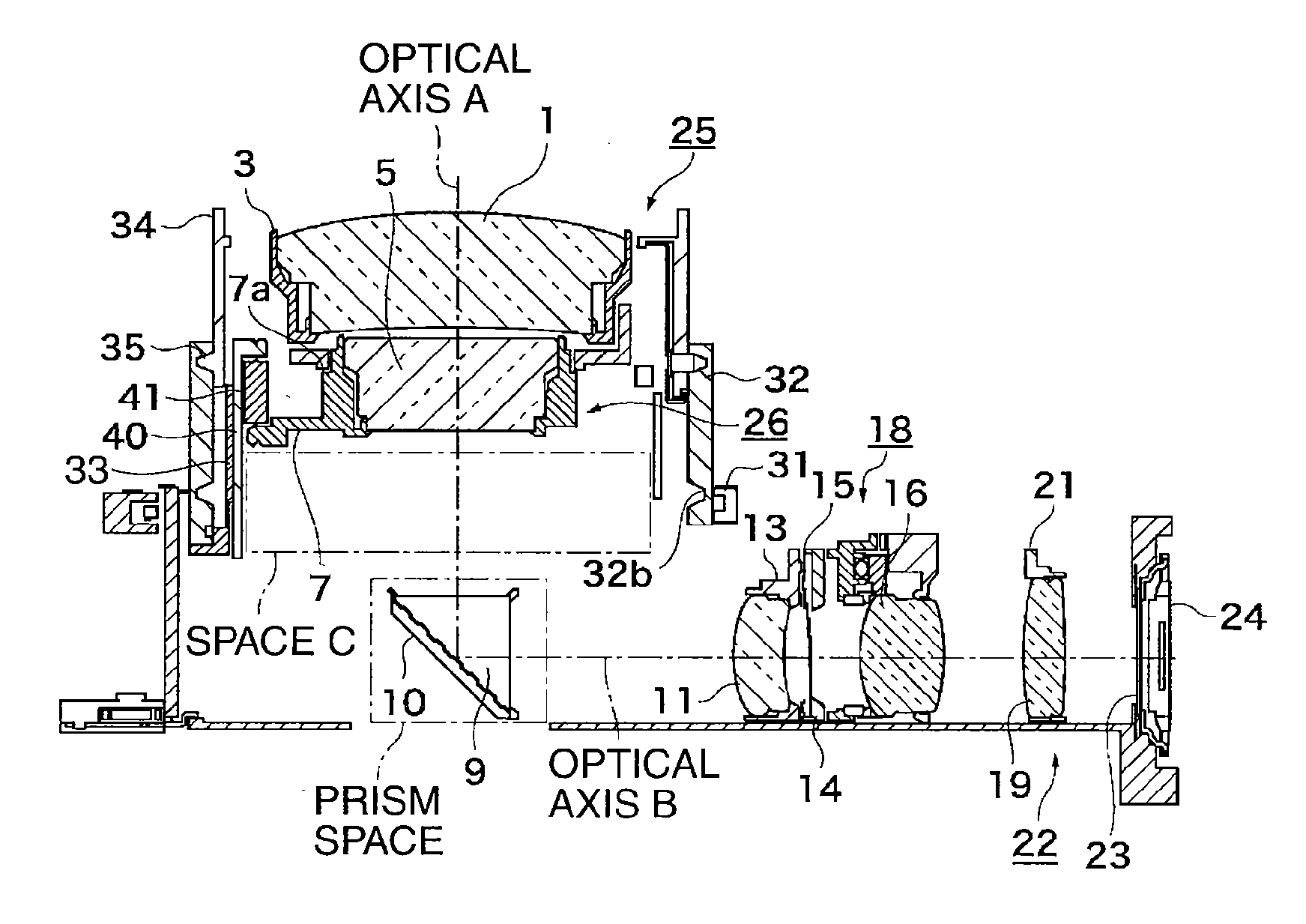

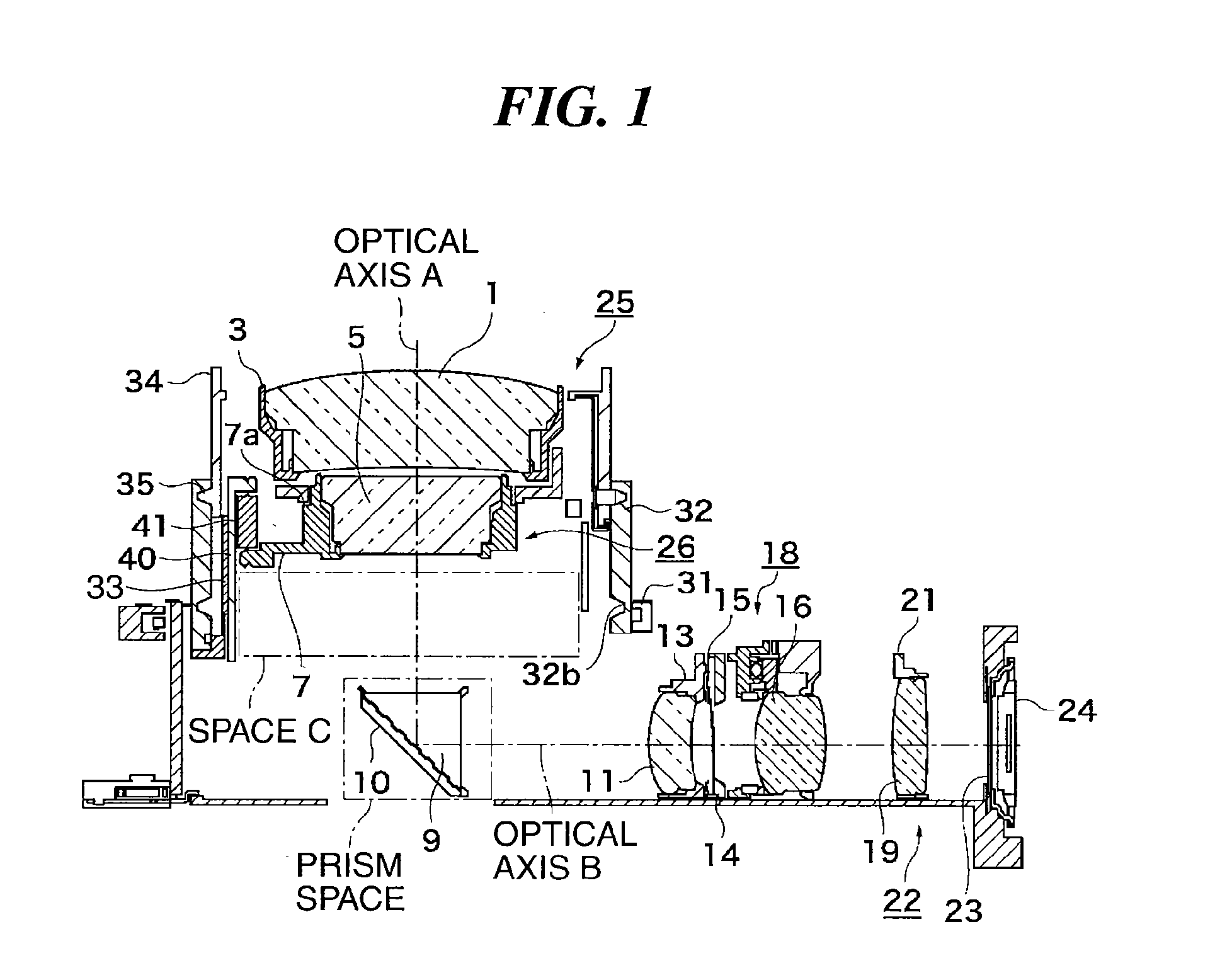

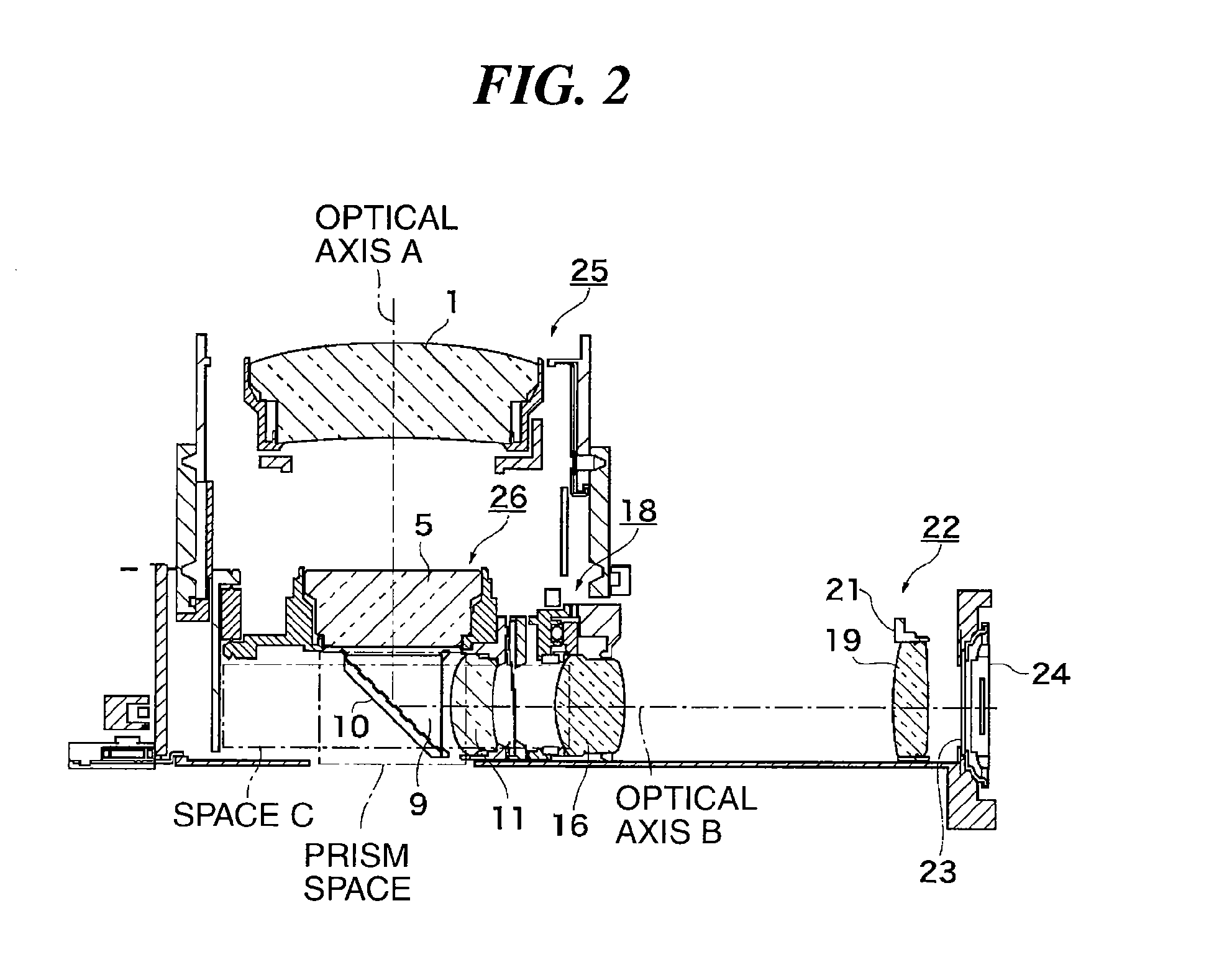

Lens barrel and image pickup apparatus

An image pickup apparatus enabling construction of a small bending optical system with high magnification. A first lens group is movably disposed toward an object on a first optical axis. A second lens group is movably disposed radially inward of the first lens group. The second lens group comprises a drive frame drivingly controlled along the first optical axis and a lens holding frame for holding the second lens group. A prism is disposed on the first optical axis, for bending light incident on the prism to thereby guide the light along a second optical axis. The prism is retracted along the second optical axis in a non-shooting state. In the non-shooting state, the second lens group is retracted and accommodated in a space defined by the drive frame and the lens holding frame and a space occupied by the prism in a shooting state.

Owner:CANON KK

Synthetic resin needles and synthetic resin composition for needles

InactiveUS20090312480A1Small overall deformationAvoid deformationMedical devicesSpecial tyresFiberSynthetic resin

A medical needle is made of a synthetic resin which is reinforced, including the point part of the needle, to reduce deformation during puncture, even when the needle is produced by injection molding. The needle is made of a synthetic resin composition which includes synthetic resin and reinforcing fiber having a length of 80 μm or below and reinforcing fiber having a length exceeding 80 μm. The number ratio of the former fiber to the whole fiber component is 40% to 90%. A synthetic resin composition for needles includes a synthetic resin and a reinforcing fiber component, wherein the composition is prepared by adding at least two kinds of fibers, namely a fiber having a mean length of 1 mm to 10 mm and a fiber having a mean length of 10 μm to 100 μm to the synthetic resin and kneading the obtained mixture.

Owner:TERUMO KK

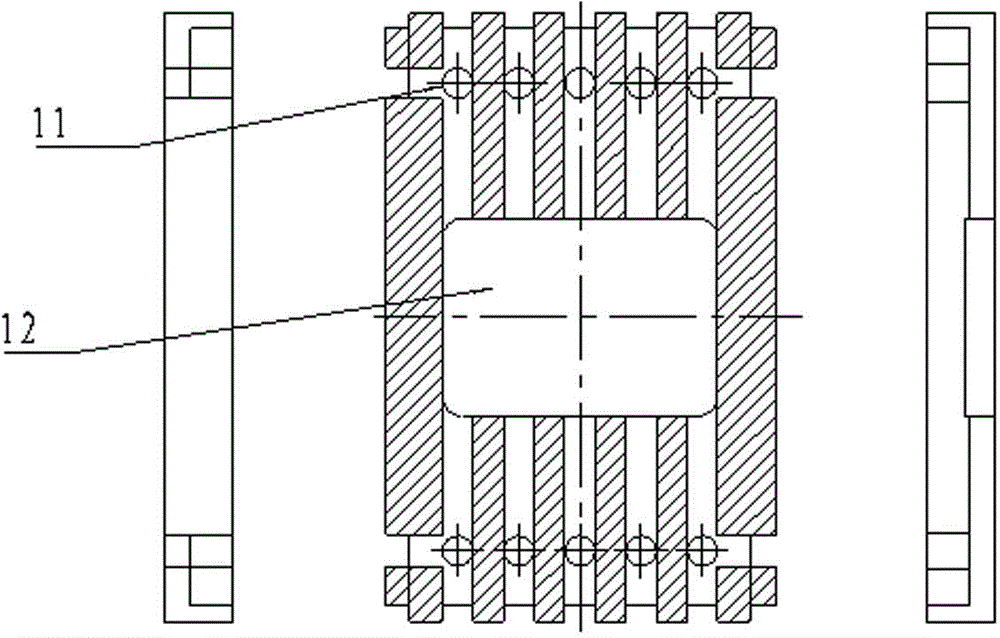

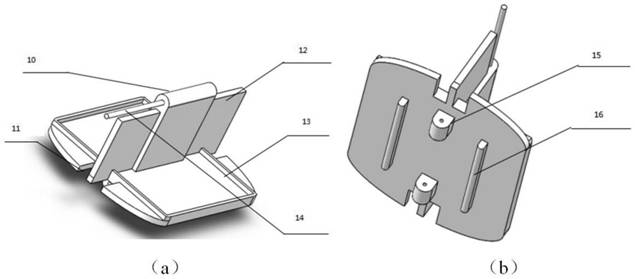

Accurate forming tool of aluminum silicon carbide composite IGBT (insulated gate bipolar translator) baseplate

ActiveCN103600053ASlow down the speed of solidificationPrevent shrinkageGearingCylindersMachining timeAluminium alloy

The invention discloses an accurate forming tool of an aluminum silicon carbide composite IGBT (insulated gate bipolar translator) baseplate. The accurate forming tool comprises an aluminizing box, a guiding pipe and positioning devices, wherein the upper part of the guiding pipe is fixedly connected with a bottom surface of the aluminizing box; the upper part of the aluminizing box is provided with a cover plate which is placed in the aluminizing box, the lower part of the aluminizing box is provided with a bottom plate which is placed in the aluminizing box, the four sides of the aluminizing box are all provided with side plates which are placed in the aluminizing box; the bottom plate is provided with an impregnation flow channel of a molten aluminum alloy liquid; at least two deformation-proof partition plates are arranged among the side plates; the guiding pipe is externally sleeved with a heat preservation device. The accurate forming tool provided by the invention has the advantages that the heat preservation device can reduce the freezing rate of an alloy liquid in the guiding pipe, a final freezing region can be controlled in the position of the heat preservation device, the aluminum alloy liquid can be used for feeding a baseplate material in the aluminizing box in time, and thus a shrinkage cavity of the material is avoided; the positioning devices can strictly control the aluminum covering quantity of the two surfaces of a baseplate, the processing time is short, the cost is low, and the production efficiency is high; the aluminizing flow channel can be used for eliminating a crackle of the material and non-uniformity of an aluminum tape and the material.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

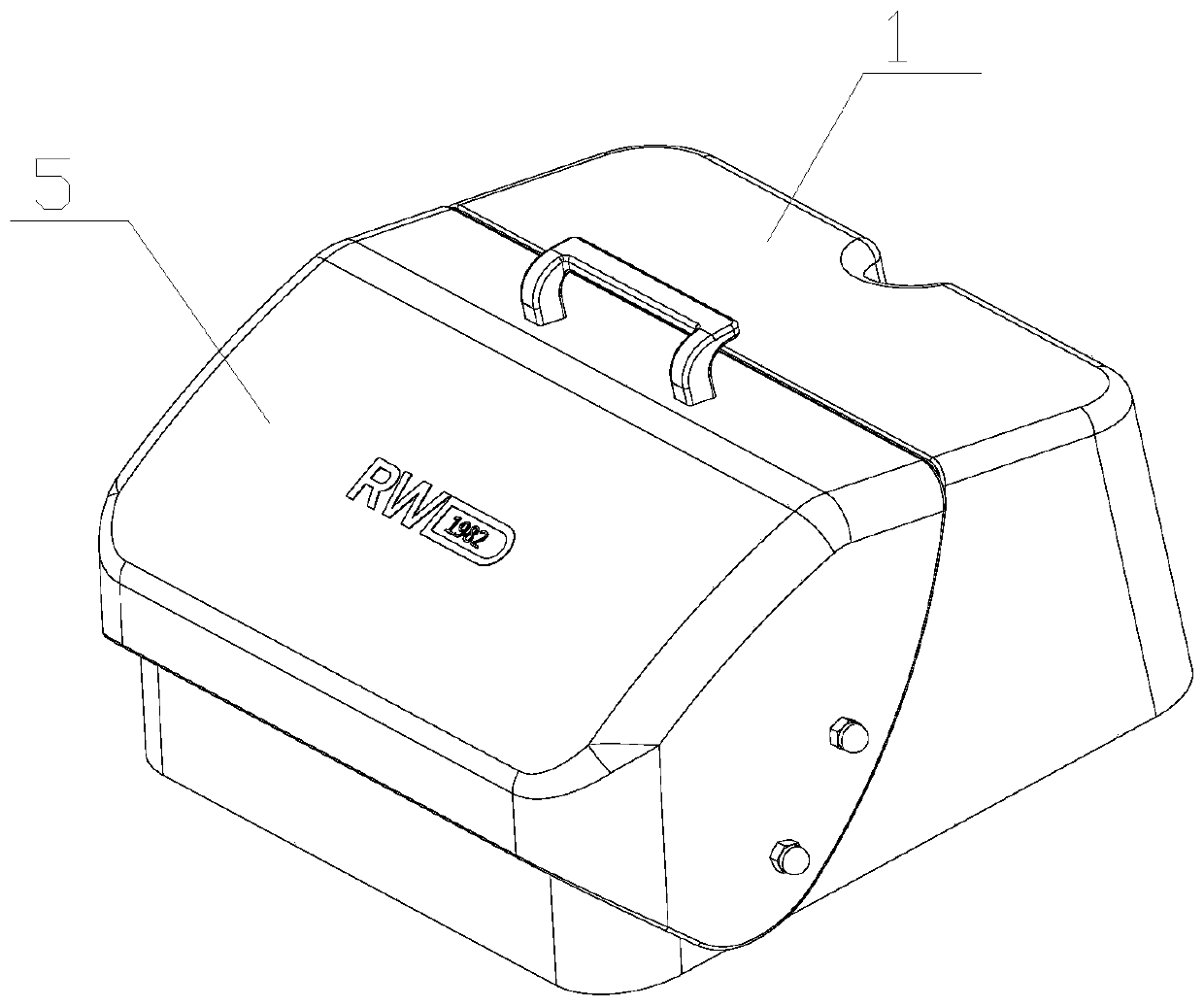

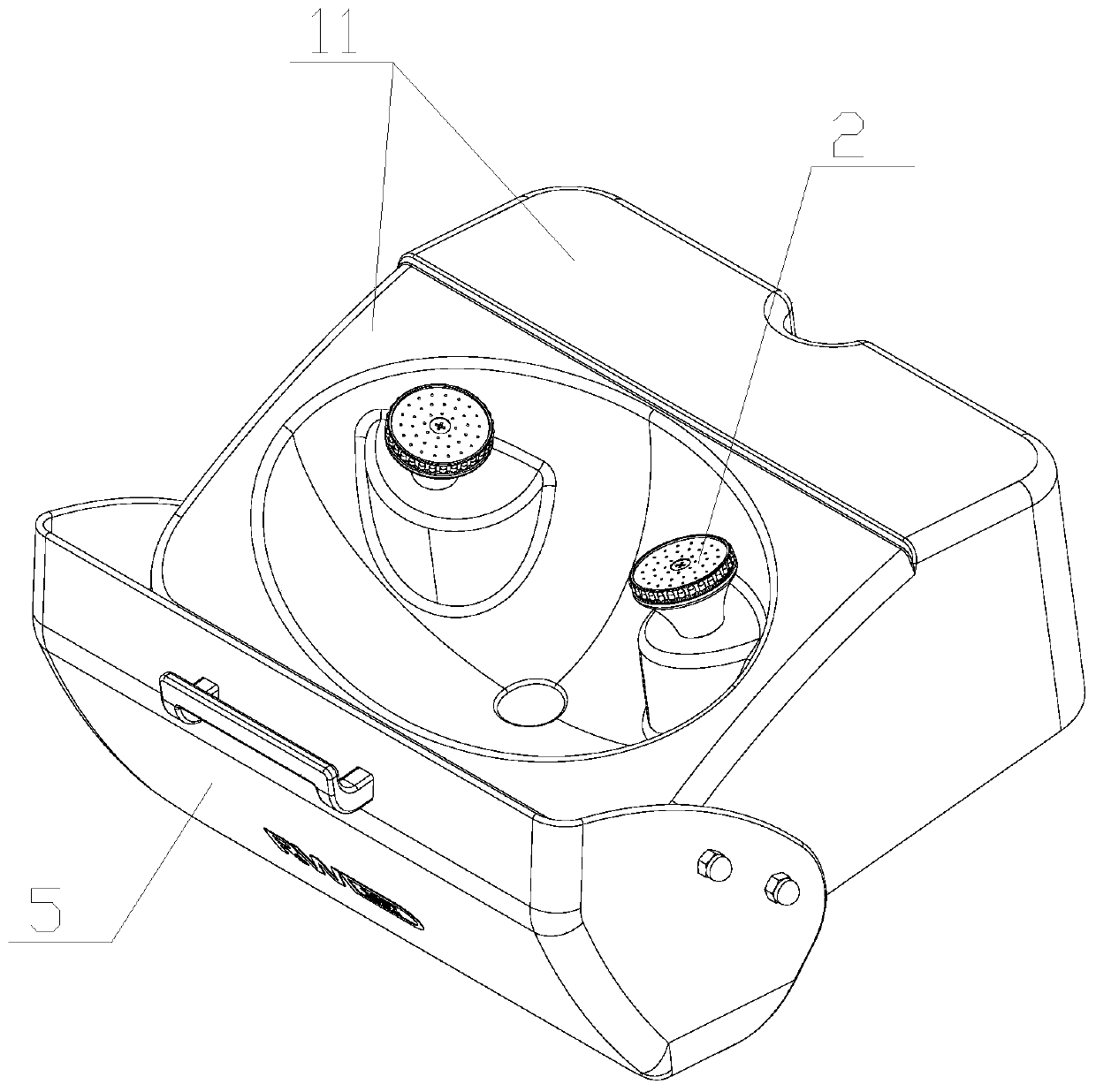

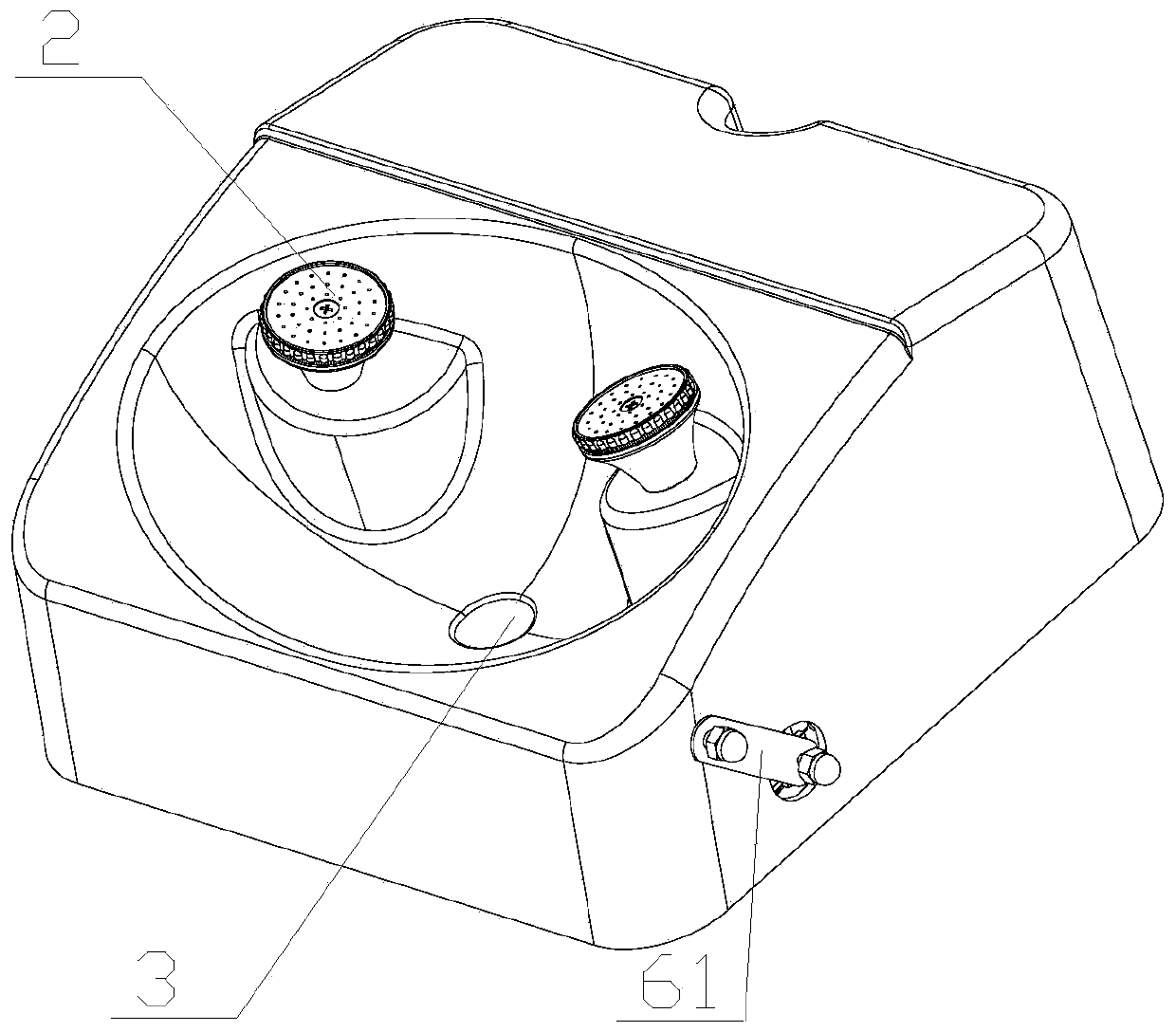

Eye washer with high using comfort

The invention discloses an eye washer with high using comfort. Two eye washing nozzles are symmetrically arranged on the left and right sides of a drainage hole; the central connection line of the twoeye washing nozzles is located at the rear part of the drainage hole; the axes of the eye washing nozzles are in inclined arrangement and have forward inclined angles alpha; the left and right opposite equal angles of the two eye washing nozzles are obliquely close to each other; and the included angle between the axes of the two eye washing nozzles is beta, so that water columns can fall into the center of the drainage hole after the eye washing nozzles spray water. The eye washing nozzles can be inclined forward, and the water columns sprayed by the eye washer can have forward inclined angles, so that the bending amplitude of a waist or a neck of a user can be reduced during using; the distance of the eye washing nozzles from the edge on the front side of an eye washing basin can be increased by backward moving the eye washing nozzles; through the forward inclined arrangement of the eye washing nozzles, the water columns can fall into the drainage hole to discharge; and situations of wetting the clothes of the user or polluting the surrounding ground caused by the splashing of water drops can be avoided by leaving the position of the drainage hole.

Owner:HEBEI RUNWANGDA SANITARY WARE MFG

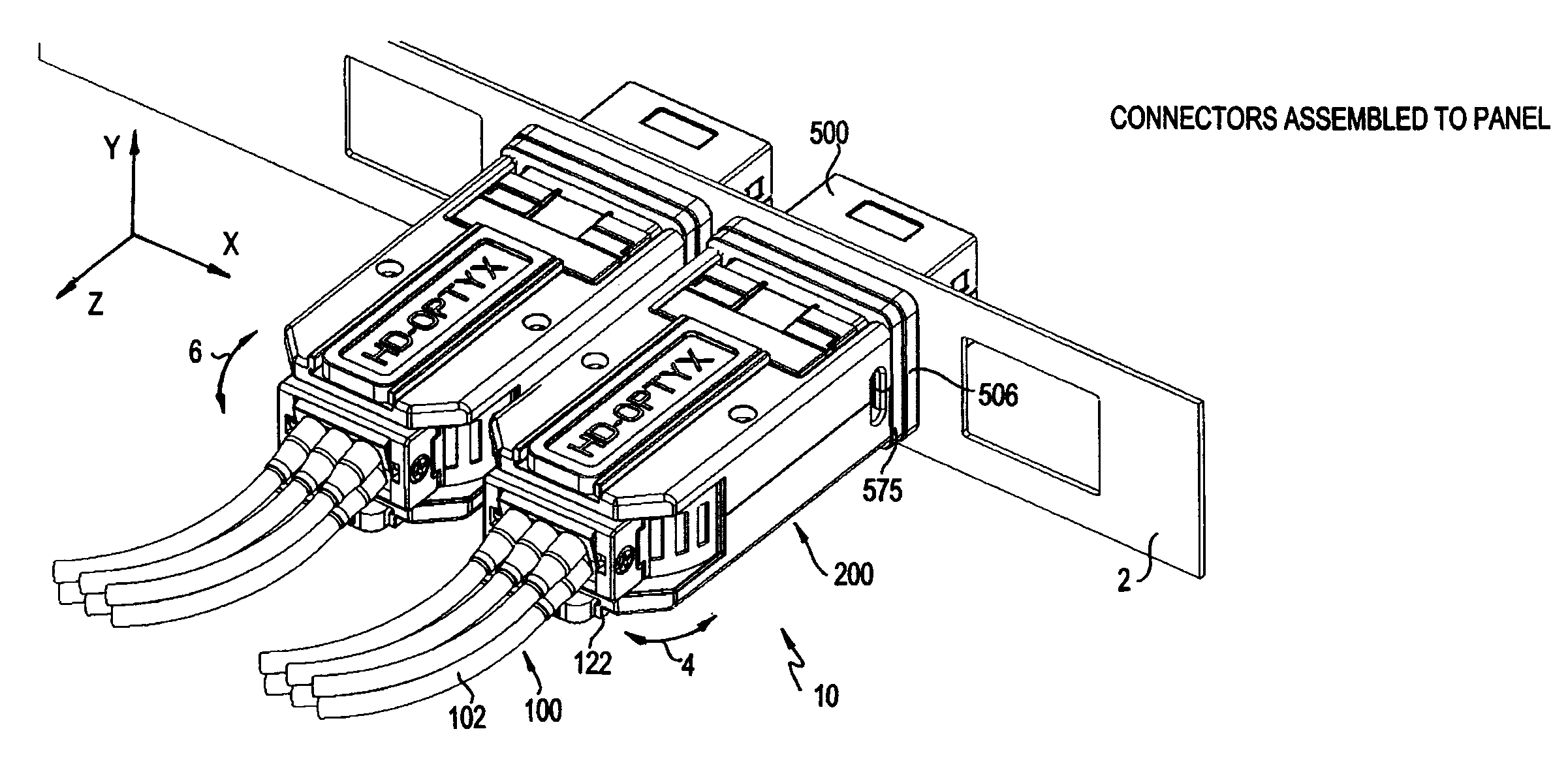

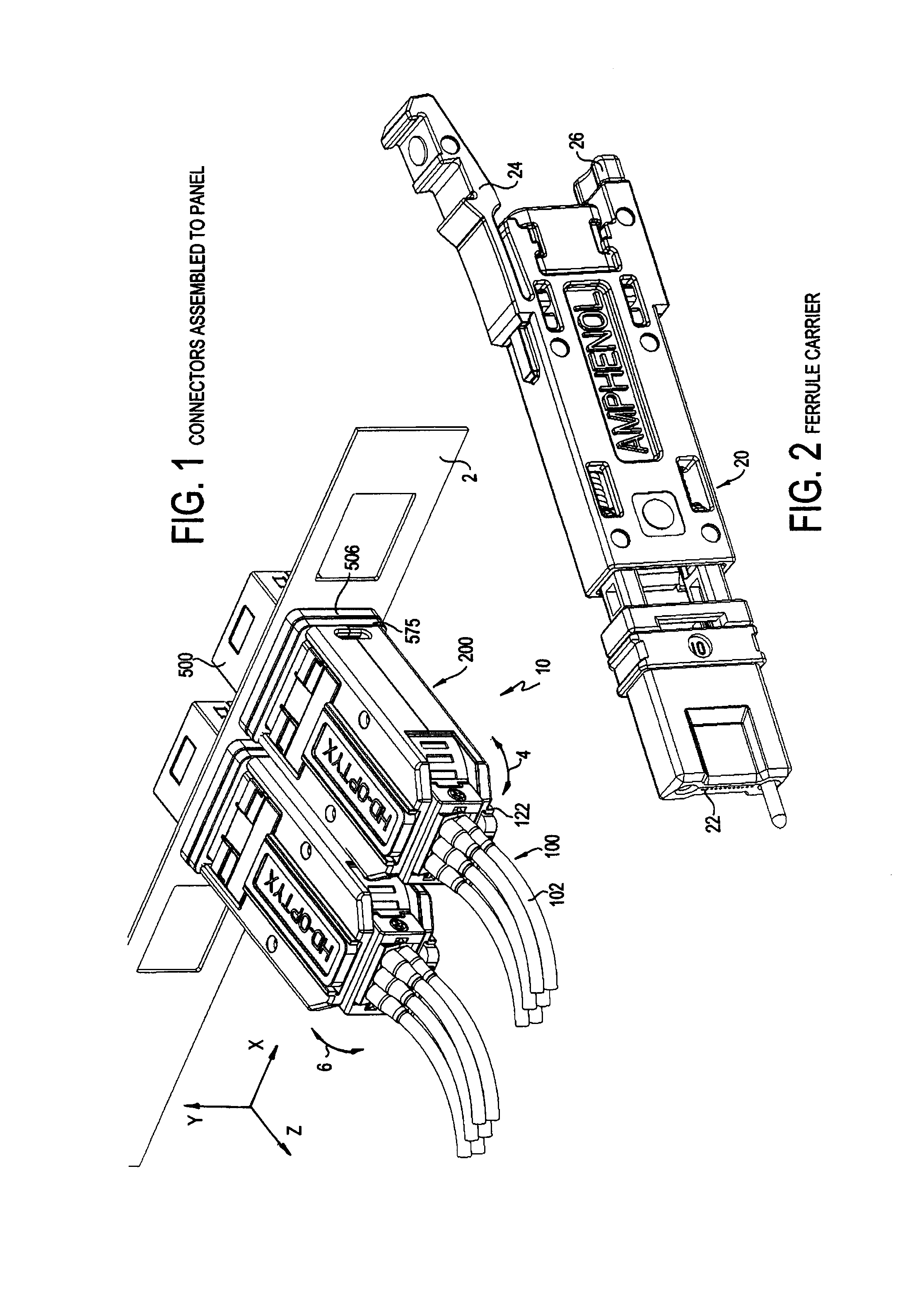

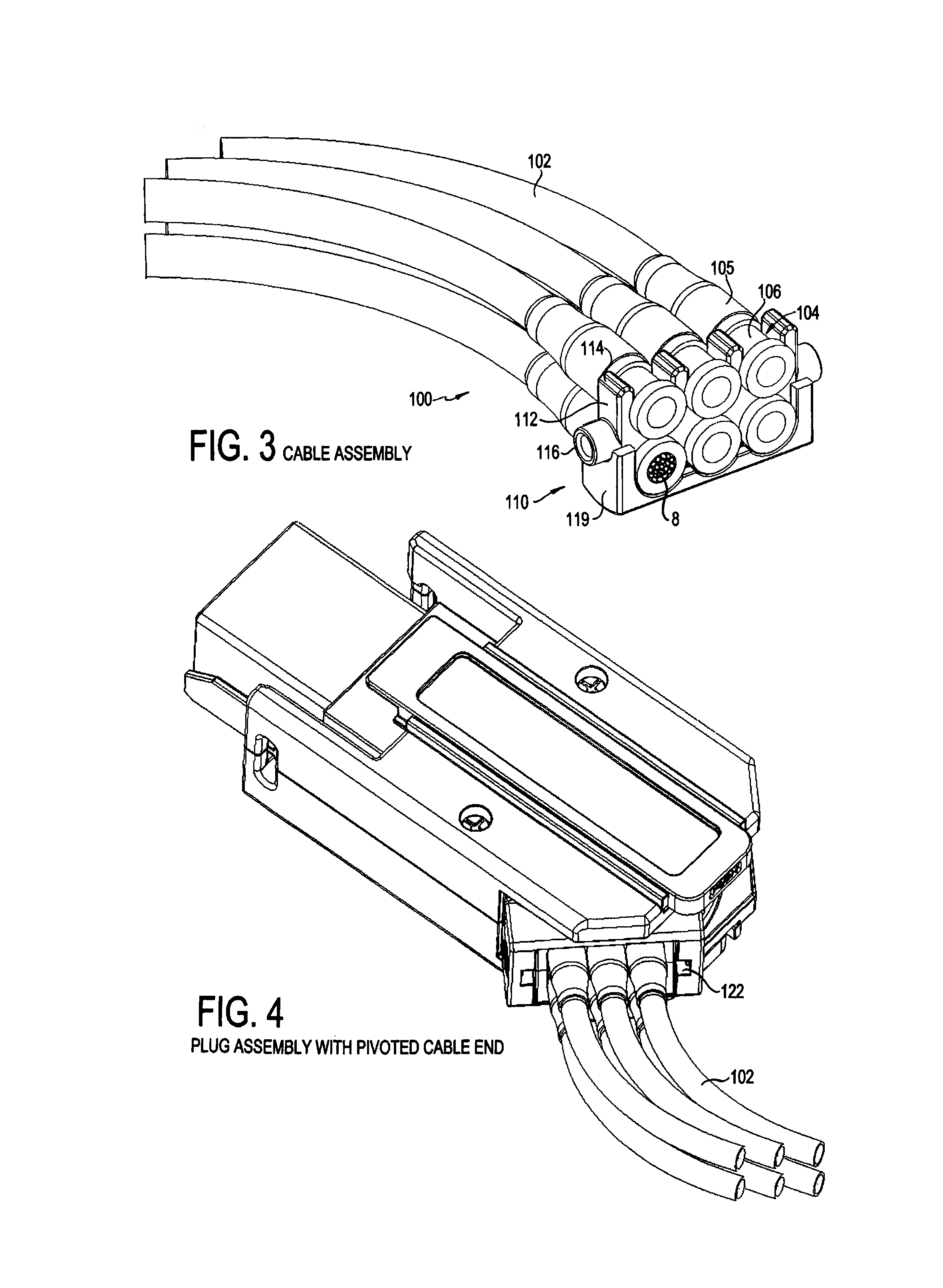

High density front panel optical interconnect

A connector assembly has a cable assembly, plug assembly and a socket assembly. The socket assembly is a female member which is received within an opening at the front face of a panel. The plug assembly is a male member which then engages the socket at the front face of the panel. The cable assembly connects the cables carrying optical fibers to the plug assembly. As the socket assembly receives the plug assembly, doors on the respective housings open and ferrule carriers carried by the socket and plug assemblies mate. The plug assembly has a movable front end which permits the fibers to move in both horizontal and vertical directions.

Owner:AMPHENOL CORP

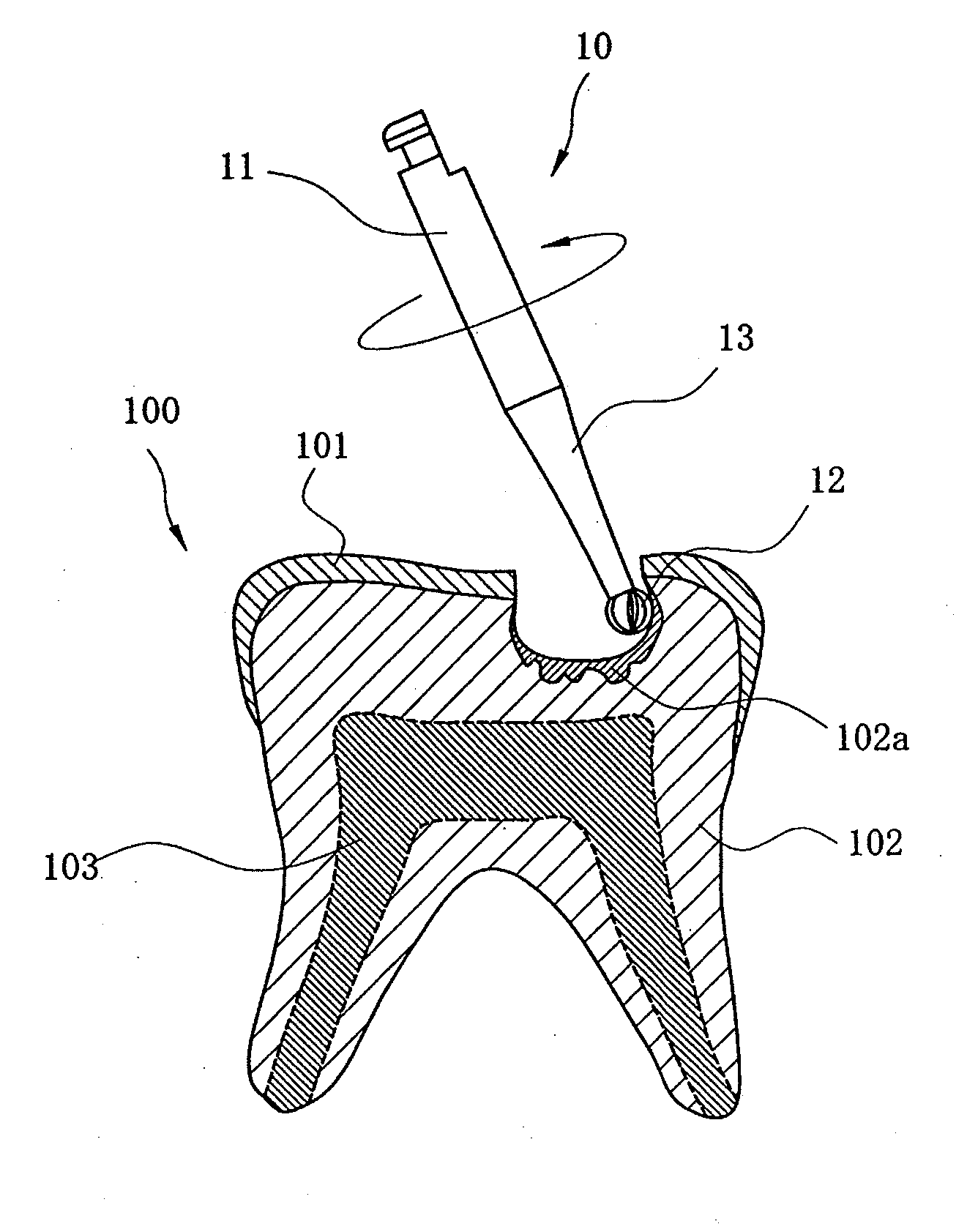

Stainless steel bur

InactiveUS20110200964A1Reduce hardnessReduce cutting forceTurning machine accessoriesMilling cuttersEtchingMaximum diameter

A stainless steel bur, which can cut minute depressions etc. and even healthy dentin when necessary, allowing a technician to detect when cutting the healthy dentin is provided. It includes a removable handle (11) connected to a hand piece on the base side, a working section (12) to which a cutting blade for cutting teeth is attached to the tip, and the working section and the handle are connected to a tapered intermediate section (13). This steel bur is formed into a fiber structure by hardening austenitic stainless steel through wire drawing. Since the tapered part bends and generates vibrations when the working section is rotated to cut healthy dentin, it can be understood that the healthy dentin is being cut, and excessive cutting may be prevented. Alternatively, excessive cutting may be prevented by processing from the maximum diameter of the working section to the tip thereof through etching or the like to round cutting blade edge and make a blunt edge.

Owner:MATSUTANI SEISAKUSHO CO LTD

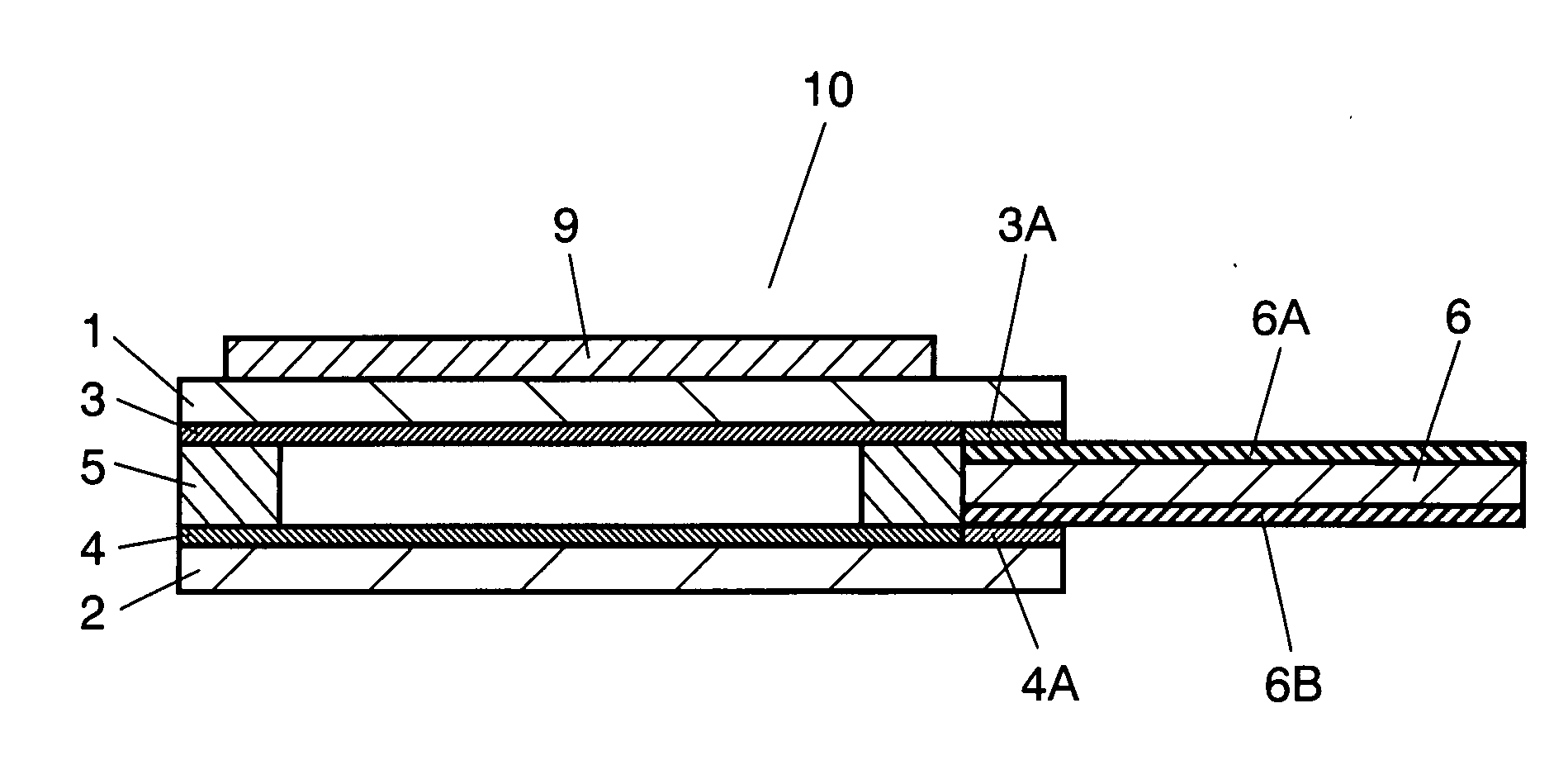

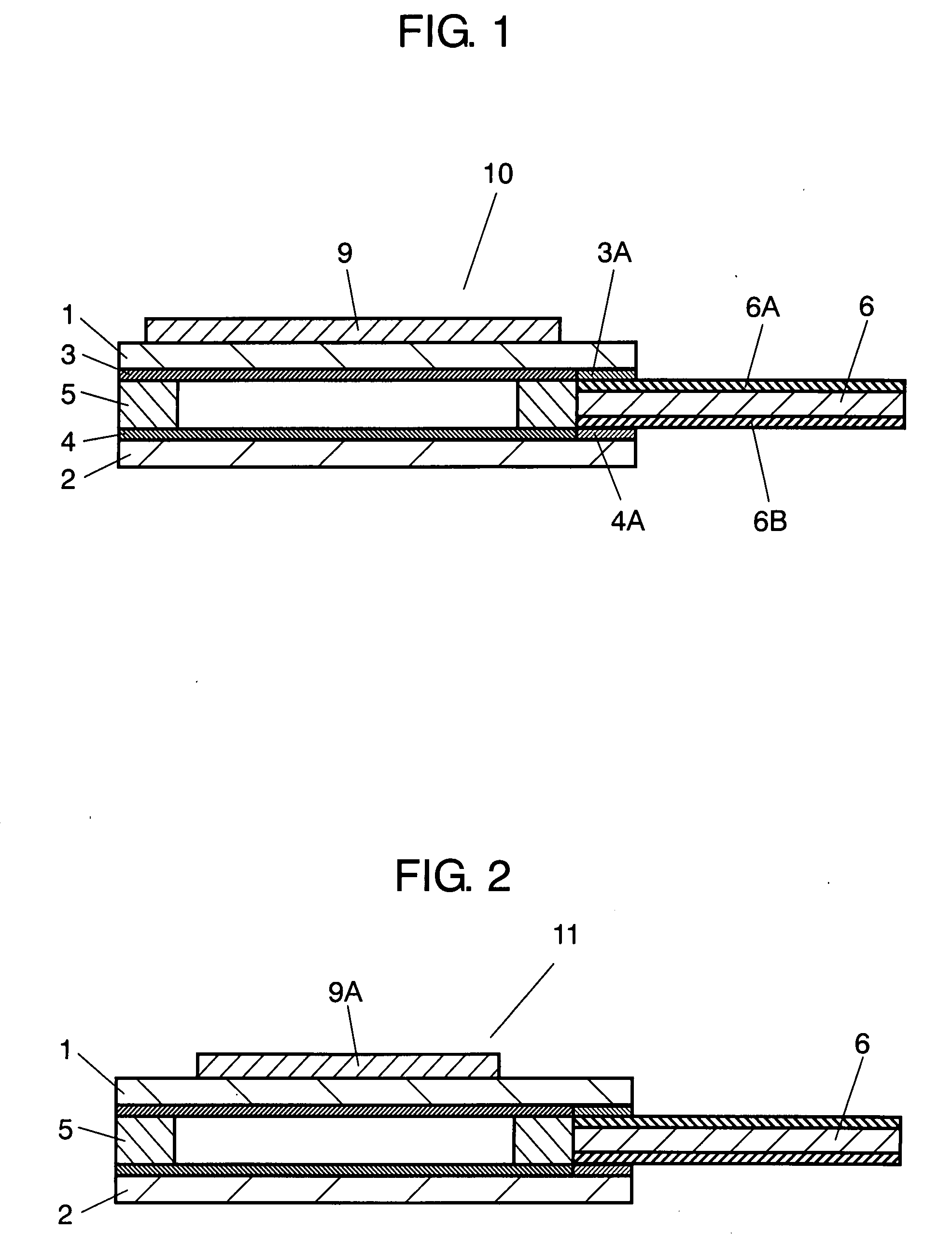

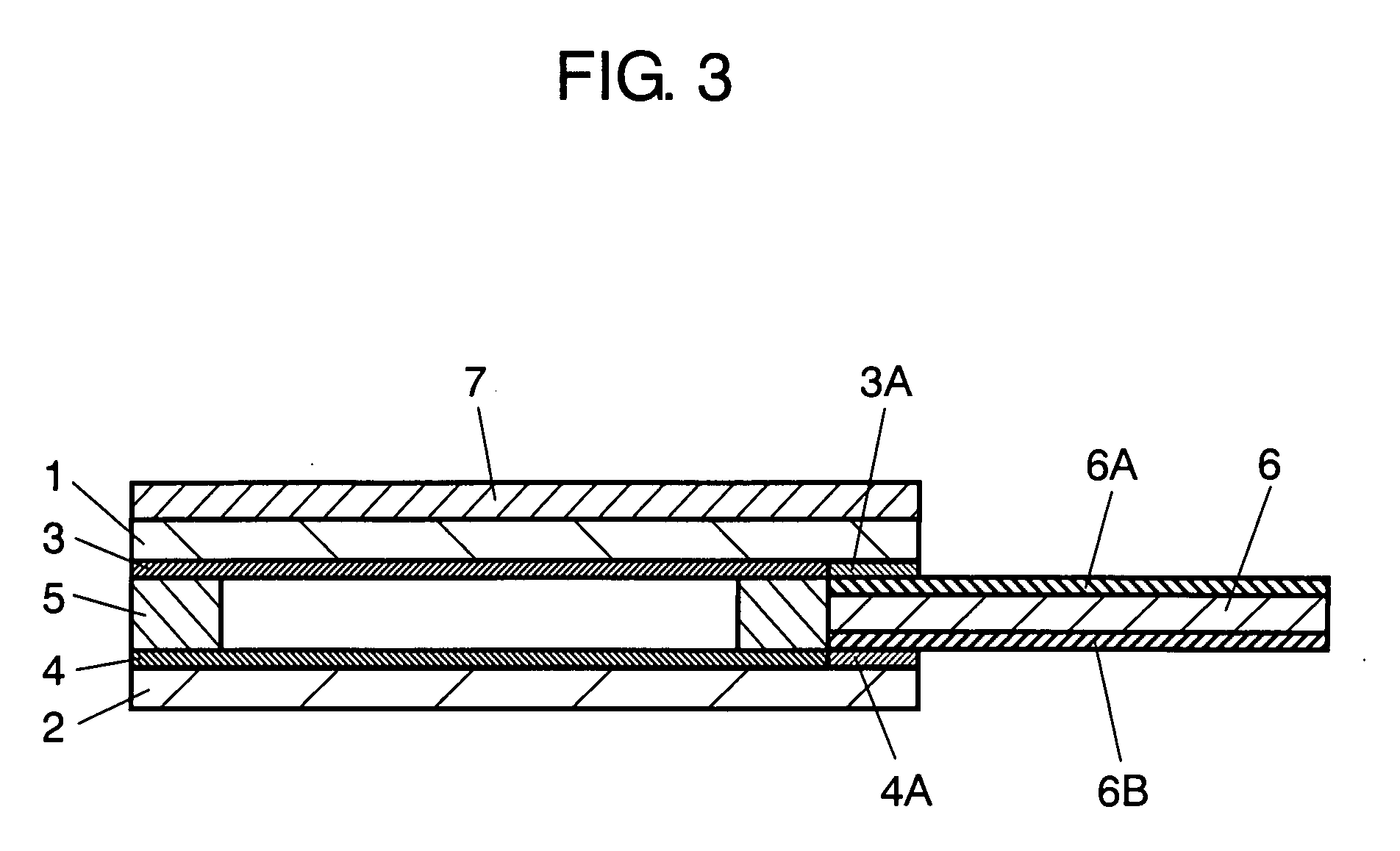

Touch panel

InactiveUS20070200259A1Easy to operateSecure electrical connectionSemiconductor/solid-state device detailsSolid-state devicesHigh humidityElectrical connection

The touch panel of the invention includes an optically transparent upper substrate having an upper conductive layer formed on an undersurface thereof, an optically transparent lower substrate having a lower conductive layer formed on an upper surface thereof and facing the upper conductive layer with a predetermined space, a spacer in a frame shape disposed between the upper substrate and the lower substrate, and a polarizing plate adhered to an upper surface of the upper substrate, in which the polarizing plate is adhered to the upper surface of the upper substrate within the outer periphery of the spacer. Because the polarizing plate is attached to the upper surface of the upper substrate but within an outer periphery of the spacer, even when the panel is exposed to a high temperature and high humidity environment, the substrate is prevented from being peeled off the spacer and a loose fitness of wiring substrate is avoided, thus a touch panel of an easy operation and a secure electrical connection is obtained.

Owner:PANASONIC CORP

Lift with support means and drive means

Owner:INVENTIO AG

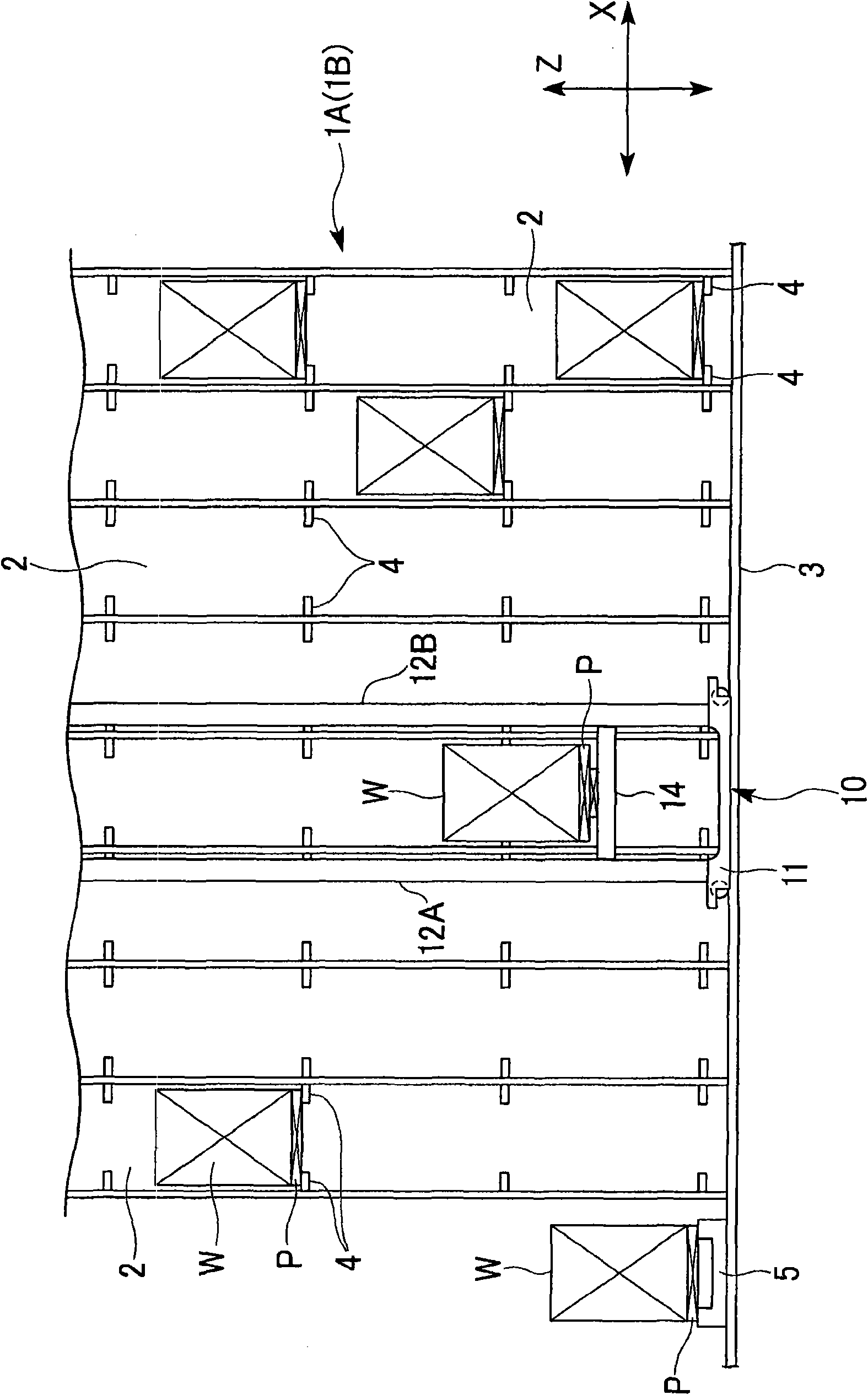

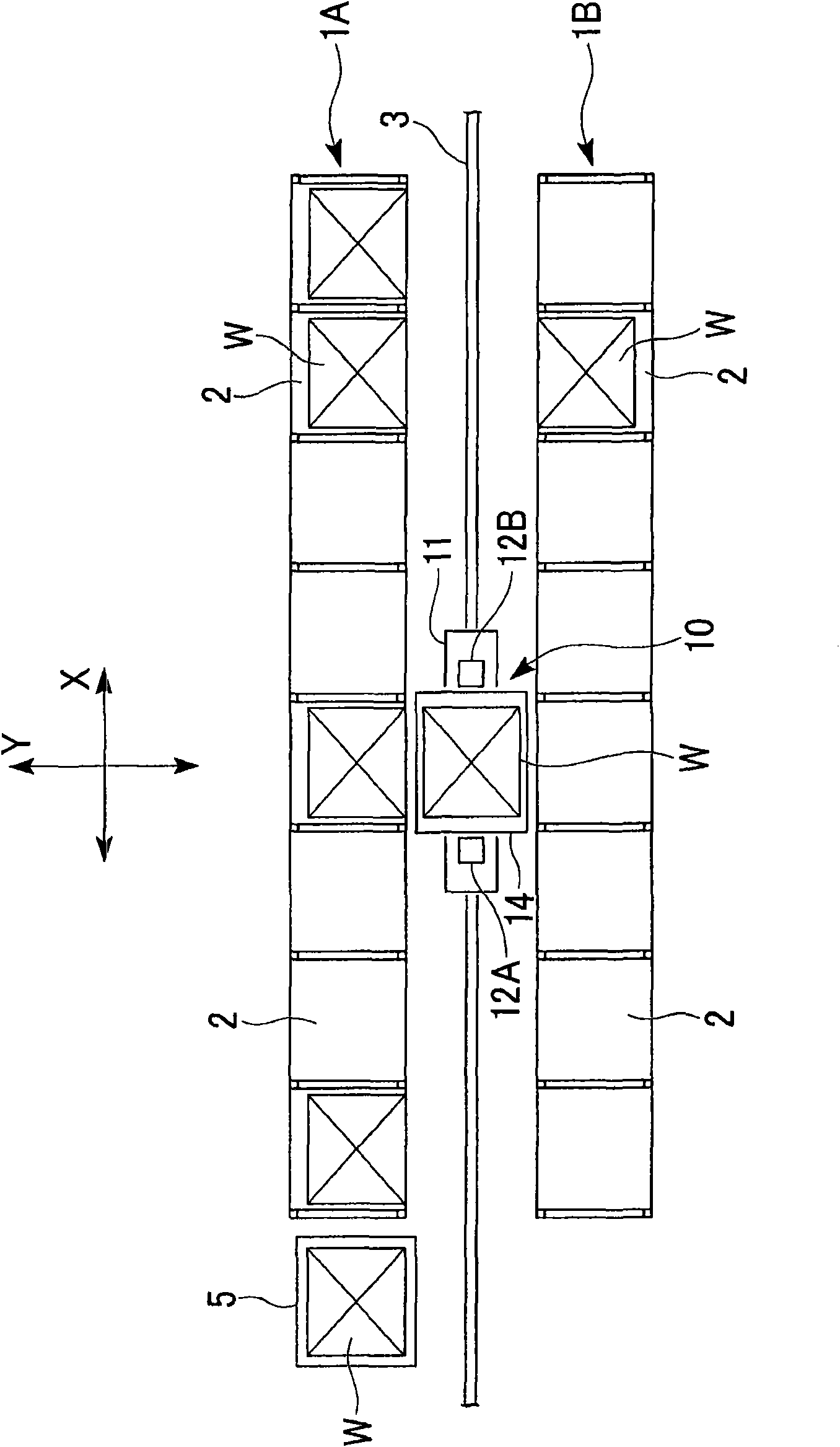

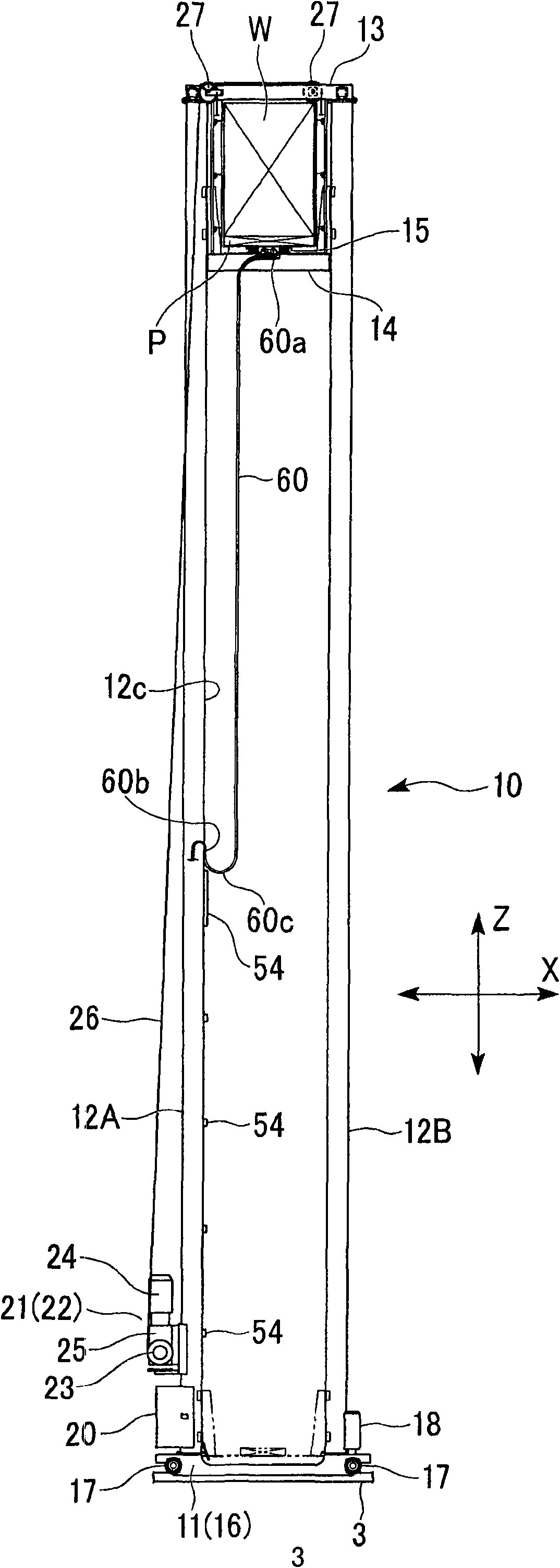

Rail walking trolley with lifting mechanism

A tower crane is provided with a trolley which walks on a rail; an upright post which is uprightly arranged on the front part and the rear part of a walking direction of the trolley in approximately center of the direction which is orthognal to the walking direction of the trolley in a horizontal plane; a rack capable of lifting along the upright pose; a lifting mechanism for lifting the rack; and cable chains used for containing a plurality of cables connected with an electrical apparatus on the rack and assembled between the rack and an approximately center part at the height direction for concavely and deviously hanging downwards for changing the bending position of the rack. The cable chains are arranged at bottom of the rack relative to a fixing part at side of the rack; the cable chains are hung along the side opposite to the rack in the side of the upright post. And a specific length from the fixing part of the rack side to a linking part is formed by a first cable which has the characteristic of concavely bending upwards, and compared with the linking part, one side of the upright post is formed by a second cable which has the characteristic of concavely bending downwards.

Owner:IHI CORP

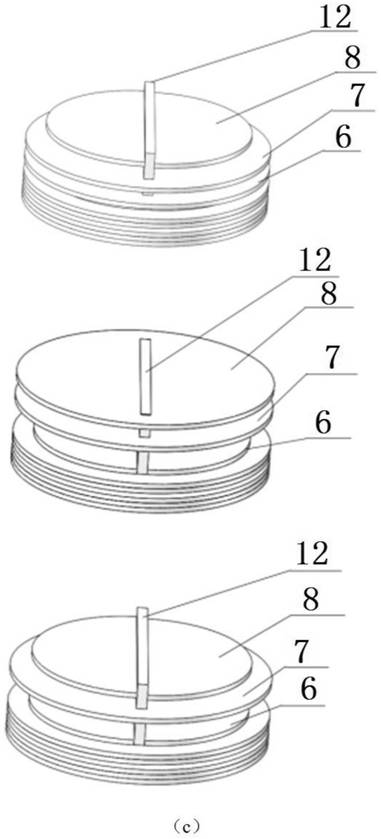

Bionic fishtail structure based on PVC gel artificial muscle driving

ActiveCN111874196AMeet performance requirementsEasy to drivePropulsive elements of non-rotary typeUnderwater equipmentStructural engineeringMechanical engineering

The invention discloses a bionic fishtail structure based on PVC gel artificial muscle driving. The bionic fishtail structure comprises a multi-joint bionic fishtail framework, a plurality of PVC gelartificial muscle driving modules, a tail fin, a tail end, a skin and other accessories. The bionic fishtail framework is composed of a pre-pressing block, a joint shaft and an installation groove. Each PVC gel artificial muscle driving module is composed of a plurality of PVC gel driving units, wherein an anode, a PVC gel film and a cathode form one PVC gel driving unit; the two PVC gel driving modules and the bionic fishtail skeleton form a driving joint. Based on the structure, bending deformation is driven in a left-right alternating mode, and therefore swing is generated.

Owner:XI AN JIAOTONG UNIV

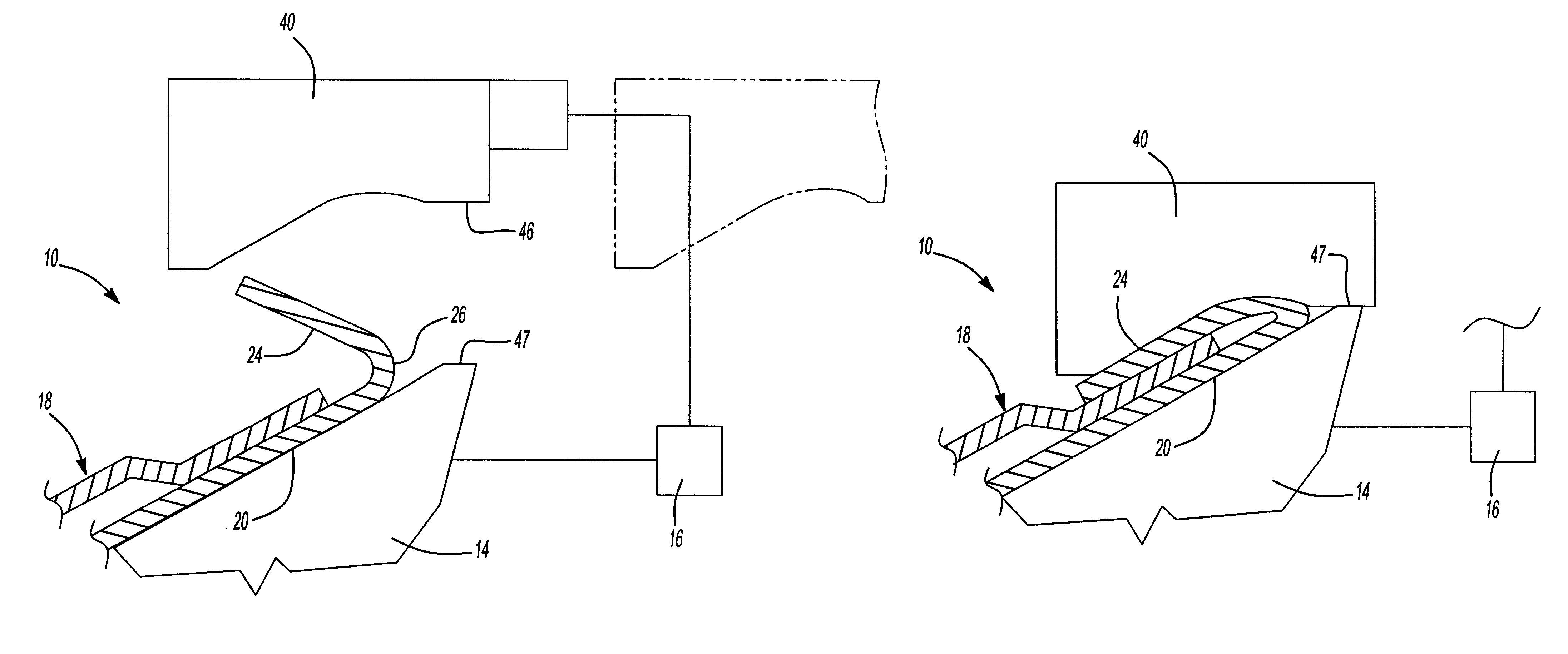

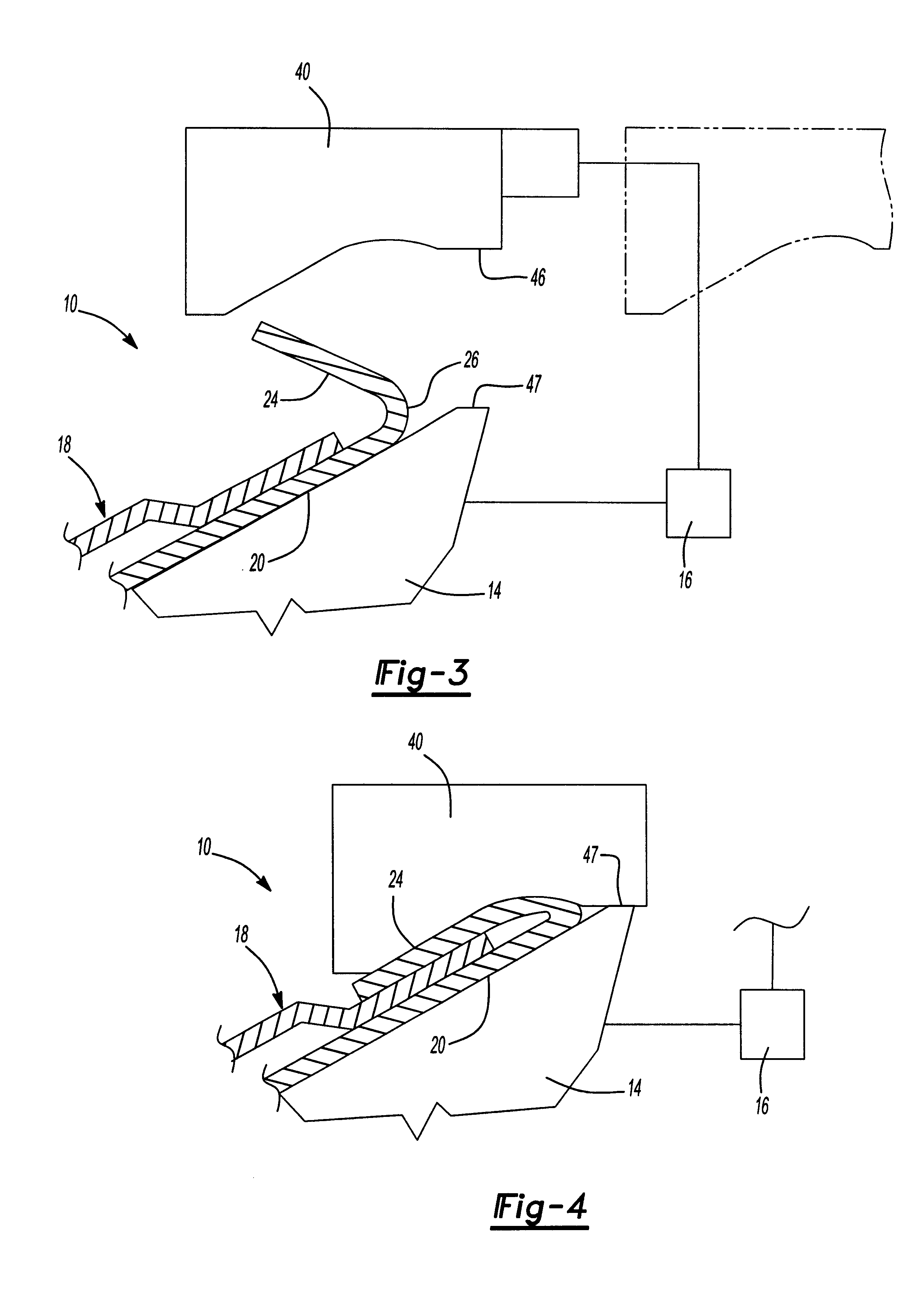

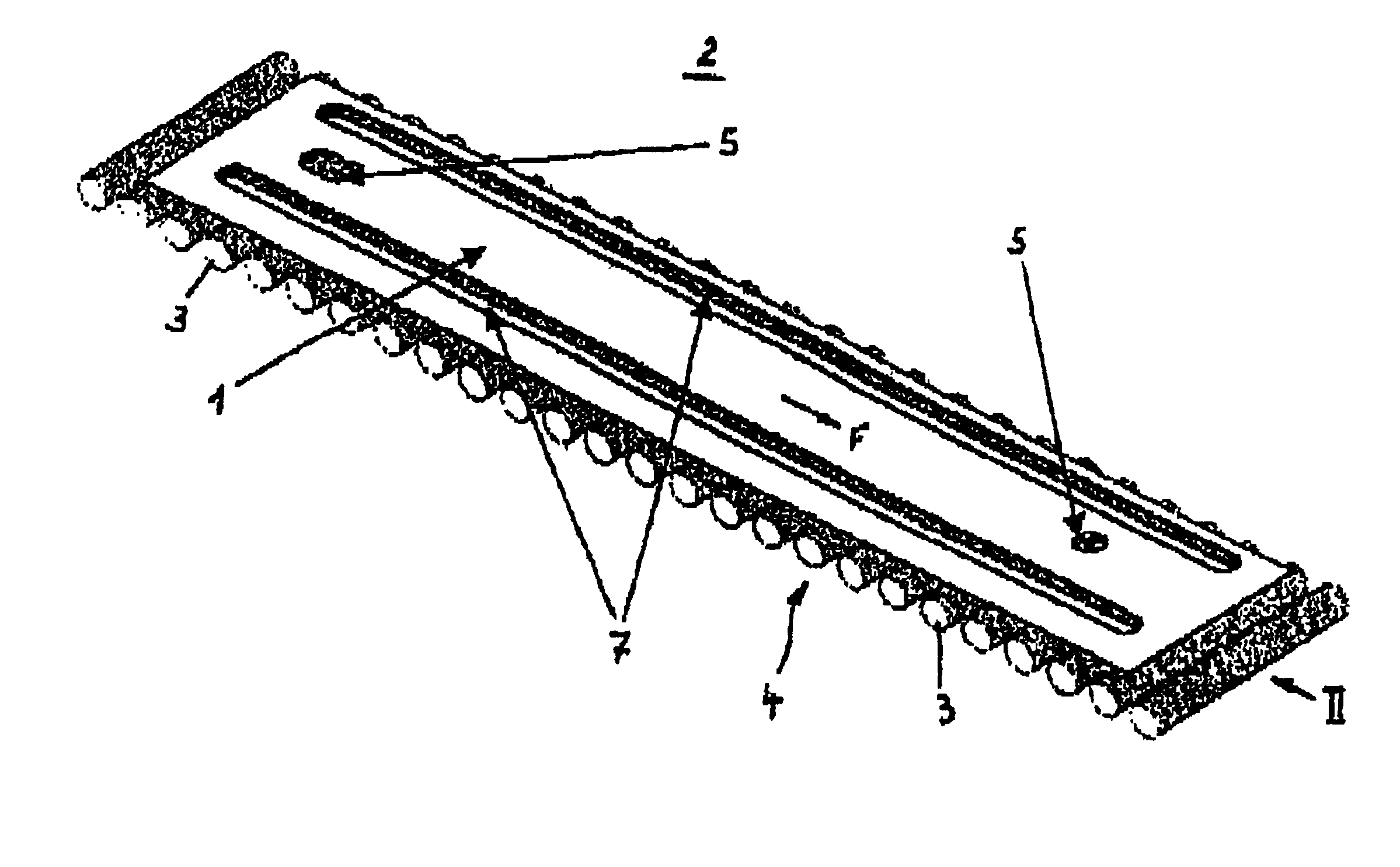

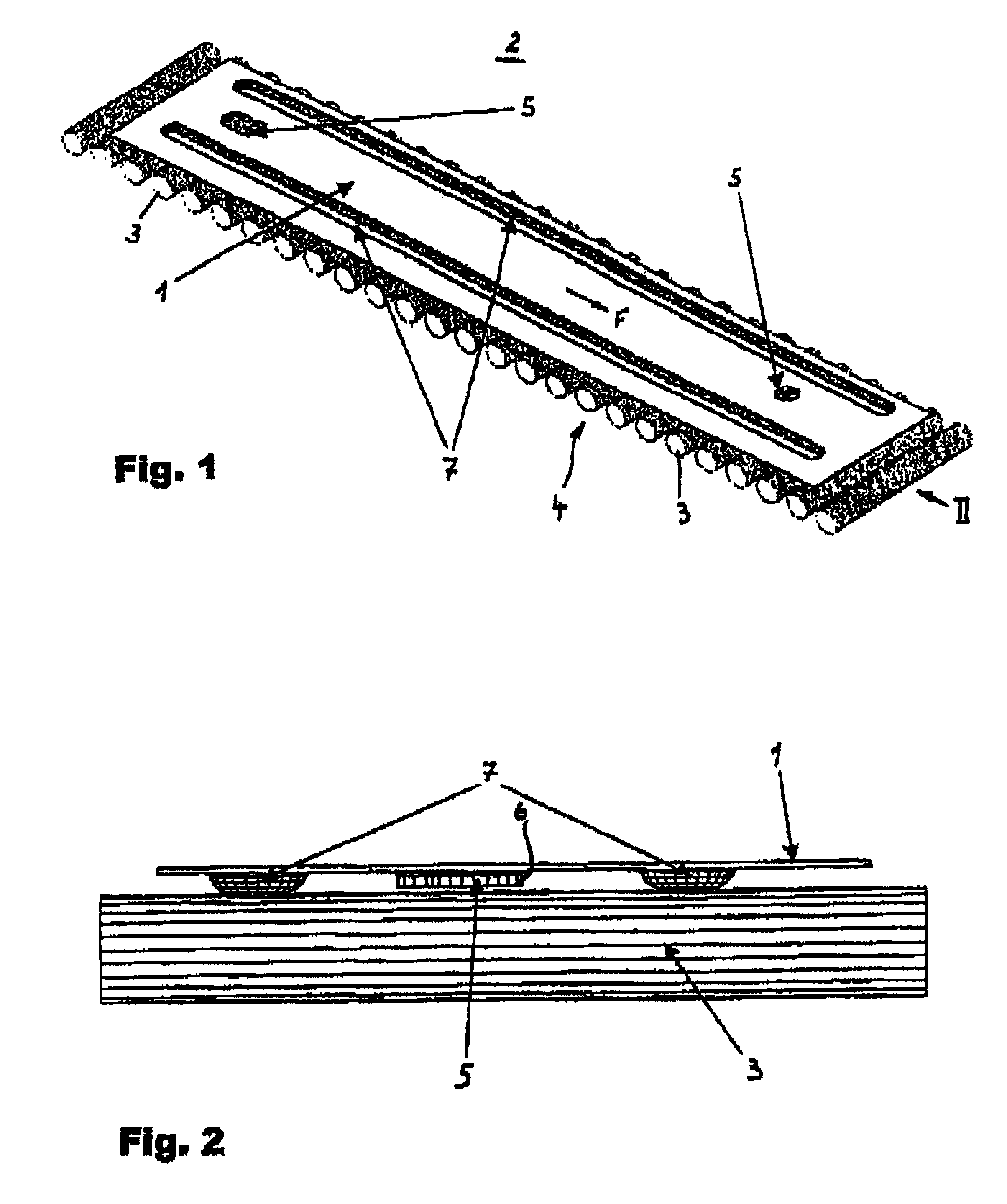

Hemming machine

InactiveUS6742372B2Small bendMinimizes hemming defectsShaping toolsMetal working apparatusEngineeringActuator

A machine for hemming a sheet metal assembly is disclosed in which the sheet metal assembly includes an inner sheet metal panel and an outer sheet metal panel. The outer panel also has an outer lip which lies in a plane transverse with respect to the plane of the inner panel from a bend line in the outer panel. The inner panel also has an outer edge spaced inwardly a few millimeters from the bend line of the outer panel. The apparatus includes a base and a nest adapted to receive and support the sheet metal assembly, and this nest is movably mounted relative to the base. A final hem tool mounted to the base performs a final hem operation. This final hem tool has a generally planar section overlying the outer edge of the inner panel and a portion of the lip following a prehem operation. The final hemming tool also includes a second curvilinear section adjacent the first planar section and this second curvilinear section overlies the remainder of the lip and extends to the bend line. A tangent of the curvilinear section intersects the plane of the first planar section at an angle of less than 20°. A conventional actuator is utilized to move the nest relative to the sheet metal assembly to compress the sheet metal assembly against the final hemming tool to complete the hem.

Owner:VALIANT CO LTD

Lens barrel and image pickup apparatus

An image pickup apparatus enabling construction of a small bending optical system with high magnification. A first lens group is movably disposed toward an object on a first optical axis. A second lens group is movably disposed radially inward of the first lens group. The second lens group comprises a drive frame drivingly controlled along the first optical axis and a lens holding frame for holding the second lens group. A prism is disposed on the first optical axis, for bending light incident on the prism to thereby guide the light along a second optical axis. The prism is retracted along the second optical axis in a non-shooting state. In the non-shooting state, the second lens group is retracted and accommodated in a space defined by the drive frame and the lens holding frame and a space occupied by the prism in a shooting state.

Owner:CANON KK

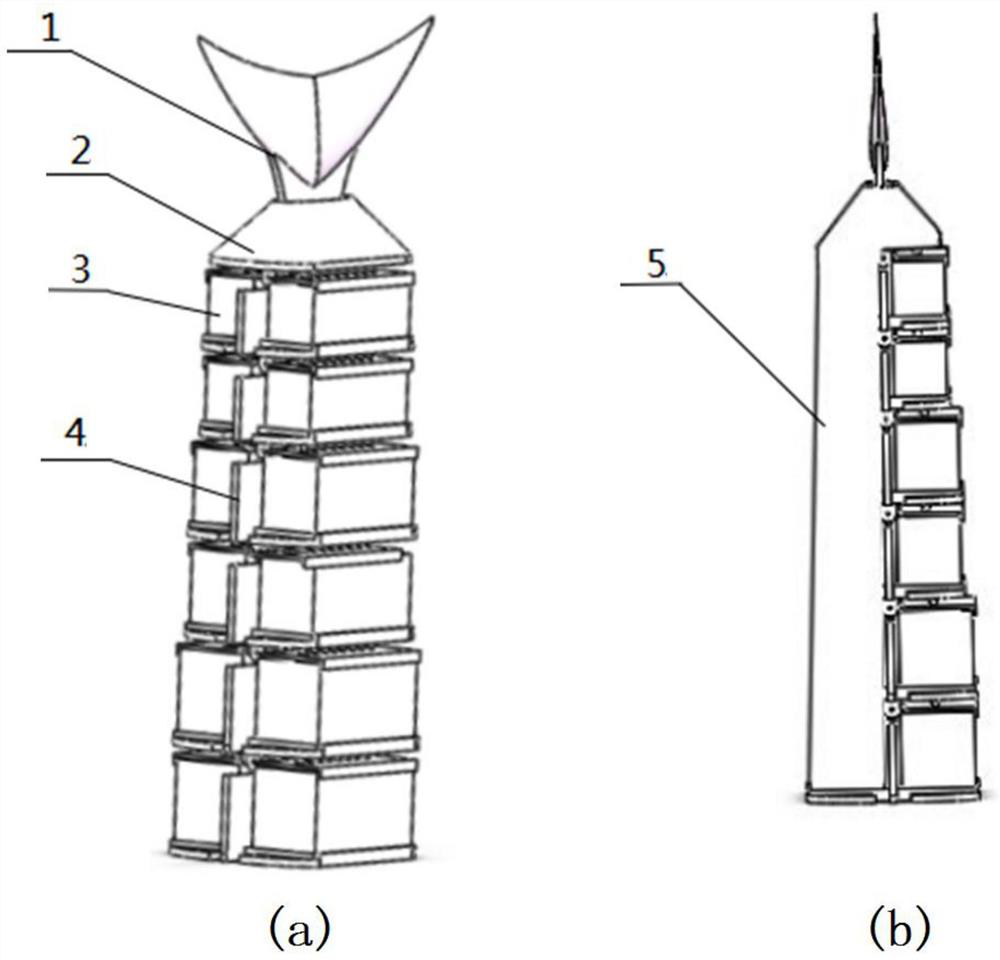

Flexible spine mechanism and kangaroo-like hopping robot

InactiveCN112171646AHighly adjustableSimple structureProgramme-controlled manipulatorSelf-moving toy figuresStructural engineeringSpinal rigidity

The invention discloses a flexible spine mechanism. The flexible spine mechanism comprises a bionic spine, pneumatic bionic muscles and supporting baffles; the bionic spine comprises an elastic plateand a plurality of bionic vertebrae different in size, the bionic vertebrae are sequentially and fixedly arranged on the elastic plate from large to small in the length direction of the elastic plate,the end, with the large size, of each bionic vertebra is the waist of the bionic spine, and the end, with the small size, of each bionic vertebra is the chest of the bionic spine; the supporting baffle plates are divided into a front support baffle plate and a rear support baffle plate; the front supporting baffle is fixedly connected with the chest of the bionic spine, and the rear supporting baffle is fixedly connected with the waist of the bionic spine; and the pneumatic bionic muscles are arranged on the two sides of the bionic spine, and the two ends of the pneumatic bionic muscles are fixedly arranged on the front supporting baffle and the rear supporting baffle correspondingly. The rigidity-variable kangaroo-like hopping robot flexible spine mechanism is simple in structure and used for solving the technical problems that at present, a hopping robot is insufficient in trunk flexibility, invariable in spine rigidity and complex in structure.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

Method for producing a hardened sheet metal section

InactiveUS6949151B2Reliable supporting surfaceTransportation safetyShaping toolsFurnace typesMaterials scienceMetal

The invention relates to a method for producing a hardened sheet metal section from a flat blank, wherein the flat blank is provided with collared holes that are collared and with two groove-like indentations which serve to support the sheet metal blank on a conveyor during heating treatment in an oven; subsequently, the blank is formed in a press tool into a sheet metal section by warm forming and where, if required, the formed indentations can be flattened; and thereafter the section is hardened while remaining clamped within the tool.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com