Rail walking trolley with lifting mechanism

A lifting mechanism and a traveling trolley technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problem of not being able to completely prevent rocking, and achieve the effect of preventing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

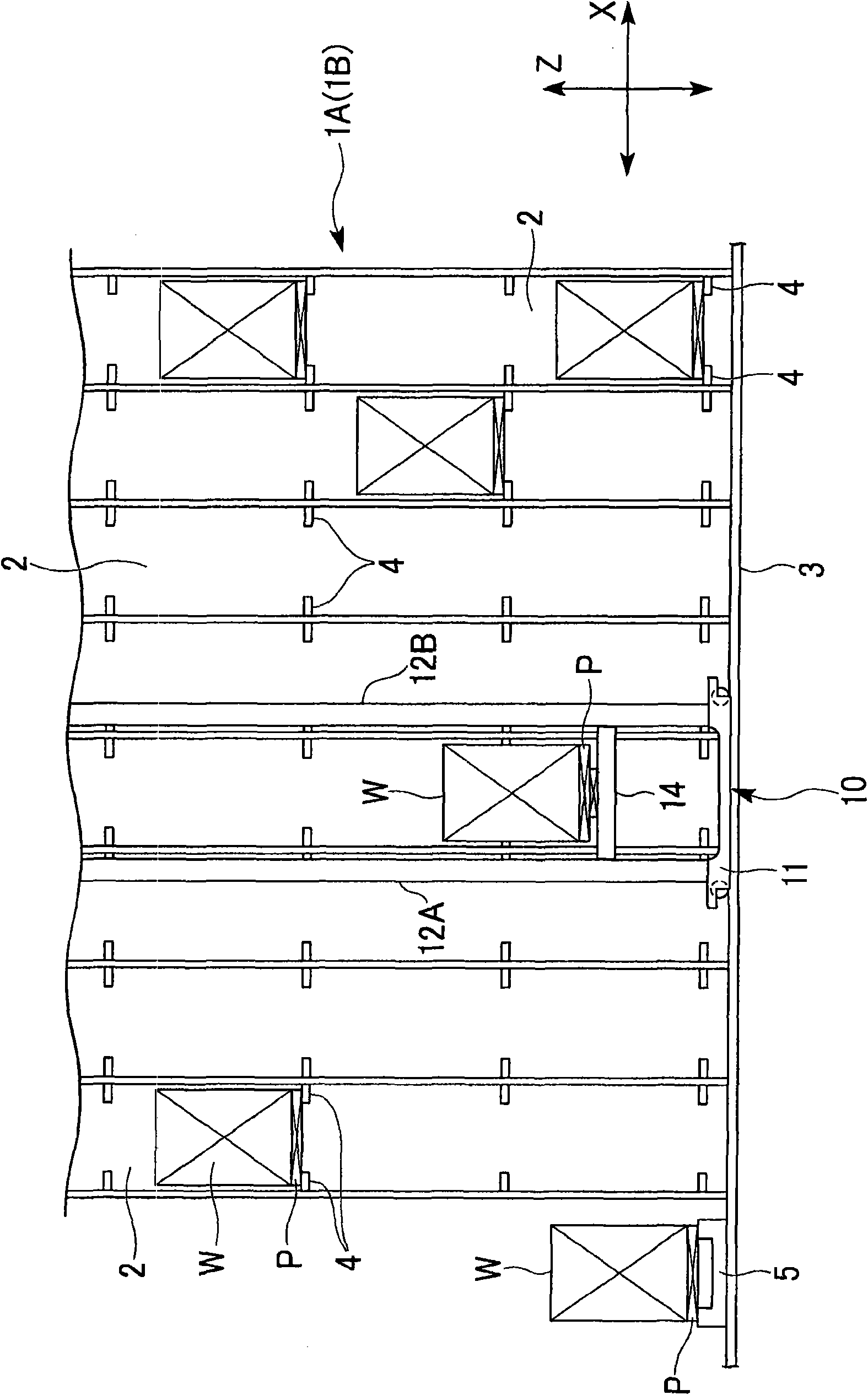

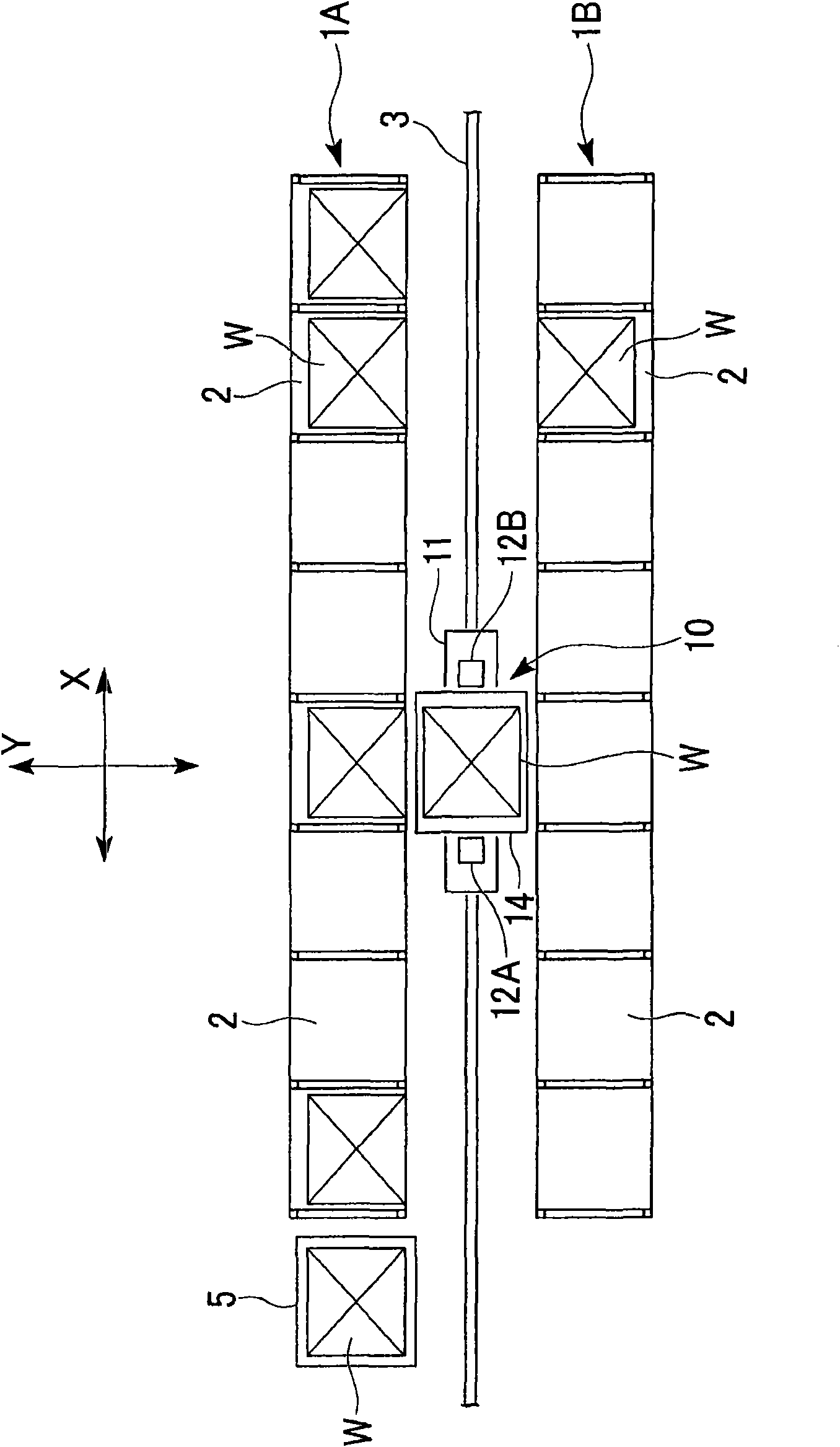

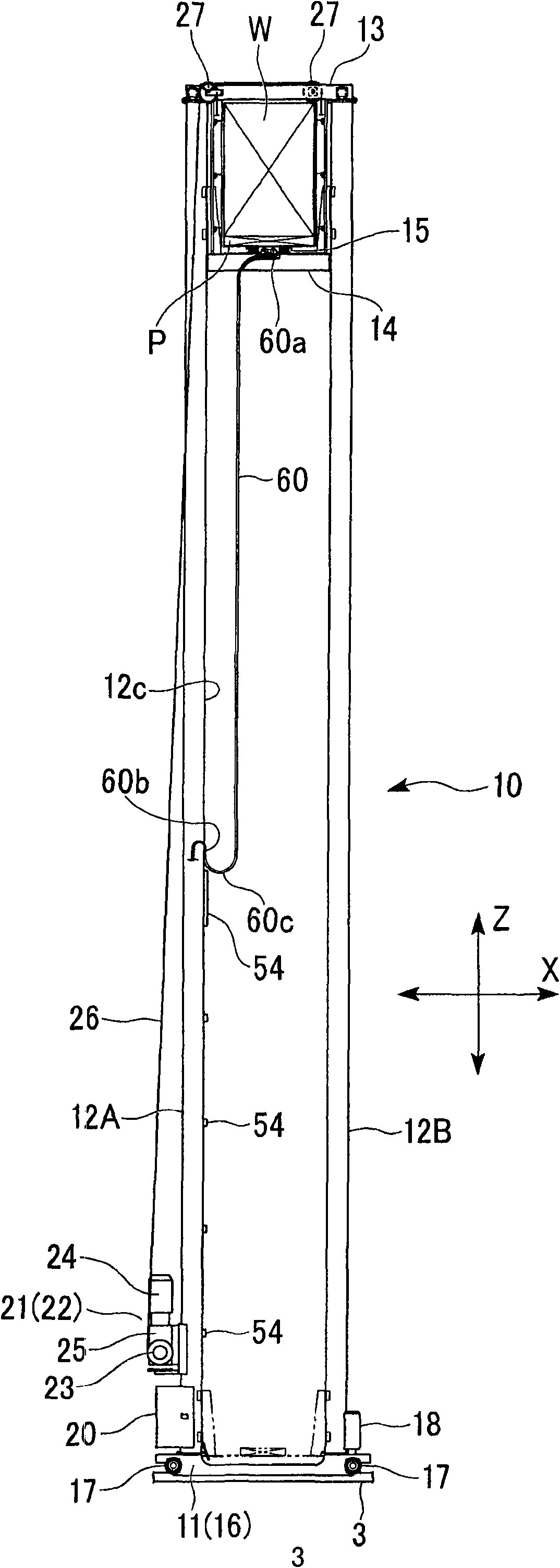

[0053] figure 1 as well as figure 2 It is a front view and a top view of the automatic warehouse equipment. The automatic warehouse equipment has two cargo storage racks 1A and 1B having a plurality of storage parts 2 in the horizontal direction and the up and down direction, and is arranged opposite to each other at a predetermined interval. Lay a guide rail (track) 3 in a straight line on the ground between the cargo storage racks 1A and 1B at positions equidistant from the two cargo storage racks 1A and 1B, and a tower crane (rail trolley with a lifting mechanism) 10 is set Be able to walk on this guide rail 3. The guide rail 3 is extended and laid to the loading and unloading platform 5 provided adjacent to the cargo storage racks 1A and 1B. In addition, the cargo storage racks 1A and 1B can also be called cargo storage racks having the multi-storey storage section 2 .

[0054] On both sides of the lower part of each storage part 2 of the cargo storage racks 1A, 1B, su...

Embodiment 2

[0100] Figure 12 It is a schematic plan view of the tower crane 10 of another second embodiment. The tower crane 100 is configured to run on two guide rails (rails) 3A, 3B arranged in parallel to each other.

[0101] The frame 116 of the trolley 111 has a rectangular frame shape in a plan view, and wheels 117 rolling on the guide rails 3A and 3B are provided at four corners thereof. On the Y-direction frame 116y of the frame 116, columns 112A, 112B are vertically fixed at positions equidistant from the guide rails 3A, 3B inside the frame 116 . The rack 114 is disposed inside the frame 116 of the trolley 111 and the columns 112A, 112B. That is, the rack 114 is arranged so as not to overlap with the trolley 111 in plan view.

[0102] In the tower crane 100 of this embodiment, although the rack 114 is raised and lowered along the columns 112A, 112B, it is the same as the previous embodiment, but since the rack 114 is arranged so that it does not overlap with the trolley 111 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com