Quantum well epitaxy structure of semiconductor laser in 940 nm-1000 nm wave band

An epitaxial structure and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of low photoelectric conversion efficiency and high operating voltage of semiconductor lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

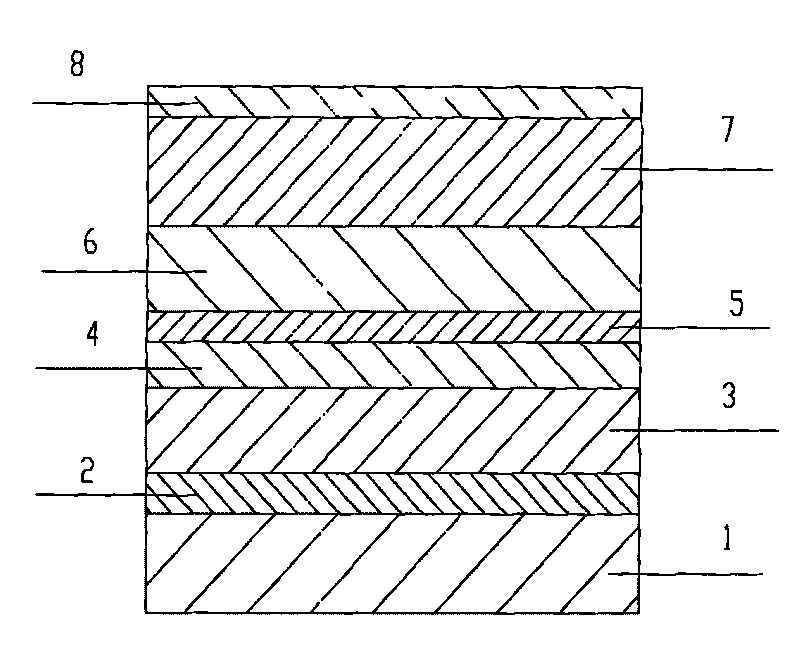

[0013] refer to figure 1 The semiconductor laser quantum well epitaxy structure in the 940nm~1000nm band provided by the present invention comprises: a substrate 1, a buffer layer 2 deposited on the substrate 1 in sequence, a lower confinement layer 3, a lower waveguide layer 4, a quantum well layer 5, an upper waveguide Layer 6, upper confinement layer 7, electrode contact layer 8, wherein: the upper waveguide layer 6 and the lower waveguide layer 4 are Al x GaAs, x=0.13~0.2; upper confinement layer 7 and lower confinement layer 3 are Al y GaAs, y=0.3-0.39.

[0014] Substrate 1: Substrate 1 is used to carry out the epitaxial growth of each layer of semiconductor laser material thereon. In the present invention, substrate 1 is N-type gallium arsenide of (100) plane, which can facilitate the injection of electrons and reduce the thickness of the substrate. Series resistance of bottom 1 material.

[0015] Buffer layer 2: The buffer layer 2 is made on the substrate 1 and is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com