Accurate forming tool of aluminum silicon carbide composite IGBT (insulated gate bipolar translator) baseplate

A composite material, aluminum silicon carbide technology, applied in the direction of transmission, rotor, cylinder, etc., can solve the problems of non-dense aluminum alloy layer, large amount of mechanical processing, high processing cost, etc., achieve small expansion and bending, eliminate cracks and aluminum strips , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

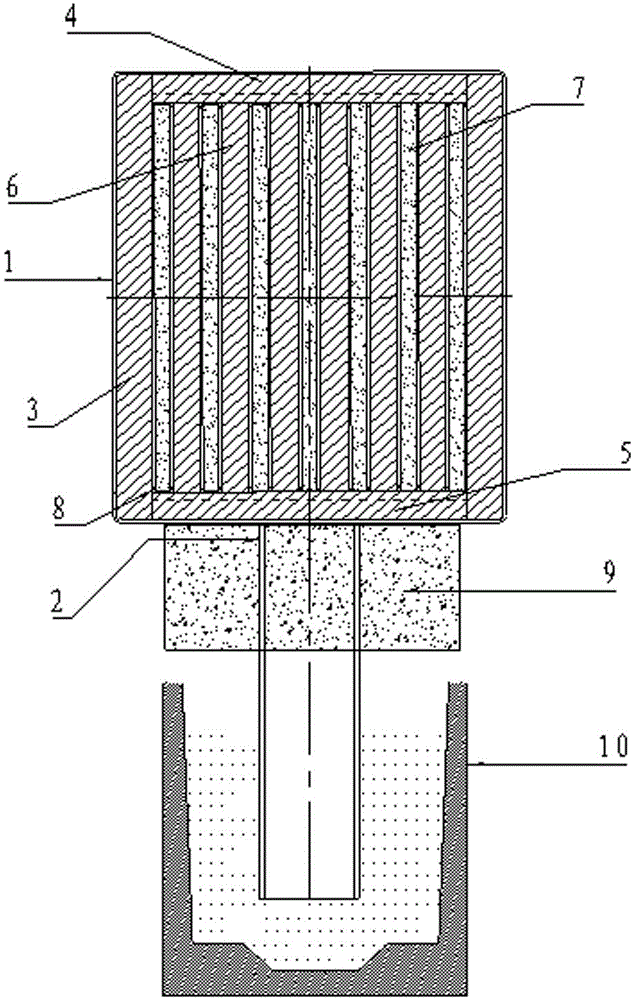

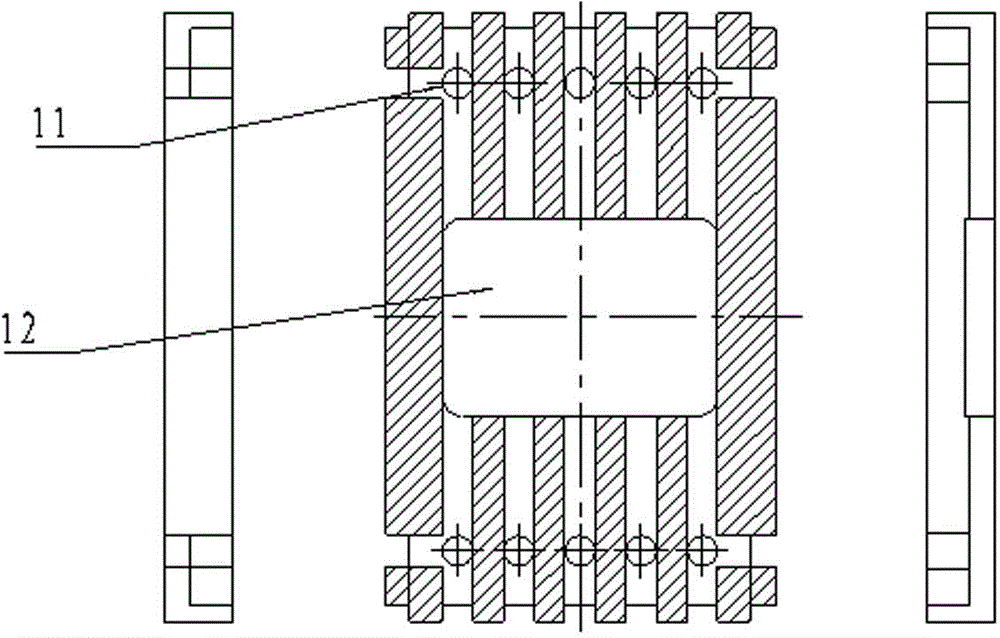

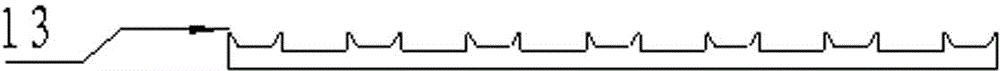

[0032] refer to figure 1 , an aluminum silicon carbide composite material IGBT substrate precision molding tooling, including an aluminized box 1, a guide tube 2 and a positioning device 8 capable of positioning SiC prefabricated parts, the upper part of the guide tube 2 is welded to the bottom surface of the aluminized box 1, The lower part of the draft tube 2 is inserted into a container containing molten aluminum alloy; the upper part of the aluminized box 1 is provided with a cover plate 4 placed in the aluminized box 1, and the lower part of the aluminized box 1 is provided with a cover plate placed in the aluminized box The bottom plate 5 in 1, the four sides of the aluminized box 1 are provided with side plates 3 placed in the aluminized box 1, and the bottom plate 5 is provided with an infiltration flow channel for molten aluminum alloy liquid. By designing the size of the infiltration flow channel , layout, to achieve the elimination of shrinkage cavity, cracks, etc. ...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is:

[0053] This example is to manufacture IGBT substrates with a size of 140mm×190mm×5mm. Each box is impregnated with 7 pieces of tooling. The overall size of the aluminized box is: 160mm×210mm×125mm. The size of the side plate is: 104mm×209mm×10mm, the size of the cover plate and the bottom plate is: 104mm×189mm×10mm, the size of the partition is 140mm×190mm×8.7mm, and the size of the SiC prefabricated part is 140mm×190mm×4.8mm , The size of the guide tube is: Φ50mm×360mm.

[0054] The assembly steps and aluminizing process are the same as those in Example 1, and a precision-formed IGBT substrate with less machining allowance can also be obtained.

[0055] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com