Laser cladding repairing method and repairing system for high-temperature alloy single crystal defects

A technology of laser cladding and superalloy, which is applied in the directions of single crystal growth, single crystal growth, self-regional melting method, etc., can solve the problems such as miscellaneous crystals and cracks in superalloy single crystals, and achieve the elimination of miscellaneous crystals and small solidification speed , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Proposed case according to the present invention, divide the following steps to carry out.

[0055] (1) Determination of crystal orientation: Take part of the tissue of the blade to be repaired, prepare samples and determine the crystal orientation by EBSD.

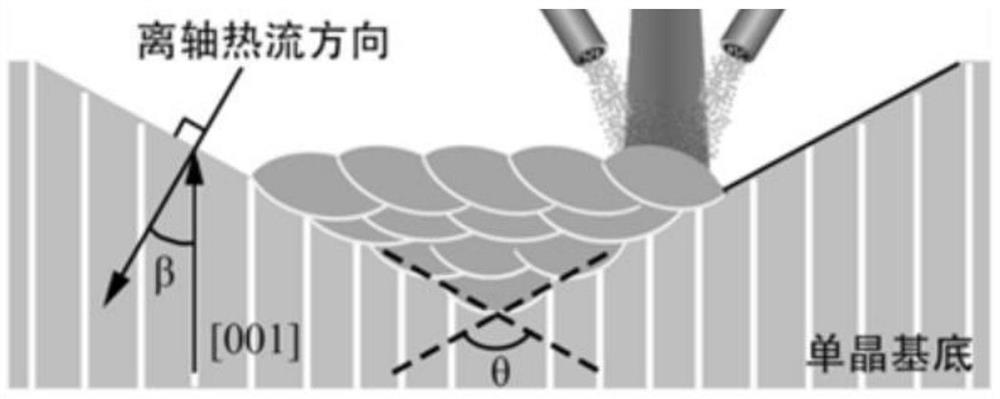

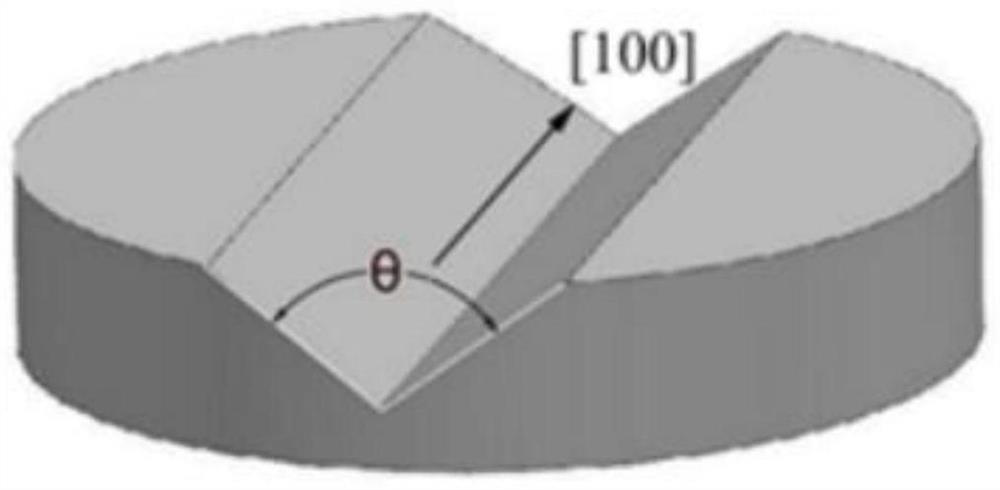

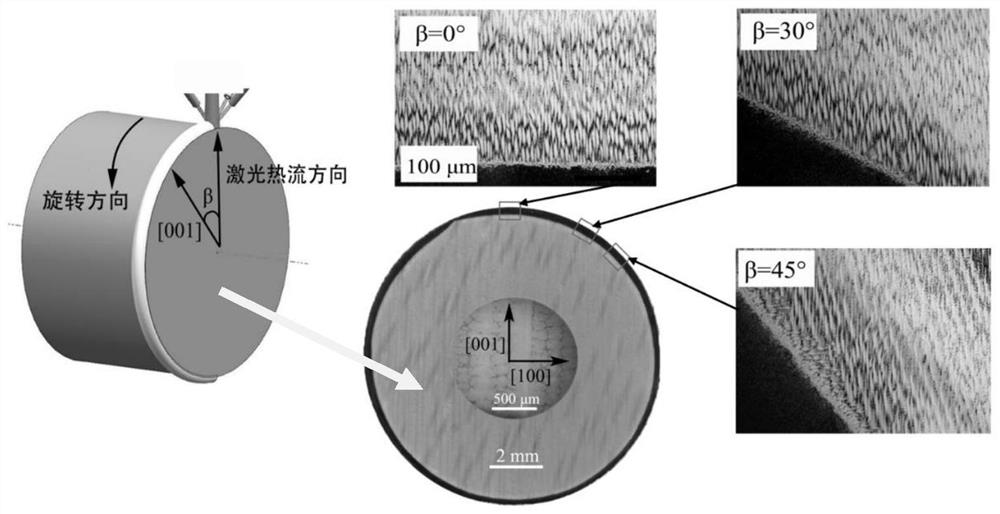

[0056] (2) Pickling: Clean the area of the turbine blade to be repaired, open a V-shaped groove, the opening angle θ is 120°, the maximum angle β between the off-axis heat flow direction and the preferred crystal direction is 30°, the laser heat flow direction is kept vertical, off-axis The direction of heat flow is perpendicular to the outline of the V-groove.

[0057] (3) Laser processing: the laser power is 1800W, the scanning speed is 30mm / s, the powder feeding amount is 12g / min, the spot diameter is 1mm, the protective gas argon gas output is 15mL / min, and the overlapping rate of multi-layer cladding layer is 50 %.

[0058] (4) Temperature adjustment: By adjusting the power of the induction heating coil, t...

Embodiment 2

[0062] The steps are the same as in Example 1, except that the maximum angle β between the off-axis heat flow direction and the preferred crystal orientation is 15°, the molten pool temperature is 700°C, the substrate temperature is -50°C, the laser power is 1200W, and the scanning speed is It is 40mm / s, the powder feeding rate is 20g / min, the spot diameter is 2mm, the output of protective gas argon is 15mL / min, and the overlapping rate of multiple cladding layers is 20%. The V-groove opening angle θ is 125° for the microstructure after laser cladding repair, the single crystal epitaxial growth is relatively complete, and the repair effect is better.

Embodiment 3

[0064] The steps are the same as in Example 1, except that the maximum angle β between the off-axis heat flow direction and the preferred crystal orientation is 10°, the molten pool temperature is 800°C, the substrate temperature is -40°C, the laser power is 600W, and the scanning speed is It is 20mm / s, the powder feeding rate is 6g / min, the spot diameter is 1mm, the output of protective gas argon is 15mL / min, and the overlapping rate of multiple cladding layers is 10%. The V-groove opening angle θ is 130° for the microstructure after laser cladding repair, the single crystal epitaxial growth is relatively complete, and the repair effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com