Centrifugal casting method of main pipeline of million-kilowatt nuclear plant

A centrifugal casting, nuclear power plant technology, applied in coating, casting molding equipment, casting molds, etc., can solve the problems of inability to meet the technical requirements of the centrifugal casting of the primary circuit main pipeline, and the inability to meet the centrifugal casting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

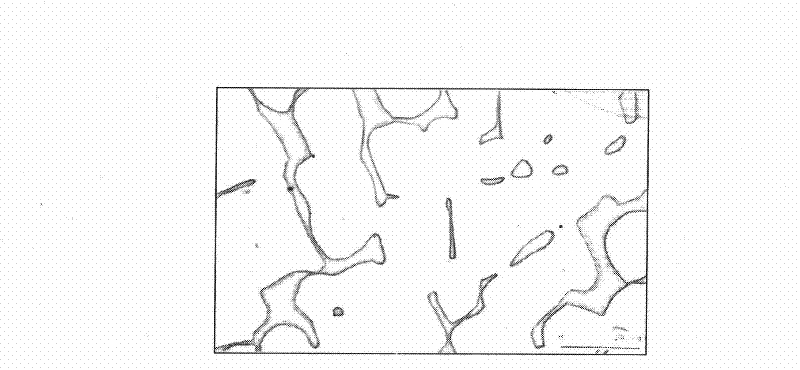

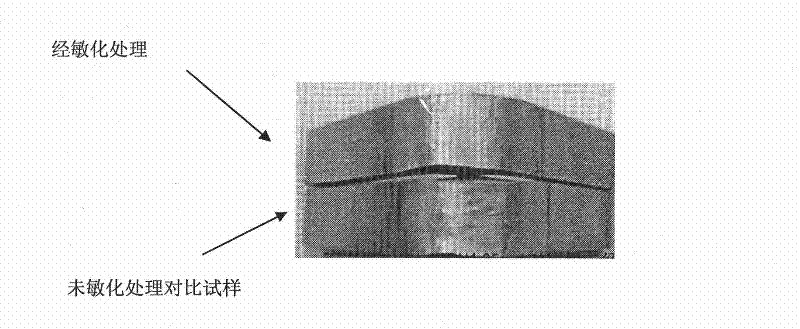

Image

Examples

Embodiment Construction

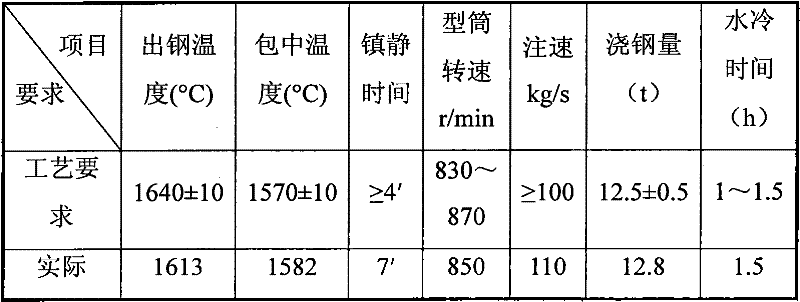

[0019] The following are specific examples of the centrifugal casting method of the present invention.

[0020] 1. Smelting

[0021] It is required that the temperature of the molten steel be controlled at 1640±10°C.

[0022] 2. Cylinder coating and centrifugal pouring:

[0023] (1), type cylinder coating and coating process

[0024] 1. The preparation process of the tube coating:

[0025] Step 1: Prepare zircon powder coating:

[0026] First, according to the ratio of 60kg water to 7 cubic decimeters of bentonite powder, mix water and bentonite powder to make bentonite slurry for zircon powder coating, and let it stand for 24-48 hours, and then mix 1 Raising the ratio of swelling slurry for zircon powder coating and mixing the swelling slurry for zircon powder coating with zircon powder evenly to prepare zircon powder coating for use.

[0027] The second step: prepare quartz powder coating: first, mix water, bentonite powder and water glass according to the ratio of 20kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com