Round billet continuous casting method and round billet continuous casting system

A round billet continuous casting and round billet technology, applied in the field of round billet continuous casting and round billet continuous casting systems, can solve the problems of low strength, bulging, billet shell creep, etc., to reduce thermal stress, reduce center segregation, The effect of slowing down the solidification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

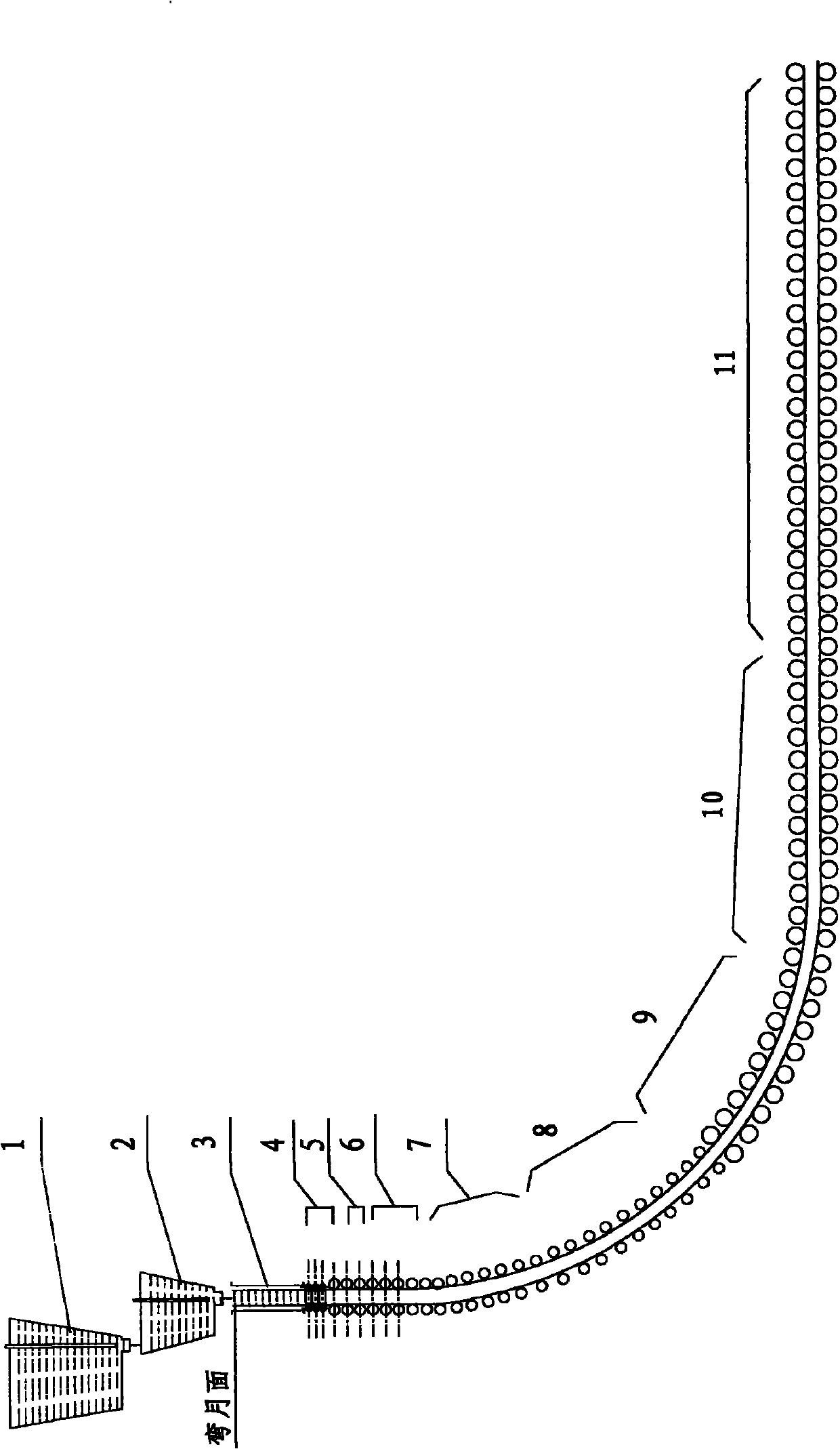

[0033] Use 34CrMo4 continuous casting round tube billet with a diameter of 430mm. Among them, the size of the upper opening of the tubular round billet crystallizer is 443mm, the lower opening is 440mm, and the length is 700mm; in the secondary cooling zone, the first spray cooling section 4, the second spray cooling section 5, the third spray cooling section 6, The lengths of the fourth spray cooling section 7 and the fifth spray cooling section 8 are 0.35m, 0.4m, 0.4m, 2.0m and 3.0m respectively; the width of each spray cooling section is the same, both are 430mm. The composition of 34CrMo4 is shown in Table 1.

[0034] Table 1

[0035]

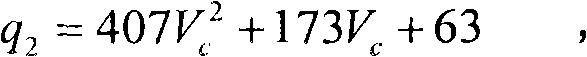

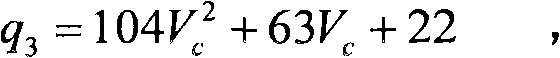

[0036] During continuous casting: the pouring temperature is 1560°C; the casting speed is V c 0.2m / min. The cooling intensity of each spray section is determined according to the round slab continuous casting method of the present invention and after error adjustment is carried out within a reasonable range, the slab cooling intensity...

Embodiment 2

[0043] Adopt the method of embodiment 1 to cast circular tube billet continuously.

[0044] During continuous casting: the pouring temperature is 1550°C; the casting speed is V c It is 0.4m / min.

[0045] The cooling intensity of each spray section is determined according to the round slab continuous casting method of the present invention and after error adjustment is carried out within a reasonable range, the slab cooling intensity on the unit area of each spray cooling section is as table 3 (in table 3 Values are shown as rounded integers).

[0046] table 3

[0047]

[0048] In addition, after the numerical values in Table 2 are calculated and obtained according to the method of the present invention, error adjustment can be performed according to the actual situation of the equipment. Specifically, the error of each spray cooling section is ±6, for example: the error of the first spray cooling section 4 is ±1, the error of the second spray cooling section 5 is ±...

Embodiment 3

[0052] Adopt the method of embodiment 1 to cast circular tube billet continuously.

[0053] During continuous casting: the pouring temperature is 1540°C; the casting speed is V c It is 0.7m / min.

[0054] The cooling intensity of each spray section is determined according to the round slab continuous casting method of the present invention and after error adjustment is carried out within a reasonable range, the slab cooling intensity per unit area of each spray cooling section is as table 4 (in table 4 Values are shown as rounded integers).

[0055] Table 4

[0056]

[0057] In addition, after the numerical values in Table 2 are calculated and obtained according to the method of the present invention, error adjustment can be performed according to the actual situation of the equipment. Specifically, the error of each spray cooling section is ±6, for example: the error of the first spray cooling section 4 is ±1, the error of the second spray cooling section 5 is ±6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com