Oil-based mud flushing liquor and preparation method thereof

An oil-based mud and flushing fluid technology, applied in drilling equipment and other directions, can solve the problems of poor cementing quality, low replacement rate and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

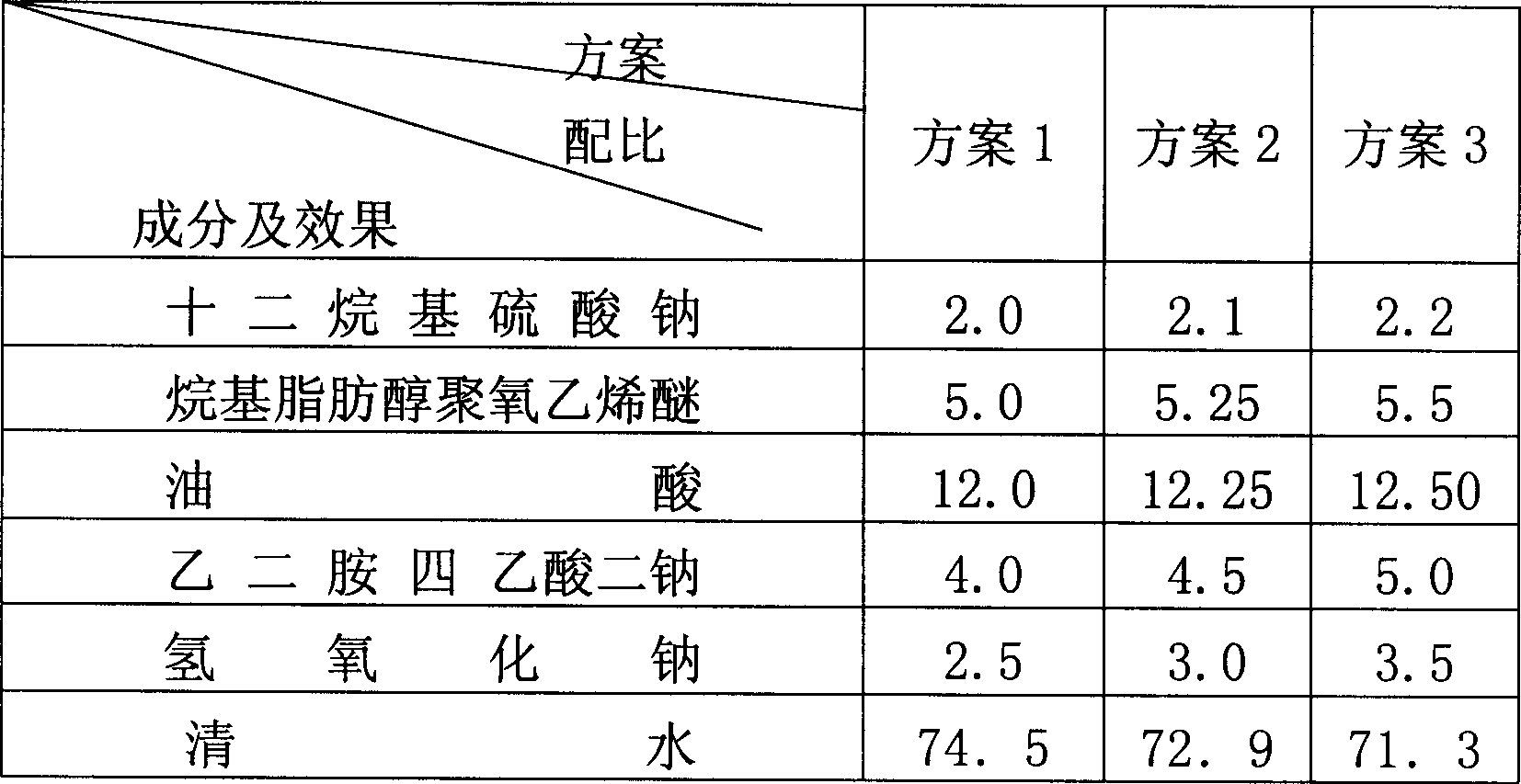

[0009] The preparation method of the flushing solution is: add 2.5-3.5 parts of sodium hydroxide and 4.0-5.0 parts of ethylenediaminetetraacetic acid into clear water by weight and stir evenly to fully dissolve them, then add 12.0-12.5 parts of oleic acid and stir for 20- 30 minutes, then add 2.0-2.2 parts of sodium lauryl sulfate and 5.0-5.5 parts of alkyl fatty alcohol polyoxyethylene ether and stir for 55-65 minutes, and finally add silicone defoamer. The molecular formula of sodium lauryl sulfate is C 12 h 25 OSO 3 Na, the molecular formula of fatty alcohol polyoxyethylene ether is RO(CH 2 CH 2 O)nH, n in the formula is 8-10, R is C 12 , where the fatty alcohol is a single fatty alcohol, and the molecular formula of oleic acid is CH 3 (CH 2 ) 7 -CH=CH-(CH 2 ) 7 COOH, the molecular formula of sodium edetate is (NaOOCH 2 c) 2 -N(CH 2 ) 2 N-(CH 2 COONa) 2 .

[0010]

[0011] In the above scheme, the ratio of each component and the effect can be seen....

Embodiment 1

[0012] Example 1. During the construction of Fangshen 10 well in Daqing, the flushing fluid prepared in the scheme 1 of the above table was applied, and the flushing rate was 100%, and it had a strong flushing ability to the two interfaces, which was beneficial to improve the displacement efficiency of the drilling fluid. Improve the bonding strength of cement sheath interface.

Embodiment 2

[0013] Example 2. During the construction of Fangshen 701 well in Daqing, the flushing fluid prepared in the above scheme 2 was applied, and the flushing rate reached 100%. Good capacity, no adverse effects such as thickening and flocculation, the bonding strength of the two interfaces is improved, and the cementing quality is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com