Method for manufacturing assembled type bridge pier by utilizing steel fiber reinforced self-compacting concrete

A self-compacting concrete and steel fiber technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problem of impact resistance, poor energy dissipation and dynamic performance of piers, unsuitable for earthquake-prone areas, and durability to be improved, etc. To solve the problem, to achieve the effect of superior dynamic performance, good durability and improved seismic performance in the seismic area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a kind of method utilizing steel fiber self-compacting concrete to prepare assembled bridge pier column, comprises the following steps:

[0028] A, configure concrete, the specific process is:

[0029] a. Prepare concrete raw materials according to the following proportions by weight: 300kg of cement, 205kg of Class I fly ash, 765kg of medium sand with a fineness modulus of 2.3, and 910kg of continuously graded crushed stone; the particle size of the continuously graded crushed stone The diameter is determined according to the gap between steel bars, and the value can be taken according to the specification; 9kg of water reducing agent, 39kg of water-soluble steel fiber, and 185kg of water; among them, the volume ratio of the water-soluble steel fiber is 0.3%-0.6%, the volume ratio of the steel fiber, etc. The effective diameter is 0.1-0.3mm, the aspect ratio is 40-70, and the tensile strength of the steel fiber is not less than 1000MPa.

[0030] b. Prepa...

Embodiment 2

[0037]The difference between Example 2 and Example 1 is that in step a, the concrete raw materials are prepared according to the following proportions by weight: 350kg of cement, 190kg of grade I fly ash, 775kg of medium sand with a fineness modulus of 3, and continuous gradation 900kg of gravel, 8kg of water reducer, 40kg of water-soluble steel fiber, and 180kg of water;

Embodiment 3

[0038] Example 3, as the optimal implementation, differs from Example 1 in that: in step a, concrete raw materials are prepared according to the following proportions by weight: 330 kg of cement, 200 kg of grade I fly ash, and a fineness modulus of 2.3-3 768kg of medium sand, 902kg of continuously graded gravel, 8.46kg of water reducing agent, 39.25kg of water-soluble steel fiber, and 181.5kg of water.

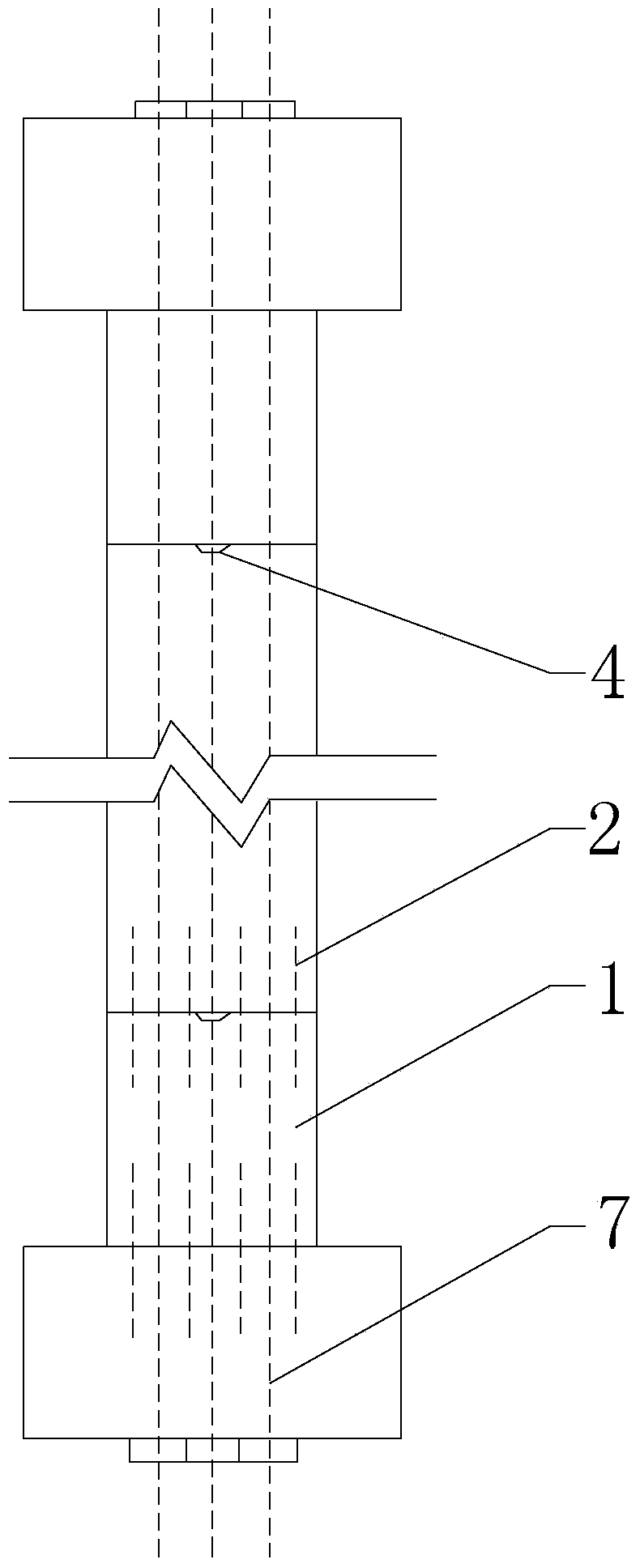

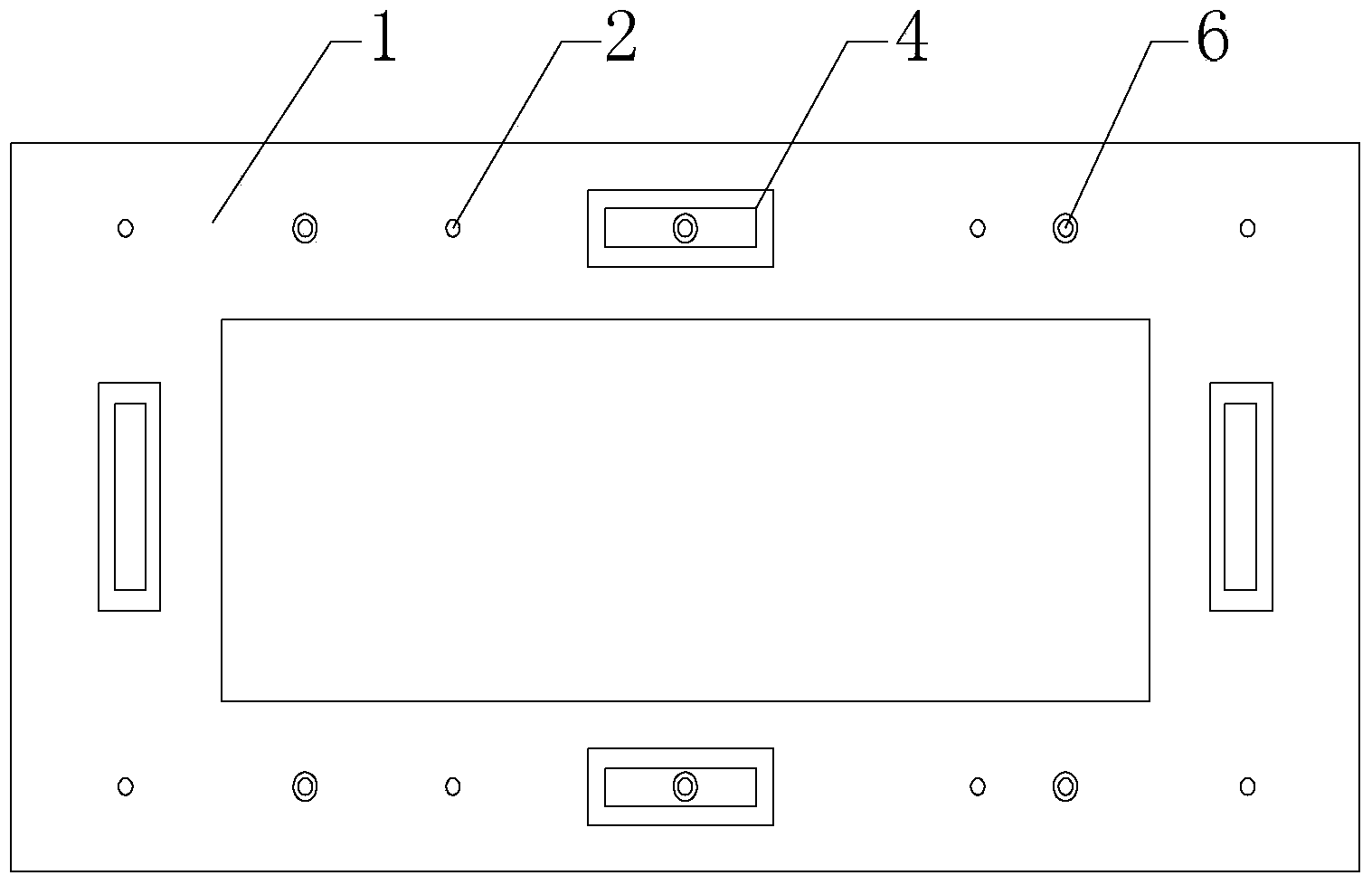

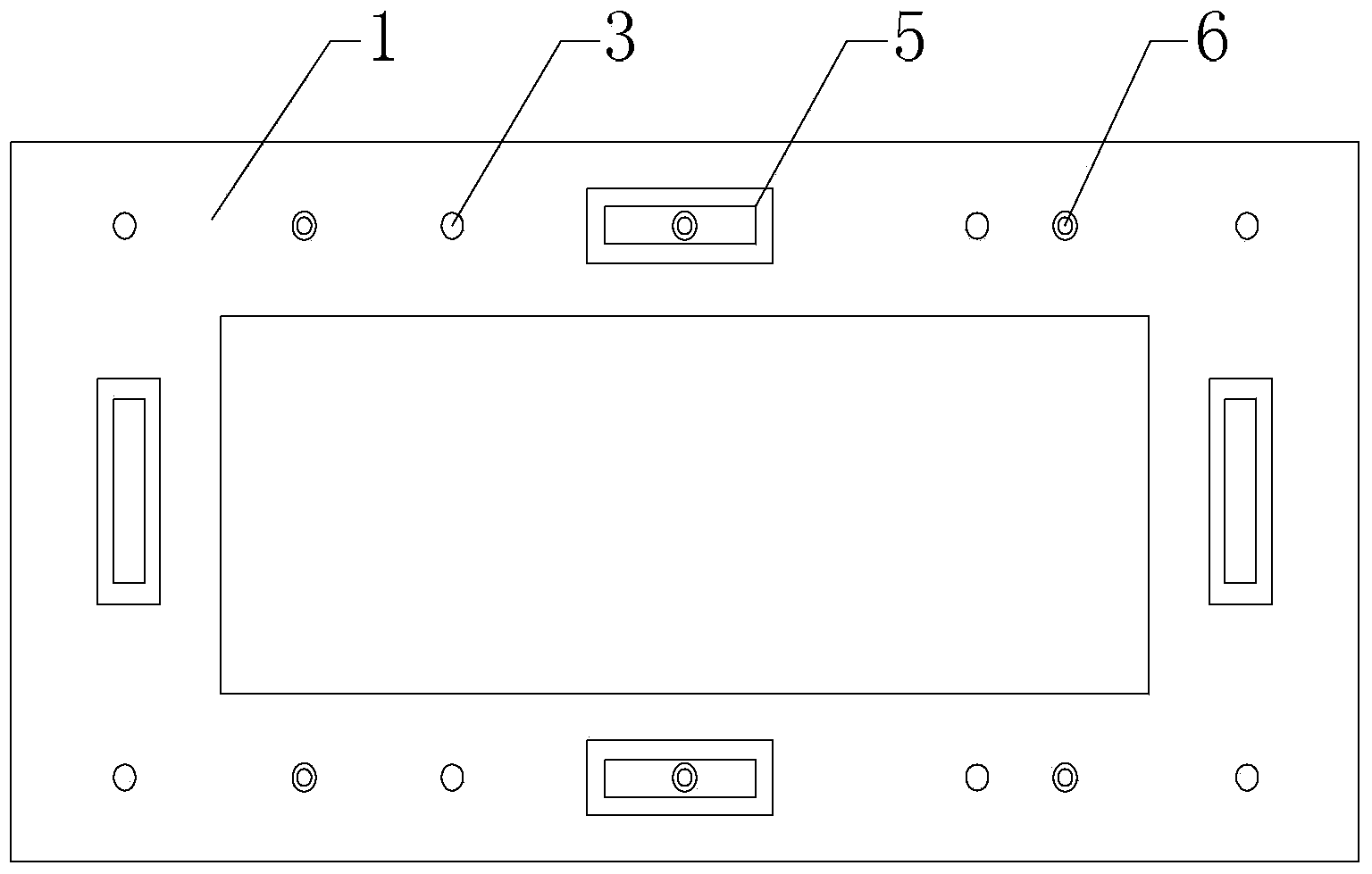

[0039] Different from the assembled pier structure mentioned in the background technology, the pier segment includes the pier segment body 1, the short steel bar and the shear key groove vertically arranged on the top of the pier segment body, and the adjacent pier segment Reserved short reinforcement holes and shear keys axially arranged at the bottom of the body; the short reinforcements and shear keys are arranged along the circumference of the cross-section of the pier segment; the hole diameter of the reserved short reinforcement holes is larger than that of the short rein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com