Prefabricated assembling type steel pipe restrained energy-dissipation connection node and construction method

A technology of joint connection and prefabrication, which is applied to building components, earthquake resistance, construction, etc., can solve problems such as poor energy dissipation capacity of plastic hinges at beam ends, difficulty in ensuring concrete compactness, and insufficient ductility in the core area of joints, etc., so as to improve shear resistance ability, delaying the rate of stiffness degradation, and ensuring the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

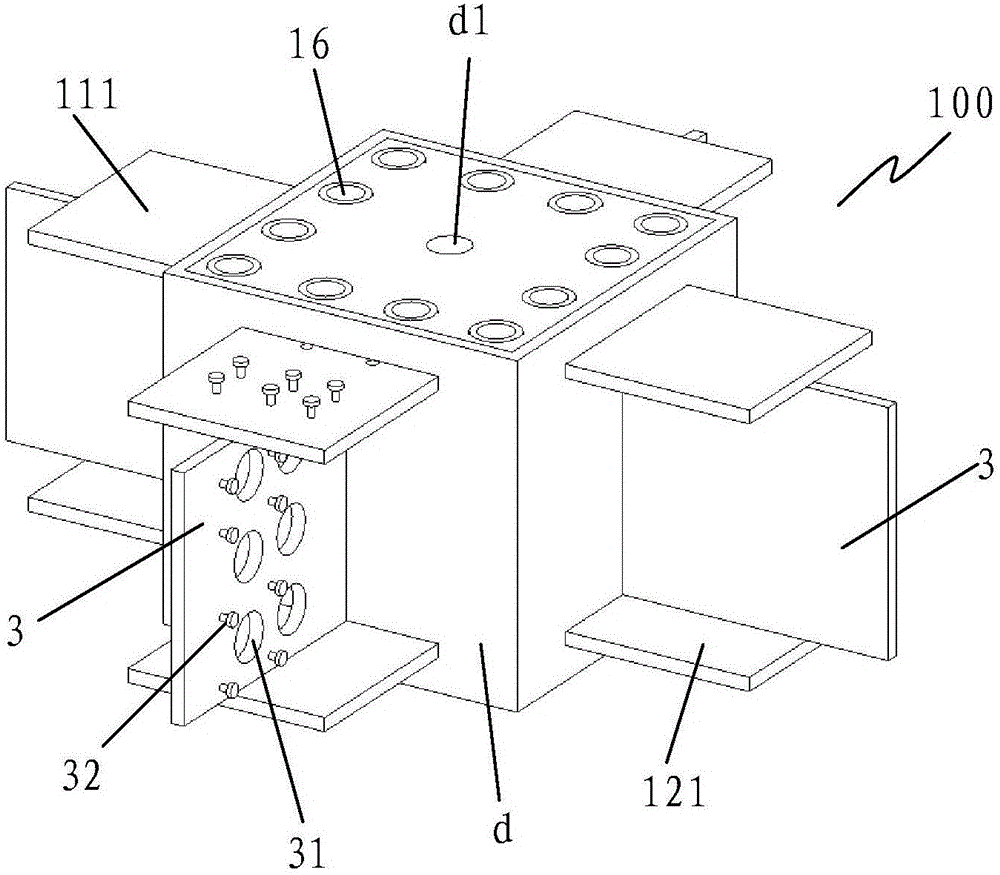

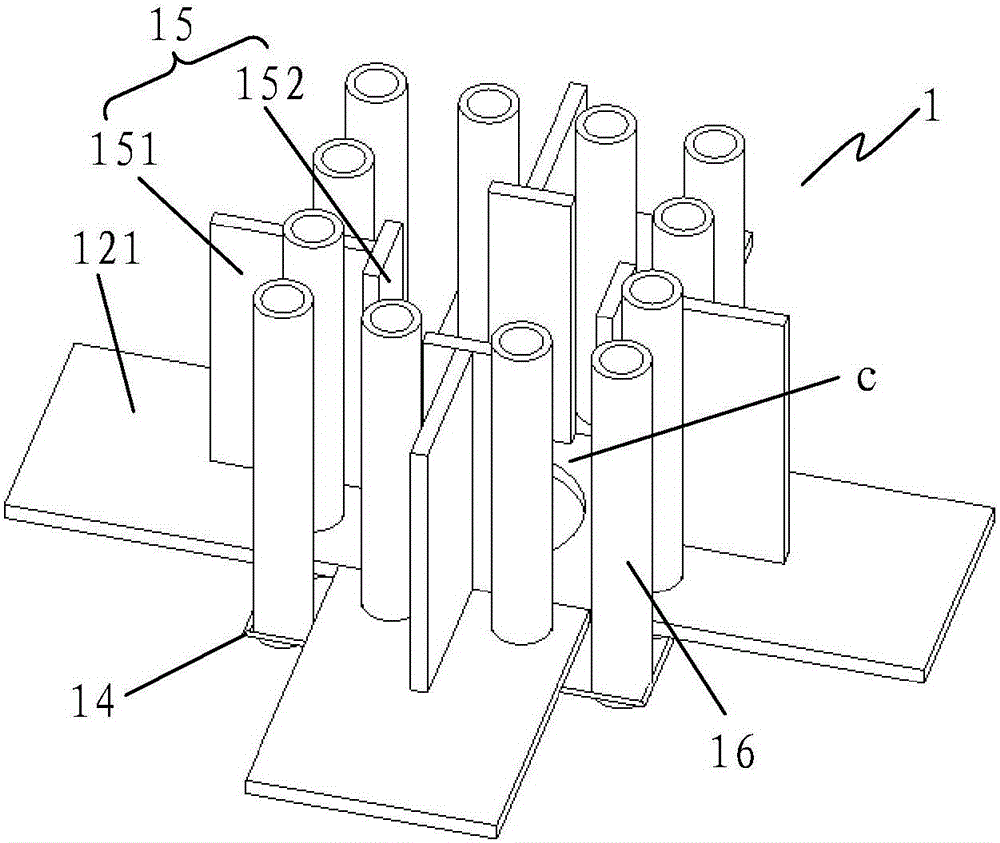

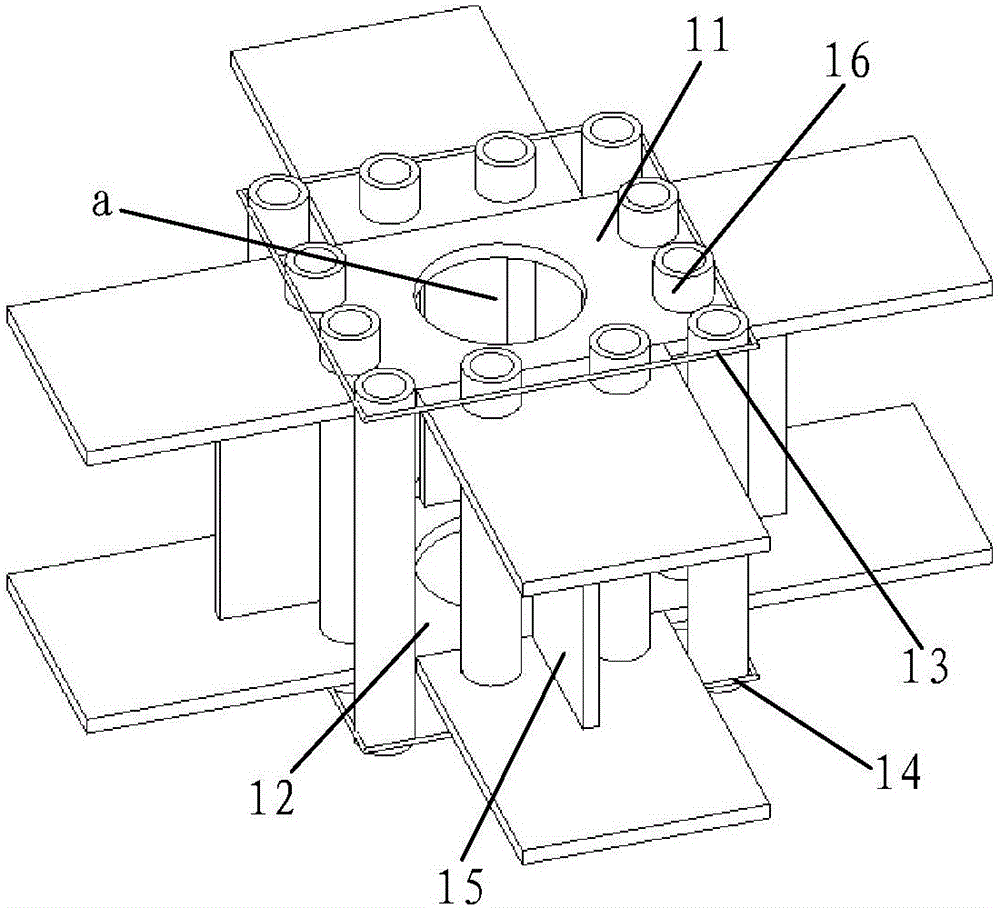

[0050] Please refer to Figure 1 to Figure 10 As shown, a preferred embodiment of the prefabricated assembled steel pipe constrained energy-dissipating connection node 100 of the present invention, the steel pipe constrained energy-dissipating connection node 100 includes a core area embedded steel component 1, four pieces and the core area embedded steel assembly The perforated outer steel plate 2 and several beam end webs 3 matched with the component 1, wherein the perforated outer steel plate 2 is perforated according to the shape of the pre-embedded steel component 1 in the core area; the pre-embedded steel plate in the core area Assembly 1 includes a pre-embedded overhanging upper flange 11, a pre-embedded overhanging lower flange 12, an upper sleeve stirrup 13, a lower sleeve stirrup 14, at least two pre-embedded overhanging webs 15 and several A pre-embedded steel sleeve 16; wherein, each pre-embedded overhanging upper flange 11 has 2-4 overhanging upper flanges 111, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com