Patents

Literature

37results about How to "Move out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

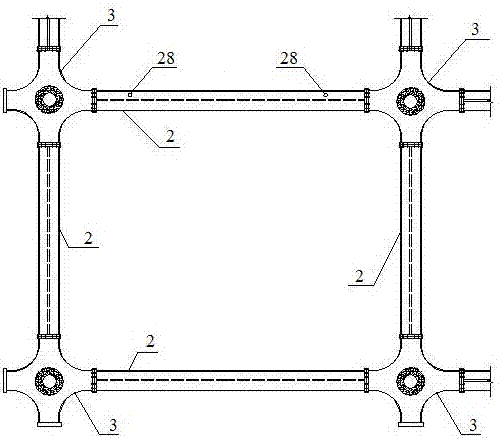

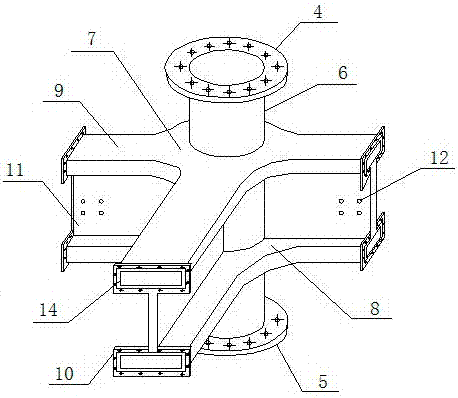

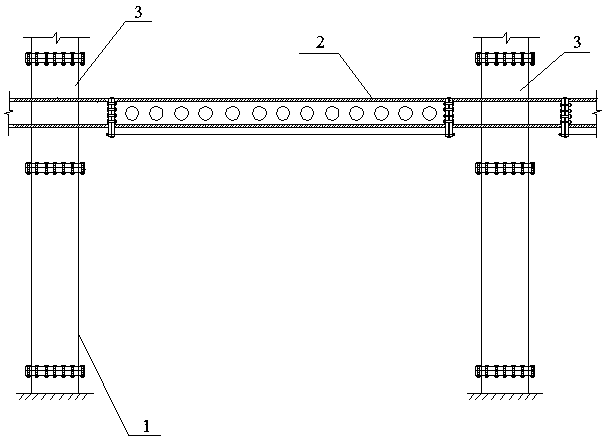

Steel pipe concrete frame with prestressing tendons and construction method thereof

ActiveCN106869315APower transmission is clearAccurate connectionLoad-supporting elementsCurve shapePre stress

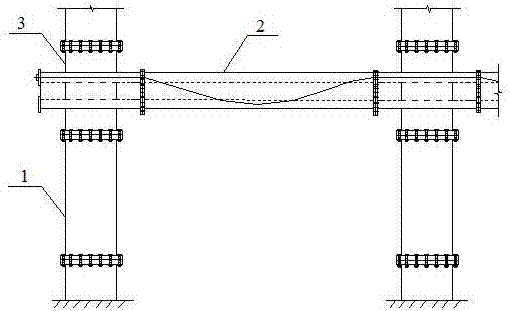

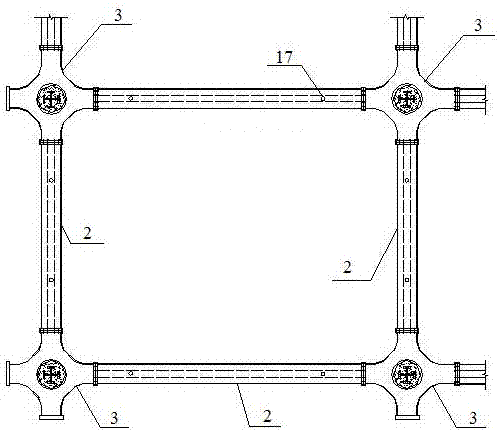

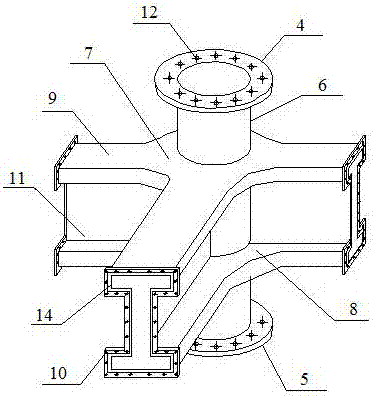

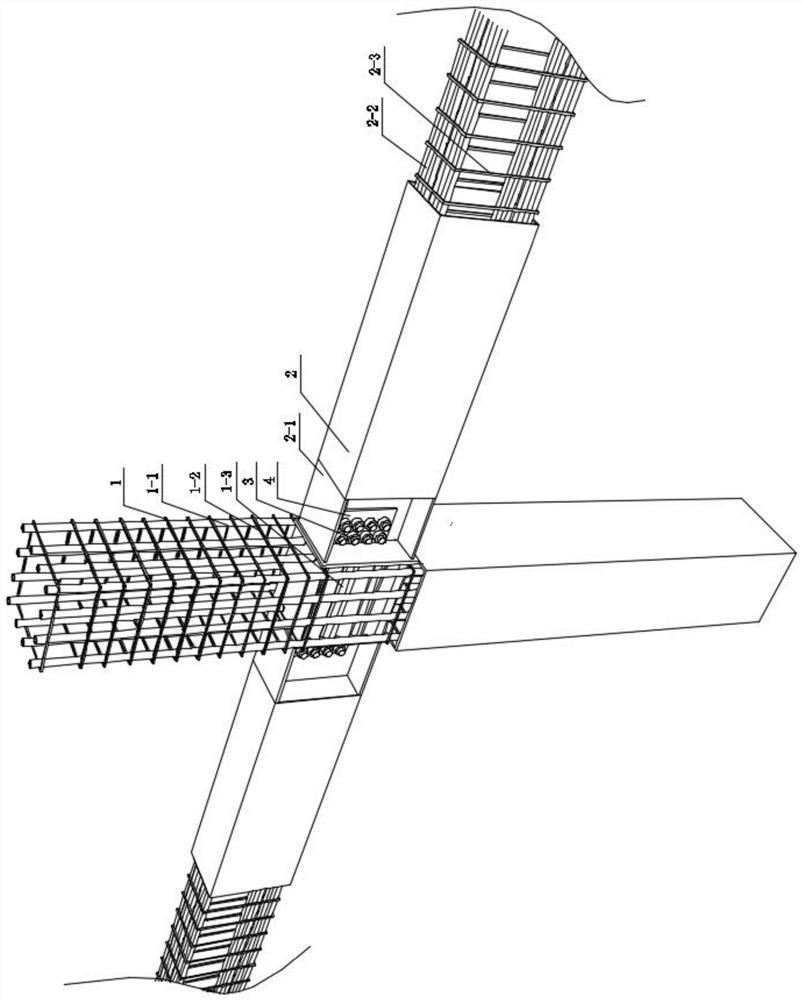

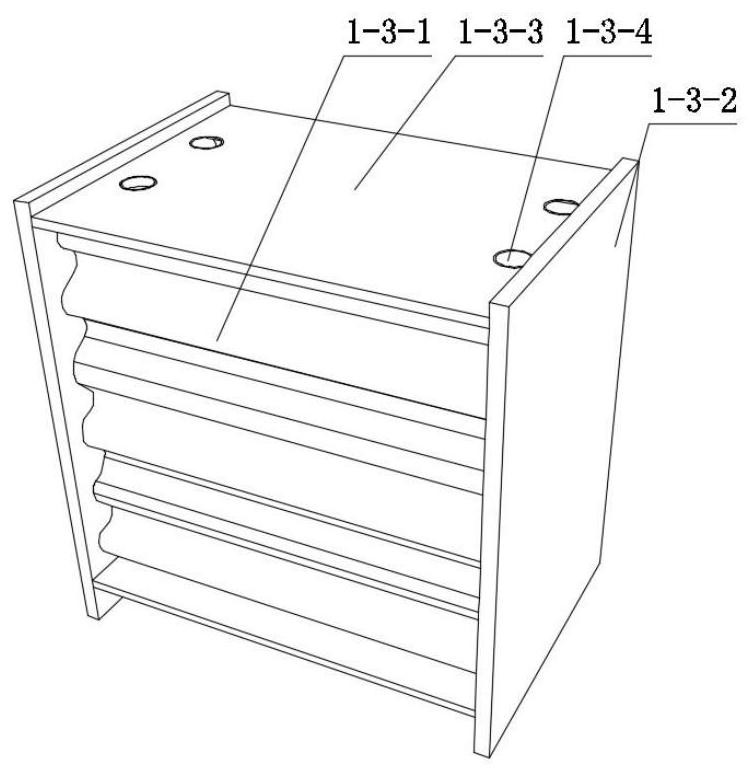

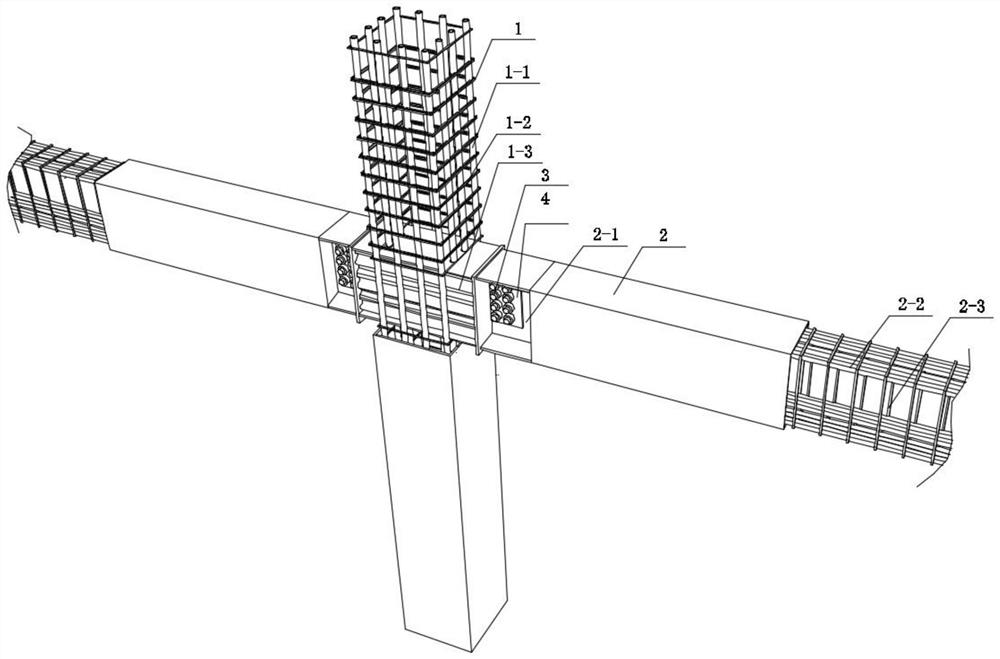

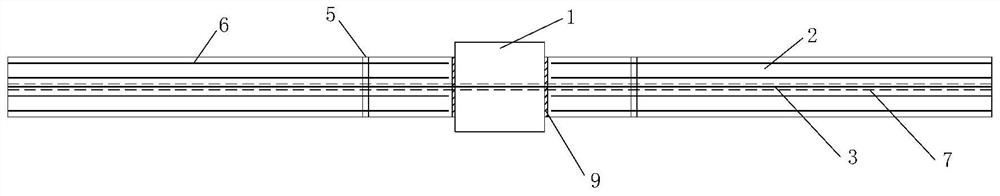

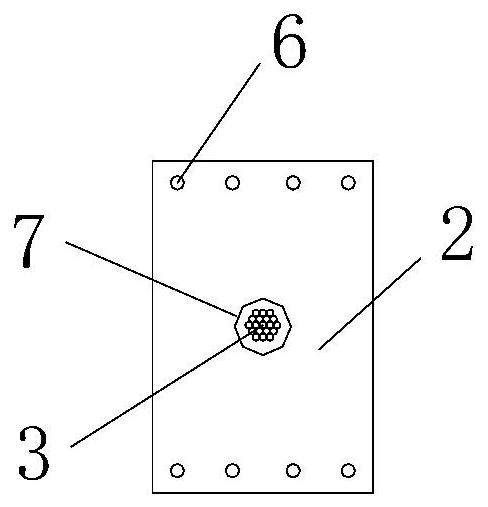

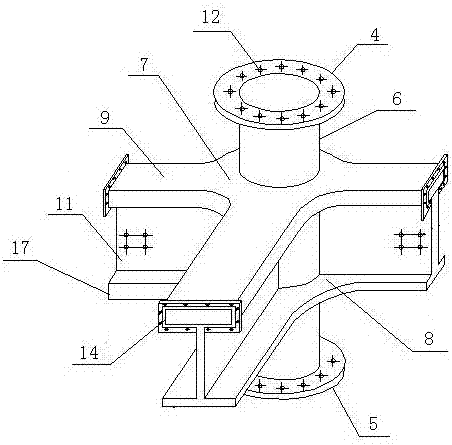

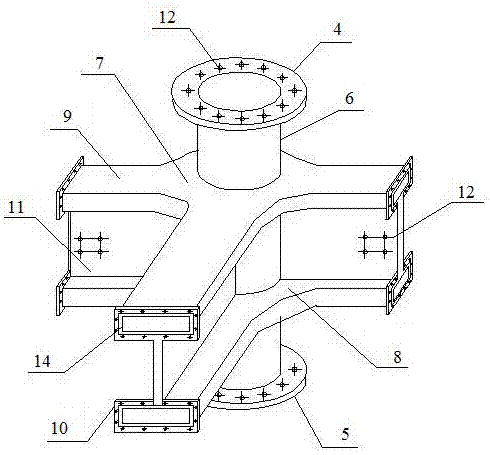

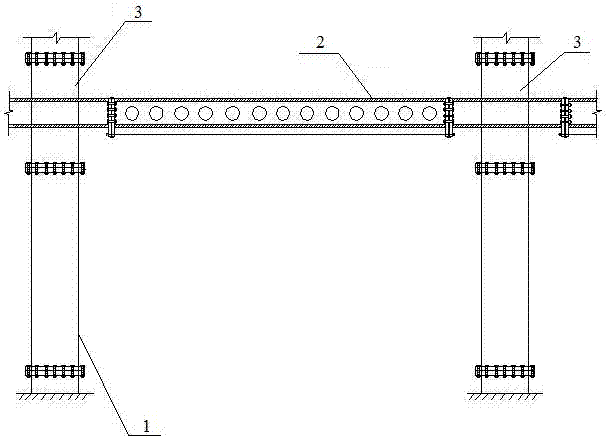

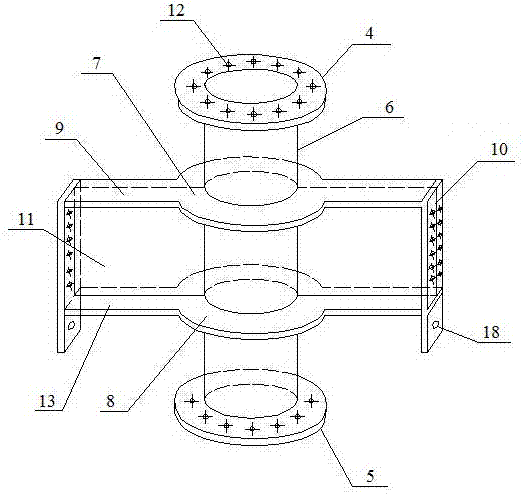

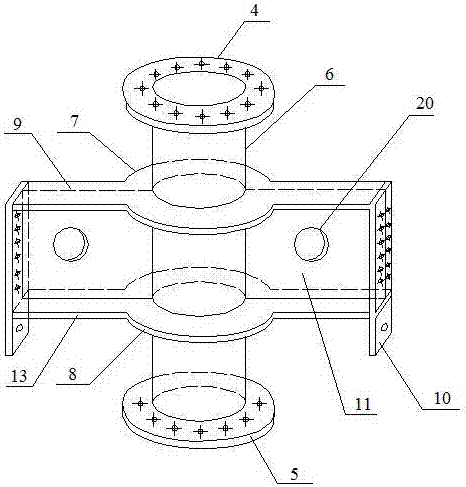

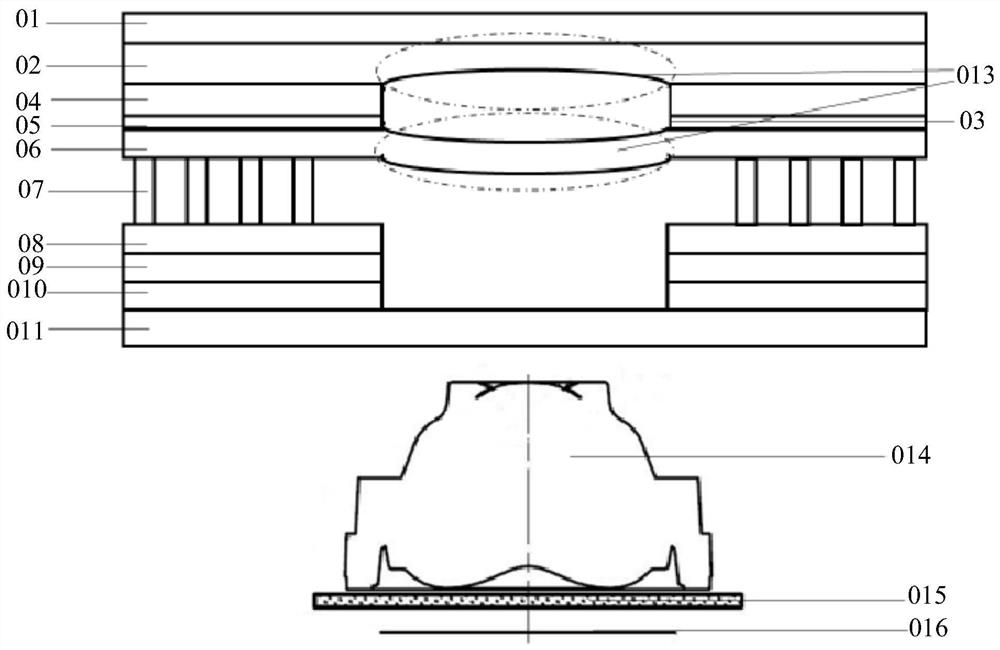

The invention relates to a steel pipe concrete frame with prestressing tendons and a construction method thereof. The steel pipe concrete frame with the prestressing tendons is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with self-compacting concrete. The composite columns are sectional-type steel pipe concrete composite columns with built-in profile steel. The composite beams are internal-prestress I-shaped steel pipe concrete composite beams. The prestressing tendons arranged in the composite beams bypass joint outer pipes from upper strengthening annular plates with cavities. The prestressing tendons are positioned through single-hole positioning plates and hole-formed double-hole main positioning plates, form symmetrical curve shapes and achieve tensioning and anchoring at joint end beams. The self-compacting fine stone concrete of the composite beams and self-compacting fine stone concrete of the joint end beams are through and form a whole with the joint outer pipes after curing. The problem that beam-column connecting joints of a novel steel pipe concrete frame with prestressing tendons are complex and liable to damage is solved.

Owner:广西万纵建设工程有限公司

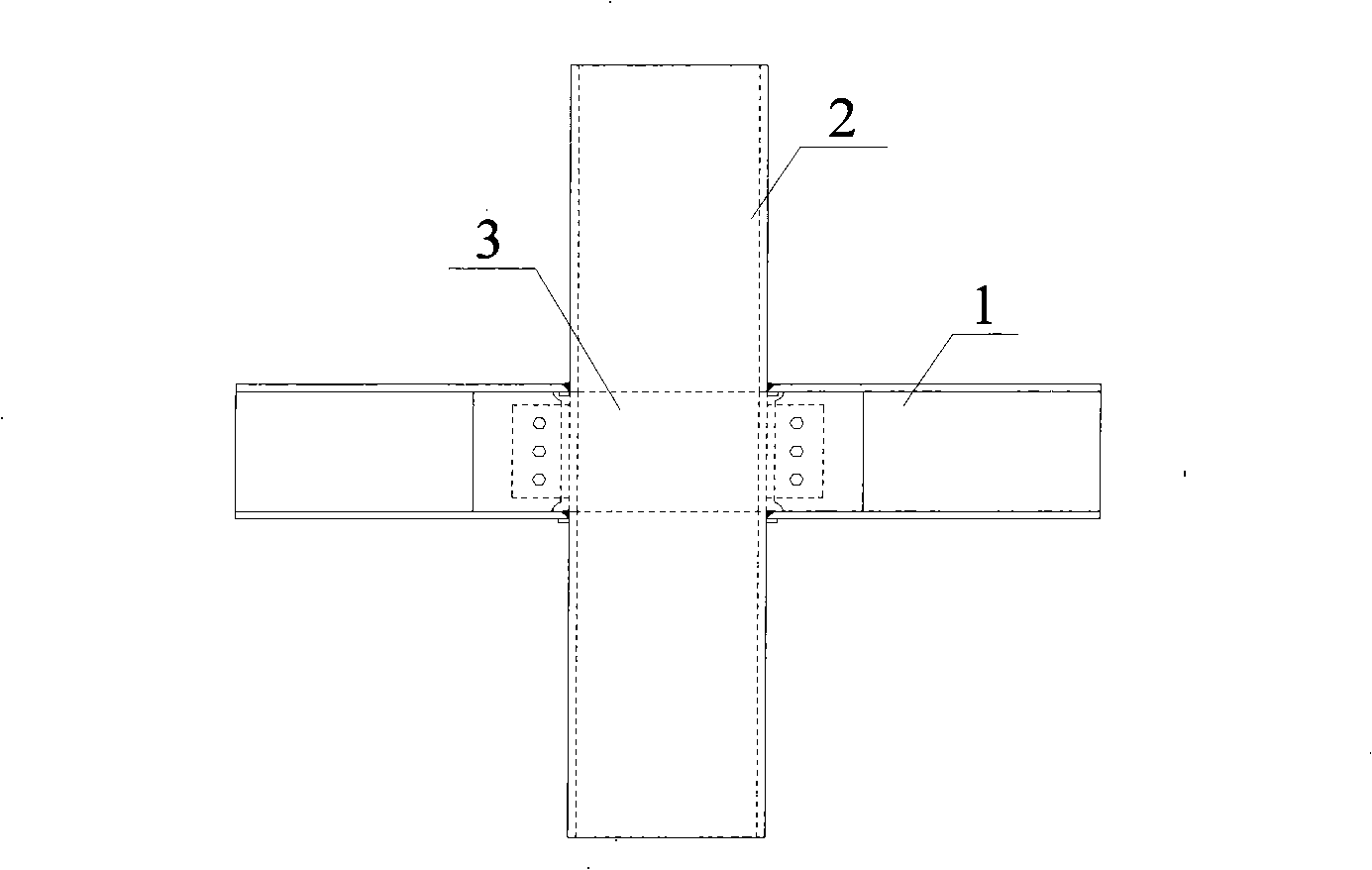

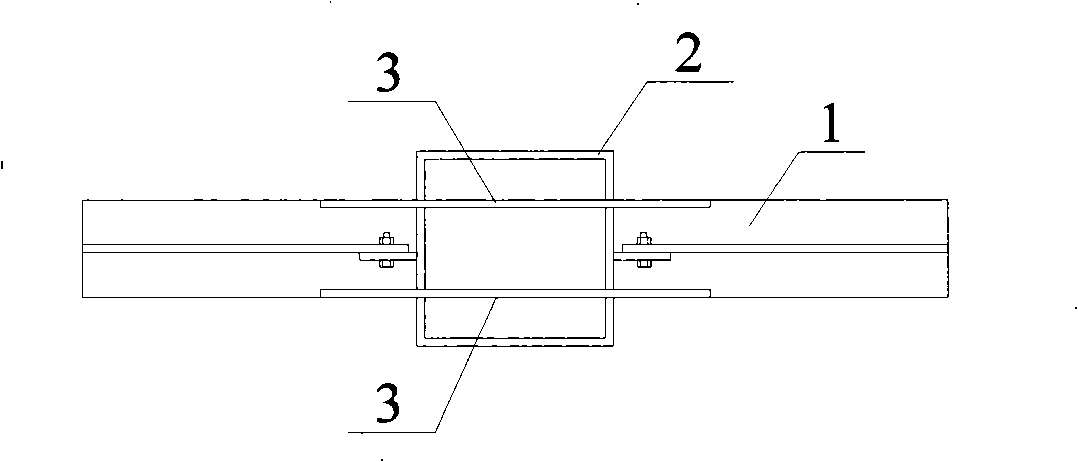

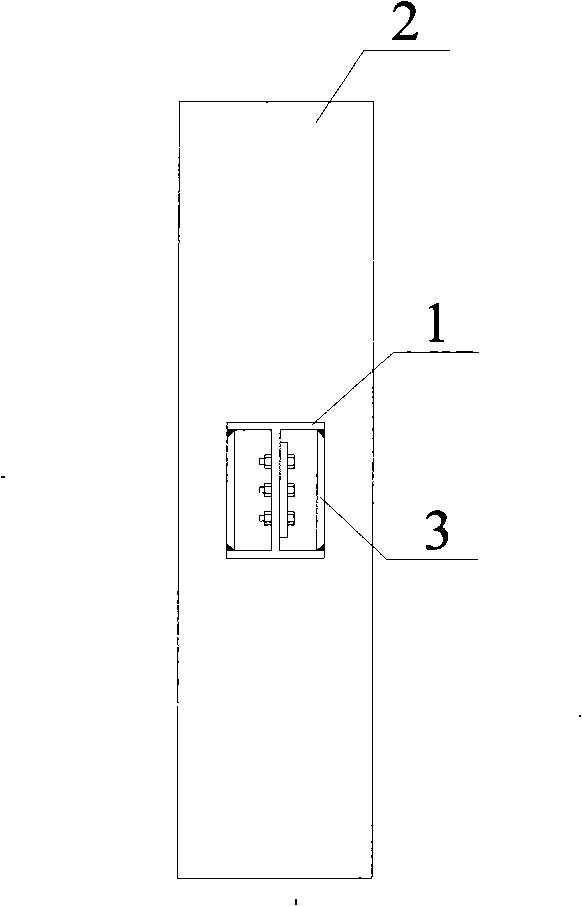

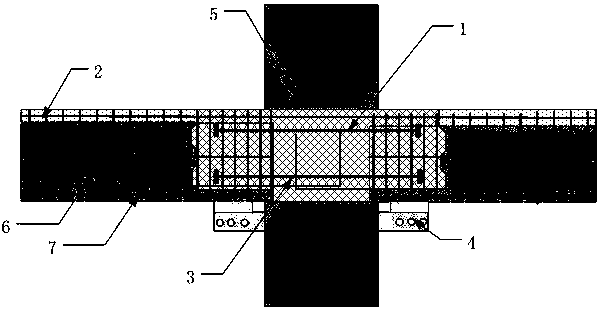

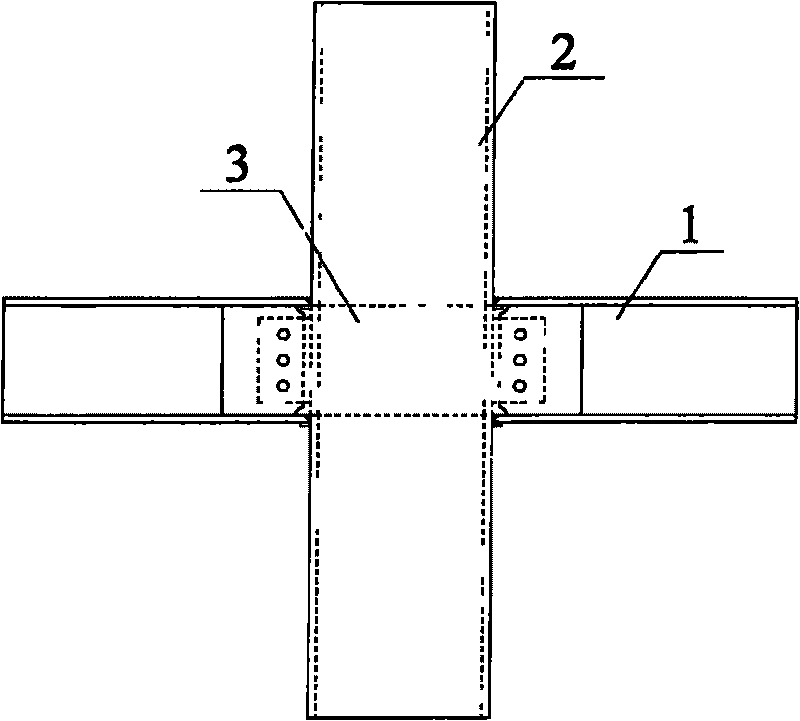

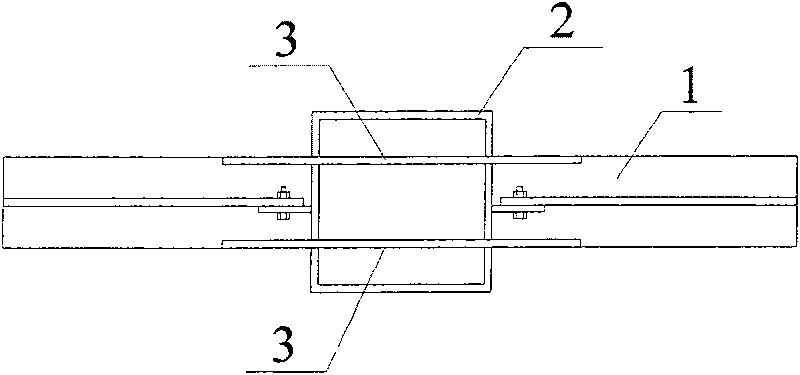

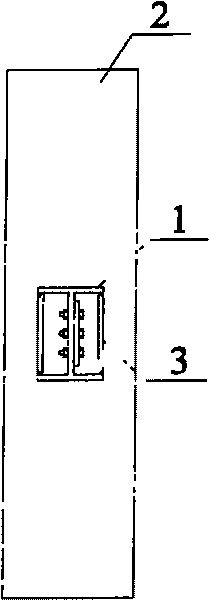

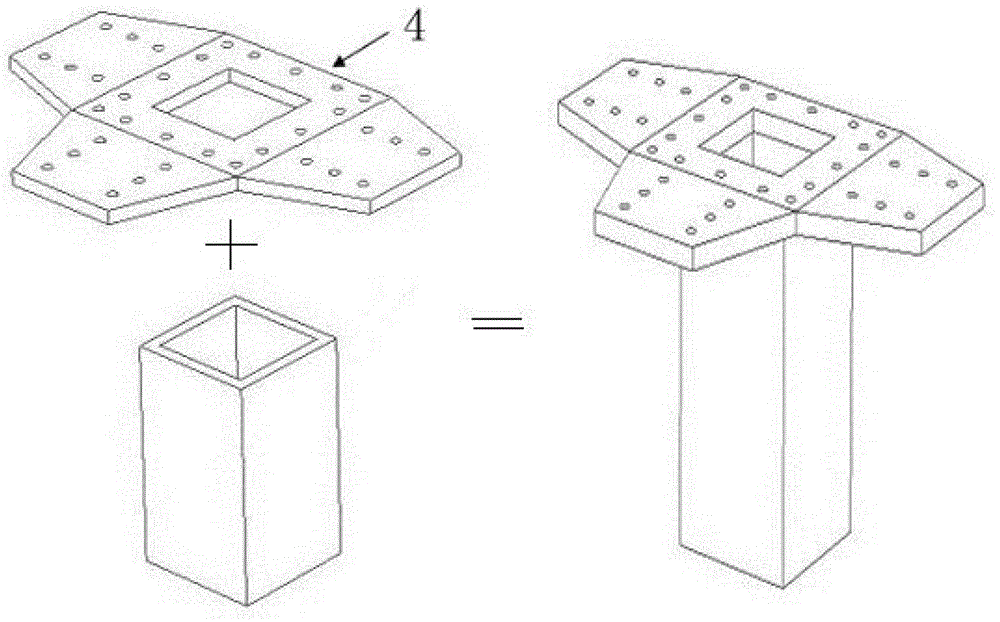

Run-through steel plate type square steel tube concrete column and axle i-beam node

InactiveCN101265724ASimple structure and processingSimple processing and structureBuilding constructionsSteel platesSteel tube

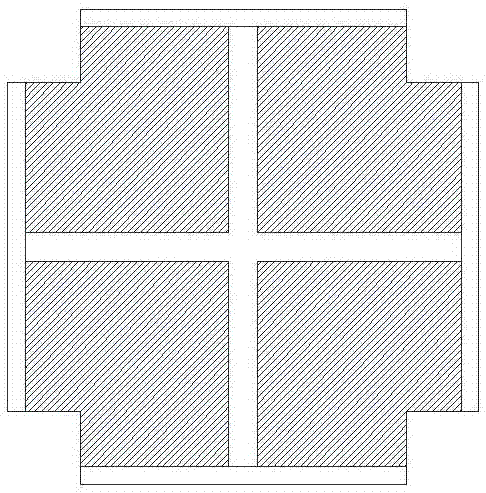

The invention relates to a square tube concrete column and an I-shaped steel beam joint of threading steel plate type in the technology field of construction engineering, and comprises the square tube concrete column, the I-shaped steel beam joint and the threading steel plate. The threading steel plate threads through the wallboard of the square tube concrete column wall plate. The threading steel plate is arranged in a vertical placement manner in the square tube concrete column, in parallel to and with the same height of the web plate of the I-shaped steel beam. A part of the threading steel plate edge protruding from the square tube concrete column is parallel and level with the I-shaped steel beam flange. The invention enhances the total bearing capacity of shearing resistance and bending resistance, and guarantees the joint work of the square tube concrete column and the I-shaped steel beam joint.

Owner:SHANGHAI JIAO TONG UNIV

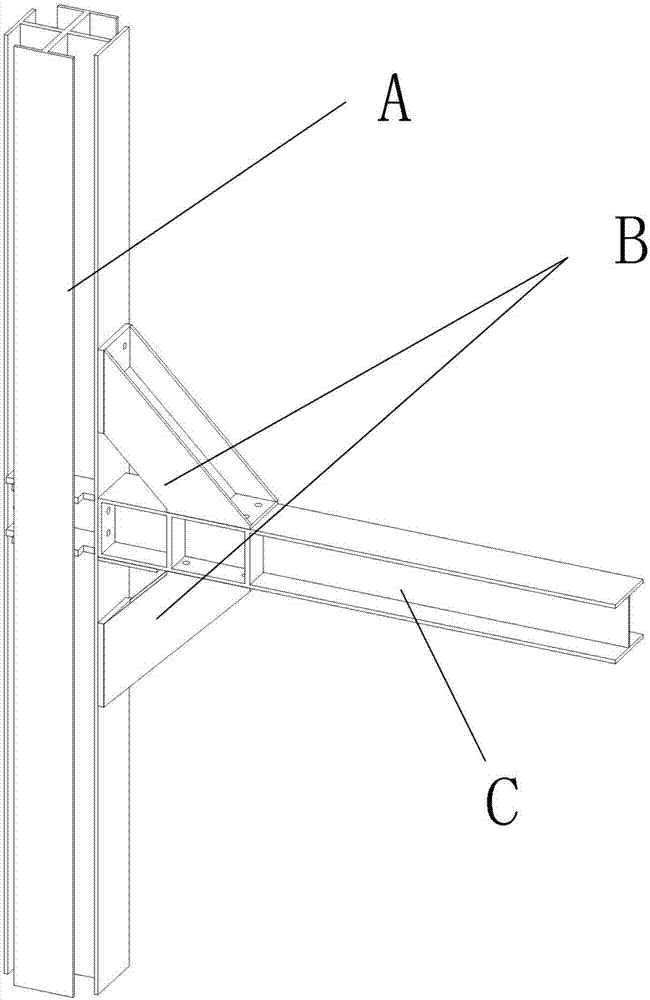

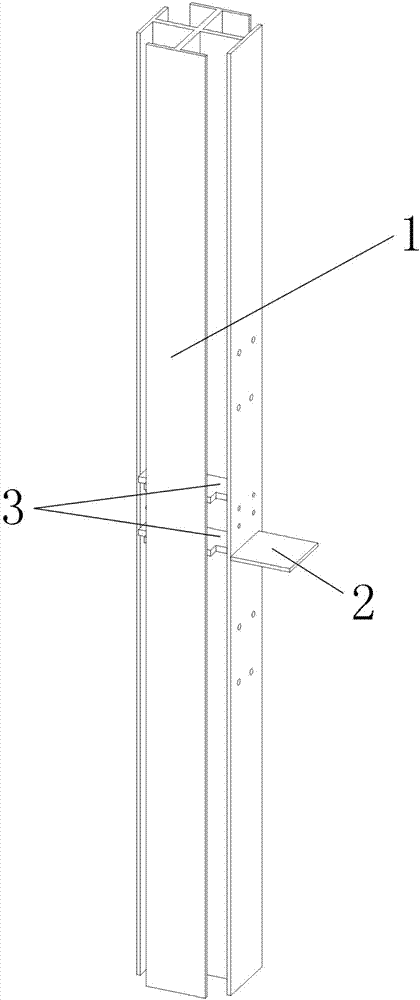

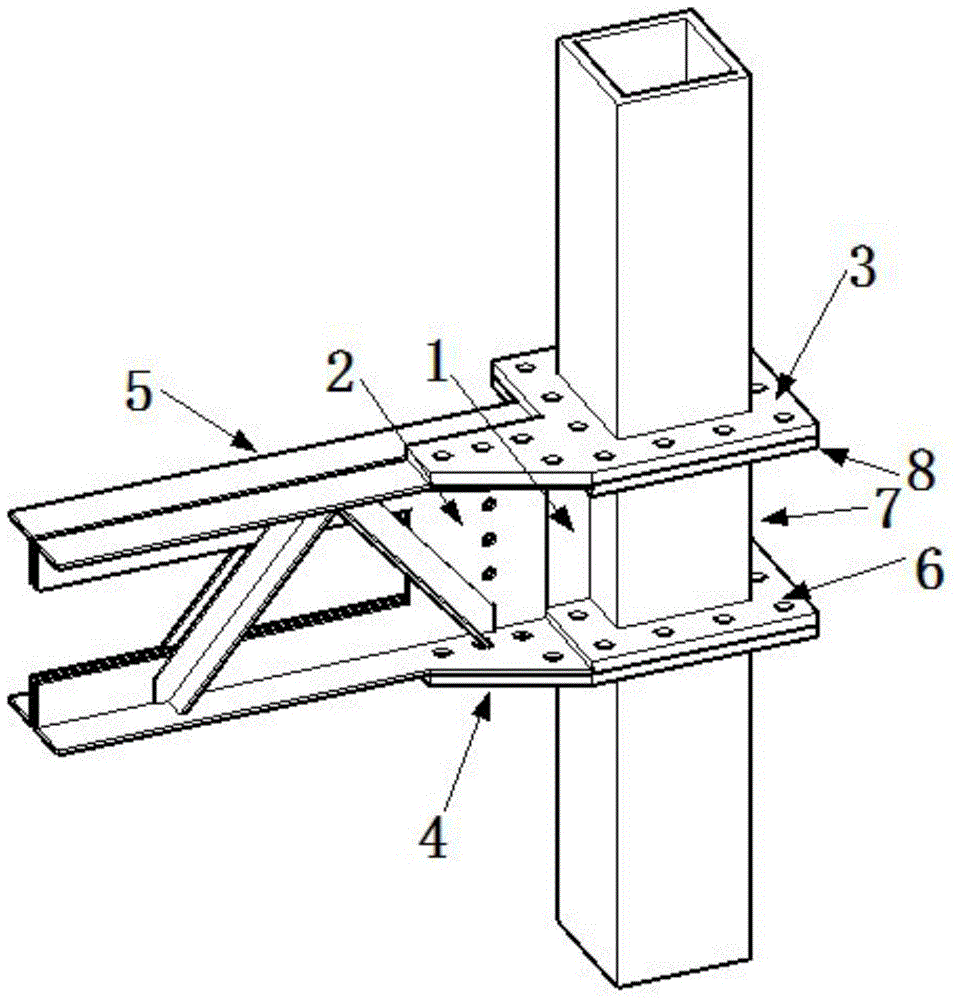

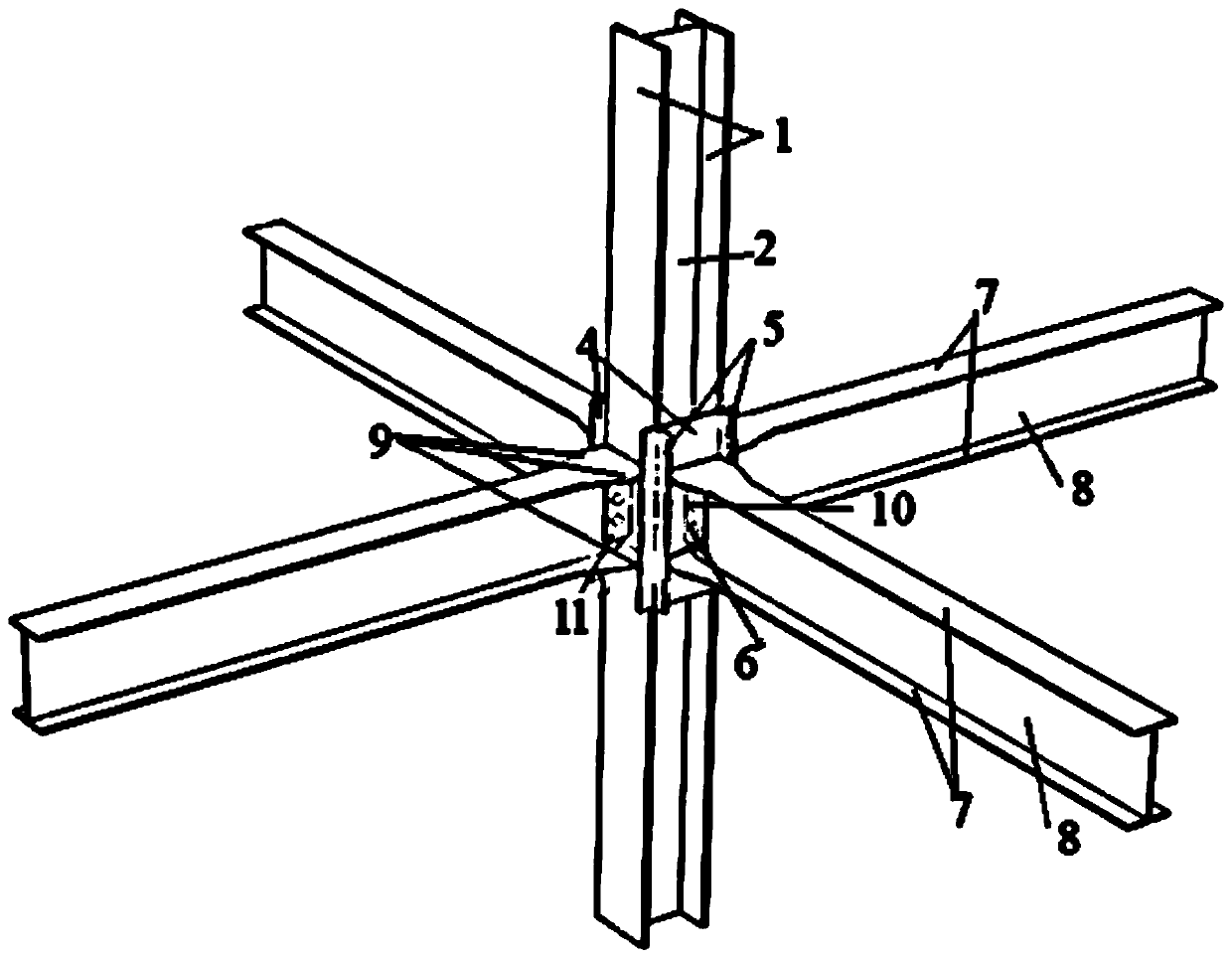

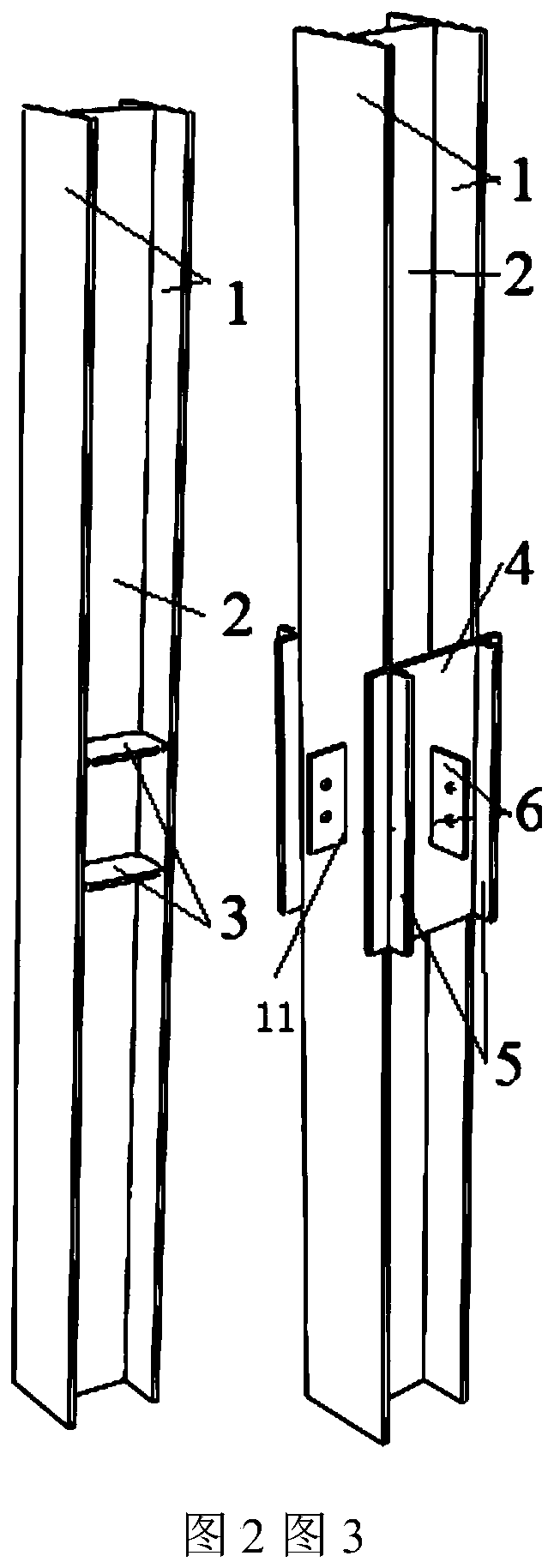

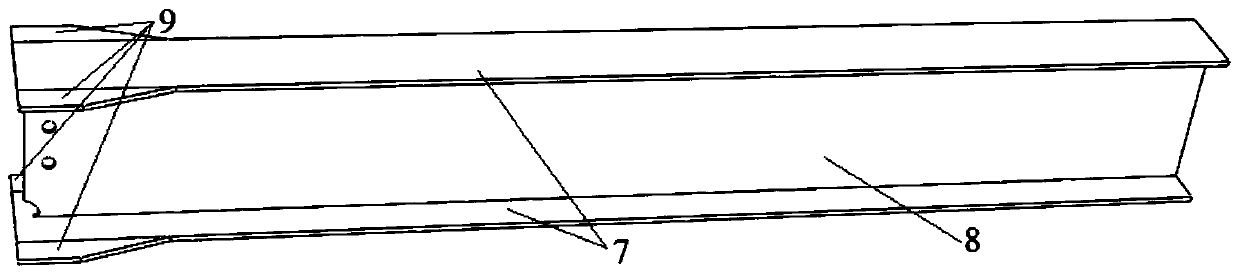

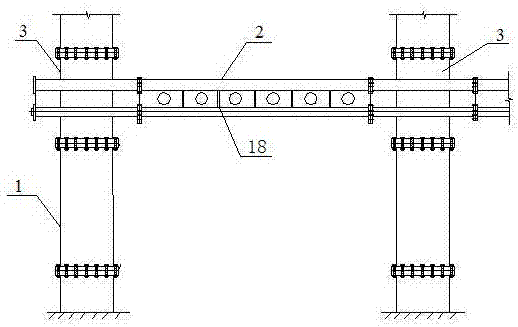

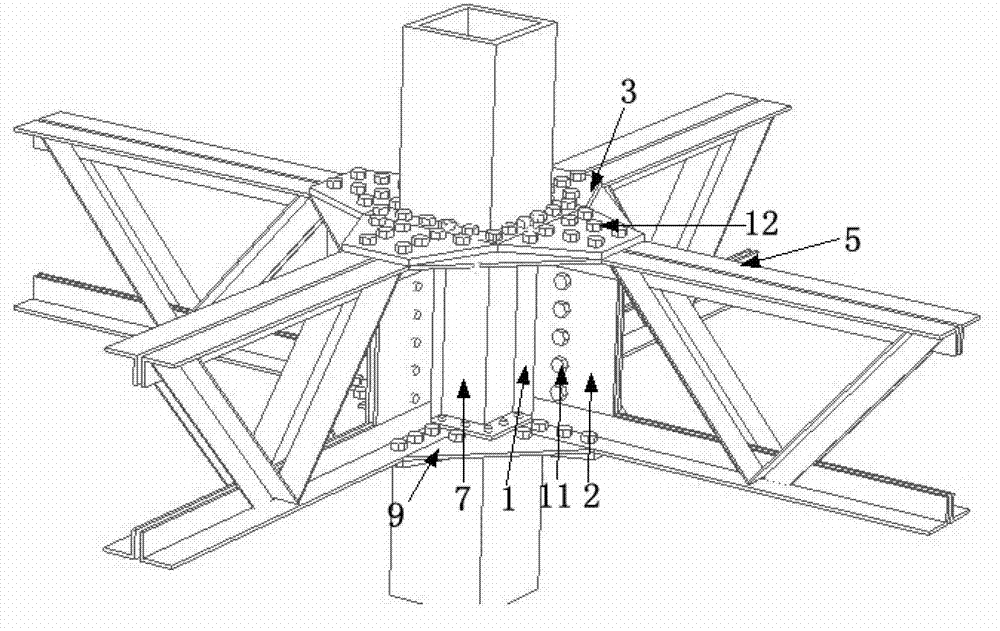

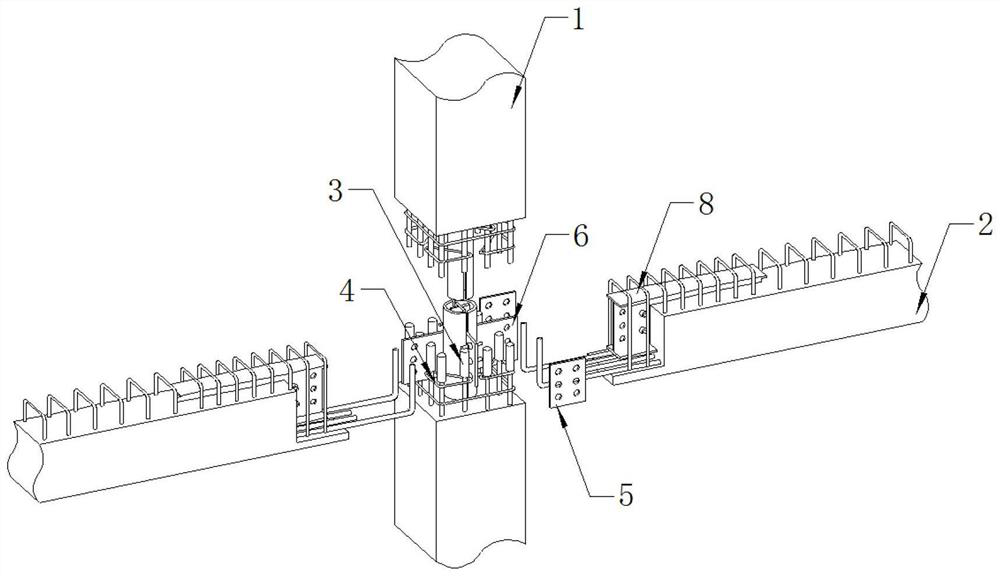

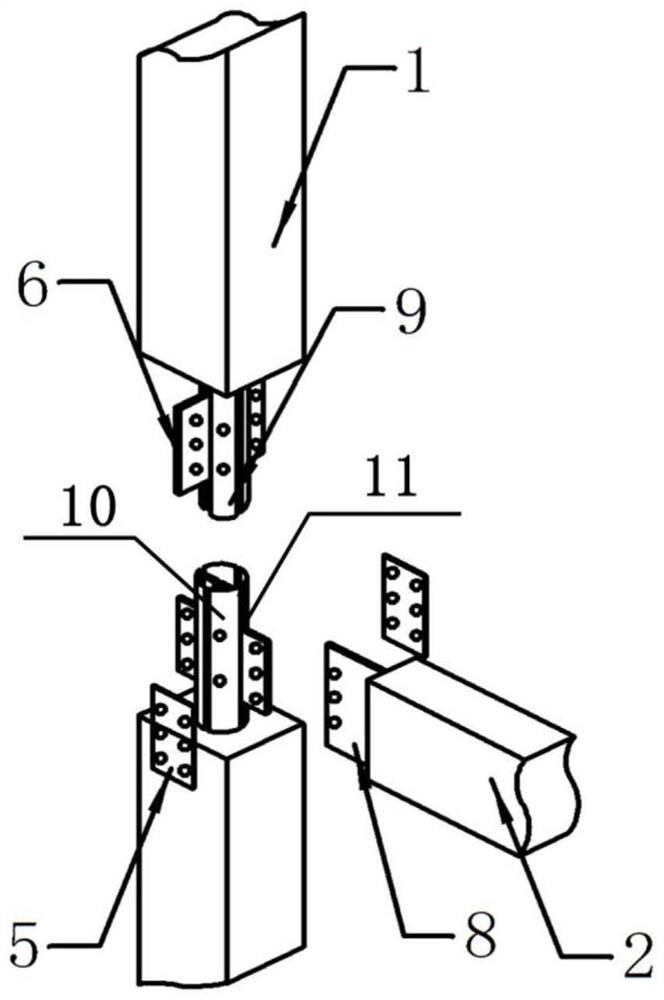

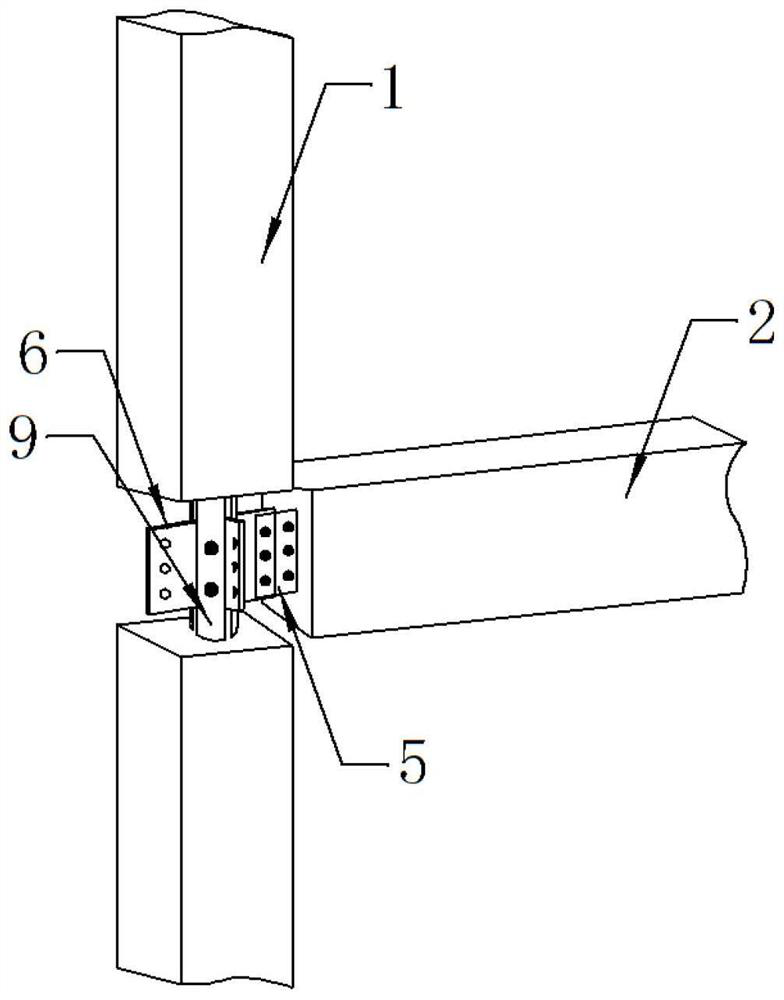

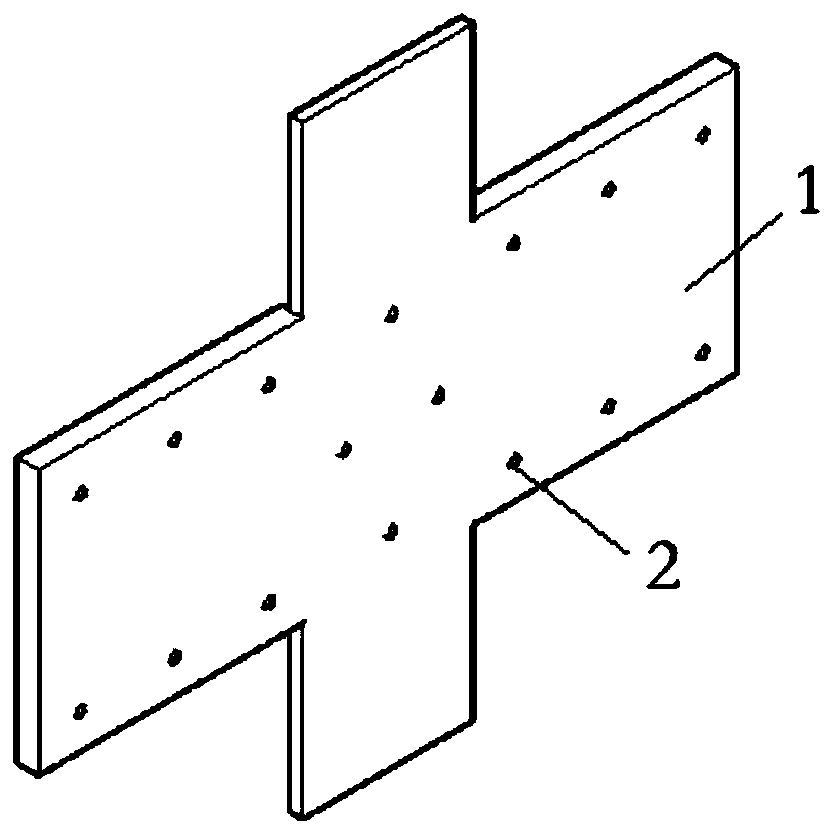

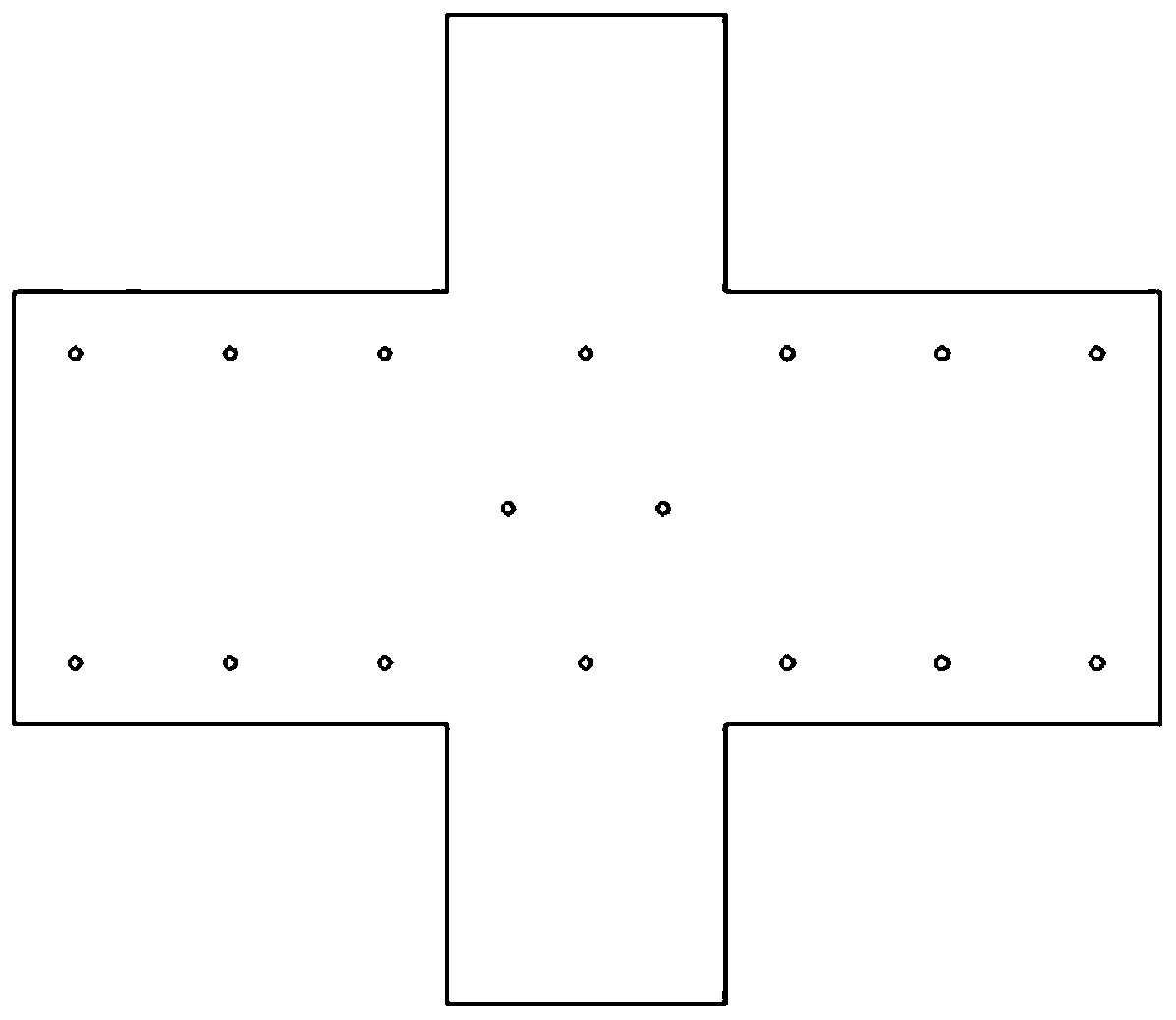

Beam-column joint connecting device with inclined strut for fabricated steel structure special-shaped column

InactiveCN107366362AIncreased bearing capacity and stiffnessReduce dosageBuilding constructionsAbnormal shapedBeam column

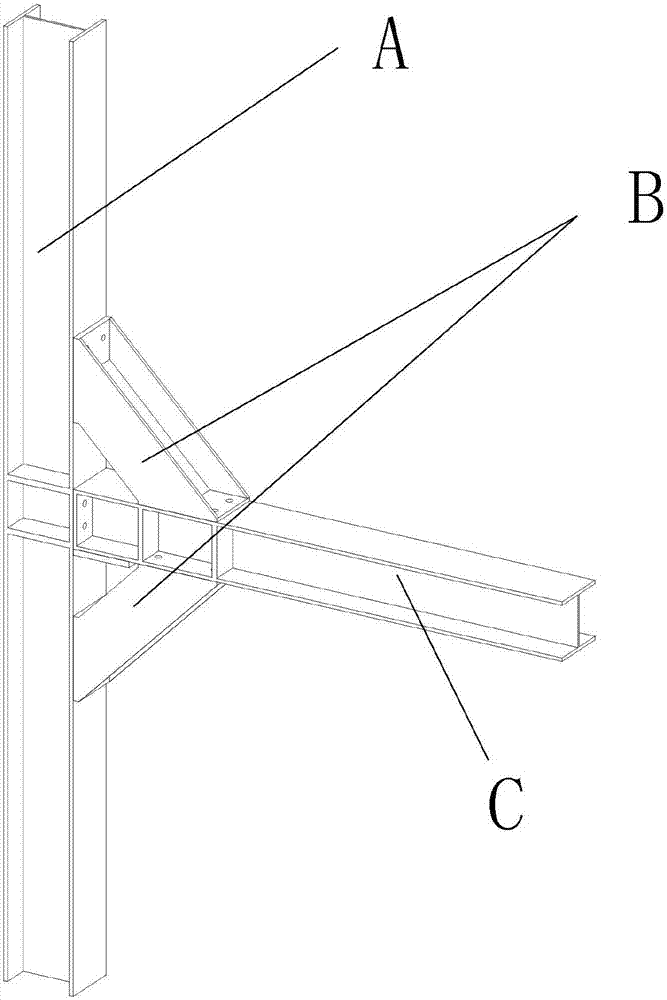

The invention discloses a beam-column joint connecting device with an inclined strut for a fabricated steel structure special-shaped column, belonging to the technical field of structural engineering. The beam-column joint connecting device comprises a column, beams and the inclined strut, wherein the column is produced by welding a cross-shaped special-shaped column, a support plate and reinforcing ribs I in a factory; and the beams are produced by welding an H-shaped steel beam, an end plate and reinforcing ribs II in the factory. All welding operations of the beam-column joint connecting device are finished in the factory; by arranging the inclined strut, the rigidity and bearing force of joints can be substantially enhanced, the use amount of bolts is reduced, the external transfer of a plastic hinge is effectively realized, damaged positions of the joints are located on the beam outside the inclined strut, and the joints are protected; by arranging the support plate, the beam can be accurately located, and meanwhile, the stability of the joints is improved; by distributing the bolts, the operation of workers is easy, the fabricating speed is greatly increased, and the fabricating quality is greatly improved; and by utilizing an onsite bolt fabricating manner, the bolts can be conveniently and rapidly fastened, the construction speed is greatly increased, the construction quality is greatly improved, the industrialized production is realized, and the onsite rapid fabricating is realized.

Owner:BEIJING UNIV OF TECH

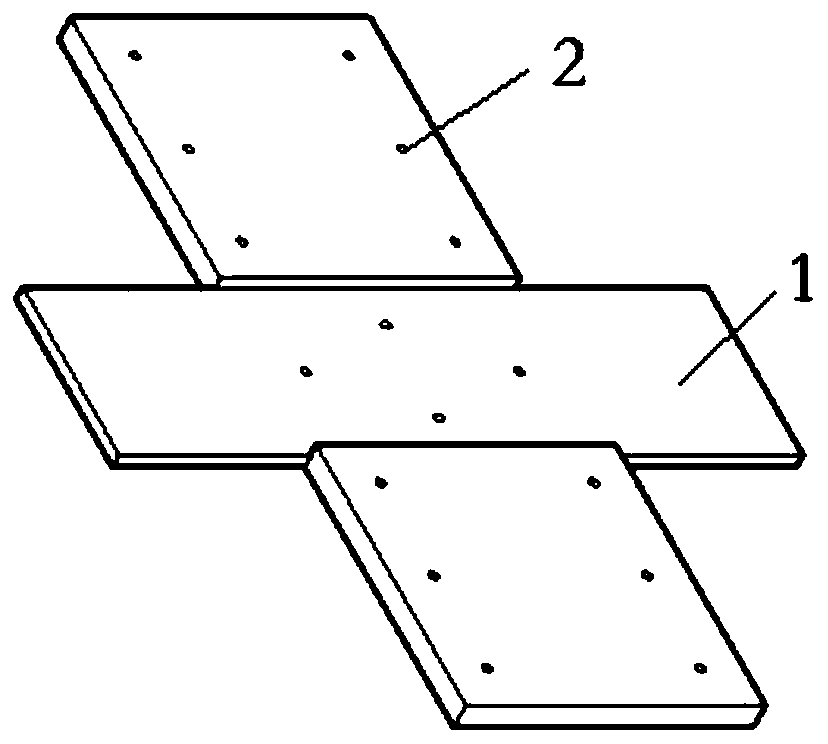

Fabricated steel structure H-shaped steel column and beam column joint connecting device with diagonal braces

InactiveCN107489197AIncrease stiffnessImprove bearing capacityBuilding constructionsEngineeringSteel columns

The invention discloses a fabricated steel structure H-shaped steel column and beam column joint connecting device with diagonal braces, and belongs to the technical field of structural engineering. The fabricated steel structure H-shaped steel column and beam column joint connecting device comprises columns, beams and the diagonal braces. The columns are formed by welding cross-shaped special-shaped columns, supporting plates and stiffened ribs I in a factory, and the beams are formed by welding H-shaped steel beams, end plates and stiffened ribs II in the factory. The forms of the diagonal braces are not limited to H-shaped steels, and the types of channel steel and T-shaped steels can also be used. According to the fabricated steel structure H-shaped steel column and beam column joint connecting device with the diagonal braces, all welding work is completed in the factory; the diagonal braces are arranged, the rigidity and the bearing capacity of joints can be greatly improved, the using amount of bolts is reduced, out-shifting of plastic hinges is realized effectively, so that the broken location of the joints is located on the beams besides the diagonal braces, the role of protecting the joints is achieved; the bolts are arranged, operation for workers is also easy, the assembly speed and quality are greatly improved; bolt assembling is adopted on site, the fastening work of the bolts is convenient and quick, the construction speed and quality are greatly improved, industrialized production is realized, and on-site assembling is quick.

Owner:BEIJING UNIV OF TECH

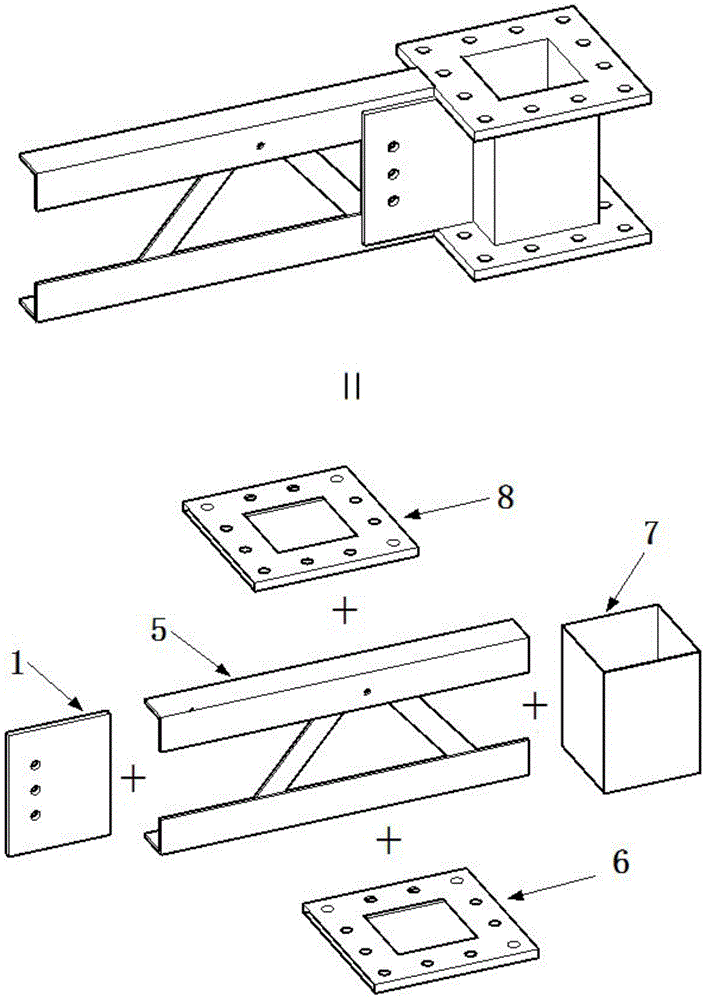

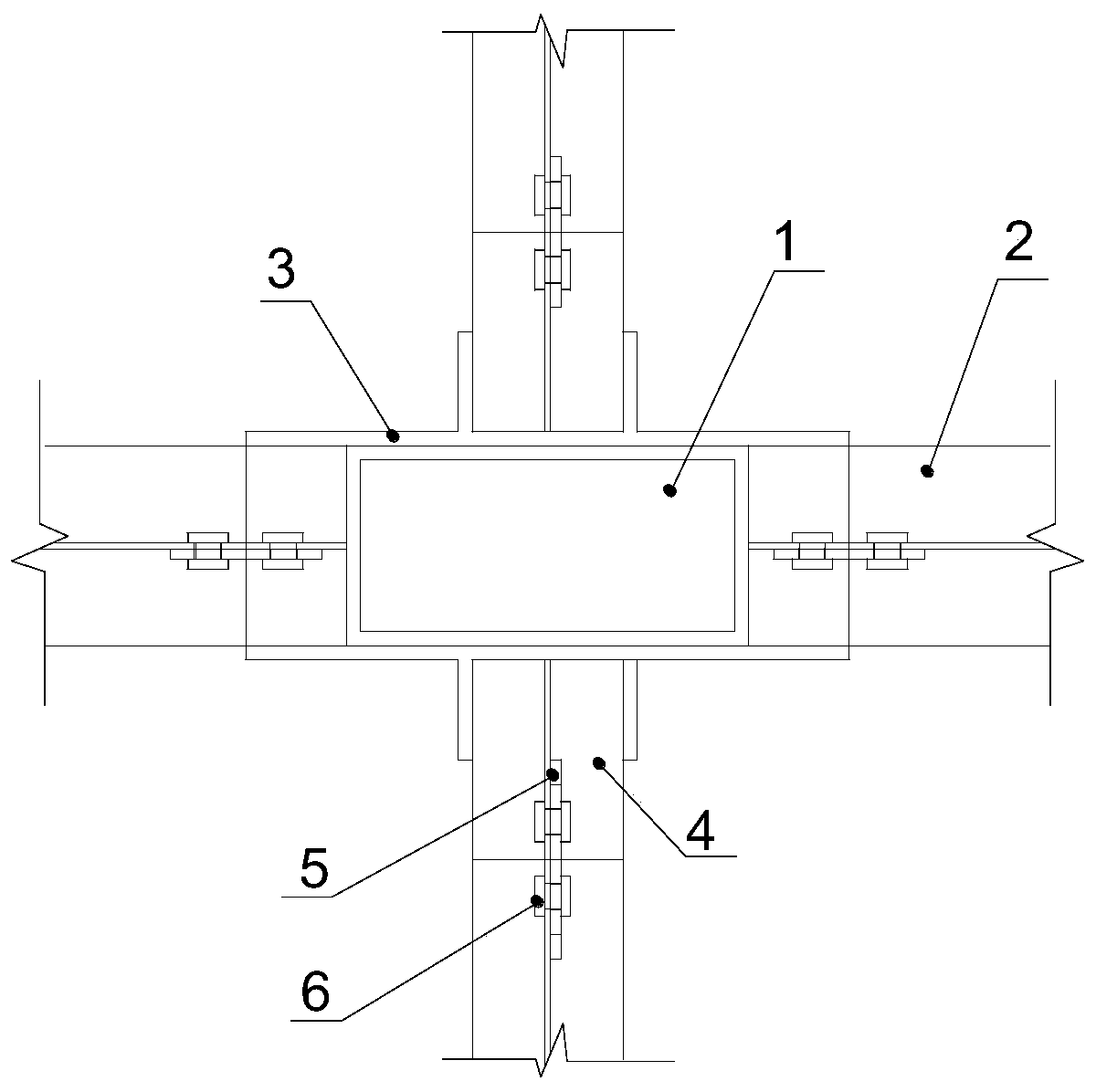

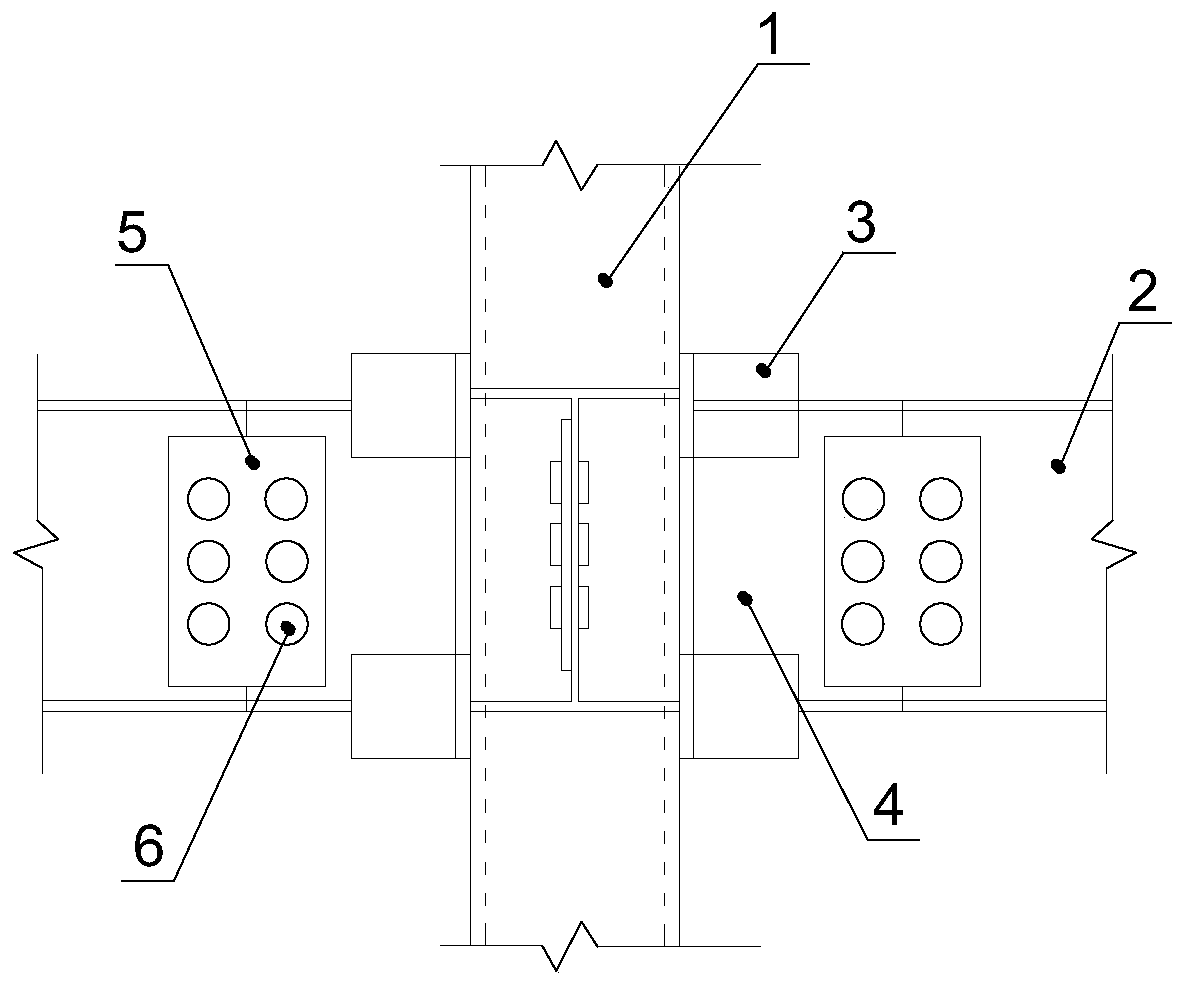

Half-welding half-bolt beam-column joint connection device of assembly type steel structure system

InactiveCN104652616AEasy to operateImprove assembly speedBuilding constructionsBolt connectionBeam column

The invention relates to a half-welding half-bolt beam-column joint connection device of an assembly type steel structure system and belongs to the technical field of structural engineering. According to the half-welding half-bolt beam-column joint connection device, a column base connecting plate, a joint short column, a joint short column upper end flange, a joint short column lower end flange and a truss beam of one side can be welded into one body in the factory; a beam end connecting plate and a truss beam end upper and lower chord rod of the other side are welded into one body in the factory; the beam end connecting plate and the column base connecting plate are connected through bolts. According to the joint connection device, welded portions can be completed in the factory, field assembly is carried out by adopting the bolts, the work of fastening of the bolts is convenient and fast, and the speed and quality of construction are greatly improved, so that the half-welding half-bolt beam-column joint connection device is applicable to the development of assembly type steel structures; meanwhile, joints of the joint connection device are rigid joints and are good in ductility and strong in load-carrying ability.

Owner:BEIJING UNIV OF TECH

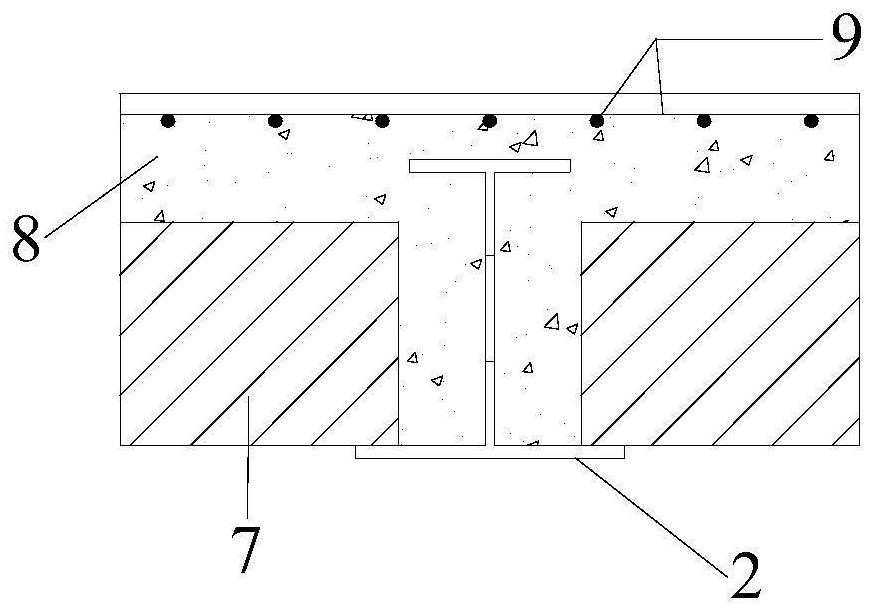

Energy dissipation and seismic mitigation joint of assembly type RPC/concrete group frame

PendingCN107905402AReduce steel consumptionSmall sectionProtective buildings/sheltersShock proofingReinforced concrete columnHigh energy

The invention discloses an energy dissipation and seismic mitigation joint of an assembly type RPC / concrete group frame. A reinforced concrete column is used as the column. The column can be precastedor casted-in-place. A prefabricated beam with a keyway is used as the beam and the upper portion of the beam is provided with a laminated layer of a certain thickness. A PC steel bar is used as the beam bottom carrying bar and the bar extends a certain length at the end of the beam. The prefabricated beam is of a partial prestressing force structure. In a prefabricated beam keyway and joint area,reactive powder concrete (RPC) with high strength and toughness is used to conduct pouring. The laminated layer on the upper portion of the beam uses normal concrete to conduct pouring. After pouringof pouring areas behind the joint are all finished, a friction damper is arranged on the beam and column junction of the beam bottom. According to the energy dissipation and seismic mitigation joint,high strength materials such as RPC or PC steel bars are taken full advantage of, the section sizes of prefabricated assembly members can be reduced, the self weight of the prefabricated members arereduced, and meanwhile, combining with the energy dissipation and seismic mitigation technology, the problem that high-strength bars consume less energy can be fully solved. The energy dissipation andseismic mitigation joint has obvious technical advantages and has large-scale promotion and application prospects.

Owner:YANGZHOU UNIV

Assembly type prefabricated beam and column connecting joint and construction method

InactiveCN111997193AImprove integritySimple structureBuilding constructionsArchitectural engineeringStirrup

The invention relates to an assembly type prefabricated beam and column connecting joint. The joint comprises a prefabricated column and prefabricated beams; the prefabricated column comprises in-column longitudinal bars, in-column stirrups and in-column embedded parts; the prefabricated beams comprise in-beam longitudinal bars, in-beam stirrups and embedded H-shaped steel; and during on-site construction, beam and column connecting steel sheets are welded to the end faces of the in-column embedded parts of the prefabricated column, and the prefabricated beams are externally connected with theend faces of the in-column embedded parts of the prefabricated column through the end of the embedded H-shaped steel and are in bolted connection with the beam and column connecting steel sheets. Theinvention further provides a construction method of the assembly type prefabricated beam and column connecting joint. According to the joint and the method, the construction is easy, the stress performance of the connecting position is excellent, the rigidity is high, and the technical problem of difficult connection of a beam and column joint in an assembly type concrete frame structure is solved.

Owner:HEBEI UNIV OF TECH

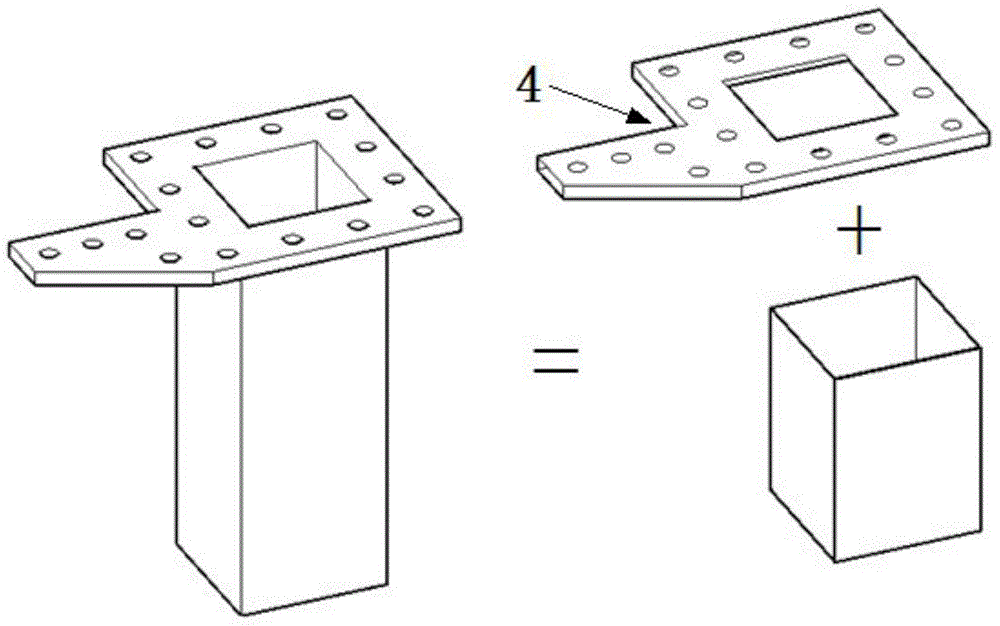

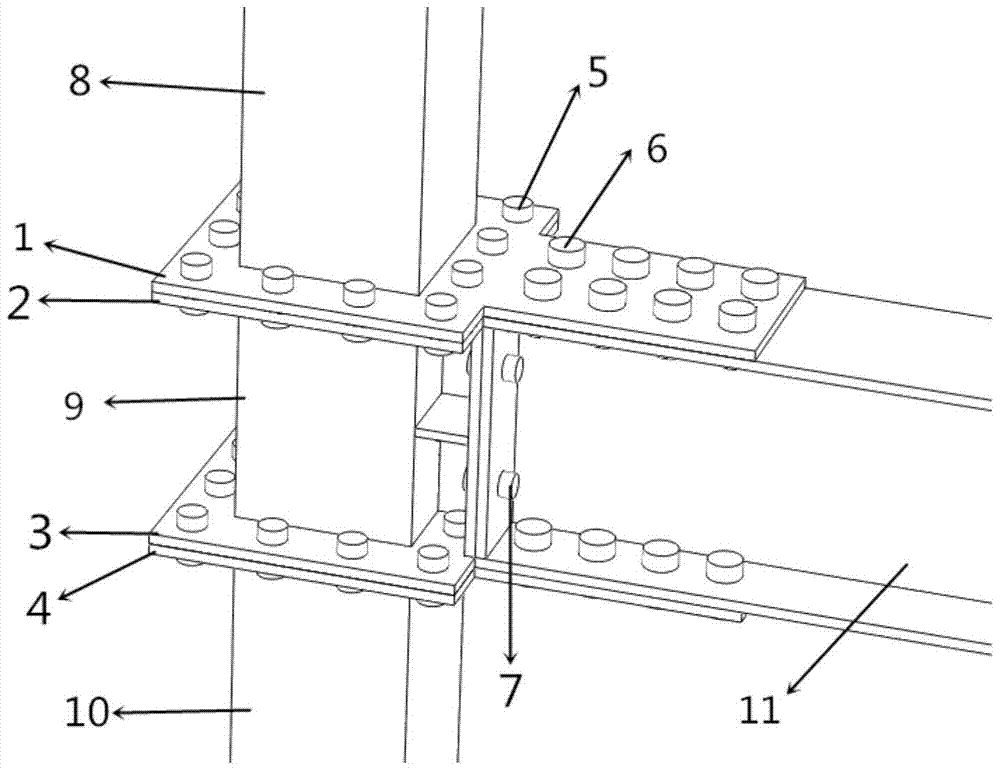

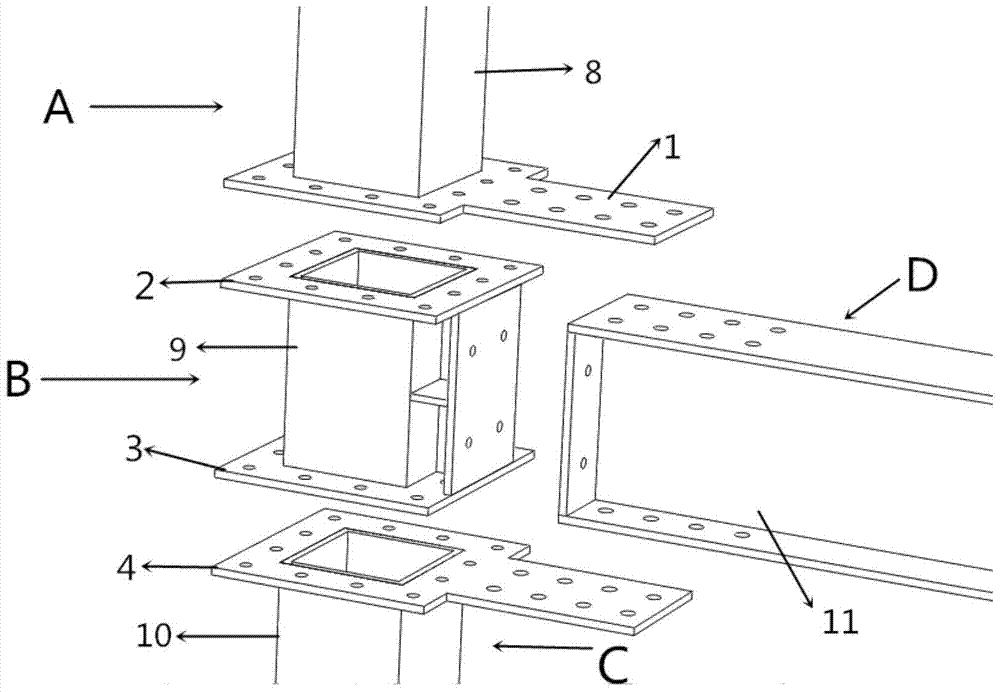

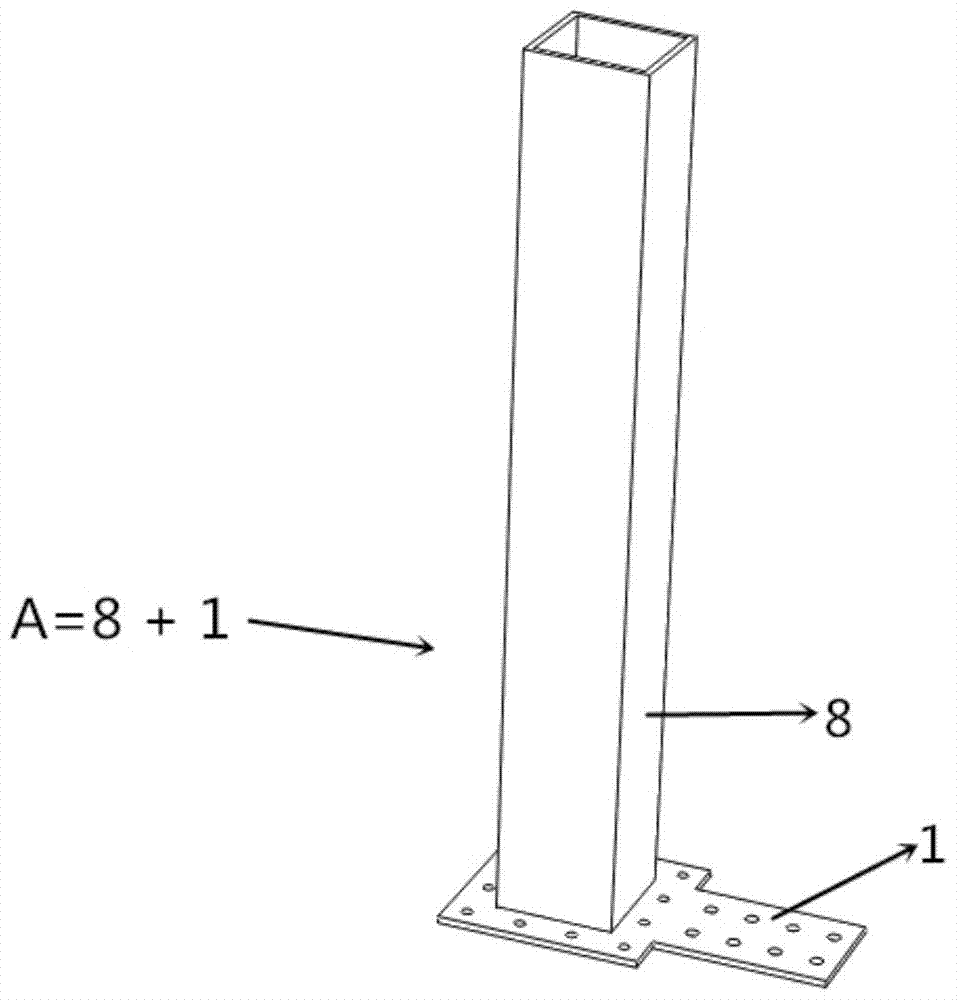

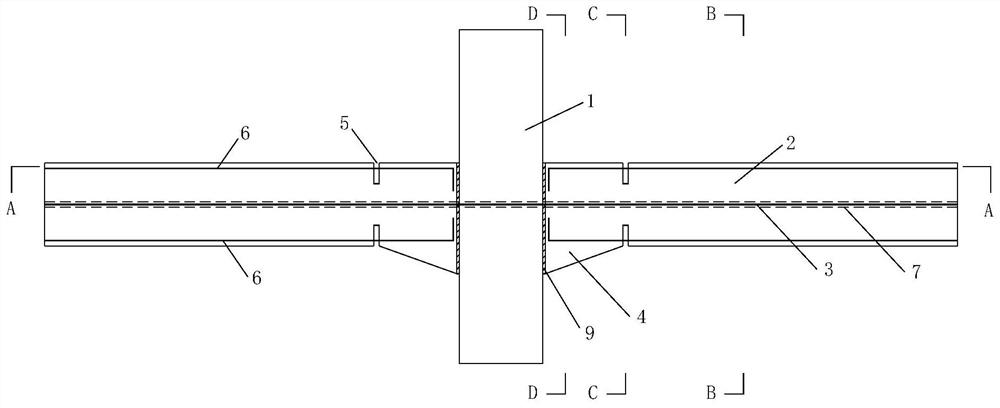

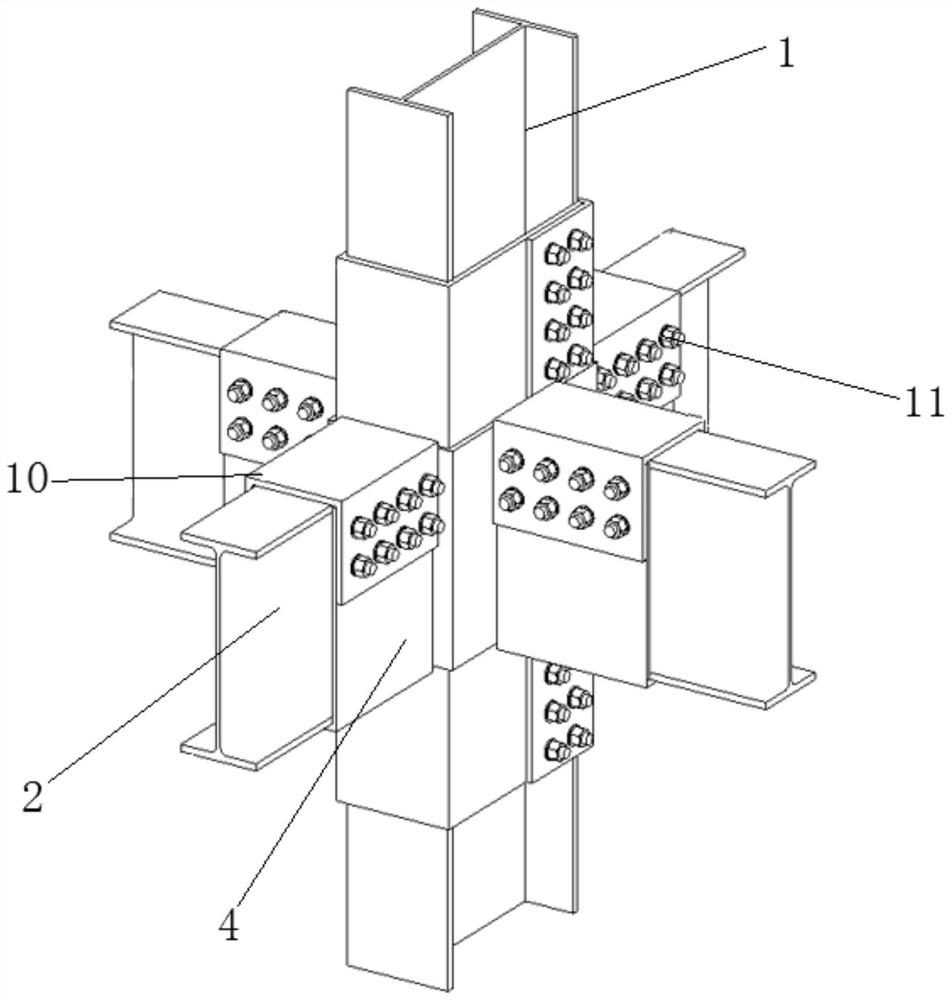

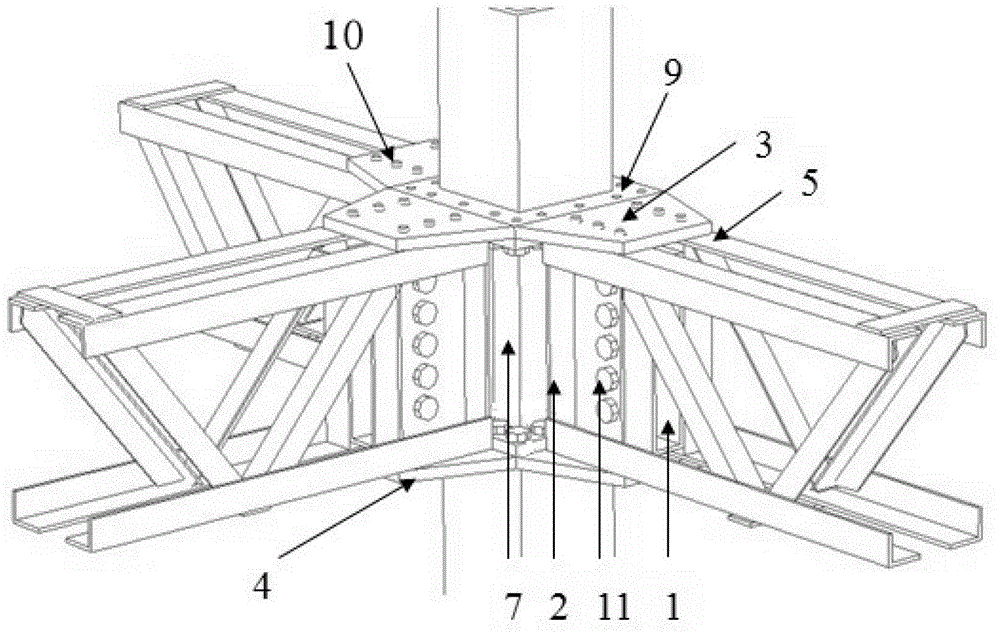

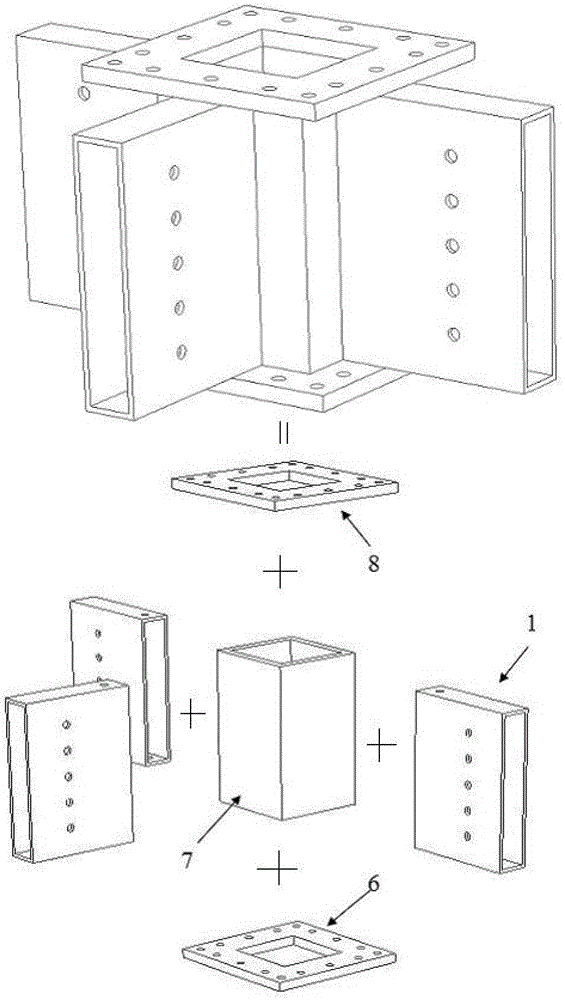

A beam-column joint connection device for a multi-story fabricated steel structure system

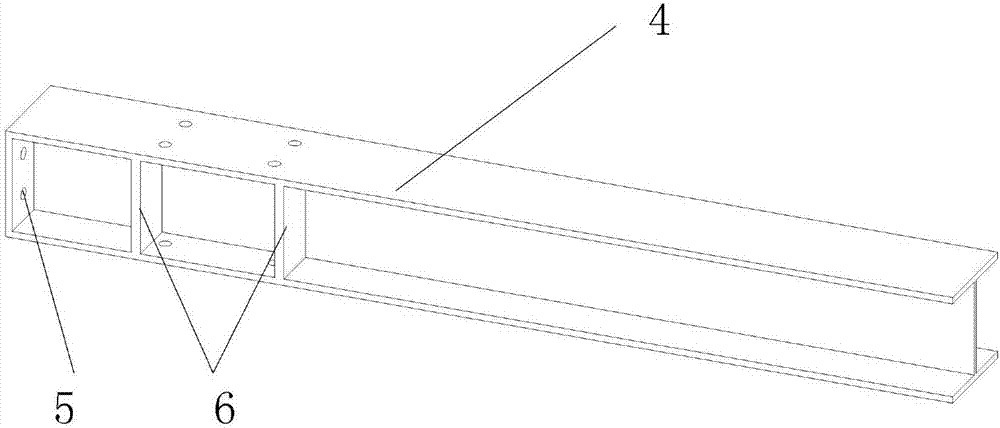

ActiveCN104652617BEasy to operateImprove assembly speedBuilding constructionsCarrying capacityEngineering

A beam-column node connection device for a multi-high-rise fabricated steel structure system, belonging to the technical field of structural engineering, including upper column flanges, node short column upper end flanges, node short column lower end flanges, lower column flanges, and upper box-shaped Column, node stub column, lower box column, I-beam, node stub column steel plate, node stub column transverse connection short steel plate, node stub column vertical connection steel plate and beam end vertical connection steel plate; upper box column and upper column The flanges are welded together at the factory. The node short column, the node short column steel plate, the node short column horizontal connection short steel plate and the node short column vertical connection steel plate are welded into one in the factory. The I-beam and the vertically connecting steel plate at the beam end are welded together in the factory. The welding part of the present invention can be completed in the factory, and the bolts are used for on-site assembly, the fastening work of the bolts is convenient and fast, the construction speed and quality are greatly improved, and it is suitable for the development of assembled steel structures. At the same time, the nodes of the present invention are rigid nodes, Good ductility and strong bearing capacity.

Owner:HUZHOU DINGXING CONSTR

Prestressed full-dry type connection assembly type concrete frame beam-column joint

PendingCN113107088ASimple connection structureImprove structure installation efficiencyBuilding constructionsConcrete beamsPre stress

The invention discloses a prestressed full-dry type connection assembly type concrete frame beam-column joint. The prestressed full-dry type connection assembly type concrete frame beam-column joint comprises a prefabricated concrete column, prefabricated concrete beams and prestressed tendons. The prefabricated concrete column and the prefabricated concrete beams on the two sides of the prefabricated concrete column are tensioned and pressed through the prestressed tendons penetrating through a beam-column joint area, and the full-dry type connection beam-column joint is formed. Longitudinal energy-consuming steel bars on the upper portions and the lower portions of the prefabricated beams do not pass through a joint column section of the prefabricated concrete column and are directly anchored at the beam ends in the modes of bending, anchoring plates and the like. According to the beam-column joint, under the earthquake action, plastic hinge outward movement is achieved through special structure measures near the ends of the prefabricated concrete beams, and structural damage is made to be away from beam-column joints. Accordingly, the joint connecting structure is simplified, the assembly type concrete frame structure mounting efficiency is improved, and the structural stress performance is improved.

Owner:JIANGSU UNIV OF SCI & TECH

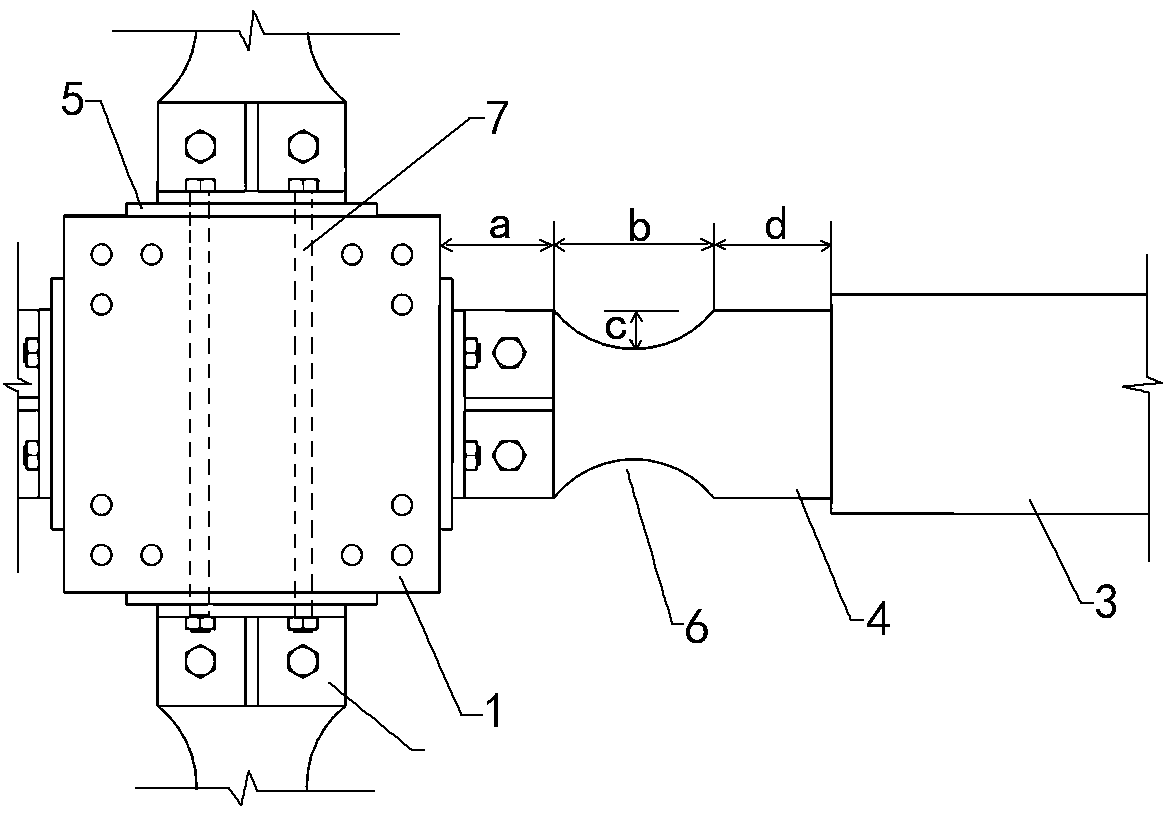

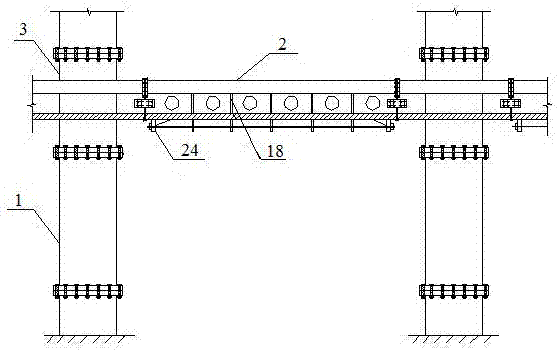

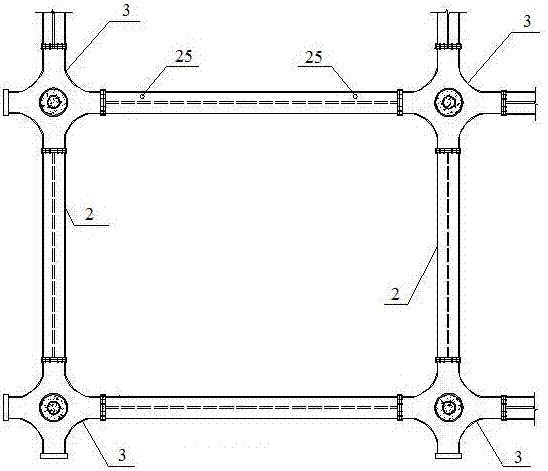

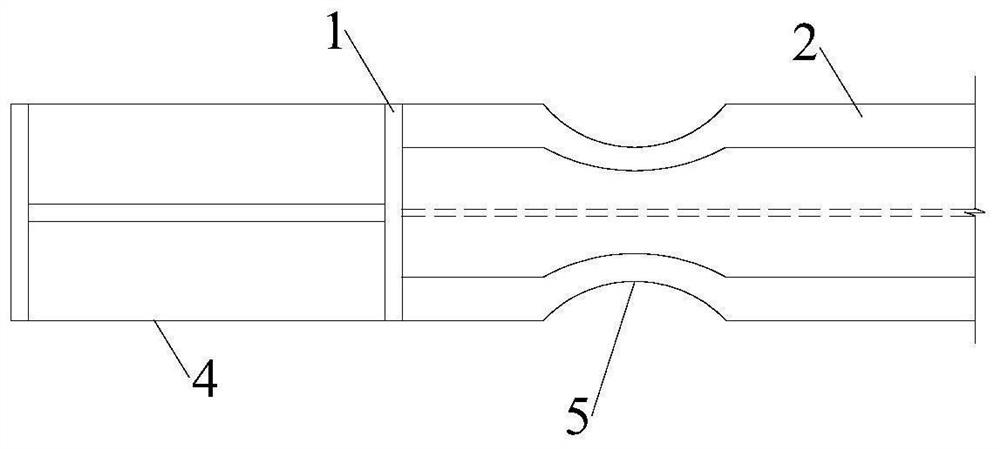

Steel-concrete beam and column connection joint with weakened section and construction method of steel-concrete beam and column connection joint

PendingCN110453782AImprove connection strengthReduce on-site workloadBuilding constructionsConcrete beamsEngineering

The invention relates to the technical field of fabricated building construction, and discloses a steel-concrete beam and column connection joint with a weakened section and a construction method of the steel-concrete beam and column connection joint. The steel-concrete beam and column connection joint comprises a concrete column, a crossbeam and the weakened section for connecting the crossbeam with the concrete column, a steel sleeve is arranged on the position, connected with the crossbeam, of the surface of the concrete column, the weakened section is arranged at the end of the crossbeam,a connecting end plate is arranged at the end of the weakened section, the surface of one side of the connecting end plate and the surface of the steel sleeve are attached and fixed by a split screw,and the split screw penetrates through the connecting end plate and the concrete column and then is fixed through locking of a locking nut; and the weakened section is H-shaped steel with flanges weakened, arc-shaped weakened parts are symmetrically arranged on an upper flange plate and a lower flange plate correspondingly, the distance a between the arc-shaped weakened parts and the surface of the concrete column connected with the arc-shaped weakened parts is 0.5-0.75 time the width of the flange plates of the weakened section, and the distance d between the arc-shaped weakened parts and theend face of the crossbeam is 0.5-0.75 time the width of the flange plates of the weakened section, wherein the formula of d<<a is met. The steel-concrete beam and column connection joint is simple instructure and convenient to mount and demount, and the energy consumption performance of a core area of the connection joint is effectively improved.

Owner:CHINA CONSTR SCI & TECH CO LTD +1

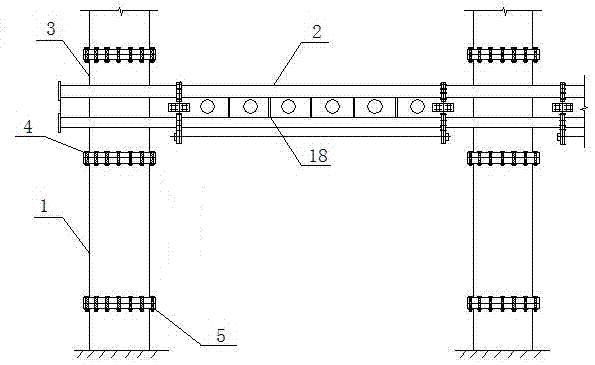

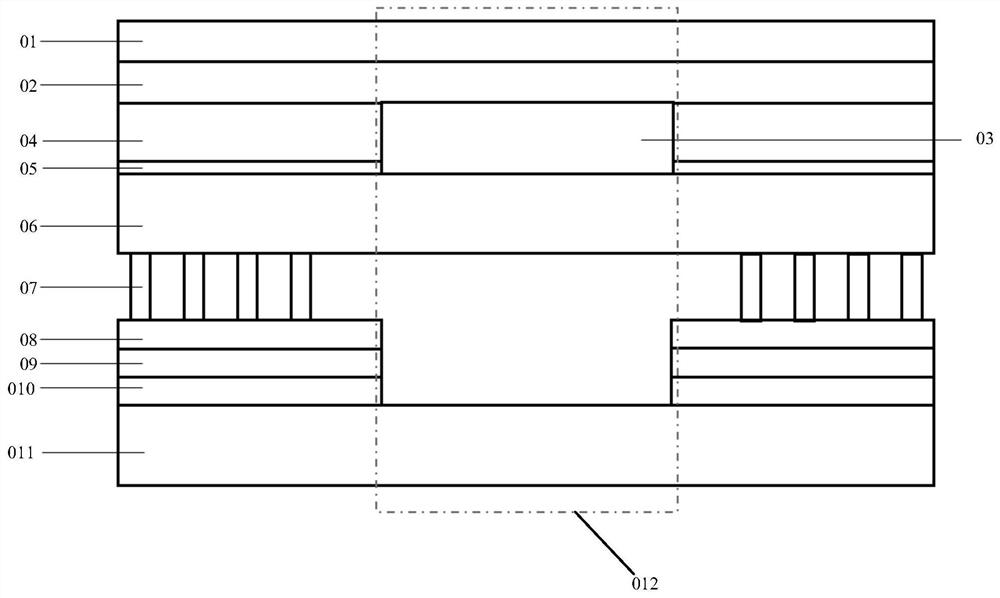

Frame formed from solid-web steel pipe concrete combination columns and combination beam, and construction method thereof

ActiveCN107246109AAvoid breakingPower transmission is clearStrutsProtective buildings/sheltersShaped beamPre stress

The present invention relates to a frame formed from solid-web steel pipe concrete combination columns and a combination beam, and a construction method thereof. The frame is formed by connecting combination columns and a combination beam through a node, wherein the combination beam is horizontally arranged between the combination columns, the node is an outer sleeve integral node filled with self-compacting concrete, the combination column is a segmental solid-web steel pipe concrete combination column, the combination beam is an I-shaped honeycomb concrete beam with an external pre-stress upper flange being rectangular steel pipe, the node is fixedly connected to the combination column through an upper connection ring and a lower connection ring, the node is connected to the combination beam through an end beam connection plate and a node web plate connection plate, and the self-compacting fine-aggregate concrete of the combination beam and the self-compacting fine-aggregate concrete in the upper wing edge steel pipe of the node end beam are communicated to each other. According to the present invention, with the frame and the construction method, the complex problem of the connection node between the solid-web steel pipe concrete combination column and the I-shaped beam having the upper flange being the rectangular steel pipe is solved.

Owner:宁波鼎信土地规划咨询有限公司

Side plate connecting beam and column joint structure and connecting method

PendingCN110359561AImprove connection strengthImprove ductilityBuilding constructionsArchitectural engineeringPlastic hinge

The invention discloses a side plate connecting beam and column joint structure and a connecting method. Two parallelly-arranged transverse reinforcing ribs are arranged between two column flanges ofan H type column, and the planes where the maximum surfaces of the transverse reinforcing ribs are located are simultaneously perpendicular to the planes where the maximum surfaces of the column flanges are located and the plane where the maximum surface of a column web is located; side plates are welded to the H type column, and lug plates are welded to the side plates; and enlarging wing platesare arranged on the two sides of beam flanges of an H type beam in the weak axis direction of the H type column, the end faces of the beam flanges and the enlarging wing plates are welded to the otherside faces of the side plates, and the side faces of the enlarging wing plates are welded to the side faces of the lug plates. Through the arrangement of the enlarging wing plate structures, the connecting strength of a beam and column joint is improved. By the adoption of the joint structure, under the effect of cyclic loading, plastic deformation is concentrated on end beam sections reinforcedby steel beam flange enlarging wings, a joint domain is in an elastic state, outward movement of a plastic hinge on the beam can be well achieved under the effect of cyclic loading, and the requirements of the ductility and the bearing performance of the joint are increased.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

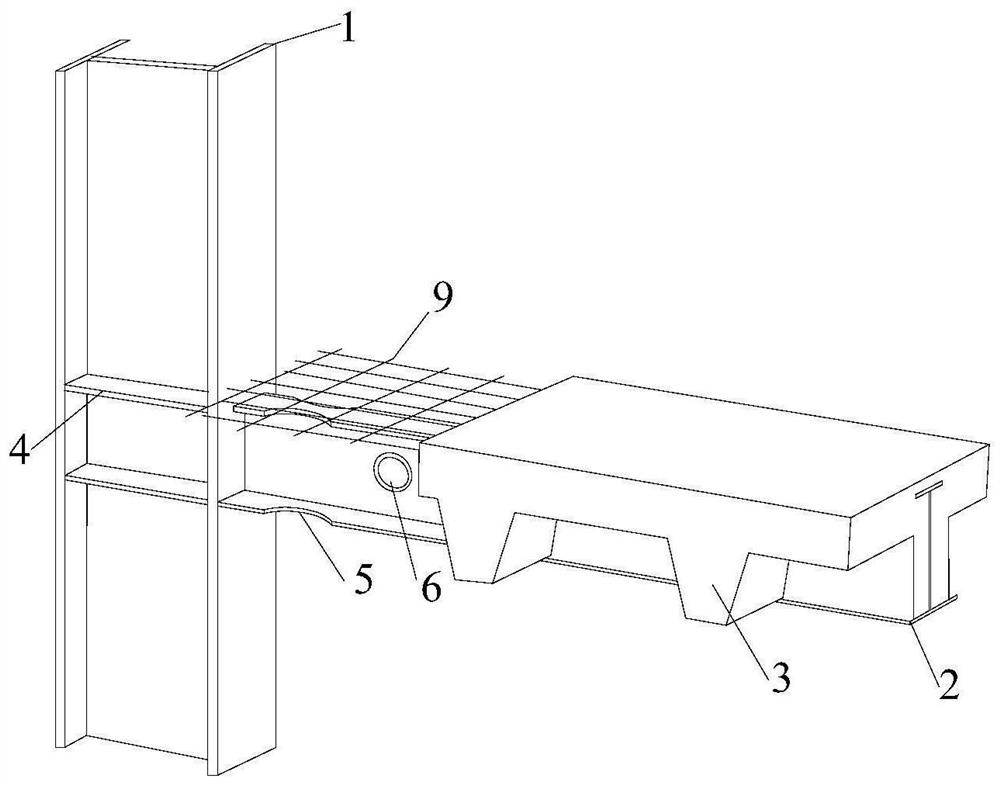

Canine bone-honeycomb type combined flat beam connecting joint

The invention discloses a canine bone-honeycomb type combined flat beam connecting joint, and relates to the technical field of building structures. The canine bone-honeycomb type combined flat beam connecting joint comprises a profile steel component and a profiled steel plate-concrete combined floor slab, wherein the profile steel component is an I-shaped steel column, and the left flange and the right flange of the I-shaped steel column are equal in width; the I-shaped steel column is perpendicular to an I-shaped steel beam, the middle of the right flange of the I-shaped steel column is fixed to the left end of the I-shaped steel beam, the lower flange of the I-shaped steel beam is wider than the upper flange, the upper flange and the lower flange are equal in thickness, and the lower flange and the right flange of the I-shaped steel column are equal in width; and the profiled steel plate-concrete combined floor slab comprises a profiled steel plate which is welded to the lower flange of the I-shaped steel beam in a lap joint mode, a concrete floor slab is arranged above the profiled steel plate, and a reinforcing mesh penetrates through the concrete floor slab. The canine bone-honeycomb type combined flat beam connecting joint has the advantages that the end flanges of the I-shaped steel beam are weakened in a canine bone mode, stress concentration of a honeycomb type combined flat beam joint welding seam area is relieved, the risk of brittle fracture of the joint area under the action of cyclic load is avoided, outward movement of a plastic hinge is realized, and the anti-seismic property is good.

Owner:CHANGAN UNIV

Framework composed of prestressed composite beams of system and construction method thereof

The invention relates to a framework composed of prestressed composite beams of a system and a construction method thereof. The framework composed of the prestressed composite beams of the system is formed by connecting composite columns with the composite beams through joints. The composite beams are horizontally arranged between the composite columns. The joints are outer sleeve integrated joints filled with self-compacting concrete. The composite columns are sectional hollow tubular concrete composite columns. The composite beams are system prestressed honeycombed I beams with flanges being rectangular steel tube concrete. Prestressed tendons arranged in rectangular steel tubes in the lower flanges of the composite beams are located in lower reinforcing cavity annular plates and bypass joint outer tubes. The prestressed tendons are positioned through single-hole positioning plates and double-hole mainpositioning plates with holes and subjected to tensioning anchorage at joint end beams. The self-compacting fine aggregate concrete of the composite beams communicates with self-compacting fine aggregate concrete of the joint end beams. By adoption of the framework, the complexity problem of the connecting joints between the system prestressed I beams with the flanges being made of rectangular steel tube concrete and the hollow tubular concrete composite columns is solved.

Owner:青岛绿建集成科技有限公司

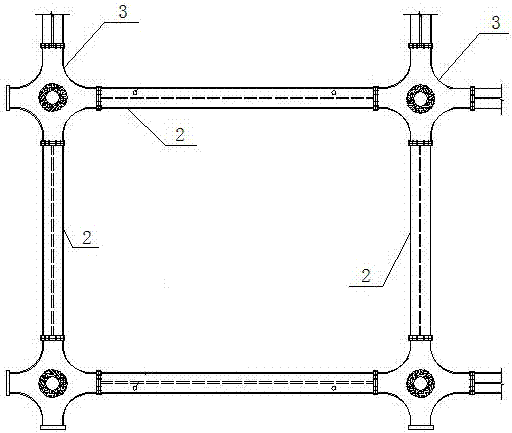

Frame system composed of hollow steel pipe concrete integral joints and construction method

ActiveCN106869326ANode force transmission is clearEasy constructionBuilding constructionsHigh strength concretePre stress

The invention relates to a frame system composed of hollow steel pipe concrete integral joints and a construction method. The frame system composed of the hollow steel pipe concrete integral joints is formed by connecting composite columns with composite beams through the joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with high-strength concrete. The composite columns are sectional type hollow steel pipe concrete composite columns. The composite beams are sectional type external-prestressing honeycombed I-shaped beams. Beam connecting plates are arranged on the side faces of the two ends of the sectional type external-prestressing honeycombed I-shaped beams. Lower beam projecting plates are arranged at the lower ends of the beam connecting plates provided with bolt holes and further provided with prestressing tendon holes. Prestressing tendons are tensioned and anchored through the lower beam projecting plates. The joints are fixedly connected with the composite columns through upper connecting rings and lower connecting rings and connected with beam connecting plates of the composite beams through lower joint projecting plates. The problem of connecting complexity of the hollow interlayer steel pipe concrete columns and the beam joints is solved.

Owner:广西大业建设集团有限公司

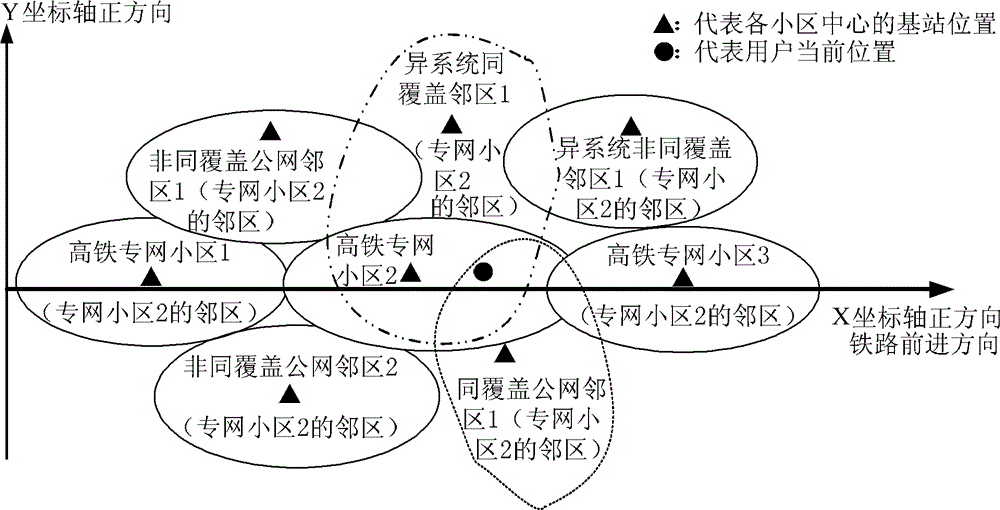

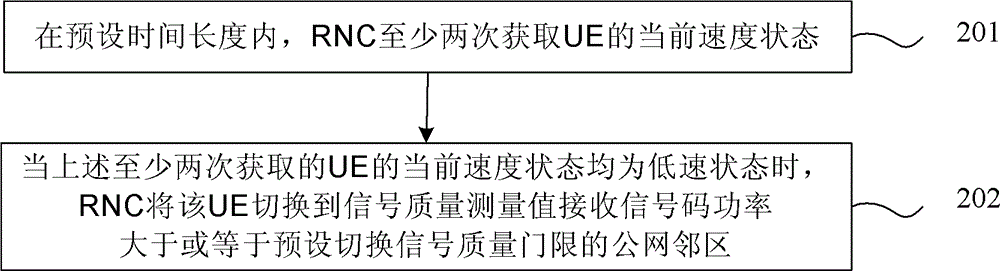

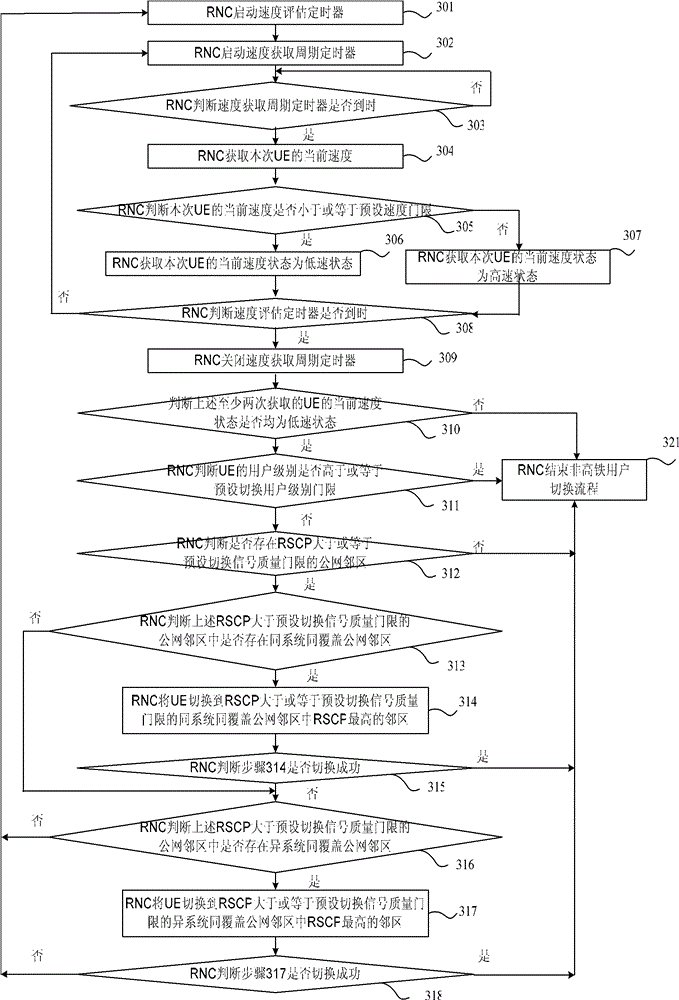

Non high-speed rail user switching method and radio network controller (RNC)

InactiveCN102938917BMove outAvoid interferenceWireless communicationCurrent velocityTelecommunications

The invention provides a non high-speed rail user switching method and a RNC. In a preset time, current speed states of a user experience (UE) are obtained for at least two times, when the UE current speed states which are obtained for the at least two times are low-speed states, the UE is switched to a public network adjacent region with received signal code power (RSCP) larger than or equal to a preset switching signal quality threshold. By aid of the non high-speed rail user switching method and the RNC, non high-speed rail users accessed in high-speed rail private networks can quit the high-speed rail private networks, non high-speed rail users are prevented from staying in high-speed rail private network areas, occupying high-speed rail private network resources and interfering high-speed rail users.

Owner:TD TECH COMM TECH LTD

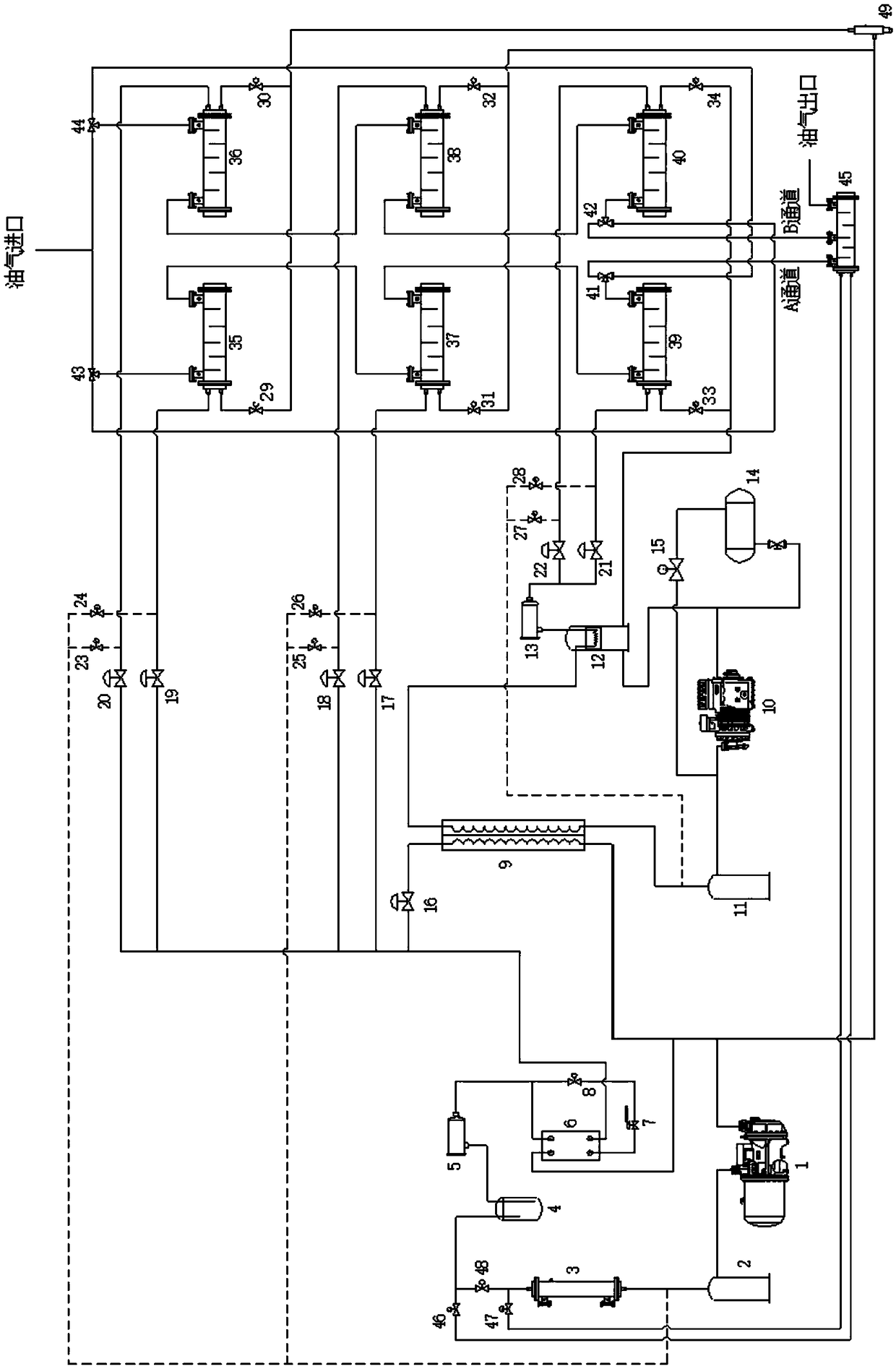

Double-heat-source defrosting oil gas recovery set capable of preventing refrigerant from migration

PendingCN109210816AShort defrost timeImprove the thoroughness of defrostingCompressorMechanical apparatusThree levelProcess engineering

The invention discloses a double-heat-source defrosting oil gas recovery set capable of preventing a refrigerant from migration. The set comprises a primary compressor refrigeration system, a secondary compressor refrigeration system, a three-level condensation bi-channel oil gas system and a double-heat-source defrosting system. Refrigerant high-temperature hot gas is combined with high temperature inlet oil gas effectively, exhausted high-temperature refrigerant gas is input to a pipe for heating defrosting when the set runs for defrosting, the high temperature hot oil gas carries out defrosting outside the pipe, defrosting is carried out in the two manners, defrosting time can be shortened greatly, and defrosting is more thorough .

Owner:NANJING WUZHOU REFRIGERATION GRP

Frame composed of composite columns and composite beam and construction method of frame

ActiveCN106869320AAvoid breakingPower transmission is clearProtective buildings/sheltersBuilding material handlingPre stressHoneycomb

The invention relates to a frame composed of composite columns and a composite beam and a construction method of the frame. The frame composed of the composite columns and the composite beam is formed by connecting the composite columns and the composite beam through joints. The composite beam is horizontally arranged between the composite columns. The joints are integrated sleeving joints filled with self-compacting concrete. The composite columns are sectional hollow tube concrete composite columns. The composite beam is a honeycomb type I beam with an external prestressed flange being a rectangular concrete filled steel tube. The joints are fixedly connected with the composite columns through upper connecting rings and lower connecting rings and connected with the composite beam through end beam connecting plates and joint webs. Self-compacting fine aggregate concrete is poured into the composite beam and joint end beams of the joints. After the self-compacting fine aggregate concrete is poured, the self-compacting fine aggregate concrete of the composite beam communicates with the self-compacting fine aggregate concrete of the joints, and the joints are integrated with joint outer tubes after curing. By adoption of the frame composed of the composite columns and the composite beam and the construction method of the frame, the problem that connection joints of hollow sandwich concrete filled steel tubular columns and I beams with flanges being rectangular steel tubes are complex is solved.

Owner:青岛同建工业科技有限公司

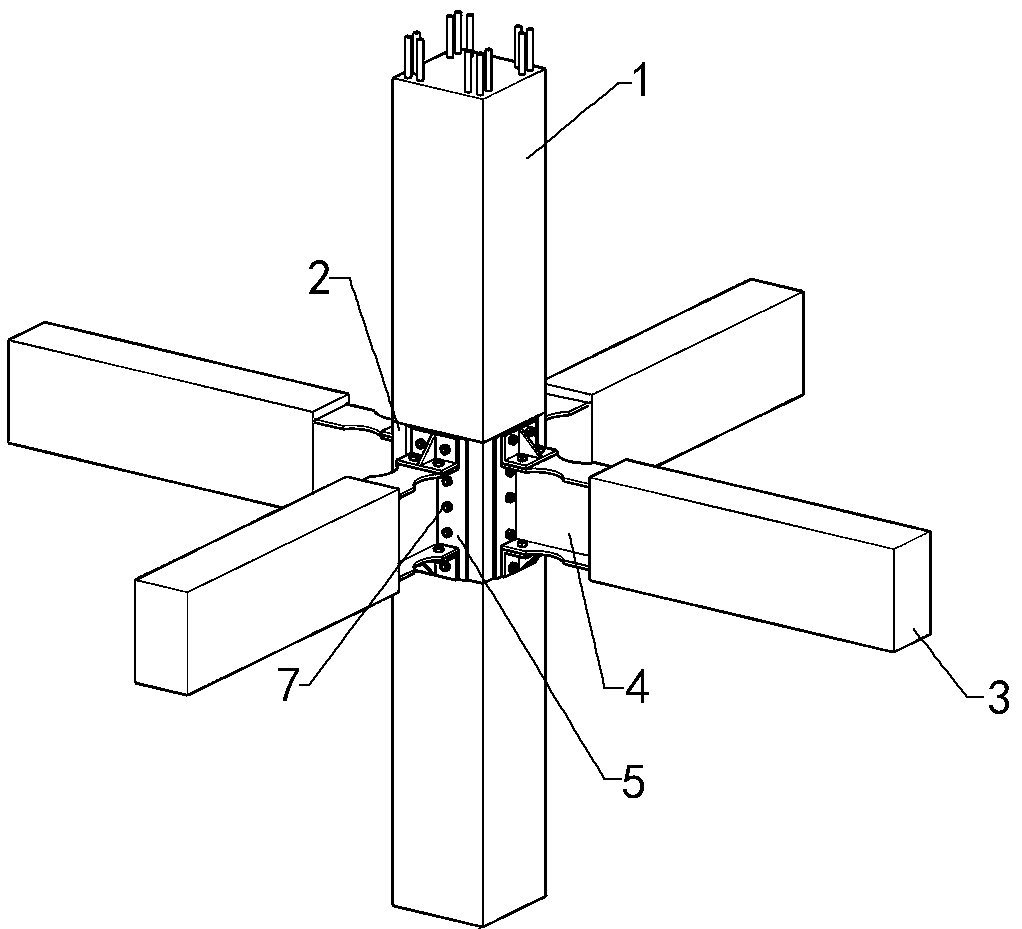

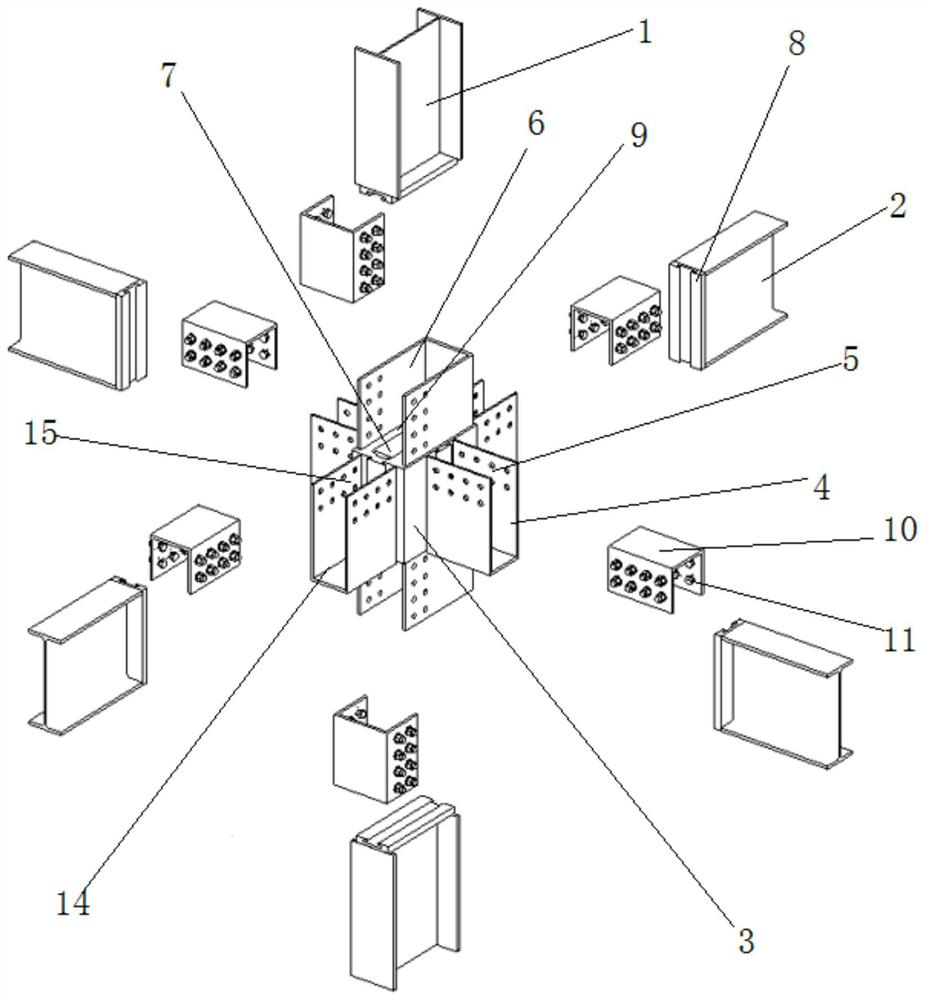

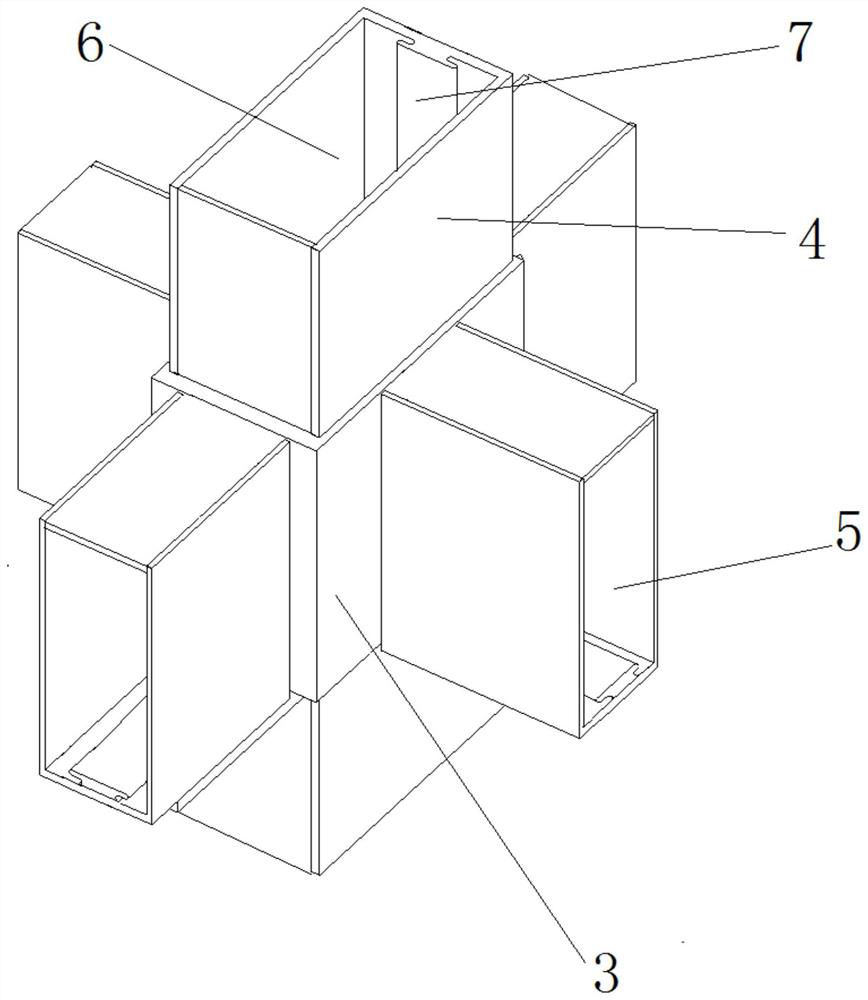

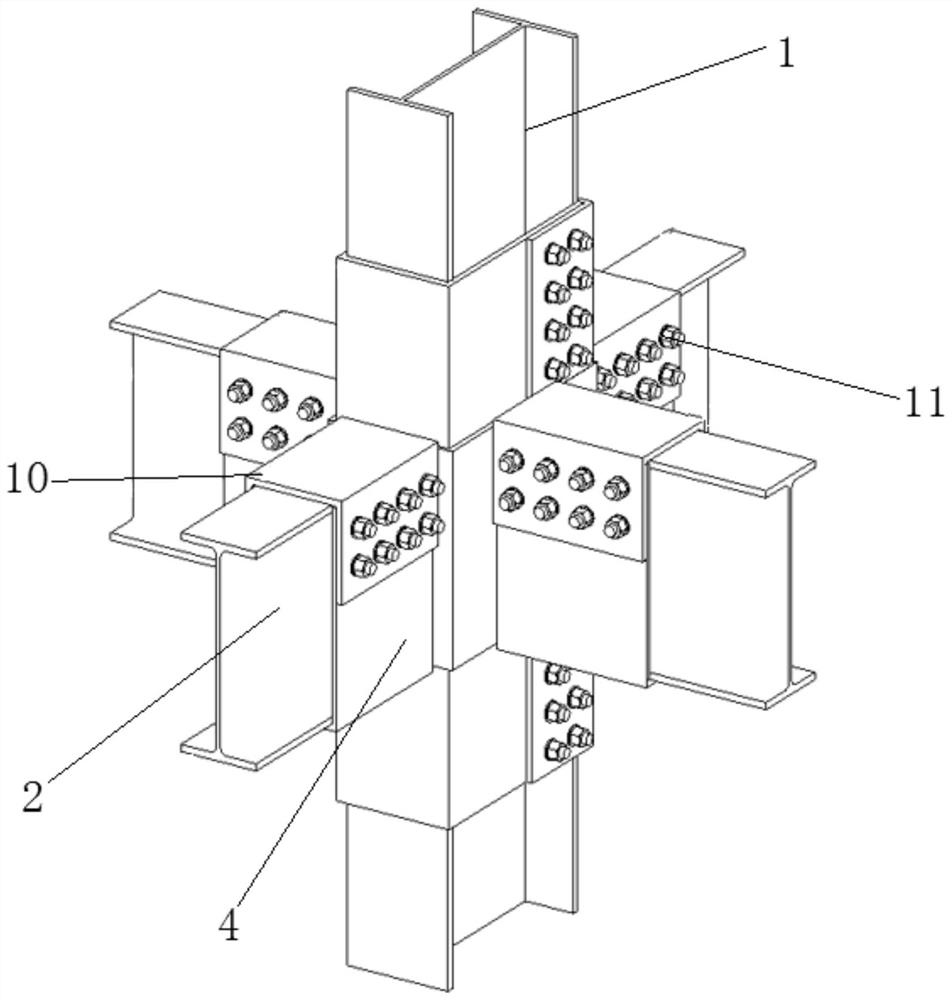

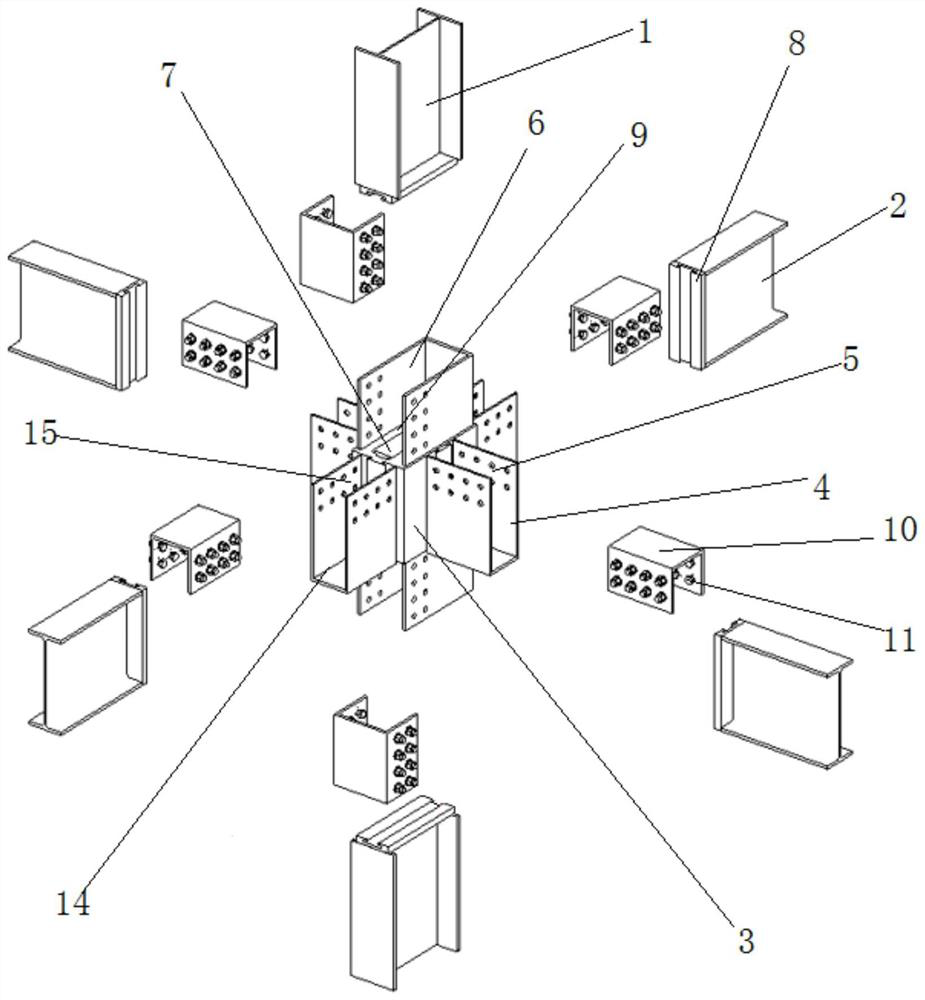

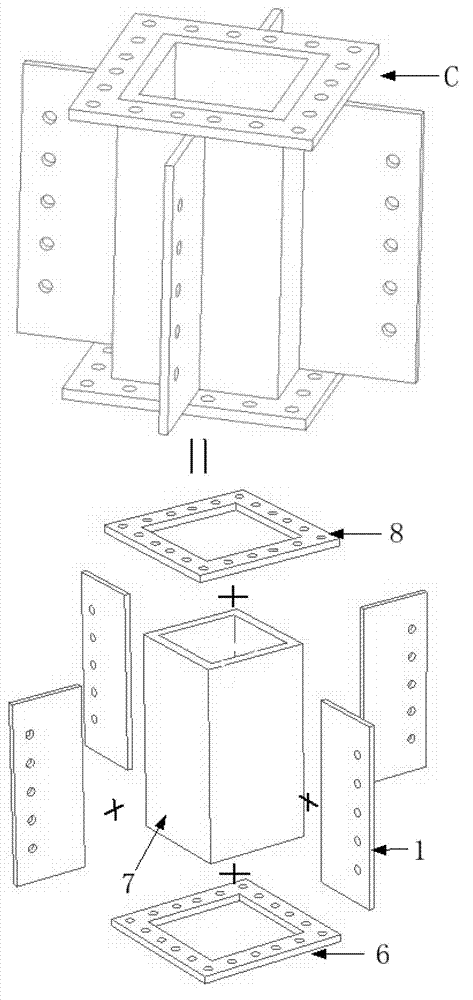

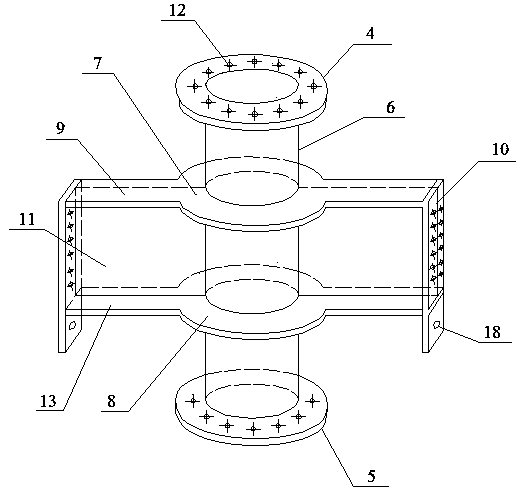

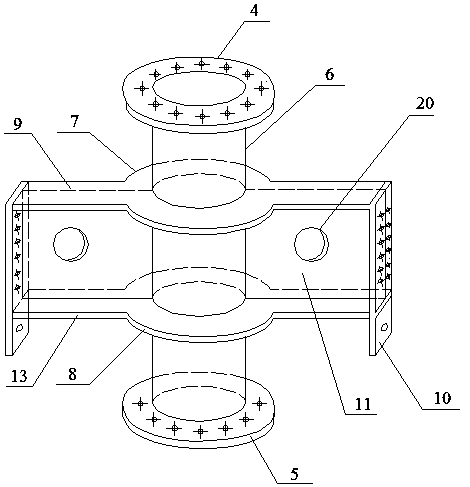

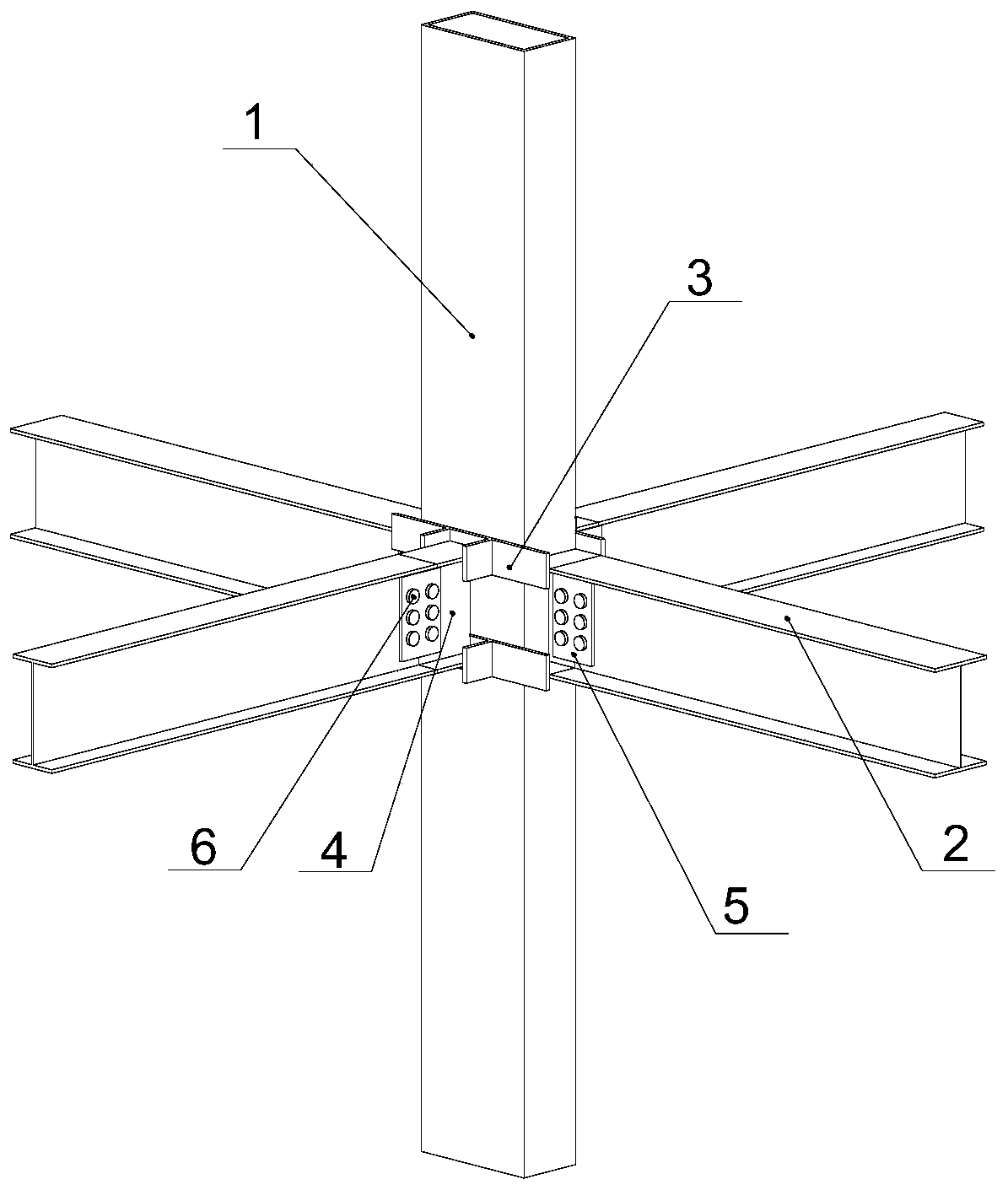

Steel structure assembly type beam column joint connecting device

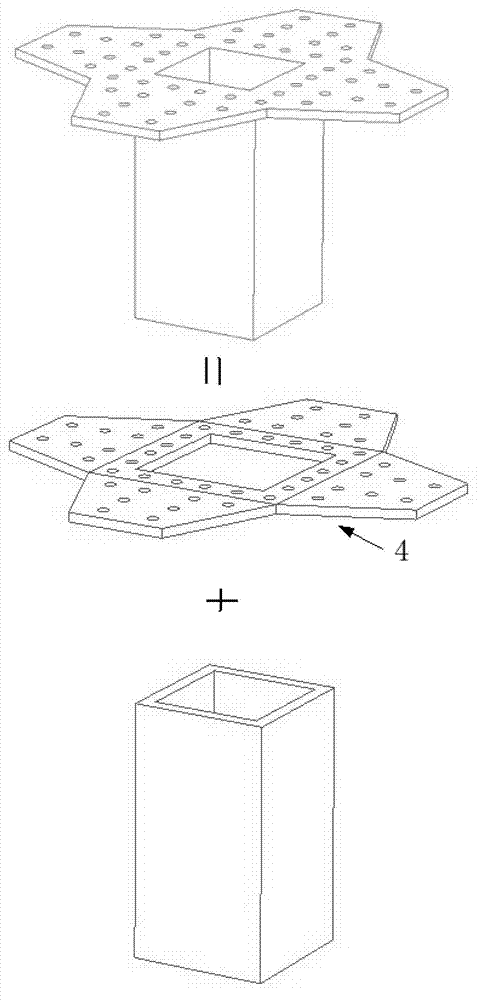

ActiveCN112681518ASave shipping spaceReduce shipping costsBuilding constructionsMechanical engineeringBeam column

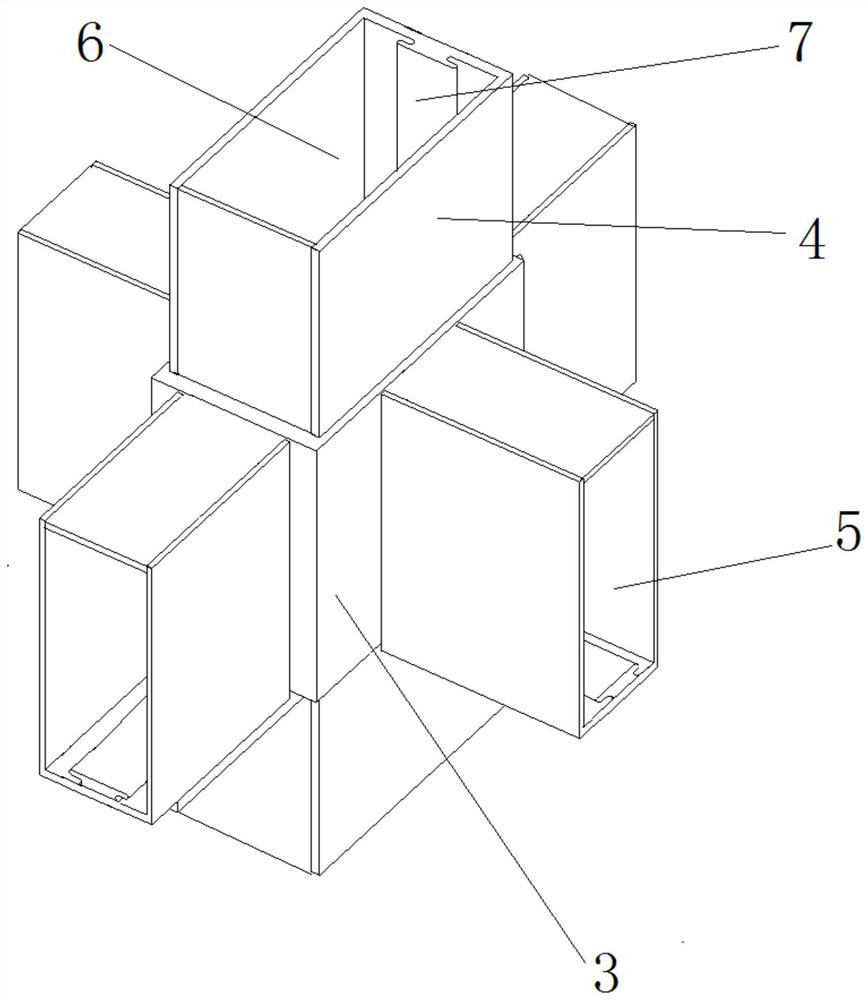

The invention discloses a steel structure assembly type beam column joint connecting device which is used for connecting a plurality of stand columns and a plurality of cross beams. The stand columns are fixedly connected through connecting boxes, the cross beams are fixedly connected through connecting boxes, and the cross beams and the stand columns are fixedly connected through connecting boxes; box-shaped connecting pieces are arranged in at least two of the six directions of each connecting box; each box-shaped connecting piece is provided with at least one opening; and at least one inner box face of each box-shaped connecting piece is provided with a guide rail. According to the steel structure assembly type beam column joint connecting device, all components are divided into parts and are connected into a whole through bolts on site. The beams, the columns and the joint connecting pieces form the whole structure. The beams and the columns are all straight rod components, the transportation space is greatly reduced, and therefore the transportation cost is effectively saved.

Owner:北京赛博思工程技术研究院

A steel structure assembled beam-column joint connection device

ActiveCN112681518BSave shipping spaceReduce shipping costsBuilding constructionsMechanical engineeringTransportation cost

This application discloses a steel structure assembled beam-column node connection device, which is used to connect several columns and several beams, between the columns and columns, between the beams and beams, and between the beams and the columns They are all fixedly connected through a connection box. Box-shaped connectors are provided in at least two directions of the six directions of the connection box. At least one opening is provided on the box-shaped connector. At least one of the box-shaped connectors has an inner Guide rails are arranged on the box surface. The assembly-type beam-column joint connection device of the steel structure provided in the embodiment of the present application converts each component into parts, and connects each component into a whole through bolts on site. Beams, columns, and node connectors make up the overall structure. The beams and columns are all straight rod components, which greatly reduces the transportation space, thus effectively saving the transportation cost.

Owner:北京赛博思工程技术研究院

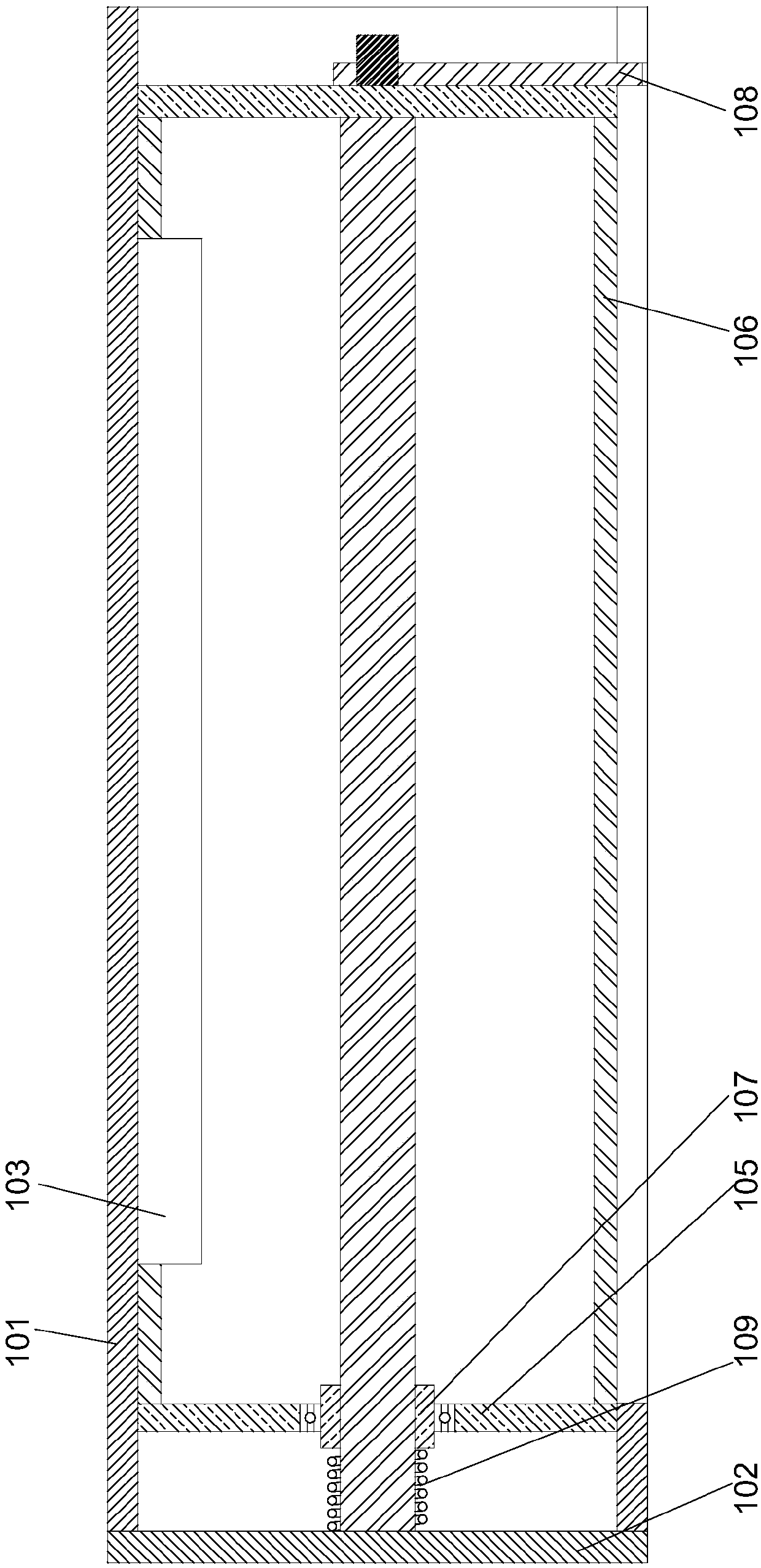

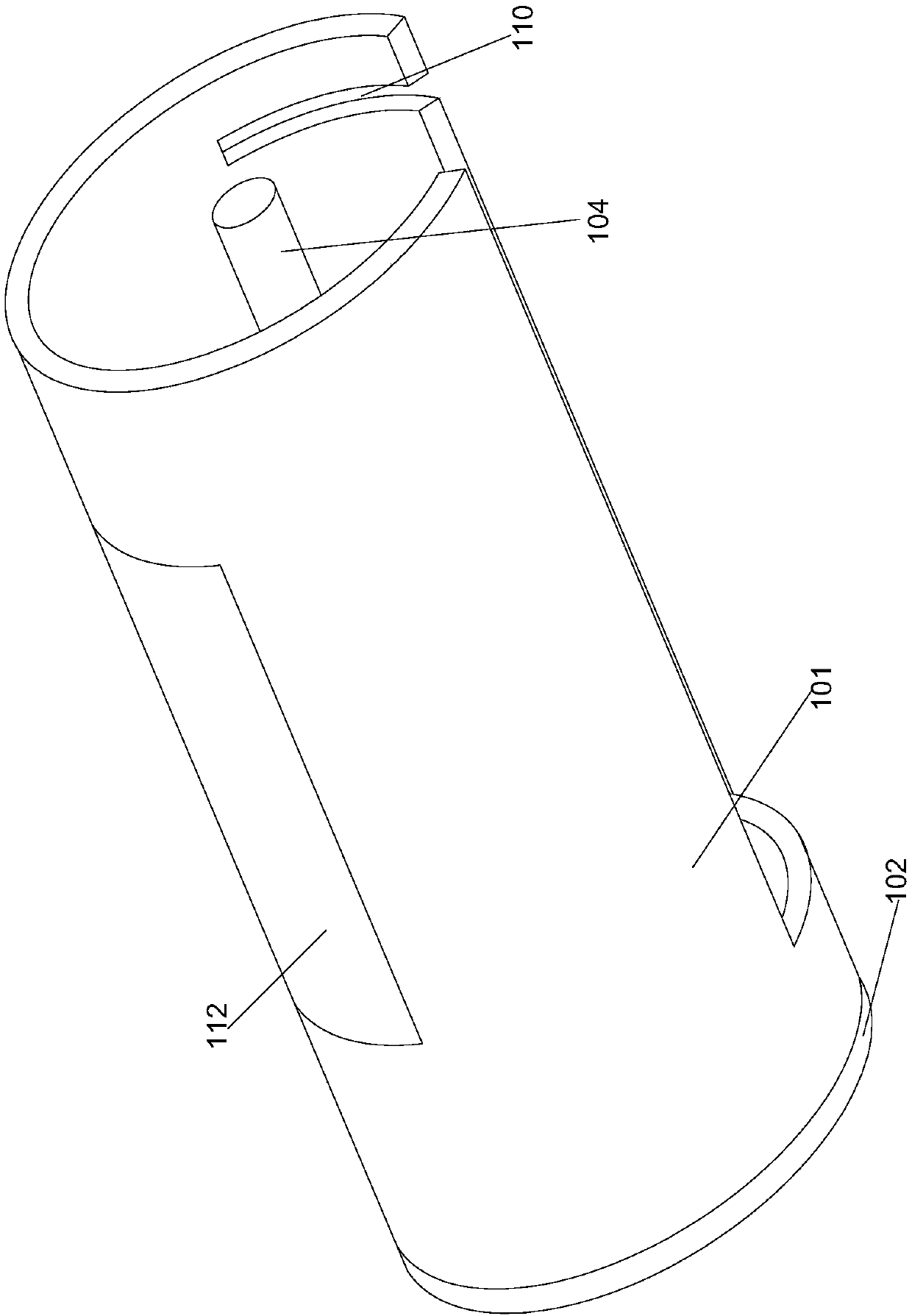

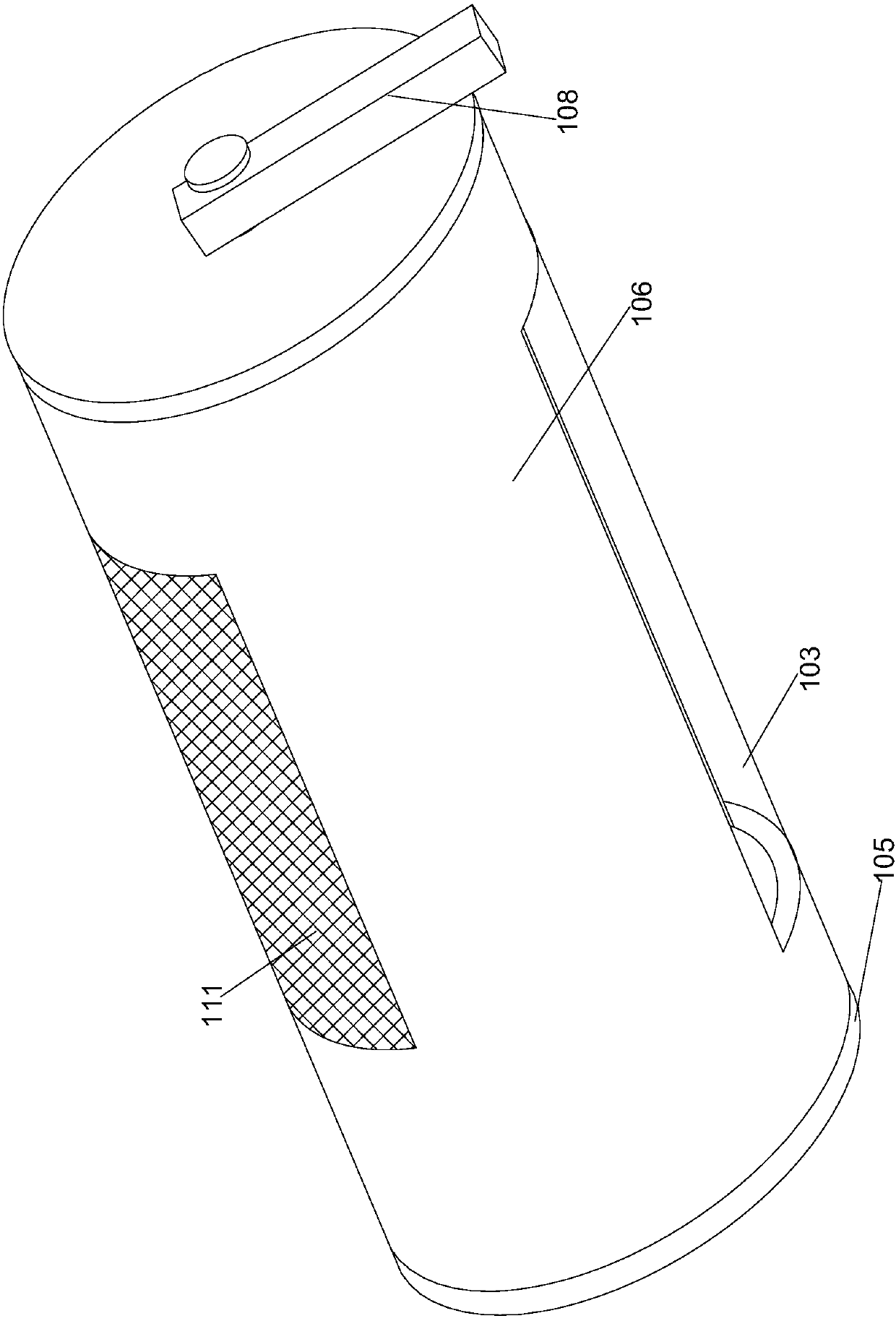

Rotary individual bee sampling mechanism

InactiveCN107668002AEasy structure and operationEasy to put inInsect catchers and killersAgricultural engineeringCentral cylinder

The invention discloses a rotary honeybee monomer sampling mechanism, which comprises a cylindrical barrel, a base is arranged at one end of the barrel, and the top view of the barrel is a 3 / 4 circle. The middle part of the cylinder body is provided with a rotating shaft coaxial with it, and one end of the rotating shaft is fixedly connected to the middle part of the base, and an inner tube is sleeved outside the rotating shaft, and the length of the inner tube is less than or equal to the length of the barrel The length of the body, the outer diameter of the inner tube is equal to the inner diameter of the cylinder, and the side wall of the inner tube is provided with an opening so that the top view of the middle part of the inner tube is a 3 / 4 circle. The two ends of the inner tube are respectively provided with sealing covers, and the sealing covers at the end close to the base are sleeved on the rotating shaft and can rotate relative to the rotating shaft. The invention can be used for storing bee samples, and can improve the defects that the existing screw cap type bee sample equipment has complicated structure and easy occurrence of bee escape.

Owner:雅安蒋氏蜜蜂园有限公司

Run-through steel plate type square steel tube concrete column and axle i-beam node

InactiveCN101265724BEnsure safetyIncreased bending stiffnessBuilding constructionsSheet steelMaterials science

The invention relates to a square tube concrete column and an I-shaped steel beam joint of threading steel plate type in the technology field of construction engineering, and comprises the square tubeconcrete column, the I-shaped steel beam joint and the threading steel plate. The threading steel plate threads through the wallboard of the square tube concrete column wall plate. The threading steelplate is arranged in a vertical placement manner in the square tube concrete column, in parallel to and with the same height of the web plate of the I-shaped steel beam. A part of the threading steel plate edge protruding from the square tube concrete column is parallel and level with the I-shaped steel beam flange. The invention enhances the total bearing capacity of shearing resistance and bend ing resistance, and guarantees the joint work of the square tube concrete column and the I-shaped steel beam joint.

Owner:SHANGHAI JIAOTONG UNIV

Electronic equipment

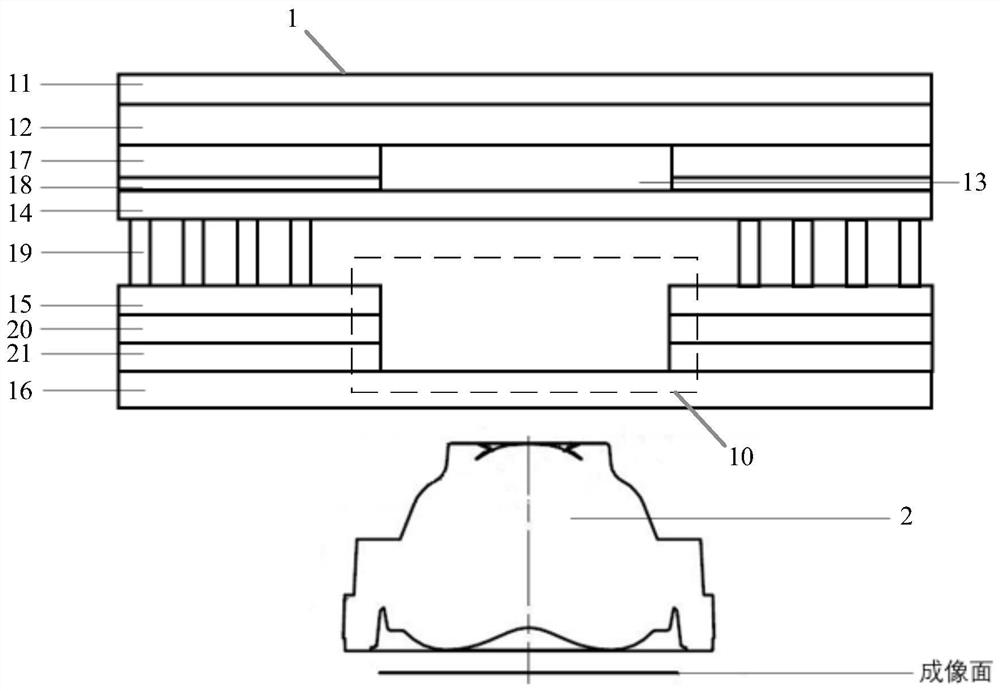

PendingCN112563314AAvoid close focus problemsMove outSolid-state devicesSemiconductor/solid-state device manufacturingLight filterMaterials science

The embodiment of the invention provides electronic equipment, and belongs to the technical field of communication. The electronic equipment comprises a screen and a camera. A cover plate, an adhesivelayer, an optical filter, a packaging layer, a wiring layer and an LTPS layer which are stacked from outside to inside are arranged at the position, corresponding to the camera, of the screen; the optical filter is located in an orthographic projection area of the camera on the screen; and an opening is formed in the wiring layer and is positioned in the orthographic projection area of the cameraon the screen. In the embodiment of the invention, the optical filter is arranged in the screen, and an adhesive structure is adjusted so that on one hand, a near-focus problem of the camera caused by an adhesive bulge phenomenon in a pole screen is avoided, and on the other hand, the optical filter is arranged in the screen instead of being arranged in the camera, outward movement of the opticalfilter is realized and the back focus of a lens is shortened; and therefore, the height of the camera is reduced, and an overall thickness is decreased.

Owner:VIVO MOBILE COMM CO LTD

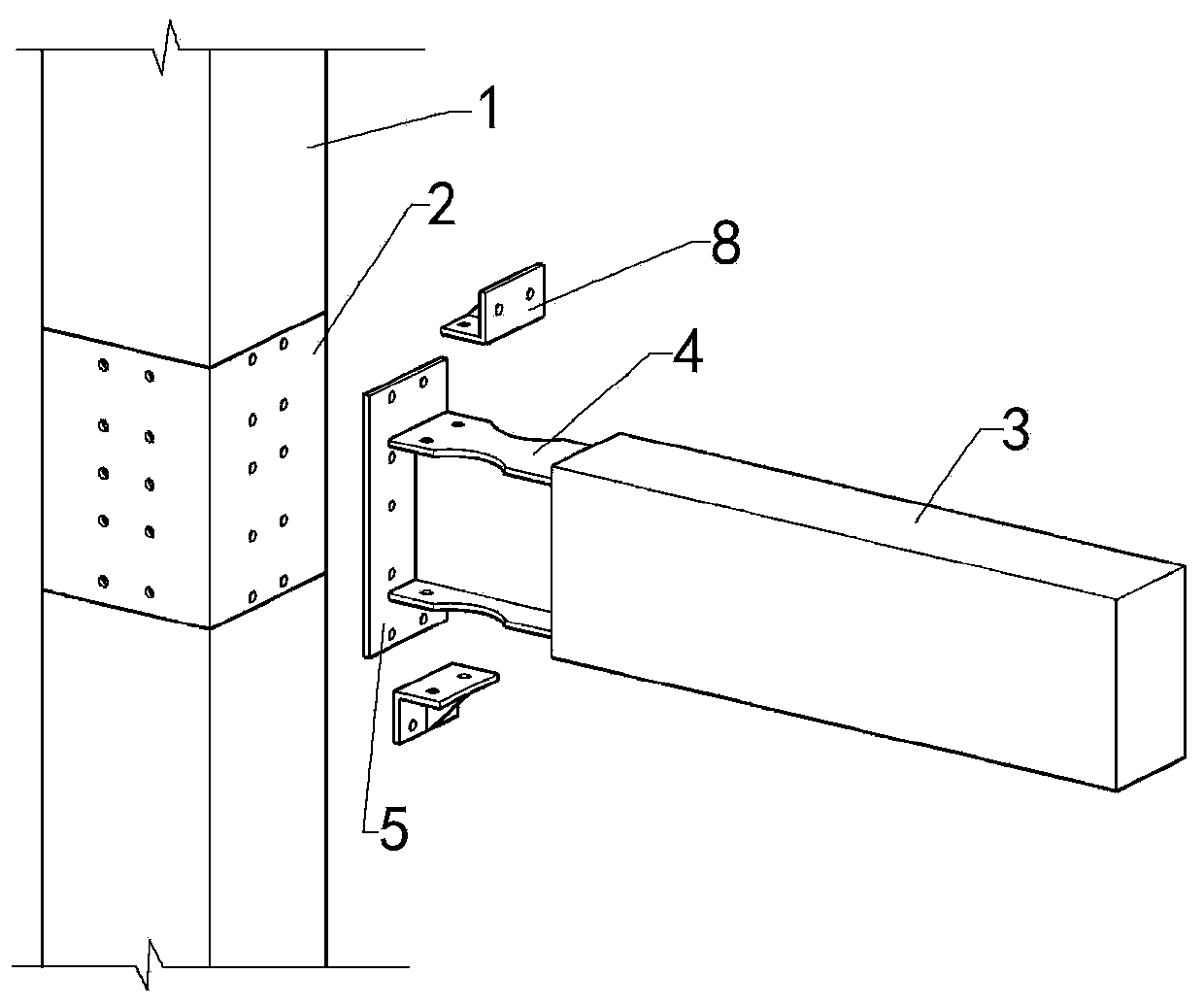

Beam-column joint connecting device of assembled steel structure system

ActiveCN103015537BEasy to operateImprove assembly speedBuilding constructionsBeam columnCivil/structural engineers

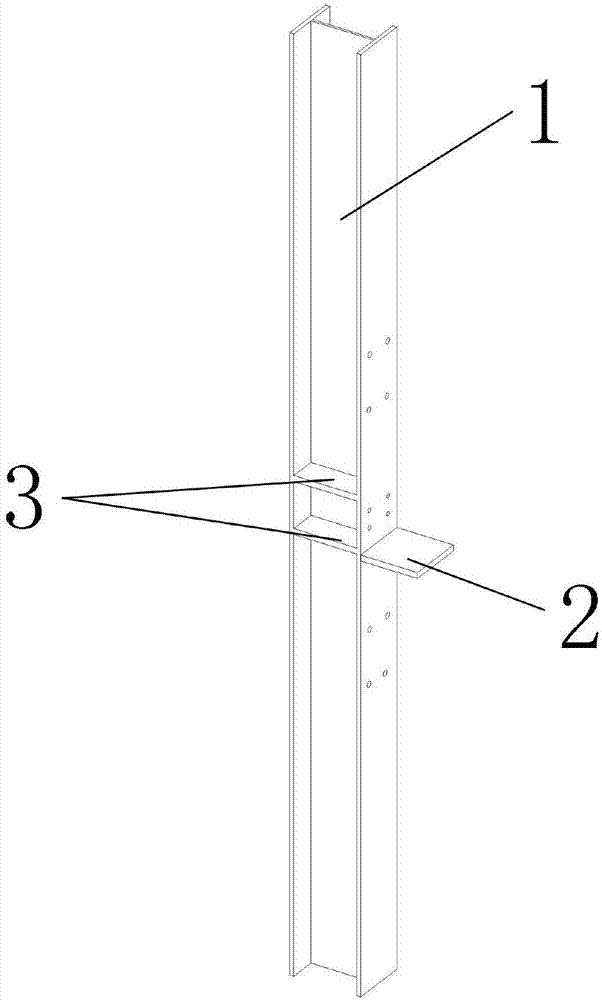

The invention relates to a beam-column joint connecting device of an assembled steel structure system, which belongs to the technical field of structural engineering. The beam-column joint connecting device comprises a column base connecting plate, beam end connecting plates, a stiffening plate, an upper column flange, a lower column flange, a truss girder end upper chord member, a truss girder end lower chord member, a joint short column lower end flange, a joint short column and a joint short column upper end flange, wherein the column base connecting plate, the joint short column, the joint short column lower end flange and the joint short column upper end flange can be welded into a whole in a factory; two beam end connecting plates and the truss girder end upper chord member and the truss girder end lower chord member are welded into a whole in the factory; and the beam end connecting plates are connected with the column base connecting plate through bolts. Welding of the beam-column joint connecting device disclosed by the invention can be completed in the factory, bolts are adopted for assembling on site, fastening work of bolts is convenient and rapid, the construction speed and quality are improved greatly, and adaptation to the development of an assembled steel structure is realized; and meanwhile, a joint is a rigid joint, and has high ductility and a high bearing capability.

Owner:CHINA RAILWAY CONSTR GROUP +1

Prefabricated concrete beam column connecting joint and connecting method

ActiveCN114000585AMove outGuaranteed bending failureProtective buildings/sheltersShock proofingConcrete beamsArchitectural engineering

The invention discloses a prefabricated concrete beam column connecting joint and a connecting method. The prefabricated concrete beam column connecting joint comprises two prefabricated concrete columns, two prefabricated concrete beams, a plurality of steel bar extrusion sleeves, a central firmware and two auxiliary fixing pieces. the central firmware comprises a cross cylinder and a cross plate; the two ends of the cross cylinder are fixedly connected with one ends of the two prefabricated concrete columns correspondingly; the cross plate is inserted into the cross cylinder; the auxiliary firmware comprises I-shaped steel and two connecting cover plates; the I-shaped steel and the precast concrete beam are integrally formed, and two ends of the I-shaped steel respectively extend out of two end surfaces of the precast concrete beam; one end of the I-shaped steel is fixedly connected with the cross plate through the two connecting cover plates; and the two prefabricated concrete columns are fixedly connected through the cross cylinder and the plurality of steel bar extrusion sleeves. The tensile strength of the prefabricated concrete beam-column connecting joint can be improved, and the shock resistance of a building applying the prefabricated concrete beam-column connecting joint is enhanced.

Owner:NORTHEAST DIANLI UNIVERSITY

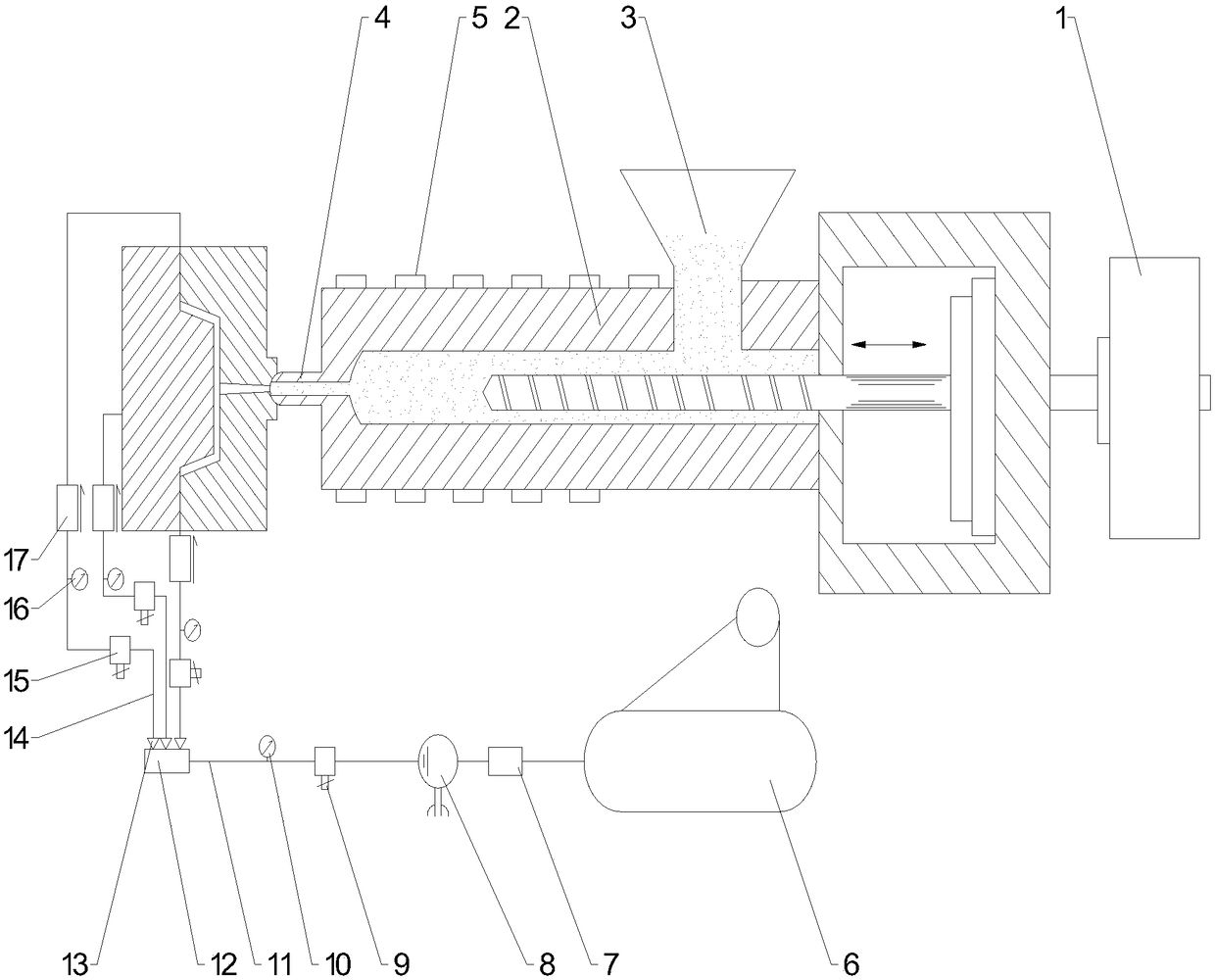

GCP assistant injection molding machine capable of improving surface quality of plastic product

The invention provides a GCP assistant injection molding machine capable of improving surface quality of a plastic product. The machine is characterized in that an air channel is transferred outwardsthrough an external flow division valve and a pipeline. Therefore, the problems of blockage and non-uniform air pressure caused by internal complex air channels can be avoided; and moreover, the flowdivision valve and the pipeline can be recycled, so that the die manufacturing cost can be extremely saved; and the adaptability is high.

Owner:TAICANG QIUJING PLASTIC MOLD

Frame System and Construction Method of Hollow Concrete Steel Tube Integral Joints

ActiveCN106869326BNode force transmission is clearEasy constructionBuilding constructionsHigh strength concretePre stress

The present invention relates to a frame system and a construction method composed of hollow concrete-filled steel tube integral joints. The frame system composed of hollow concrete-filled steel tube integral joints is composed of composite columns and composite beams connected through joints, and the composite beams are arranged horizontally between the composite columns. The joints are jacket integral joints filled with high-strength concrete; the composite column is a segmental hollow tubular concrete composite column, the composite beam is a segmental externally prestressed honeycomb I-beam, and the segmental externally prestressed honeycomb I-beam Both ends of the beam are equipped with beam connection plates, the lower end of the beam connection plate has a beam lower protrusion plate, bolt holes are set on the beam connection plate, prestressed tendon holes are also set on the beam lower protrusion plate, and the prestressed tendons are tensioned and anchored through the beam lower protrusion plate ; The node is fixedly connected to the composite column through the upper connecting ring and the lower connecting ring, and the node is connected to the beam connecting plate of the composite beam through the lower protruding plate of the node. The invention solves the problem of complex connection between the hollow interlayer concrete-filled steel tube column and the beam node.

Owner:广西大业建设集团有限公司

A method for strengthening the exterior joints of reinforced concrete frame structures

ActiveCN107435445BImprove seismic performanceIncreased shear strengthClimate change adaptationBuilding repairsFiberRebar

Owner:SHANGHAI INST OF TECH

Pi-shaped piece node of flat steel tube concrete column

The invention discloses a pi-shaped piece node of a flat steel tube concrete column. The pi-shaped piece node of the flat steel tube concrete column includes four corbels for being connected to a flatsteel tube concrete column of a rectangular structure and further includes four pi-shaped steel plates, the four corbels pass through the four pi-shaped steel plates to be positioned in the positions, used for connecting H-shaped steel beams, of the four side surfaces of the flat steel tube concrete column respectively, the four corbels are also fixedly connected with the connecting side surfacesof the flat steel tube concrete column by a welding method, the four H-shaped steel beams are fixedly connected with the four side surfaces of the flat steel tube concrete column through the four corbels respectively. Compared with a traditional external rib ring plate node, the pi-shaped piece node has a smaller convex angle in a room. The relative positions of beams and columns in a project canbe adjusted by adjusting the position of pi-shaped steel plate legs. The column at the entire joint is not broken, the node stiffness is ensured, the force is reasonable, the concrete is easy to pour, the construction process is simple, and the force transmission is clear.

Owner:TIANJIN UNIV +1

Beam-column joint connecting device for multi-story/high-rise assembly type steel structure system

The invention relates to a beam-column joint connecting device for a multi-story / high-rise assembly type steel structure system, and belongs to the technical field of structural engineering. The device comprises beam end box type connecting pieces, vertical connecting channel steel, upper column flanges, lower column flanges, truss beam end upper and lower chord members, a joint short column lower-end flange, a joint short column and a join short column upper-end flange, wherein the beam end box type connecting pieces, the joint short column, the joint short column upper-end flange and the joint short column lower-end flange can be welded into a whole in a factory; two pieces of vertical connecting channel steel and the truss beam end upper and lower chord members are welded into a whole in the factory; and the two pieces of vertical connecting channel steel are connected with the beam end box type connecting pieces through bolts. Welded parts of the joint connecting device can be finished in the factory, and are assembled in situ by the bolts, the fastening work of the bolts is convenient and quick, the construction speed is greatly increased, the construction quality is greatly improved, and the device is adapted to the development of an assembly type steel structure; and in addition, a joint is a rigid joint, and is high in ductility and bearing capacity.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com