Prestressed full-dry type connection assembly type concrete frame beam-column joint

A technology of beam-column joints and prefabricated concrete, which is applied in the direction of architecture and building construction, can solve the problems of high cost of energy-consuming devices and inconvenient construction, etc., achieve strong energy-dissipating capacity, reduce the reinforcement ratio of stirrups, reduce stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

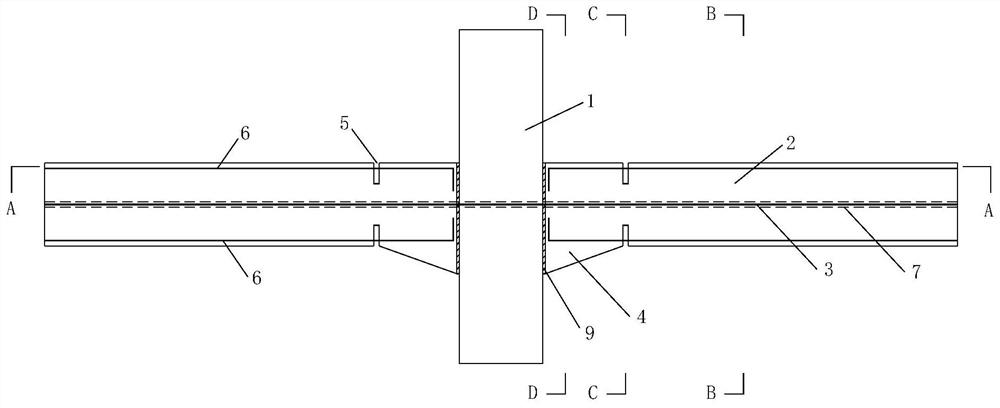

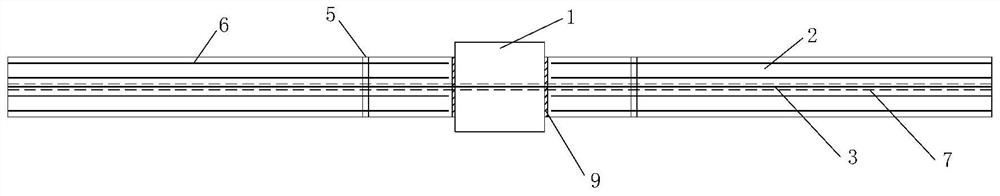

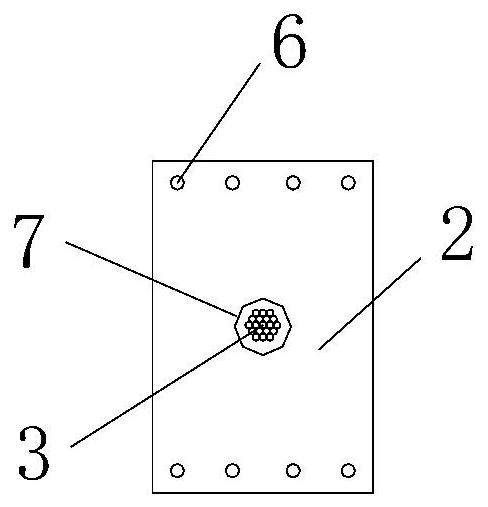

[0045] A prestressed full-handed connection assembled concrete frame beam column node, such as Figure 1 ~ 5 As shown, including prefabricated concrete columns 1, prefabricated concrete beams 2, prestressed ribs 3, plus axis 4, gap 5, and energy consumption 6.

[0046] The pre-concrete column 1 and the preform beam 2 thereof are passed through the pre-stress hole 7 provided in the inner interior of the three, forming a full drying connecting beam node. The prefabricated concrete beam 2 is perfused between the high-strength mortar 9 between the prefabricated concrete beam 2 and the prefabricated concrete column 1. The pre-concrete beam 2 is longitudinally run through a plurality of conventional steel bars 6, and the energy consuming ordinary steel bib 6 does not directly anchor in the beam end by bending form. Prefabricated concrete beam 2 is provided with a plus 4 in the end edge of the prefabricated concrete column 1, the plus 4 length is 0.8 to 1.2 times the prefabricated concret...

Embodiment 2

[0048] A prestressed full-handed connection assembled concrete frame beam column node, such as Figure 6 ~ 10 As shown, including prefabricated concrete columns 1, prefabricated concrete beams 2, prestressed thumbers 3, plus 4, and energy consumption ordinary steel bars 6.

[0049] The pre-concrete column 1 and the preform beam 2 thereof are passed through the pre-stress hole 7 provided in the inner interior of the three, forming a full drying connecting beam node. The prefabricated concrete beam 2 is perfused between the high-strength mortar 9 between the prefabricated concrete beam 2 and the prefabricated concrete column 1. The pre-concrete beam 2 is longitudinally run through a plurality of conventional steel bars 6, and the energy consuming ordinary steel bib 6 does not directly anchor in the beam end by bending form. The prefabricated concrete beam 2 is provided with a plus 4, and the plus 4 length is 0.8 to 1.2 times the prefabricated concrete beam 2 beam. The pre-stretcular ...

Embodiment 3

[0051] A prestressed full-handed connection assembled concrete frame beam column node, such as Figures 11-15 As shown, including prefabricated concrete column 1, prefabricated concrete beam 2, prestressed rib 3, gap 5, and energy consumption ordinary steel 6.

[0052] The pre-concrete column 1 and the preform beam 2 thereof are passed through the pre-stress hole 7 provided in the inner interior of the three, forming a full drying connecting beam node. The prefabricated concrete beam 2 is perfused between the high-strength mortar 9 between the prefabricated concrete beam 2 and the prefabricated concrete column 1. The pre-concrete beam 2 is longitudinally run through a plurality of conventional steel bars 6, and the energy consuming ordinary steel bib 6 does not directly anchor in the beam end by bending form. Prefabricated concrete beam 2 top surface top surface 5, the distance of the gap 5 to the prefabricated concrete beam 2 beam is 0.8 to 1.2 times the preform of the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com