A method for strengthening the exterior joints of reinforced concrete frame structures

A reinforced concrete and frame structure technology, applied in building construction, construction, building maintenance, etc., can solve problems such as poor applicability of space nodes, FRP damage, poor durability, etc., to achieve convenient construction, improve shear strength, and durability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

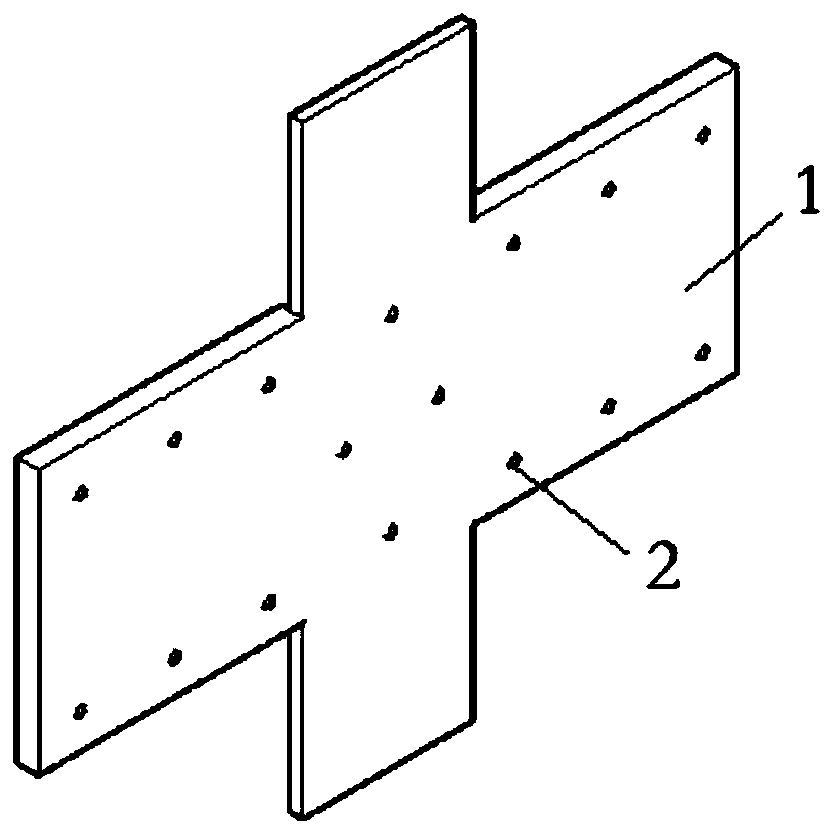

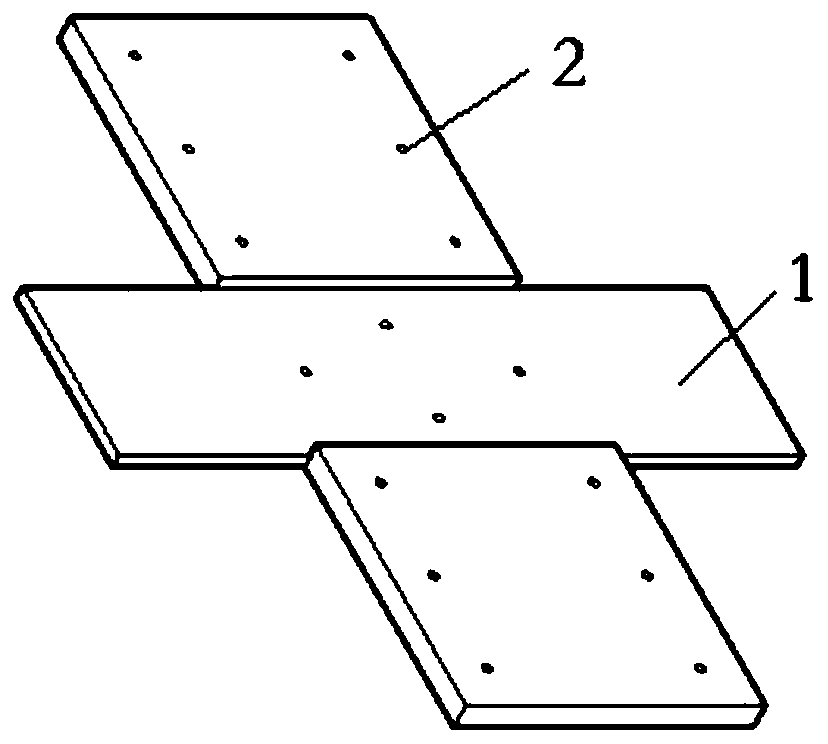

[0068] Please refer to Figure 1a — Figure 4 , taking the node in a side frame as an example, the cross-sectional size of column 3 is 450×450mm, and the cross-sectional size of beam 4 is 350×700mm. Node strong member" problem (such as insufficient configuration of stirrups in the core area).

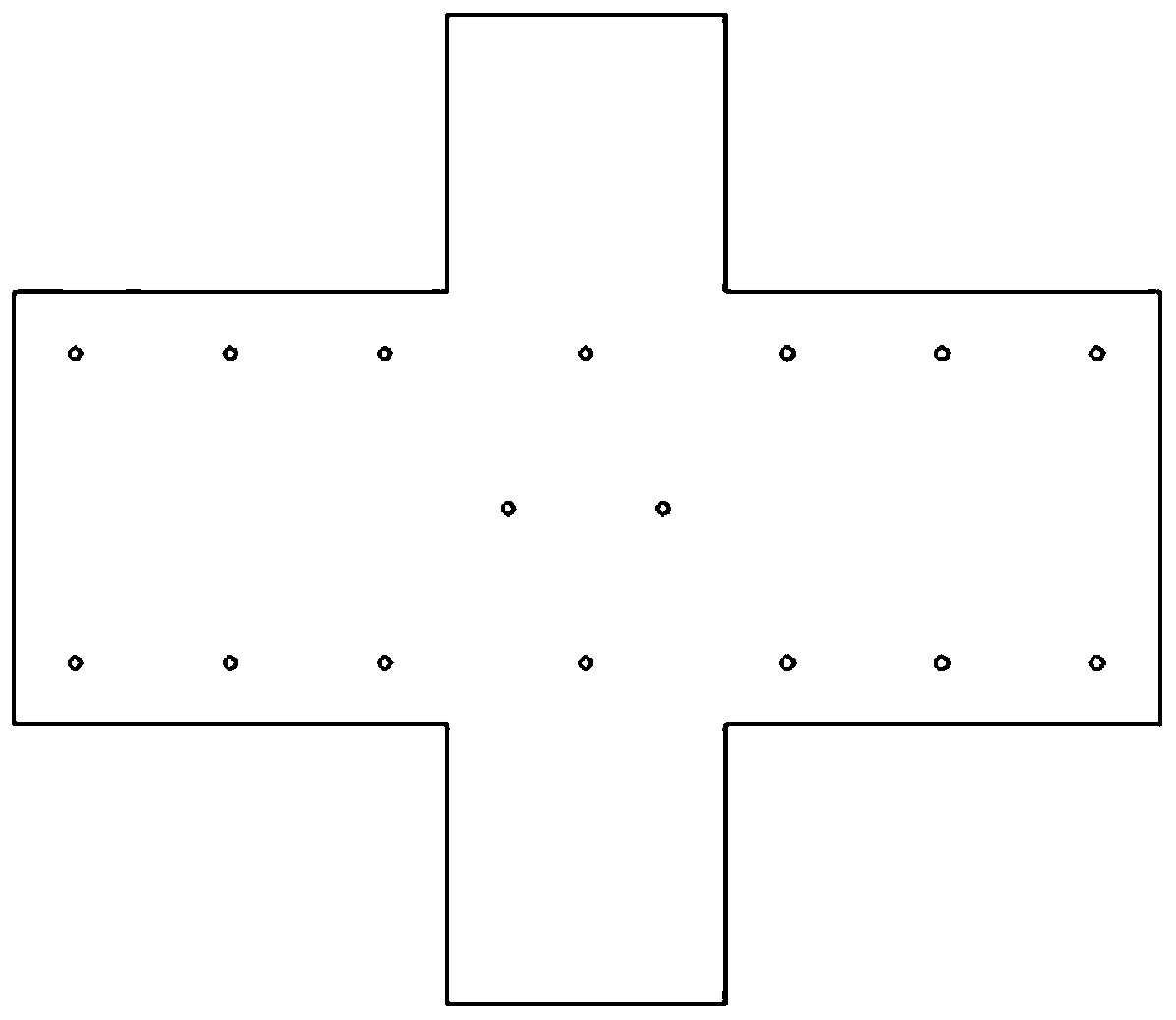

[0069] According to the condition of the nodes to be reinforced, the shape and size of PVA-ECC prefabricated slab 1 are shown in Fig. 1-a, 1-b and 1-c. The column end is 55mm thick. A total of 16 reserved holes 2 are placed symmetrically with a diameter of 18 mm. The core area is distributed in a rhombus shape. The four holes are all located on the midline of each side of the core area and are 100 mm away from each side. The specific positions are shown in Figure 1-c.

[0070] Make the template, ensure that the beam end is 25mm lower than the column bottom membrane, and arrange the foam cylinder with a diameter of 18mm in the corresponding position; then inject the stirred PVA-ECC ma...

Embodiment 2

[0076] Please refer to Figure 5a — Figure 8 , taking the edge joint of a side frame as an example, the cross-sectional size of column 3 is 450×450mm, and the cross-sectional size of beam 4 is 350×700mm. Node strong member" problem (such as insufficient configuration of stirrups in the core area).

[0077] According to the conditions of the nodes to be reinforced, the shape and size of the PVA-ECC prefabricated slab 9 are shown in Figures 5-a, 5-b and 5-c. The column end is 55mm thick. A total of 10 reserved holes 2 are placed symmetrically with a diameter of 18 mm. The core area is distributed in a rhombus shape. The four holes are all located at the center line of each side of the core area and are 100 mm away from each side. The specific positions are shown in Figure 5-c.

[0078] Make the template, ensure that the beam end is 25mm lower than the column bottom membrane, and arrange the corresponding position of the cylindrical foam with a diameter of 18mm; then inject t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com