Plastic container including plastic hinge assembly

a plastic container and hinge technology, applied in the field of plastic containers, can solve the problems of preventing cost-efficient automation, affecting the safety of workers, and affecting the safety of workers, and it is difficult to prevent the pin from working its way ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The container illustrated in FIG. 1 is exemplary as many other container configurations may benefit from the subject matter of the present invention. Additionally, the hinge assembly and the manner of securing the lid(s) to the container body is also exemplary. The invention is not necessarily meant to be limited to the container and hinge assembly shown in the drawings.

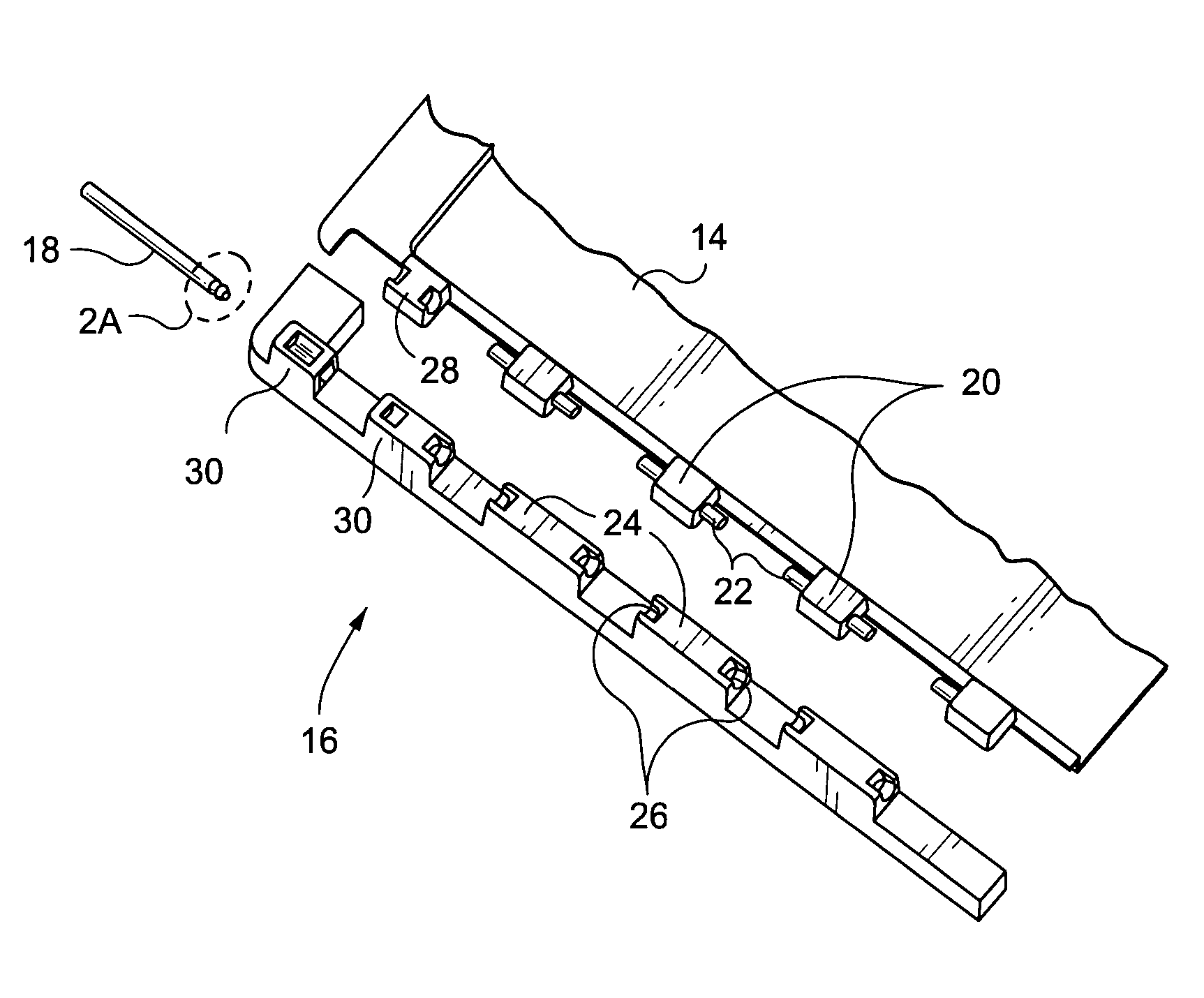

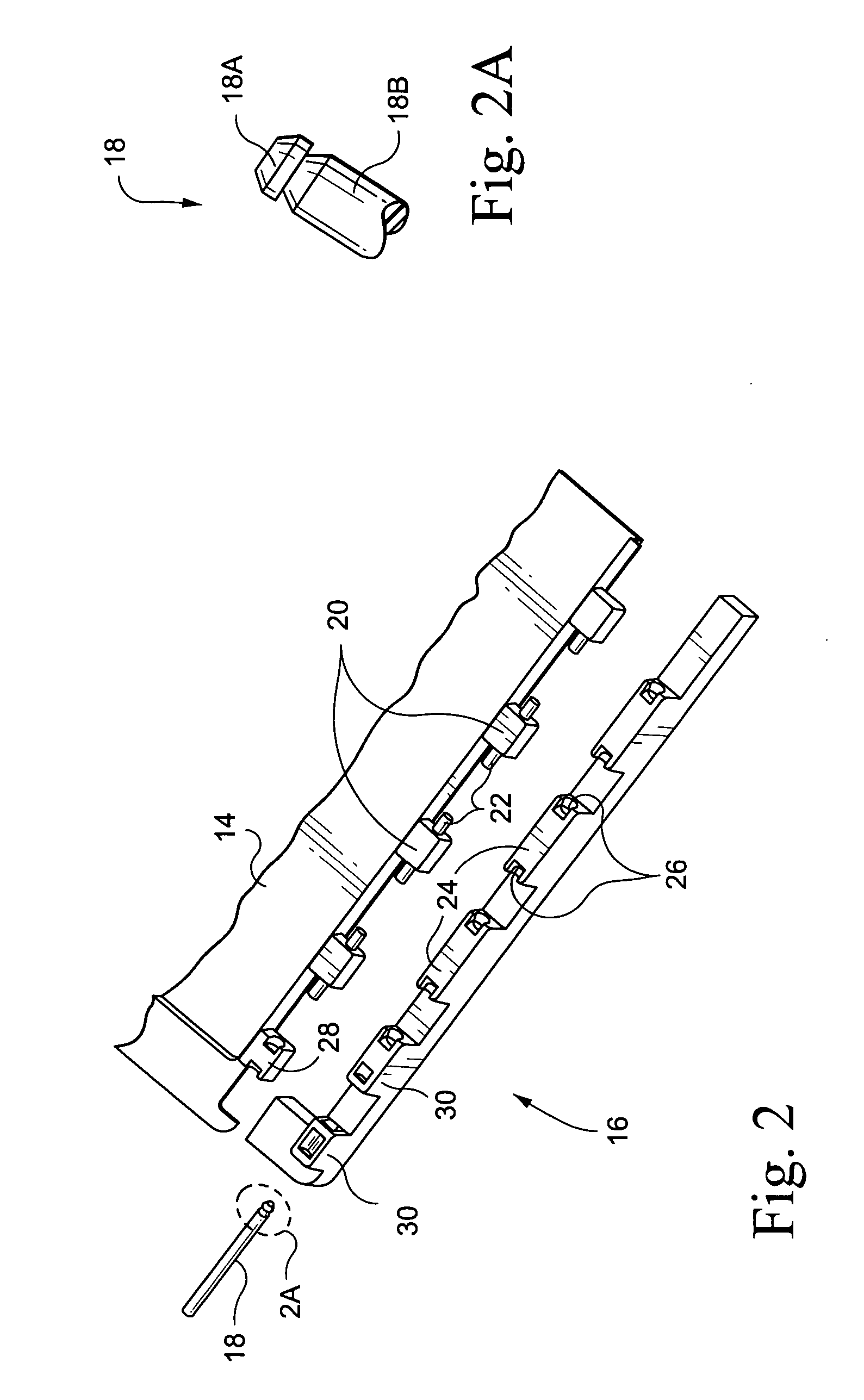

[0017] The container 10 in FIG. 1 includes a main body portion 12 formed by a bottom, side walls and end walls. A pair of complementary shaped lid members 14 are secured via a hinge assembly 16 to an uppermost surface of the side walls as shown. With the exemplary container shown in FIG. 1, in a closed position, the lid members 14 cooperate to close the container 10. Of course, the container 12 may alternatively include a single lid member or even additional lid members.

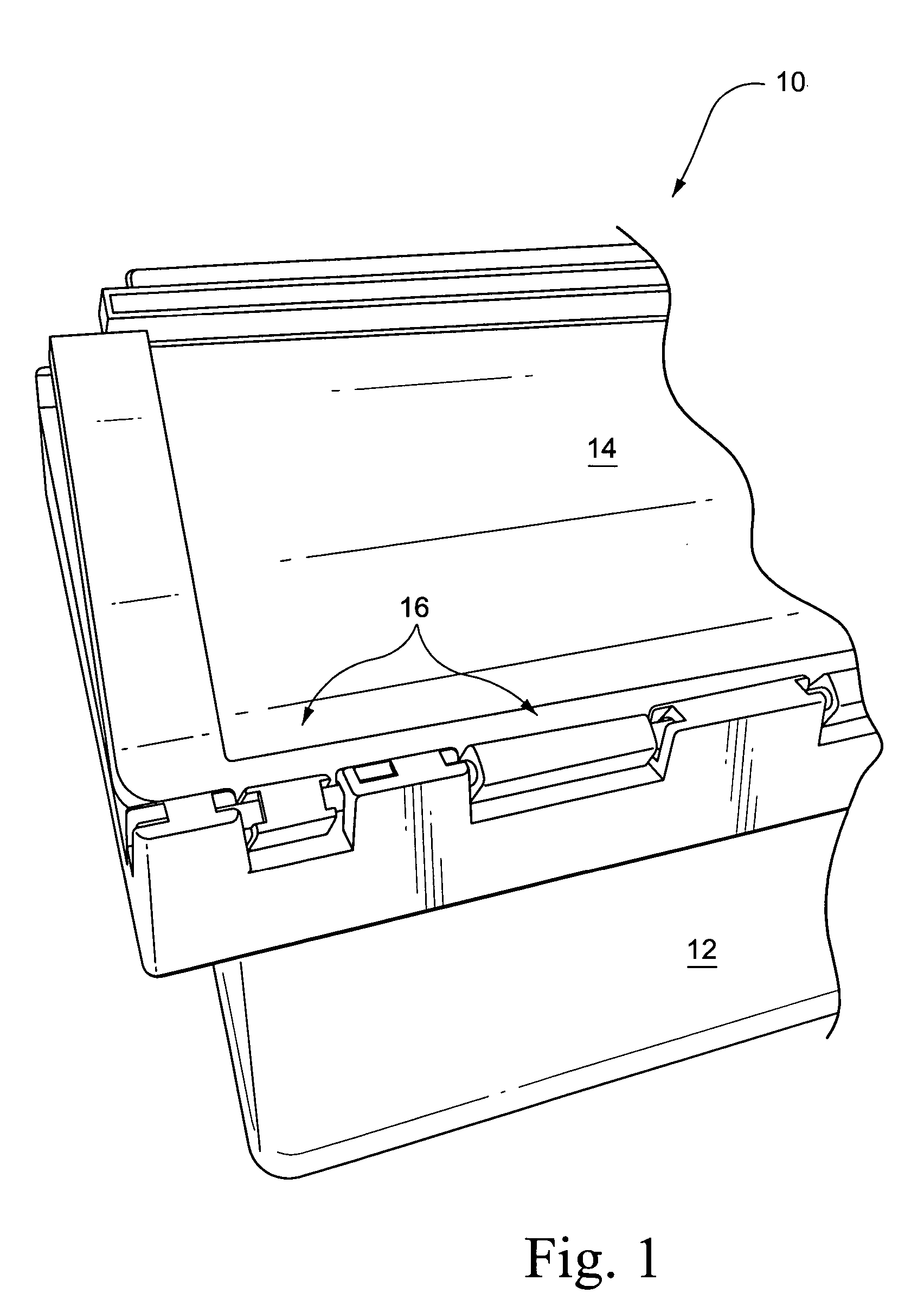

[0018] With continued reference to FIG. 1 and with reference to FIG. 2, the hinge assembly 16 is preferably formed entirely of molded plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com