Energy-dissipation beam column node of buckling-restrained bracing

An anti-buckling support and anti-buckling energy consumption technology, applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems of difficult post-earthquake repairs and limited building functions, and achieve easy post-earthquake repairs without affecting building functions , the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

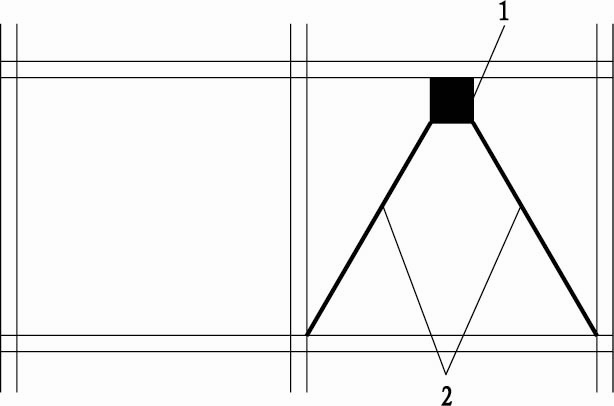

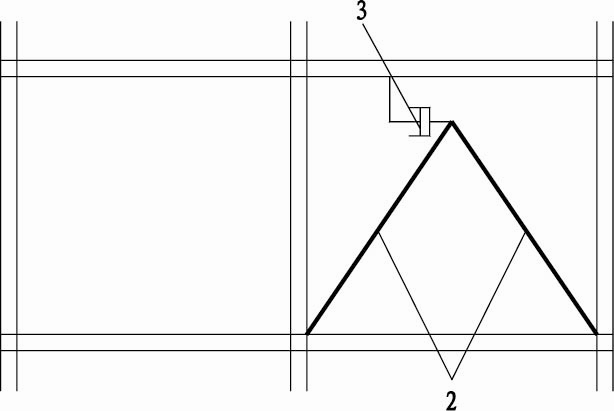

[0007] Specific implementation mode one: combine Figure 9~Figure 15 Note that the buckling-resistant braced energy-dissipating beam-column node 9 in this embodiment includes an I-shaped steel column 9-1 and an I-shaped steel beam 9-2; the buckling-resistant braced energy-dissipating beam-column node 9 in this embodiment also includes two steel Backing plate 9-3, two angle steel connectors 9-4 and two anti-buckling energy-dissipating support members; the two anti-buckling energy-dissipating support members consist of one anti-buckling energy-dissipating upper support member 9-5 and one anti-buckling energy-dissipating support member The lower supporting member 9-6 is composed of; two steel backing plates 9-3 are fixed on the outer surface of the same column flange 9-1-1 of the I-shaped steel column 9-1, and the two steel backing plates 9- 3 is arranged in one-to-one correspondence with two angle steel connectors 9-4, and the steel backing plate 9-3 is located between the I-sha...

specific Embodiment approach 2

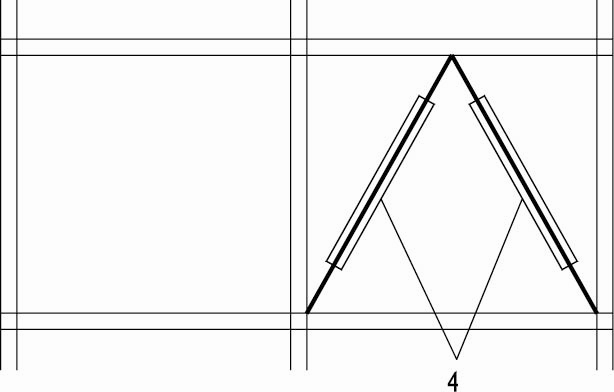

[0008] Specific implementation mode two: combination Figure 9~Figure 15 Explain that the anti-buckling energy-dissipating upper support member 9-5 of this embodiment consists of a T-shaped upper core plate 9-5-1, two T-shaped upper restraints 9-5-3 and two lateral upper limit members 9- 5-2 composition; each of the two side end faces of the long upper core plate 9-5-1-1 in the width direction of the T-shaped upper core plate 9-5-1 is processed with a lateral upper limit member 9-5- 2 The first grooves 9-5-1-2 that match in shape, each first groove 9-5-1-2 is equipped with a lateral upper limit piece 9-5-2, T-shaped upper core plate 9 The short upper core plate 9-5-1-3 of -5-1 and the column flange 9-1-1 of the I-shaped steel column 9-1 and the beam web 9-2-1 of the I-shaped steel beam 9-2 Tightly connected, one of the two T-shaped upper restraints 9-5-3 is arranged on the long upper core plate 9-5-1-1 of the corresponding T-shaped upper core plate 9-5-1 and the two side upwa...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 9~Figure 15 Description, the column flange 9-1-1 of the I-shaped steel column 9-1 with the steel backing plate 9-3 of the present embodiment, two steel backing plates 9-3 and two angle steel connectors 9-4 between the two side plates of the two angle steel connectors 9-4 and the beam web 9-2-1 of the I-shaped steel beam 9-2, the buckling-resistant energy dissipation upper support member 9 -5 and between the column flange 9-1-1 of the I-shaped steel column 9-1 and the beam web 9-2-1 of the I-shaped steel beam 9-2 and the buckling-resistant energy dissipation lower support member 9-6 and The column flange 9-1-1 of the I-shaped steel column 9-1 and the beam web 9-2-1 of the I-shaped steel beam 9-2 are respectively fastened and connected by a plurality of high-strength bolts. With such setting, the connection is reliable, and the overall strength after connection is high. Others are the same as the first embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com