Patents

Literature

69results about How to "Does not affect cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

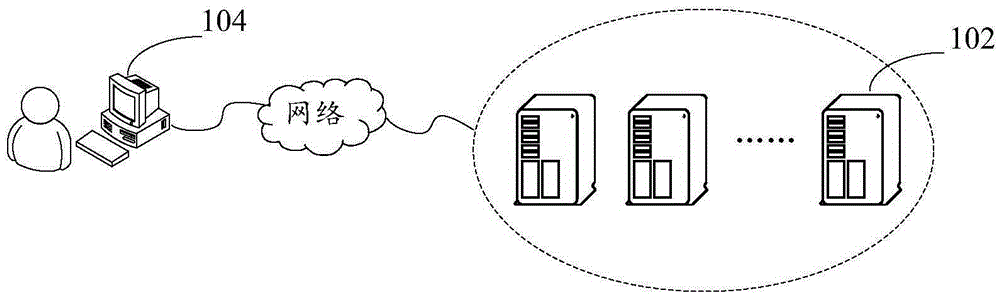

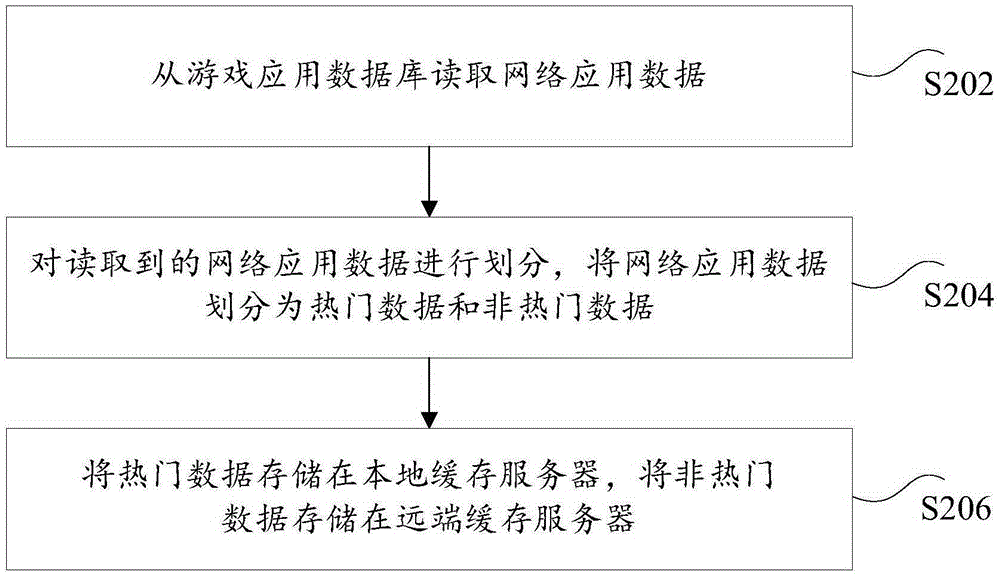

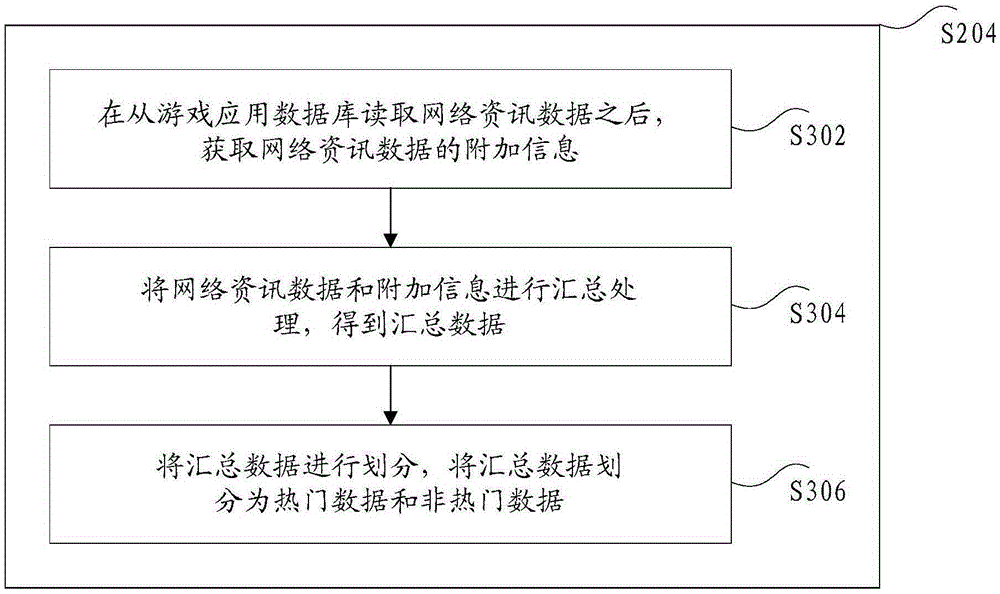

Method, device and system for data caching, applicable to game application

ActiveCN106649349AImplement storageDoes not affect costWebsite content managementSpecial data processing applicationsCache serverData access

The invention discloses a method, device and system for data caching, applicable to a game application. The method for the data caching comprises the steps that network application data is read from a game application database; the read network application data is divided, and the network application data is divided into hot data and non-hot data; and the hot data is stored in a local cache server, and the non-hot data is stored in a far-end cache server, wherein the local cache server and the far-end cache server are used to provide network access services. According to the invention, the technical problem that data access efficiency and data cache cost cannot be guaranteed at the same time can be solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

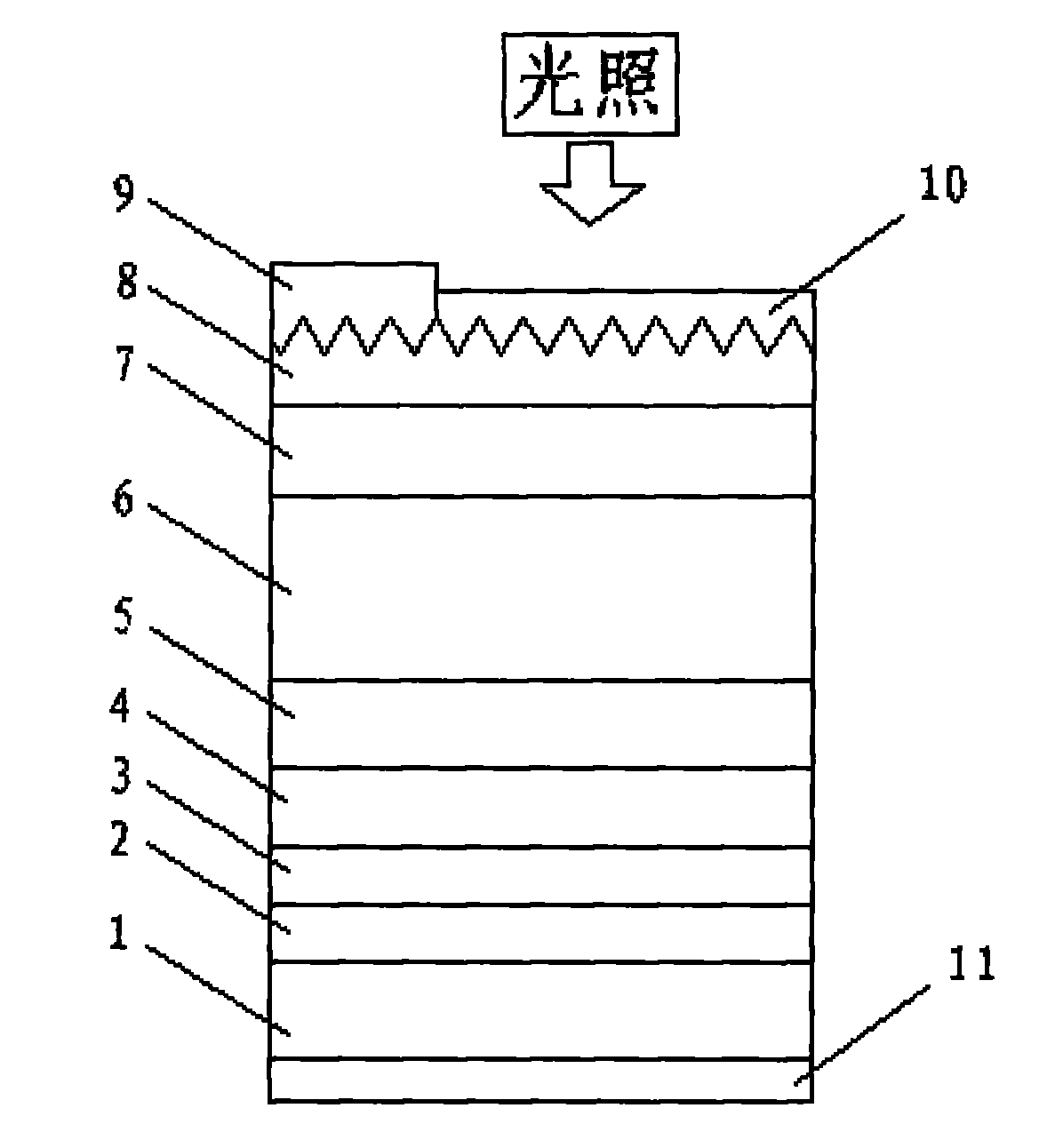

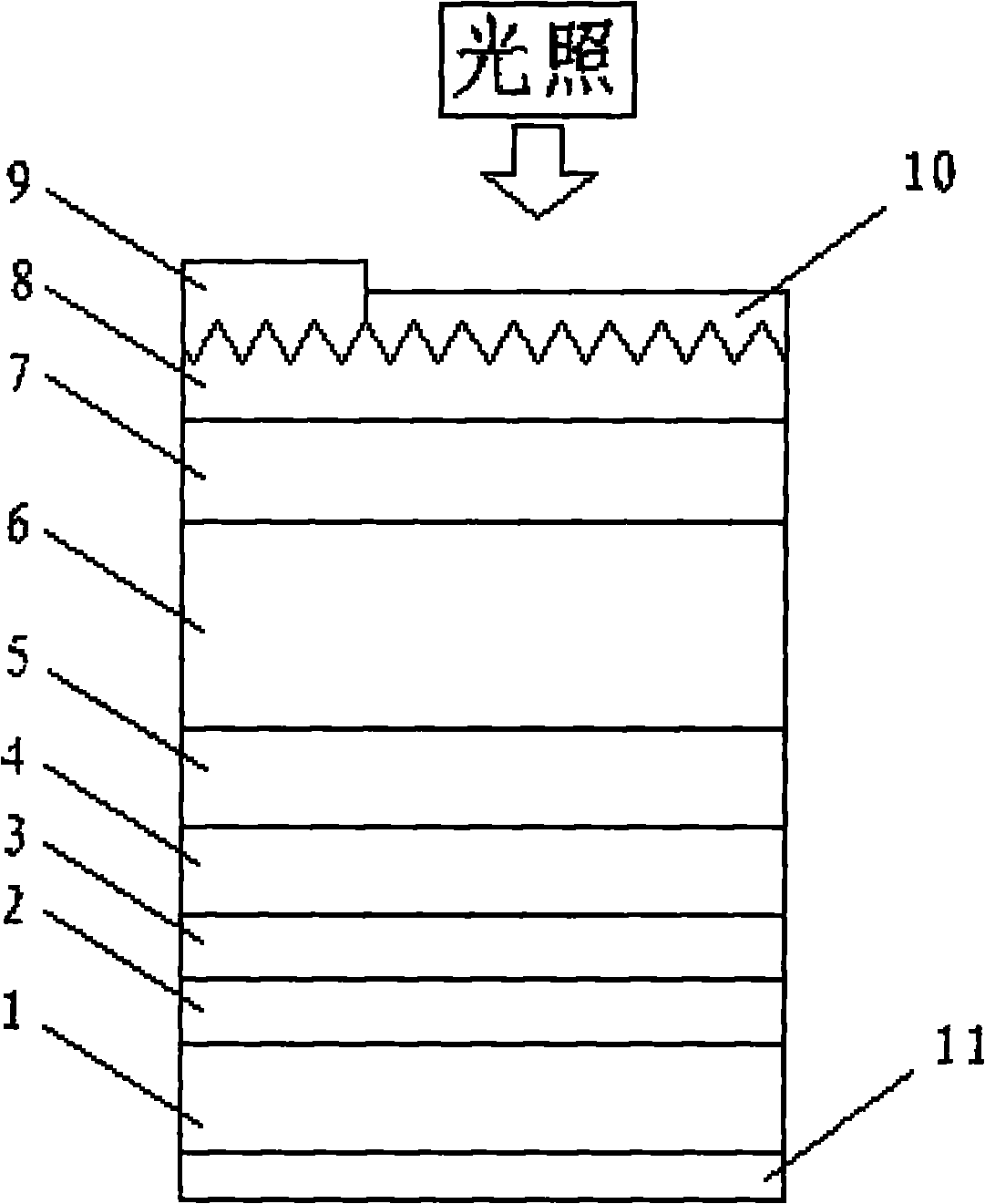

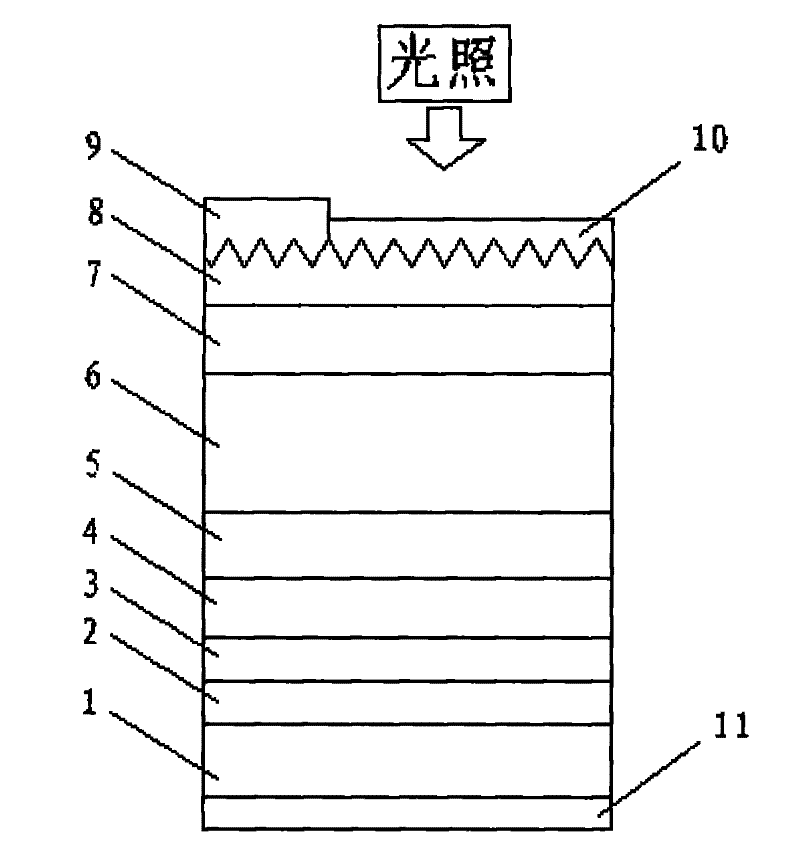

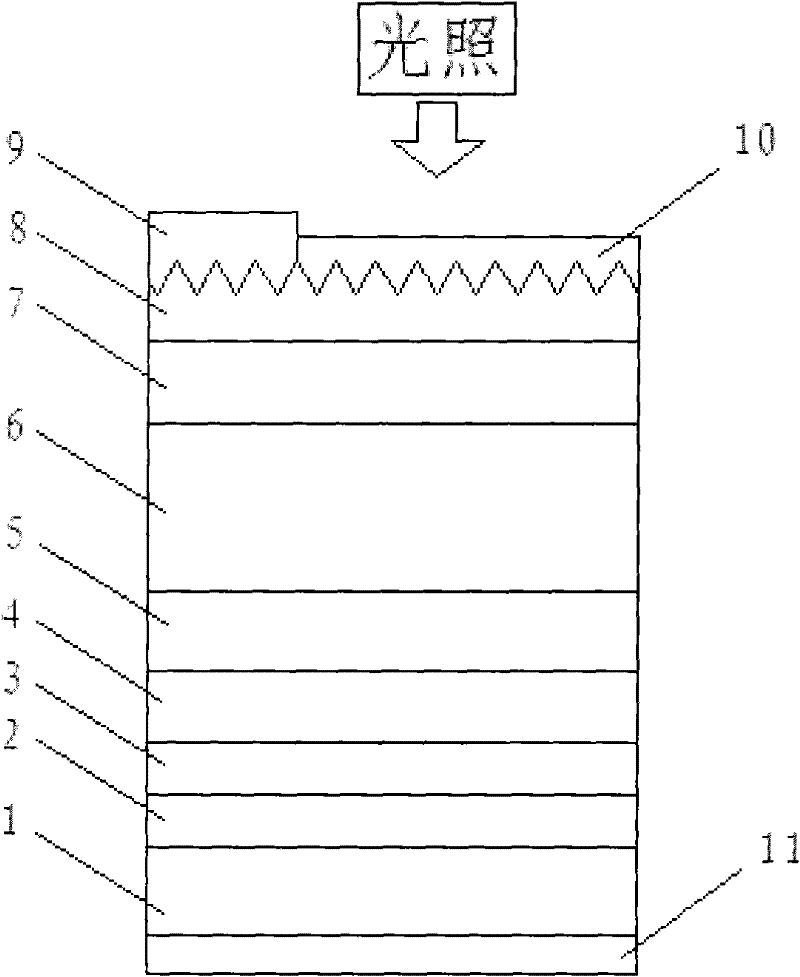

Solar cell

InactiveCN101866967AReduce manufacturing costImprove conductivityFinal product manufacturePhotovoltaic energy generationThermal expansionSolar cell

The invention relates to a silicon-based single-junction gallium indium nitride solar cell which comprises a back electrode (11), a silicon substrate (1), a seed crystal layer (2), a buffer layer (3), an n-type doped GaN buffer layer (4), an InaGal-aN layer (5), an unintentional doped InbGal-bN layer (6), a p-type doped IncGal-cN layer (7), a window layer (8), a positive electrode (9) and an anti-reflection conductive film (10) which are arranged from bottom to top, wherein the silicon substrate and the InaGal-aN layer is are an n-type doped structure, the seed crystal layer and the buffer layer are made of ZnO material, the window layer is made of p-type heavily doped GaN, and the anti-reflection conductive film covers areas of the window layer other than the positive electrode. The solar cell can quite effectively solve the problems of lattice matching, thermal expansion coefficient matching and the like encountered when a GaN film extends from the silicon substrate, and has the advantages of low manufacturing cost, high sunlight absorbability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

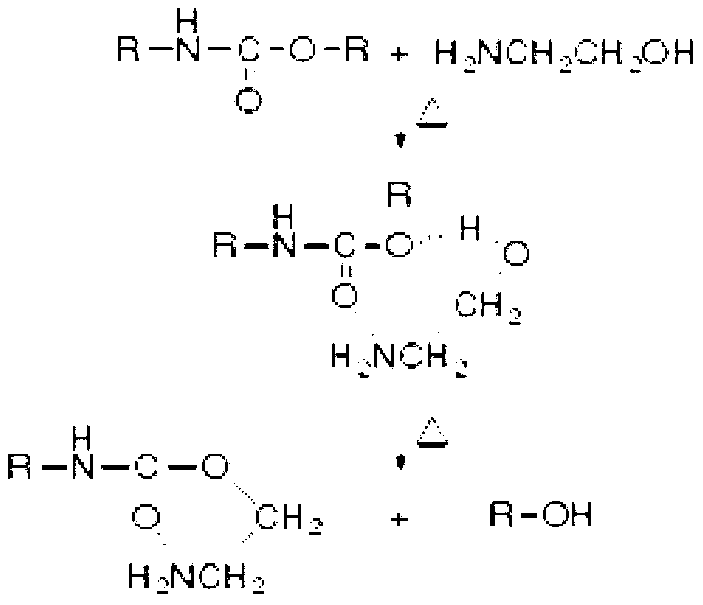

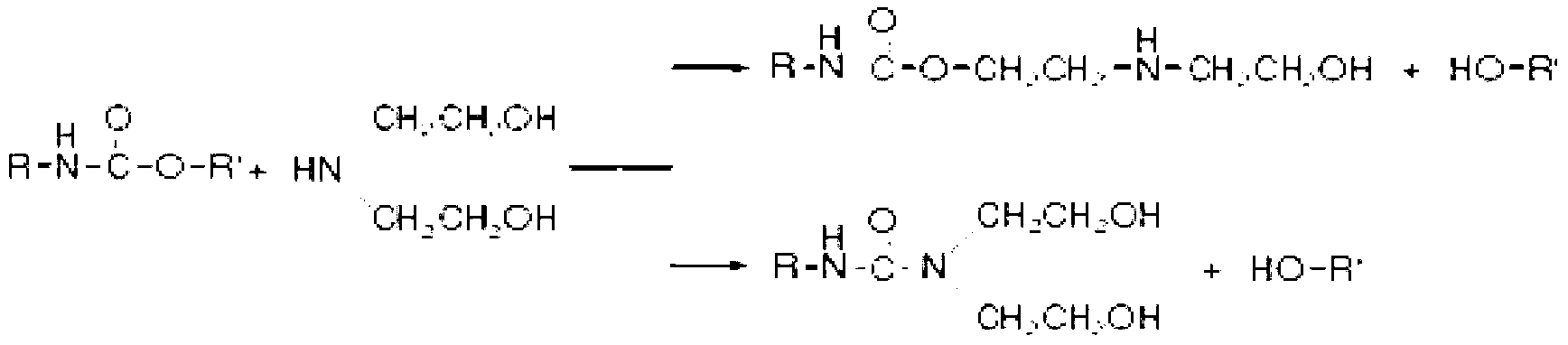

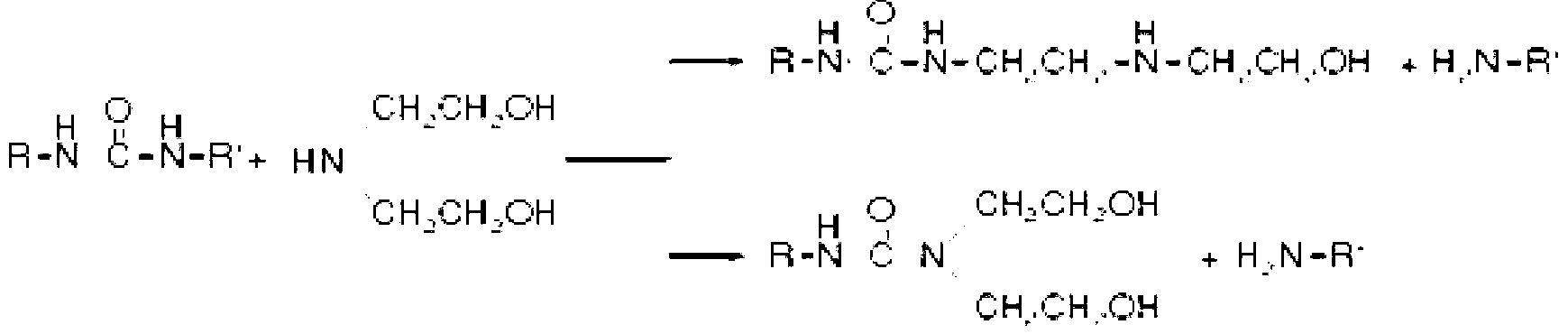

Method for recycling polyhydric alcohol by degrading thermal-insulation polyurethane foam materials for buildings

InactiveCN103159981AImprove performanceDoes not affect reusePlastic recyclingAlcoholThermal insulation

The invention relates to a method for recycling polyhydric alcohol by taking waste materials of thermal-insulation polyurethane foam materials for buildings and reproducing polyurethane foams. The method comprises the steps of adding proper amounts of antioxidants, alcoholysis agents, alcoholysis assistant agents and catalysts in presence of oxygen (in atmosphere which is not protected by inert gas), and recycling the thermal-insulation foam materials for the buildings. The hydroxyl value, acid value and the like of the polyhydric alcohol recycled by utilizing the method are all accordant with government standards. The recycled polyhydric alcohol can be used for partially replacing polyether polyol to reproduce the polyurethane foams. Compared with previous inventions, the method has the advantages that (1) in the atmosphere which is not protected by the inert gas, the industrial production process is simple, and the cost is saved; (2) the degraded polyhydric alcohols in the method are solid materials on an upper layer and a lower layer, and the separation is simple; and (3) the recycled polyhydric alcohol can be used for directly replacing the polyether polyol with a mass fraction of 20-50% to reproduce the polyurethane foams, and the foam property is good.

Owner:TIANJIN UNIV

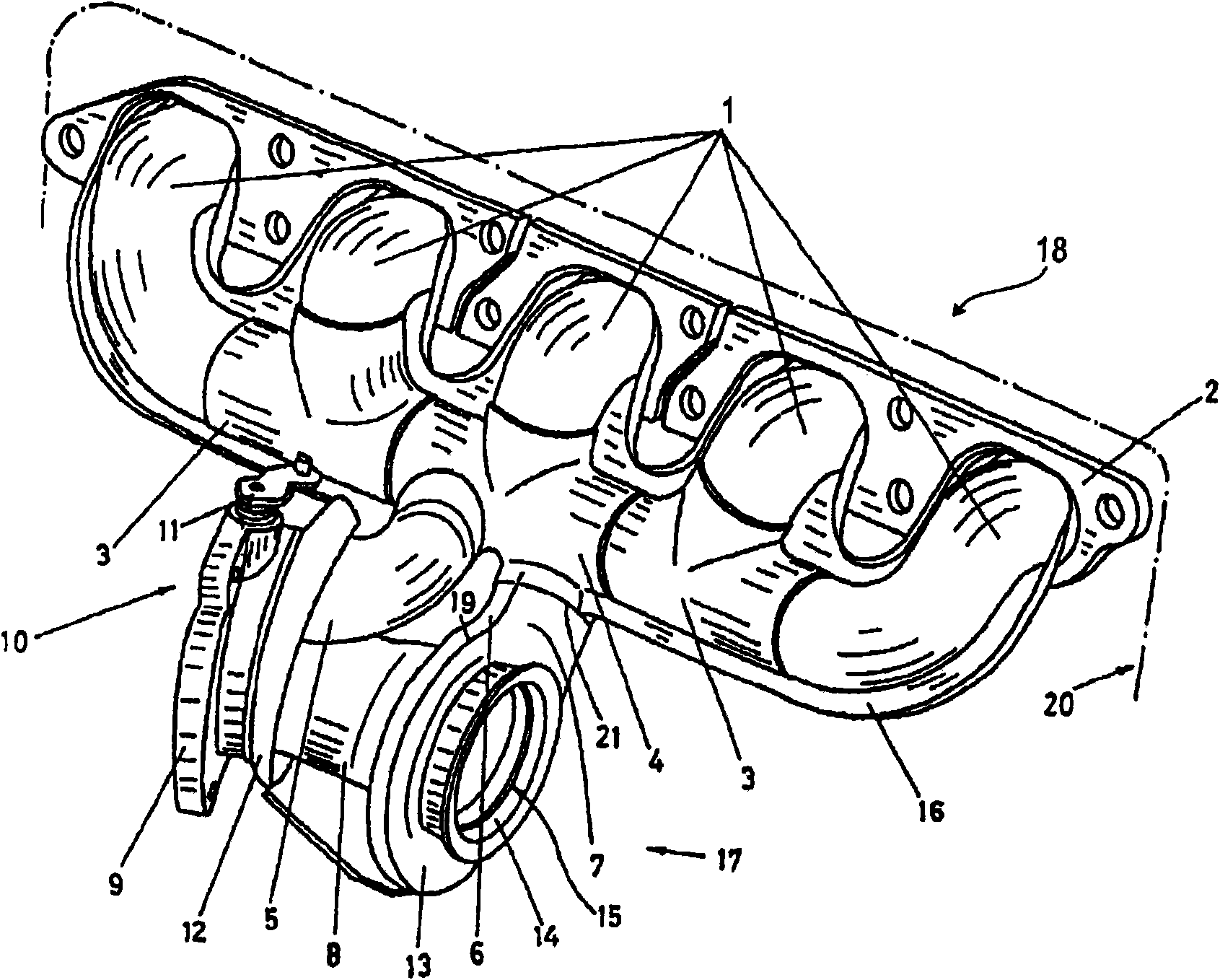

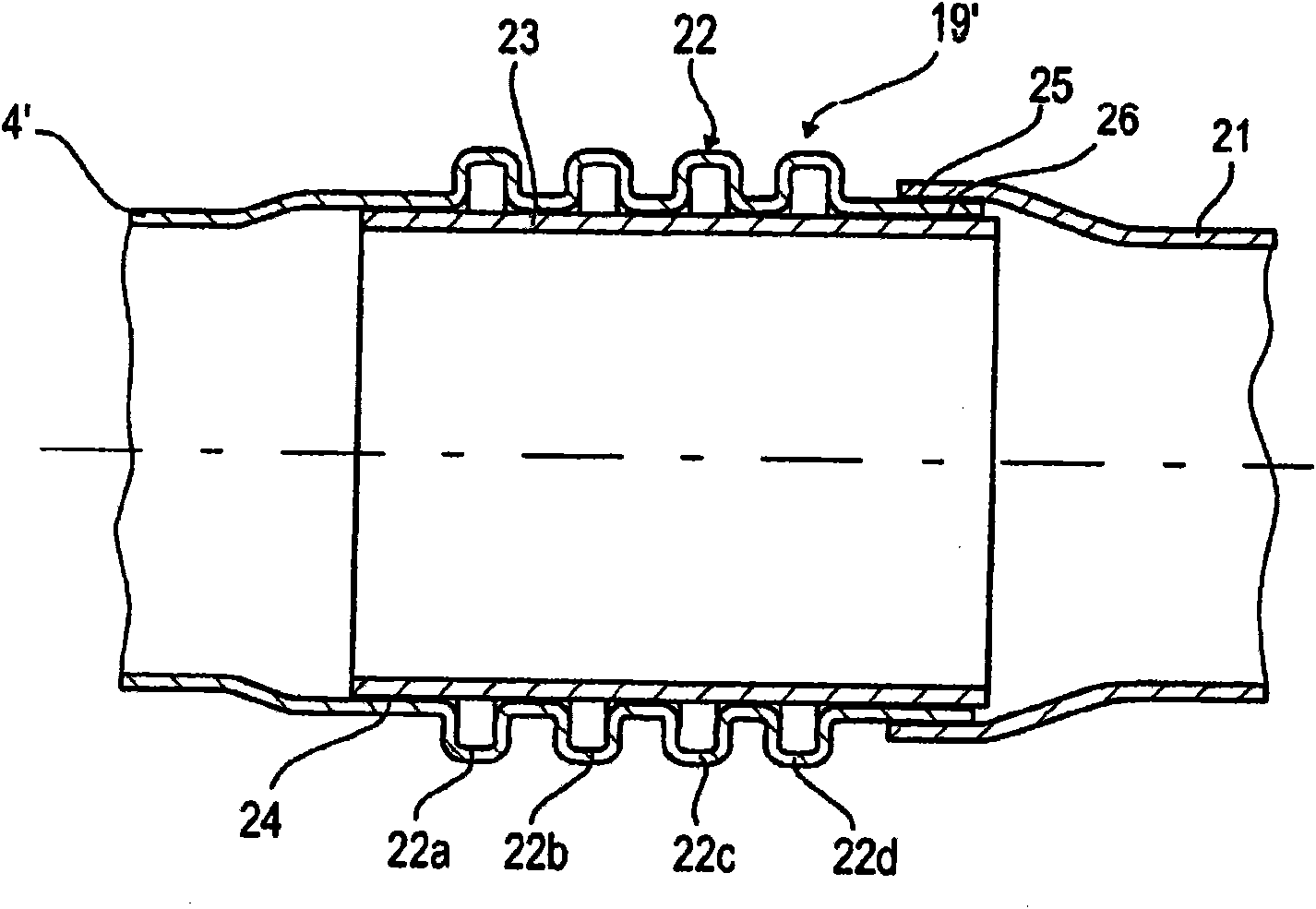

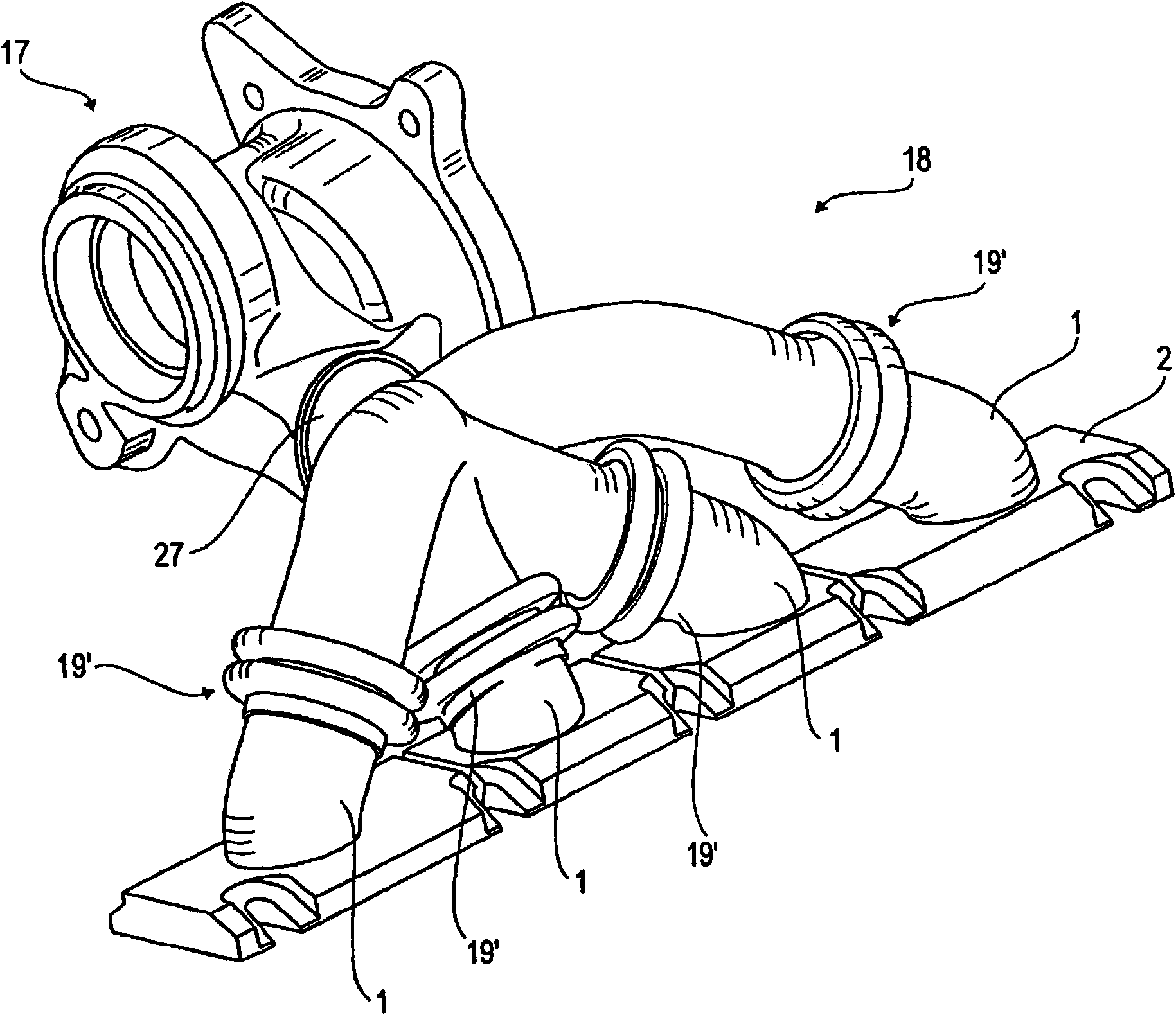

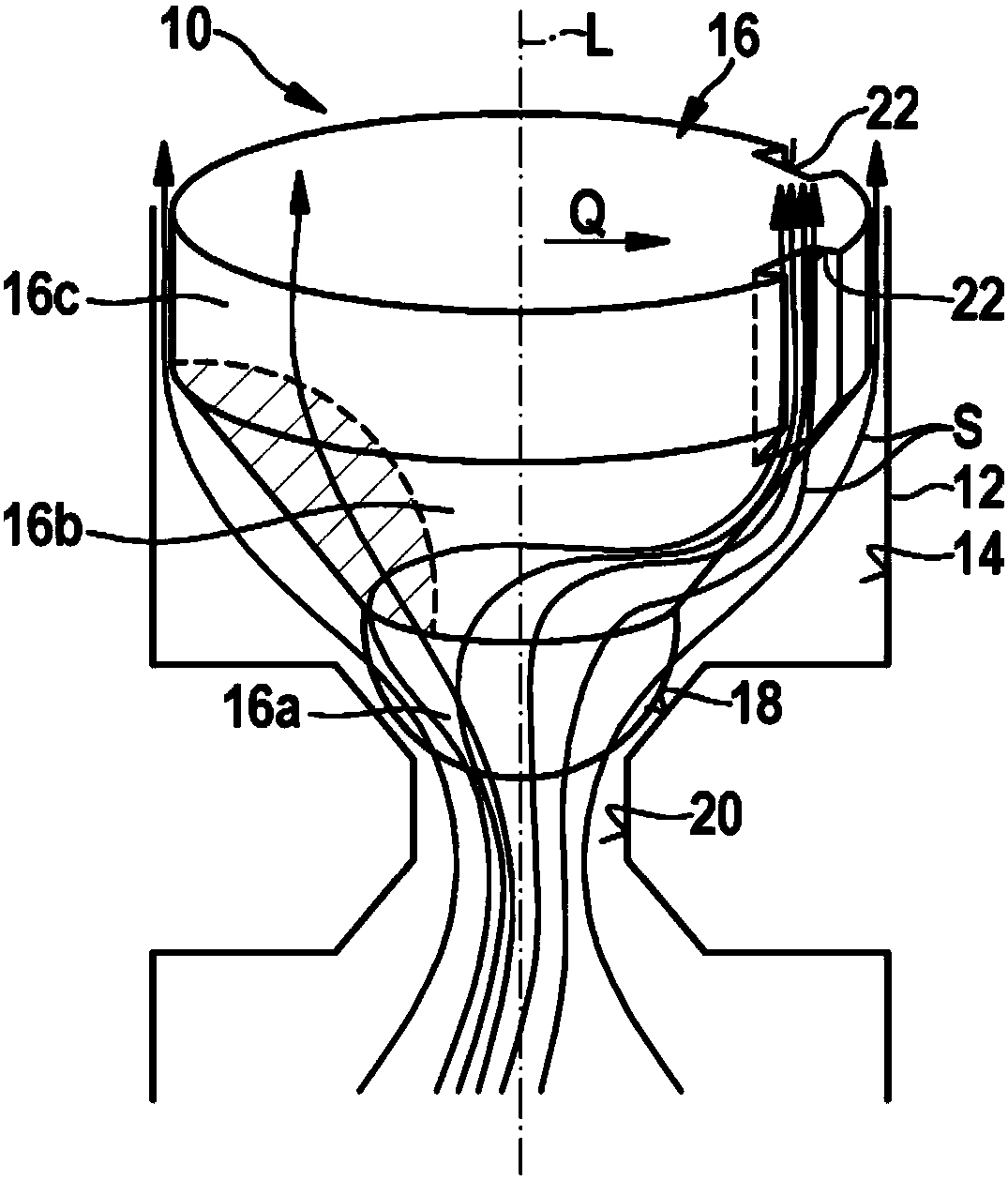

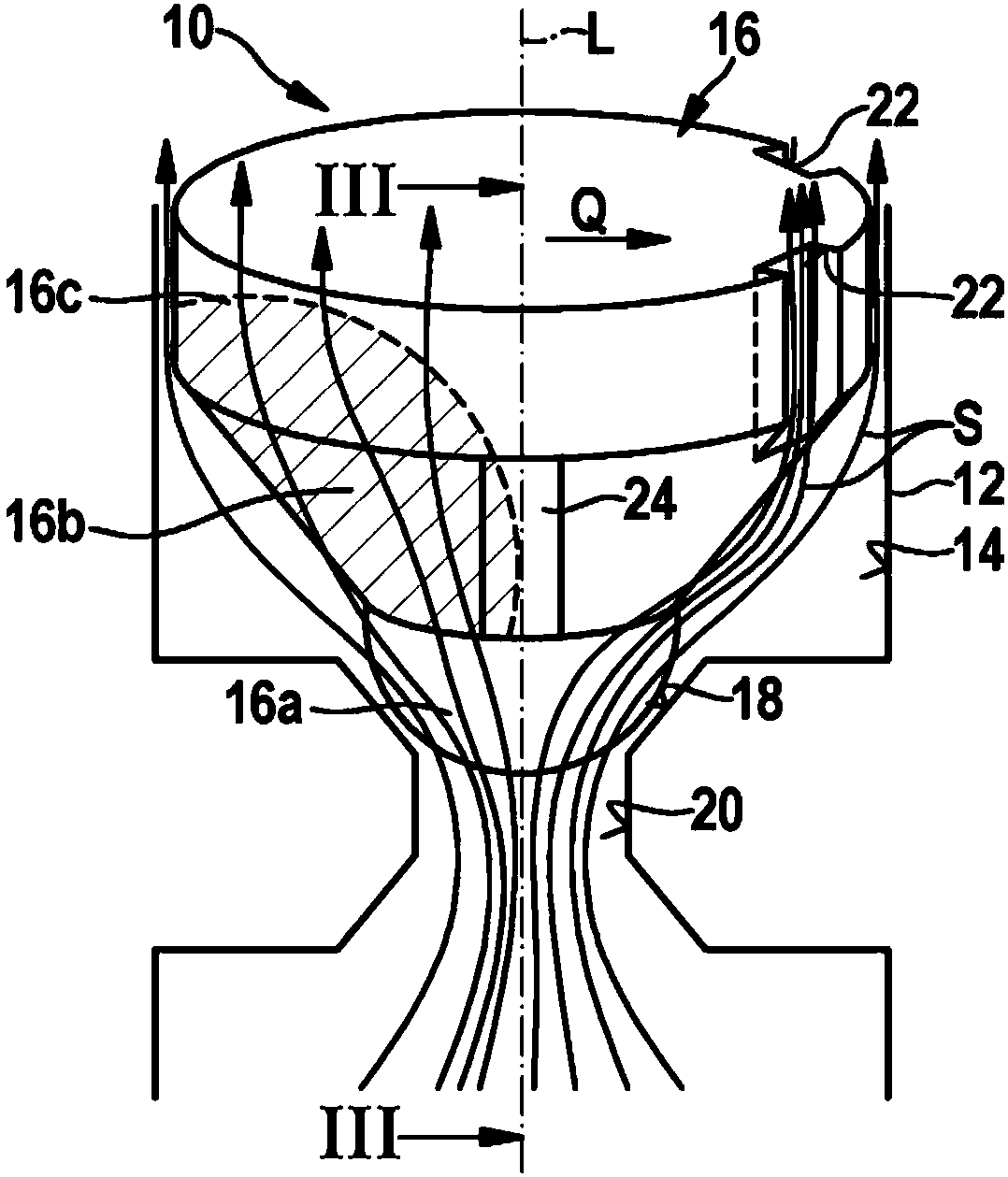

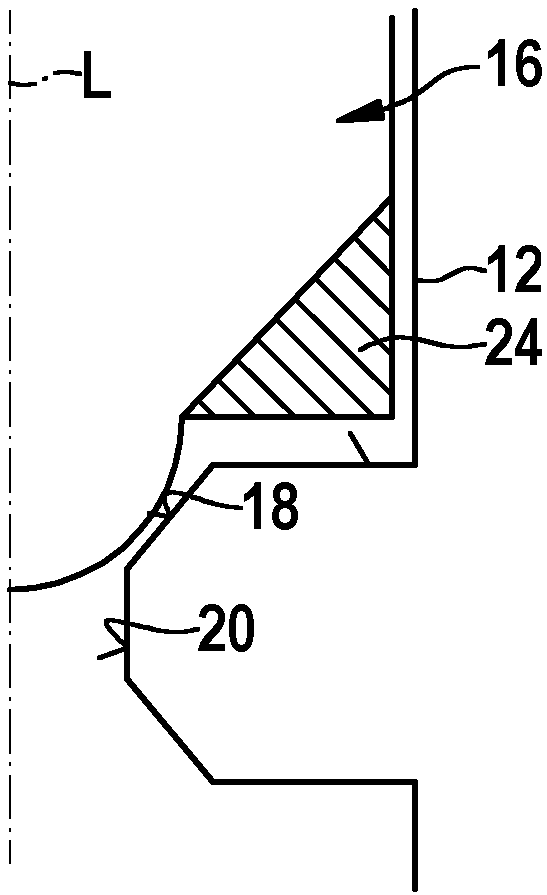

Exhaust manifold of an internal combustion engine

InactiveCN101960113ANo efficiency lossDoes not affect costExhaust apparatusCombustion enginesCombustionTurbocharger

The invention relates to an exhaust manifold (18) of an interna! combustion engine (20), with a number of exhaust pipe bends (1) corresponding to the number of cylinders of the internal combustion engine (20), said exhaust pipe bends being brought together at one end into an input flange (2) which can be fastened to the internal combustion engine (20), and being brought together at the other end; with a supply gas duct (21 ) which is connected at one end to a collector component (4) and at the other end to a rotor space (15) of a turbine housing (17) of a turbine of an exhaust-gas turbocharger; and with at least one compensator (19') for compensating for thermal stresses in at least one exhaust pipe bend (1) and the supply gas duct (21), wherein the at least one compensator (19') is designed as a component which is integrated in at least one exhaust pipe component (1).

Owner:BORGWARNER INC

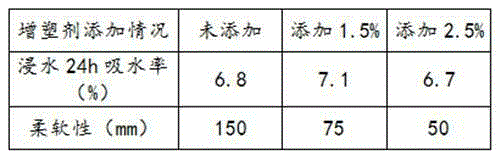

Colored flexible face brick for internal wall and external wall decoration

The invention provides a colored flexible face brick applied to internal wall and external wall decoration, and the colored flexible face brick can widely replace ceramic tiles. The colored flexible face brick comprises, by weight, 10-20% of polymer emulsion, 1-2% of curing agents, 1.5-2.5% of plasticizers, 0.2-0.5% of thickeners, 60-75% of colored quartz sand and 12-14% of water, and the raw materials are mixed, stirred, scraped in batches and formed, cut and dried at the temperature ranging from 45 DEG C to 90 DEG C to form the face brick, the polymer emulsion is pure acrylic emulsion or silicon acrylic emulsion, the curing agents are toluene diisocyanate or diphenylmethane diisocyanate or aliphatic poly-cyanate, the thickeners are cellulose ether thickeners or polyurethane thickeners, and the colored quartz sand is colored quartz sand with the fineness being 140 meshes to 40 meshes and formed by smashing and screening natural colored minerals. The colored flexible face brick has the advantages of being simple in formula, low in cost, rich in color, good in water resistance and flexibility and the like and is an ideal material for replacing the ceramic tiles to be applied to internal wall and external wall decoration.

Owner:广东龙湖科技股份有限公司

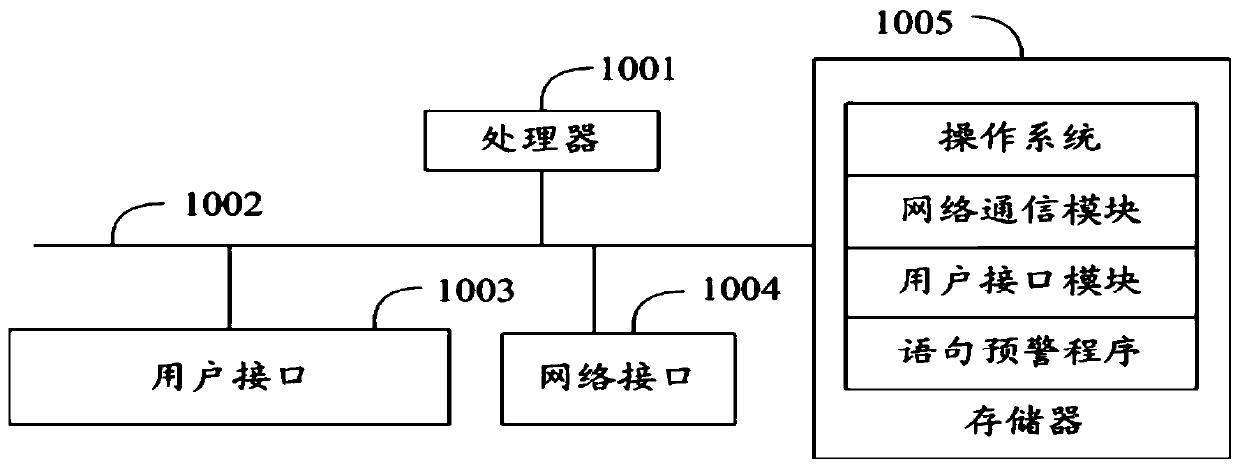

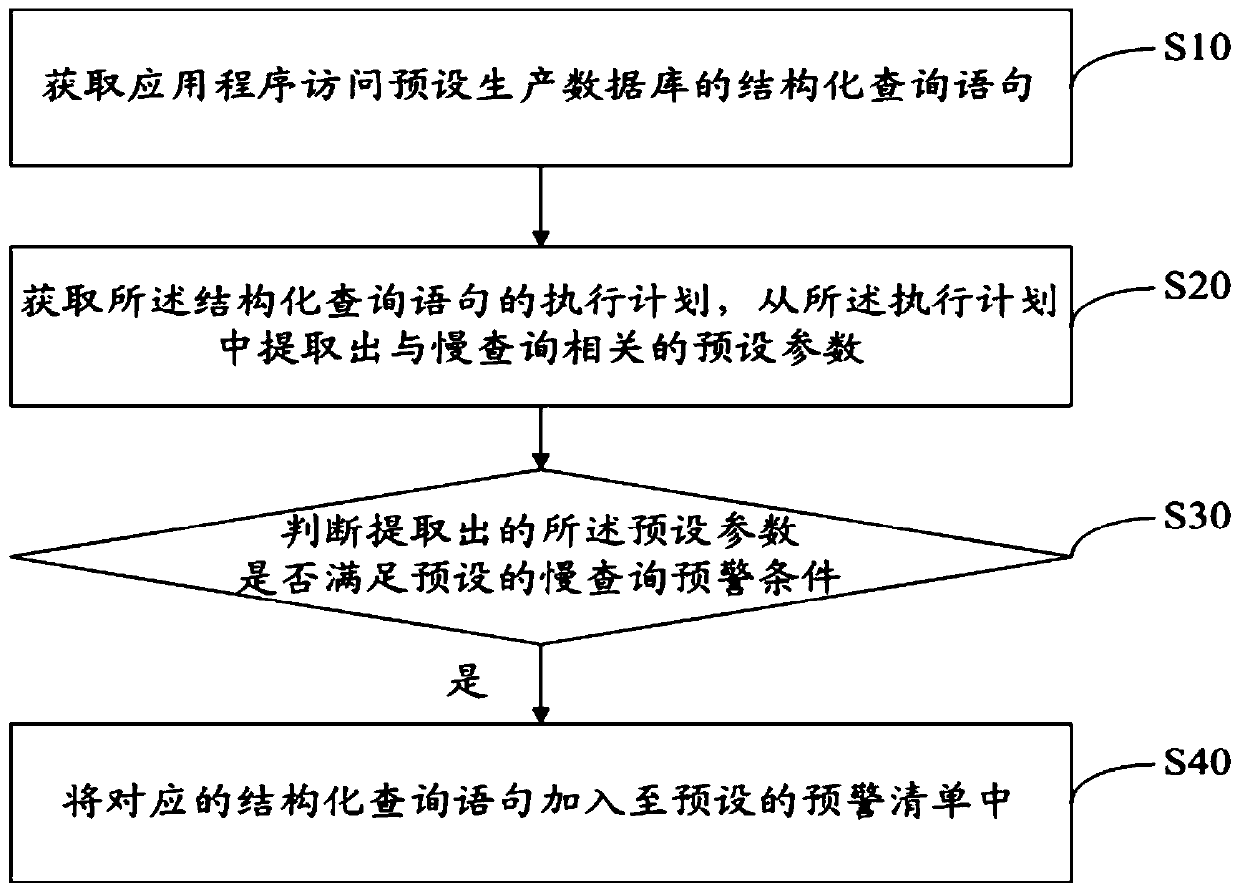

Statement early warning method and device, equipment and computer readable storage medium

PendingCN110019349ALow costReduce optimization costsDigital data information retrievalSpecial data processing applicationsExecution planApplication software

The invention discloses a statement early warning method. The method comprises the steps of obtaining a structured query statement of an application program accessing a preset production database; obtaining an execution plan of the structured query statement, and extracting preset parameters related to slow query from the execution plan; judging whether the extracted preset parameters meet a preset slow query early warning condition or not; and when the preset parameter satisfies a preset slow query early warning condition, adding the corresponding structured query statement into a preset early warning list. The invention further discloses a statement early warning device, equipment and a computer readable storage medium. The optimization cost of slow query can be reduced on the premise that the performance of the production database is not influenced.

Owner:WEBANK (CHINA)

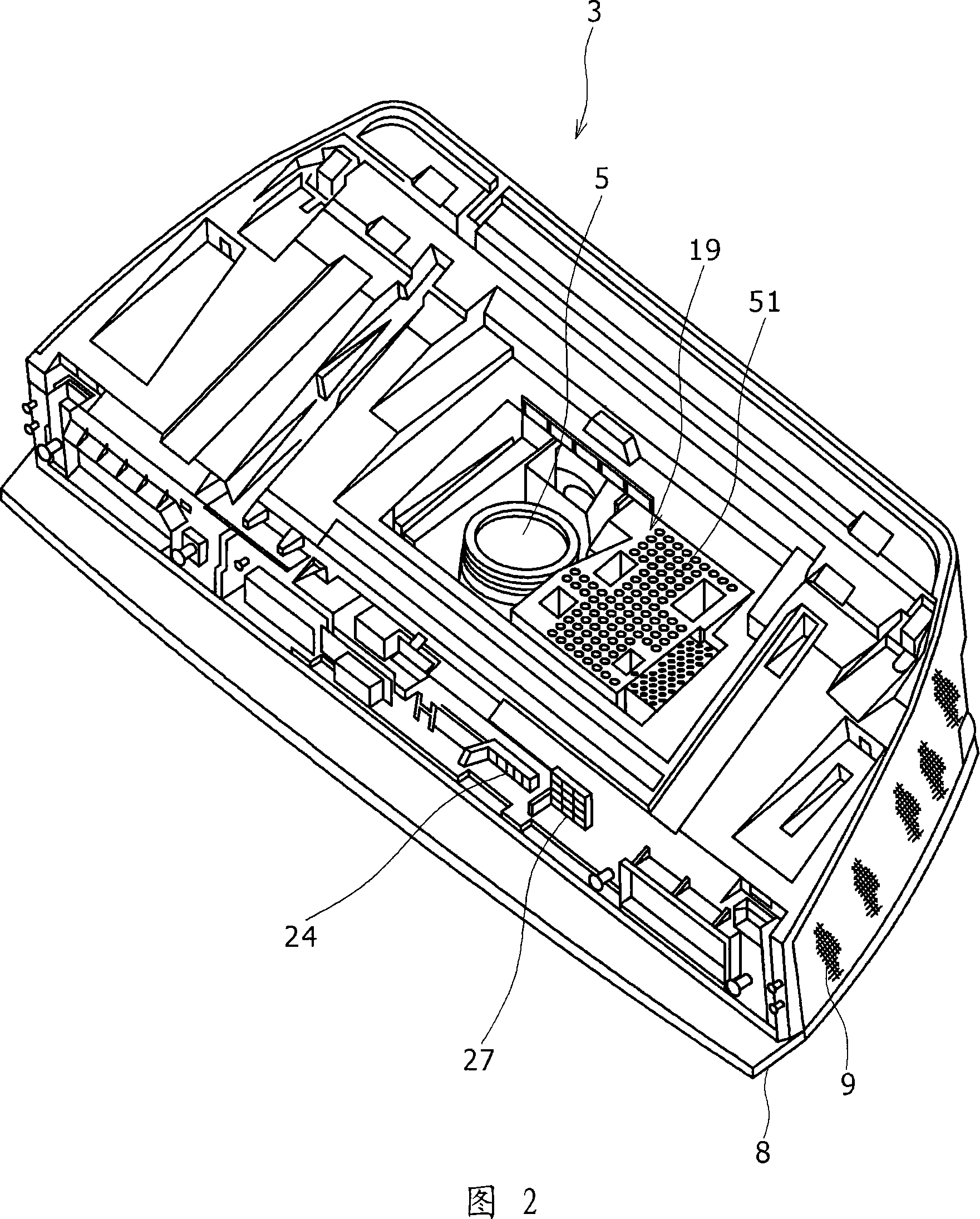

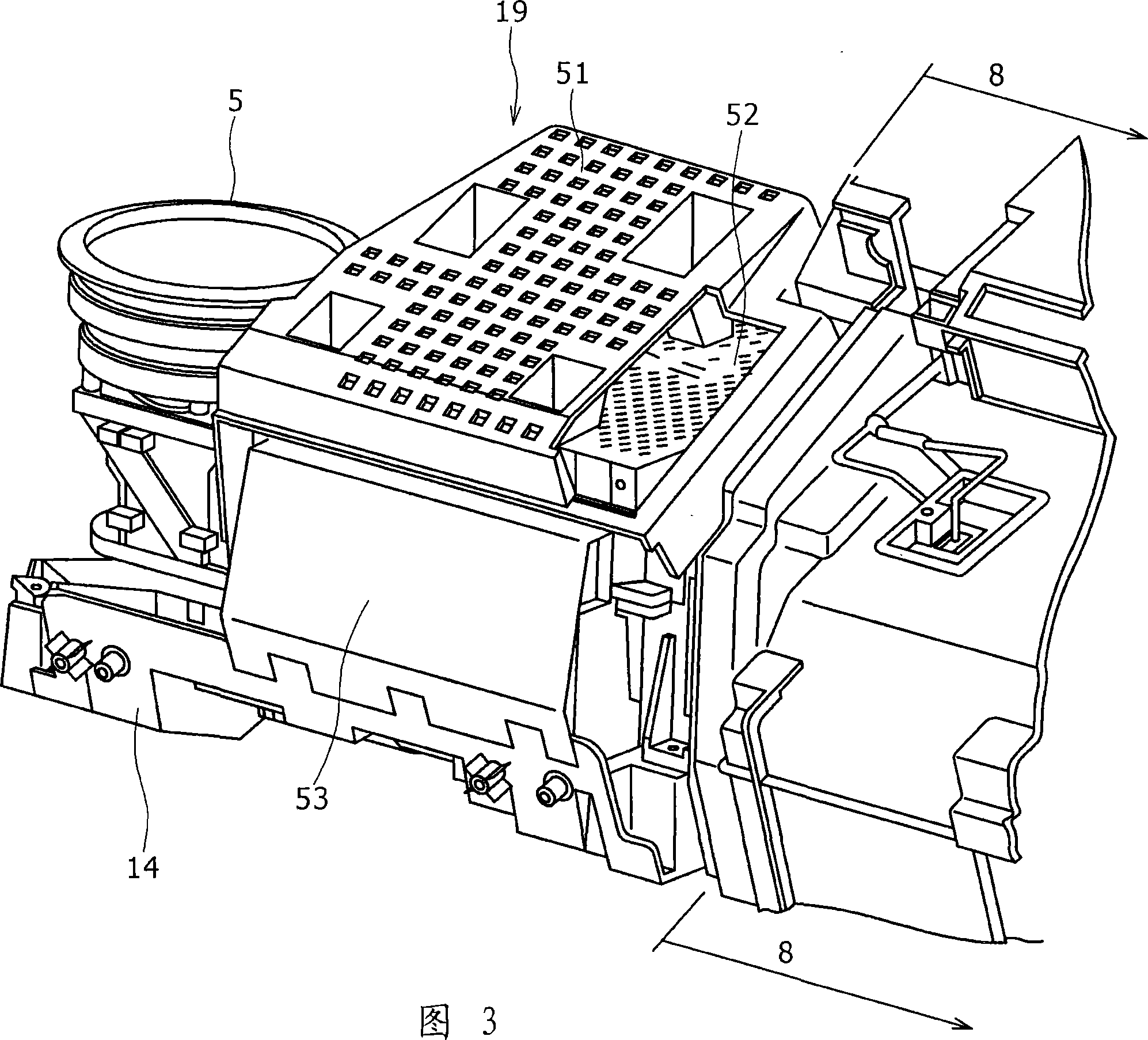

Automatic dedusting device and automatic dedusting method

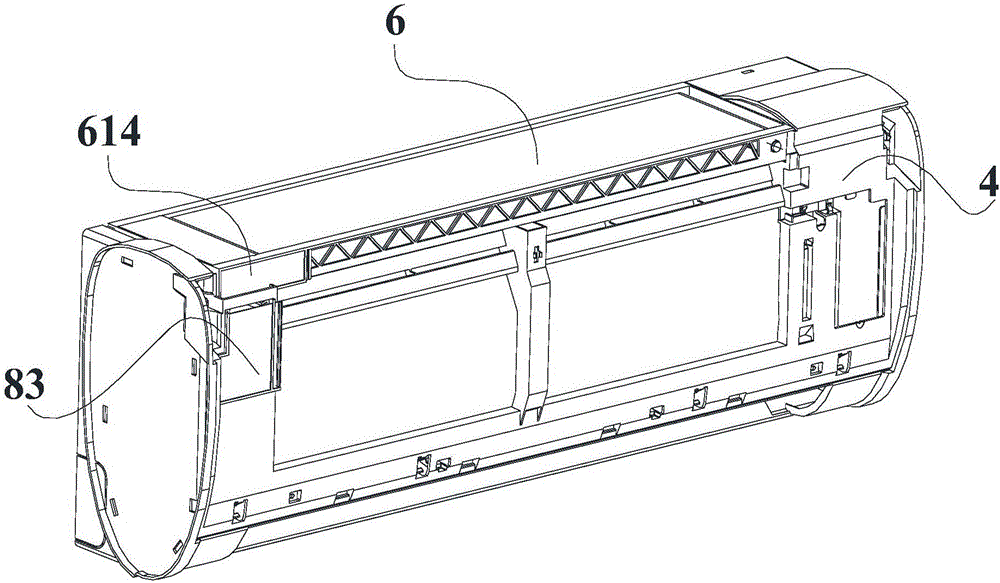

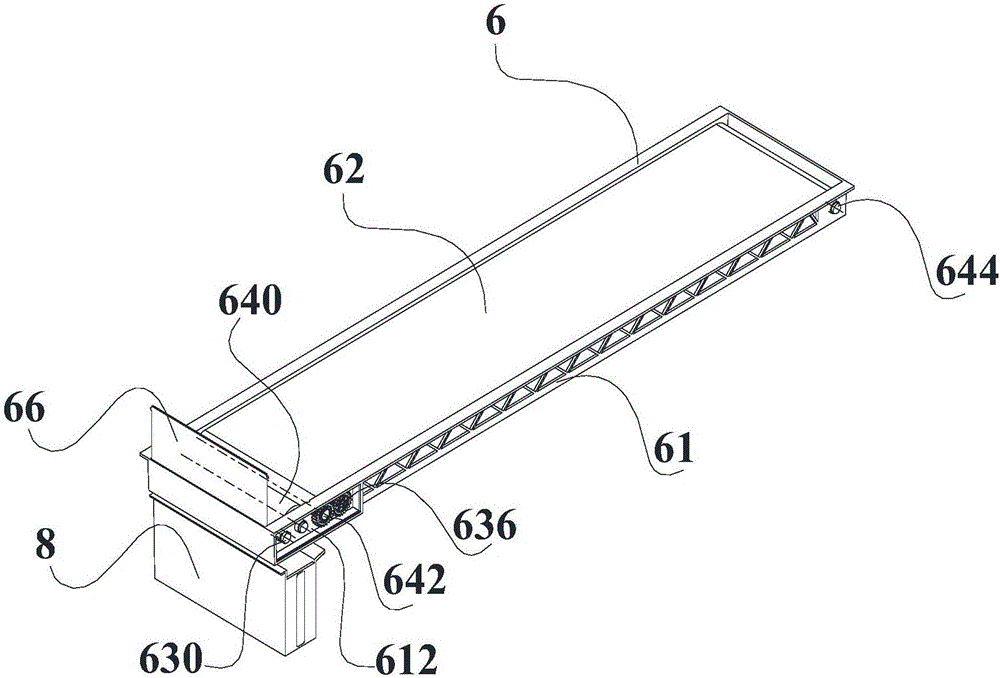

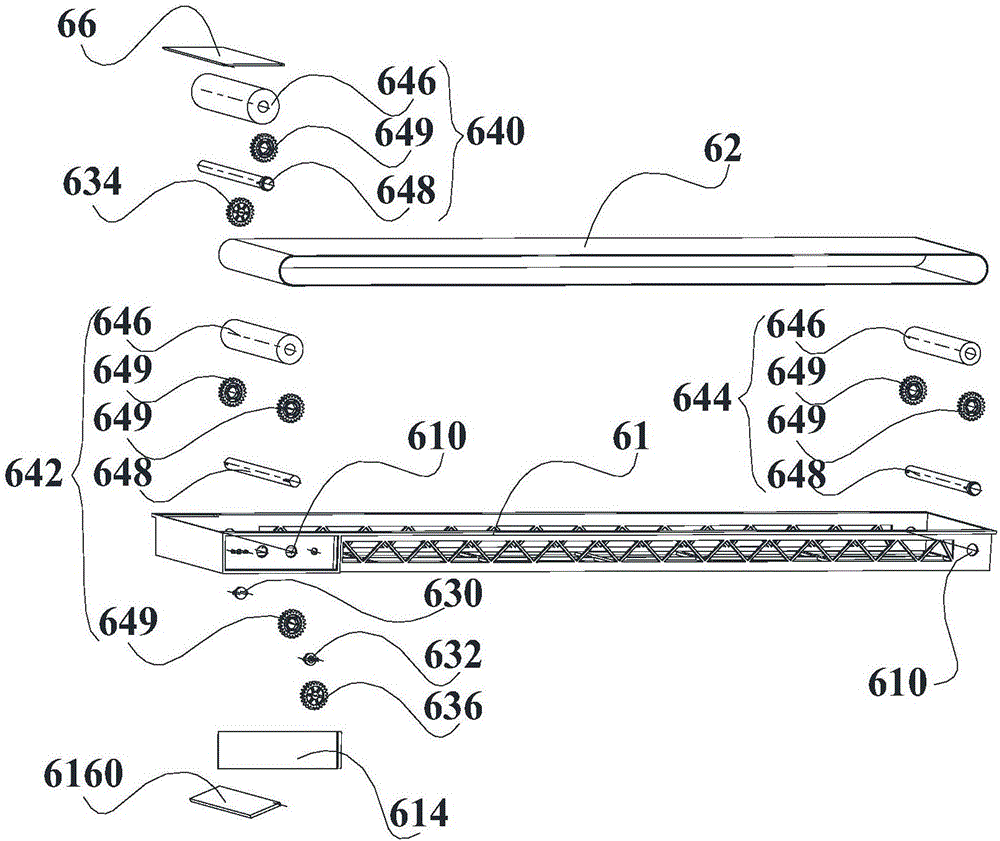

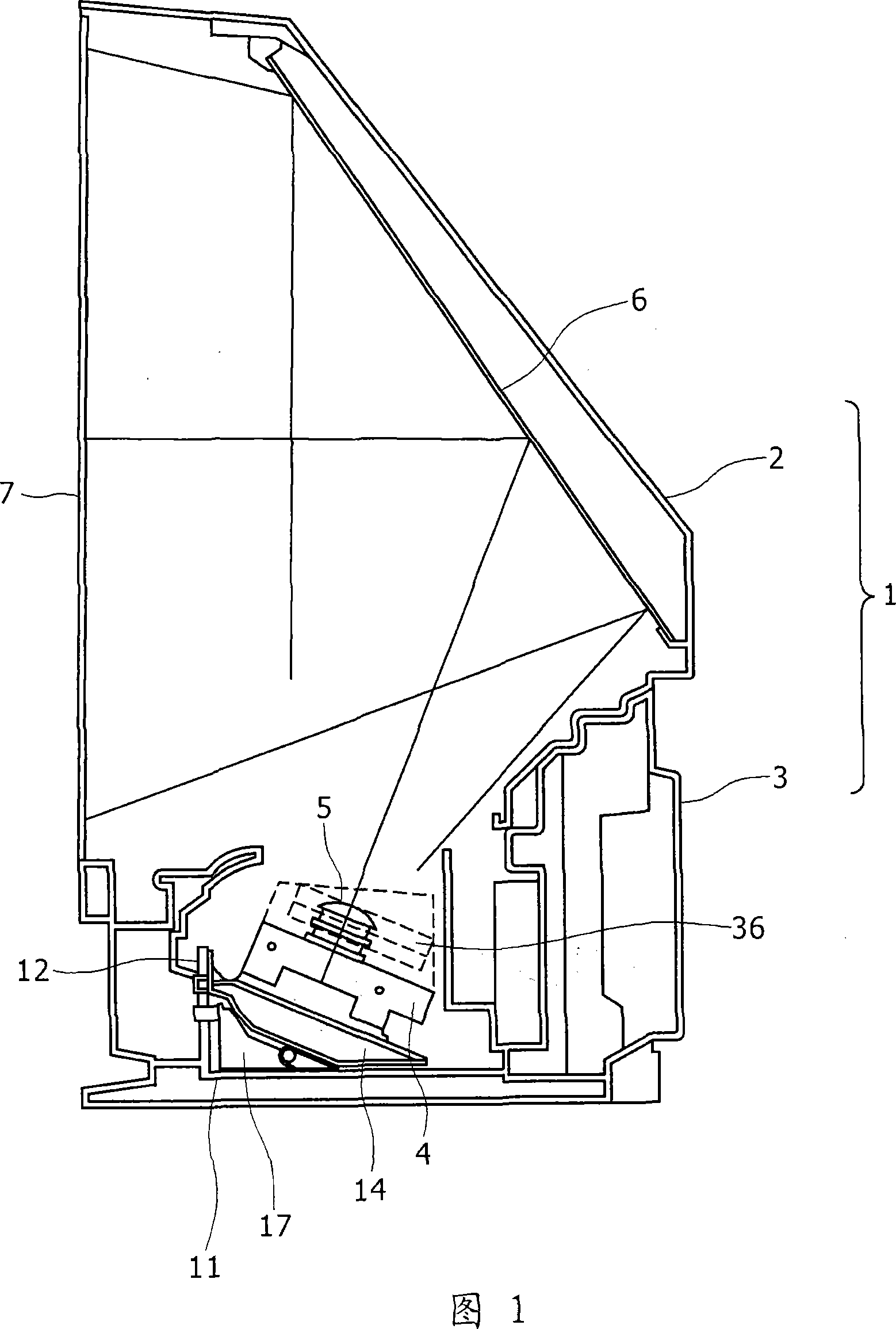

ActiveCN106705288ASave air intake requirementsDoes not affect air intake requirementsMechanical apparatusLighting and heating apparatusClosed loopConveyor belt

The invention provides an automatic dedusting device for an air conditioner. The air conditioner comprises an air inlet and a surface frame. The air inlet is formed in the upper end surface of the surface frame. The automatic dedusting device comprises a grid assembly which comprises a supporting housing, a filter screen, a driving device and a rolling brush assembly; the supporting housing is a cavity with openings at the upper and lower ends, a pivot hole is formed in the side wall of the supporting housing, the rolling brush assembly is pivoted to the pivot hole, the filter screen is of a closed loop structure connected end to end, the filter screen covers the opening of the supporting housing, the filter screen is wound to the rolling brush assembly, a conveyor belt is arranged at the edge of the filter screen, the rolling brush assembly drives the filter screen to operate through the conveyor belt, and the driving device of the air conditioner drives the rolling brush assembly to rotate. The automatic dedusting device provided by the invention is arranged in a position of the air inlet of a split wall-mounted air conditioner and can achieve an effect of automatically cleaning ash, so that use by a user is facilitated to the maximum extent.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Cable fixture

InactiveCN101046218AChanged condition of the conductive connectionSolve EMC problemsTwo-part coupling devicesSheet joiningElectric cablesChassis

A cable fixture including a holding section for holding a cable relative to a chassis; and a fitting section formed integrally with the holding section and operative to fix the holding section to the chassis, wherein the cable is fitted, from one side, to and hooked on a hole provided in the vicinity of an opening formed in the chassis for permitting the cable to pass therethrough, by the fitting sections provided at both end portions of the holding section, and the wiring direction of the cable fixed by the holding section coincides substantially with the fixing direction in fixation of the chassis by the fitting sections.

Owner:SONY GRP CORP

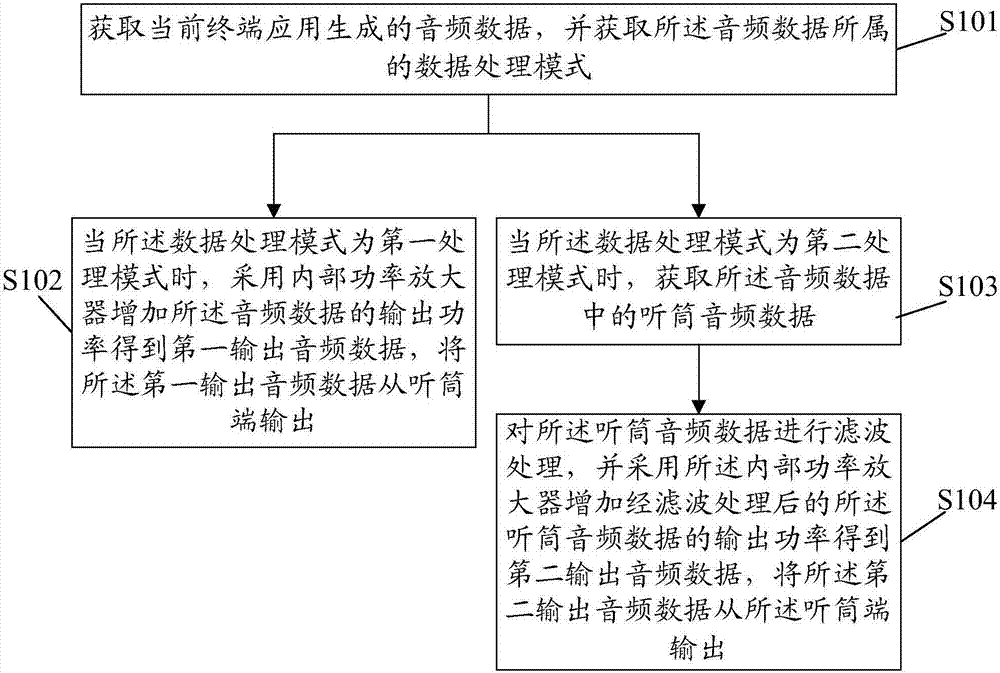

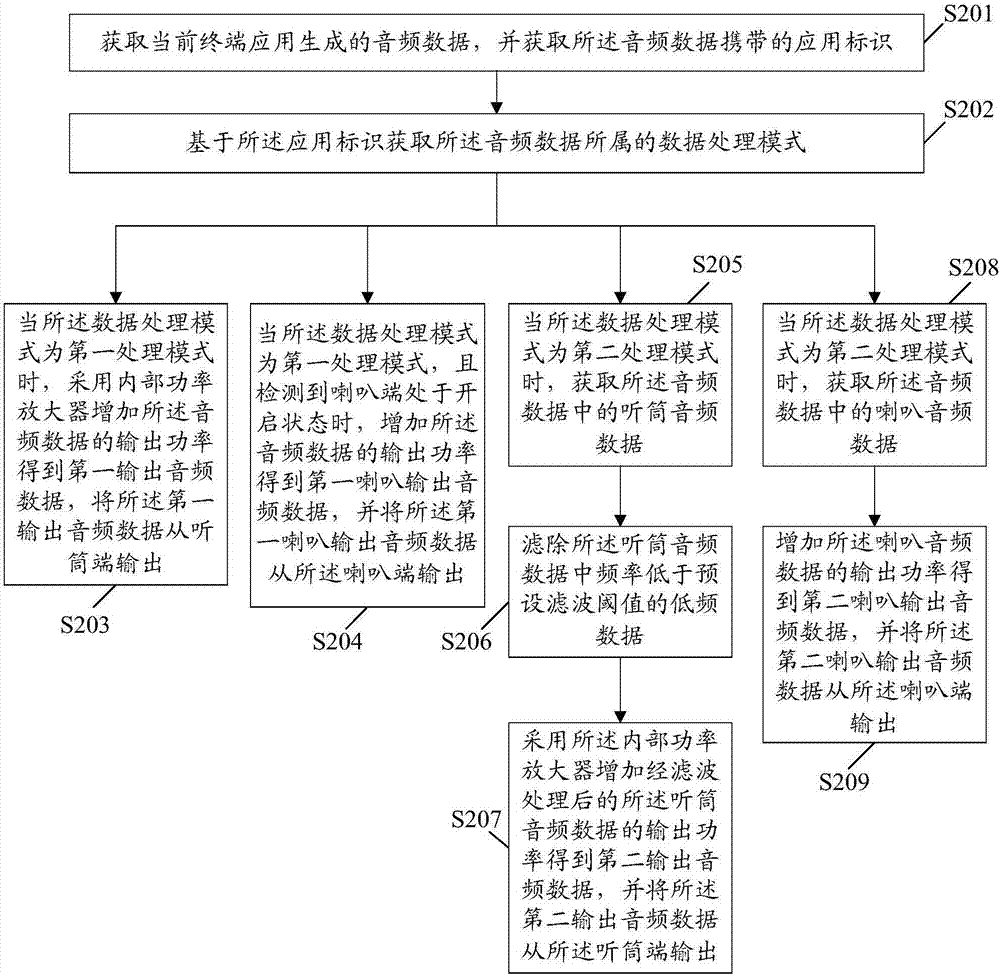

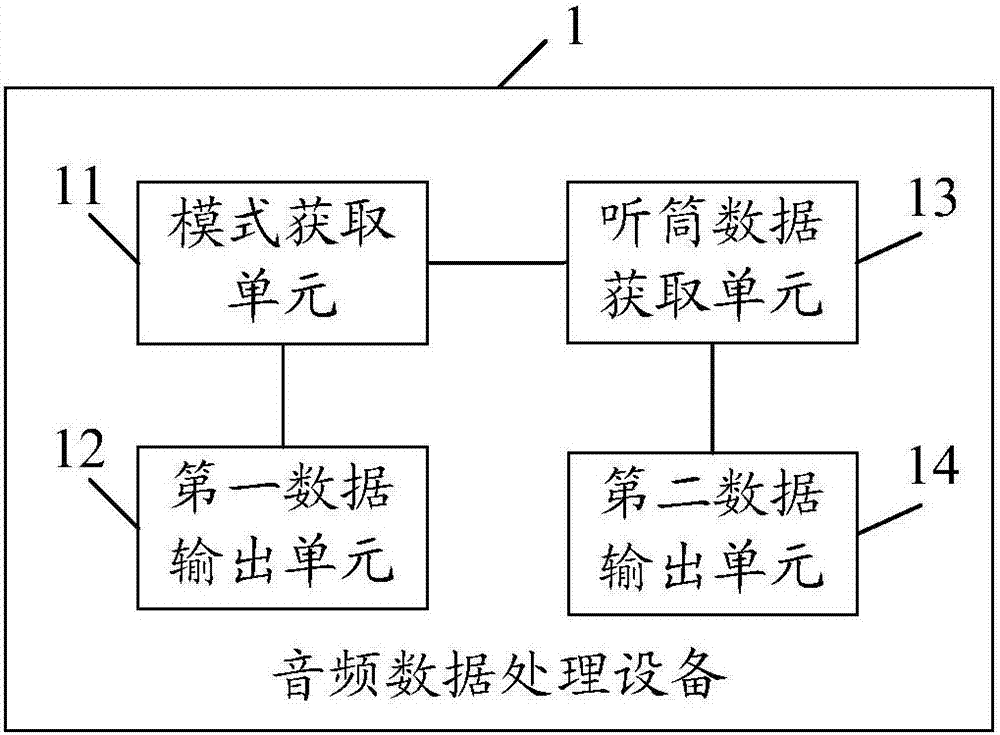

Audio data processing method and device thereof

InactiveCN106886387AIncrease output powerIncrease usageImpedence networksSound input/outputAudio power amplifierComputer terminal

Embodiments of the present invention disclose an audio data processing method and a device thereof. The audio data processing method comprises: acquiring audio data generated by a current terminal application and acquiring a data processing mode to which the audio data belongs; when the data processing mode is a first processing mode, increasing the output power of the audio data by using an internal power amplifier so as to obtain the first output audio data, and outputting the first output audio data from the headphone side; acquiring headphone audio data in the audio data when the data processing mode is the second processing mode; and carrying out filtering processing on the headphone audio data, increasing the output power of the filtered headphone audio data by using the internal power amplifier so as to obtain the second output audio data, and outputting the second output audio data from the headphone side. According to the method and device disclosed by the embodiments of the present invention, the working mode switching of the loudspeaker 2-in-one device can be controlled by software, and the usage rate of the loudspeaker 2-in-one device is improved on the basis of not affecting the hardware cost.

Owner:SHENZHEN GIONEE COMM EQUIP

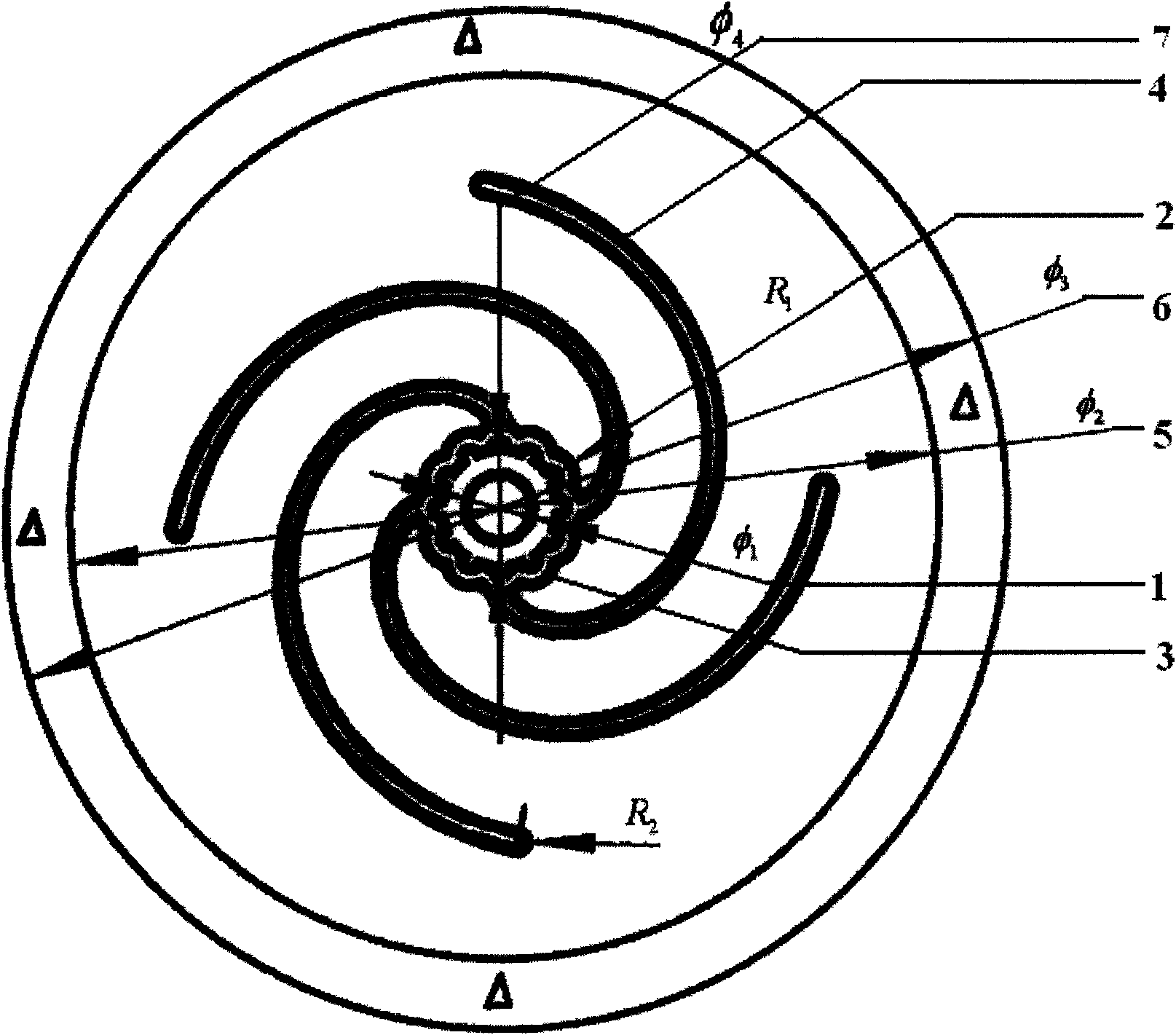

High-speed thyristor

InactiveCN101685831AImproved gate control turn-on timeImprove diThyristorSocial benefitsEconomic benefits

The invention relates to a high-speed thyristor of a KK200A-KK1600A series. The high-speed thyristor comprises a center gate electrode, a gear type enlarged gate electrode inner base circle, a bulge type enlarged gate electrode outer base circle, an evolvent type enlarged gate electrode separate finger, an edge chamfer angle using an inner circle and an outer circle as boundaries, and a conventional short-circuit point. The high-speed thyristor is characterized in that an aluminum layer of the evolvent type enlarged gate electrode separate finger is connected with a center enlarged gate electrode. The high-speed thyristor is helpful for improving correlative performances of a complete machine system which is designed and manufactured by adopting devices of the series, has a better market prospect, and is favorable for obviously improving the economic benefits and the social benefits of the devices of the series and correlative products of the complete machine system.

Owner:HANGZHOU HANAN SEMICON

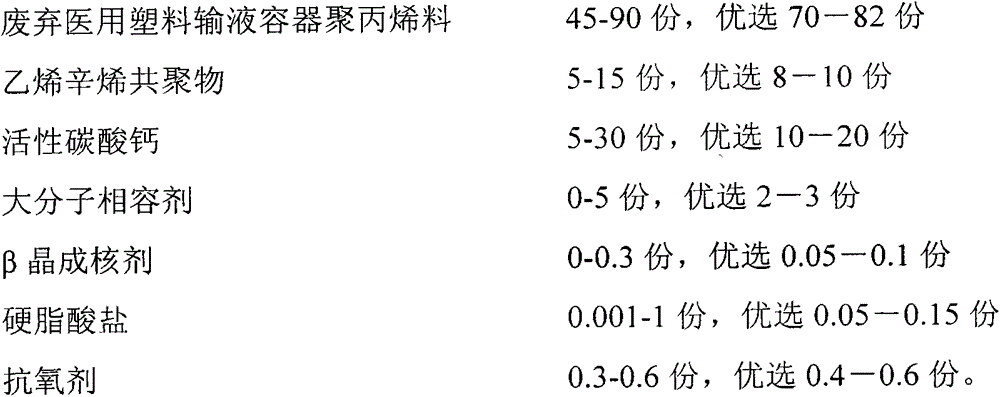

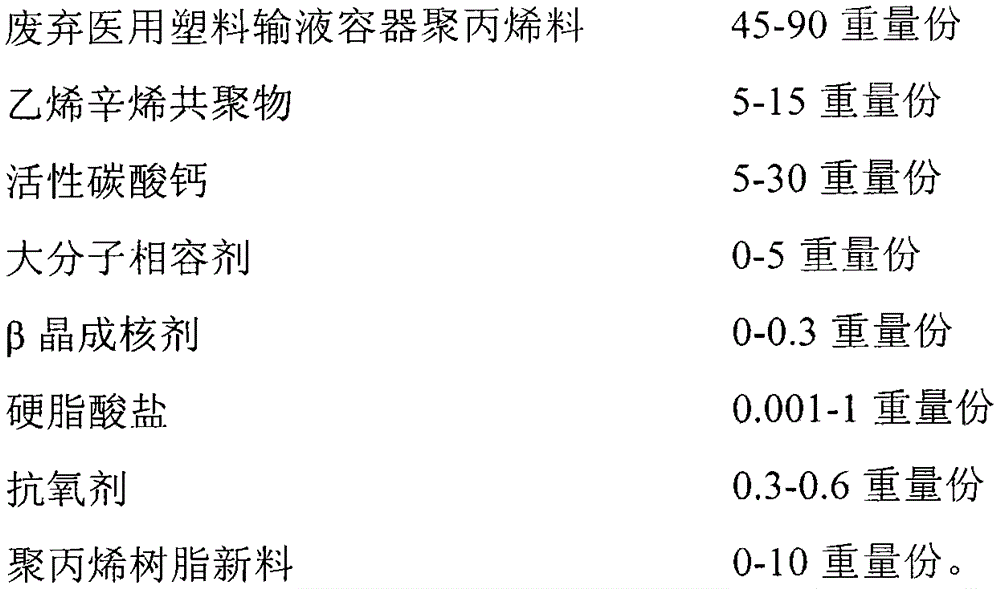

Toughened regenerated modified granule manufactured through polyolefin of waste medical plastic transfusion container

The invention discloses a toughened regenerated modified material manufactured through polyolefin materials of a waste medical plastic transfusion container and a manufacturing method and purpose of the toughened regenerated modified material. The toughened regenerated modified material is good in tenacity, easy to process, low in cost and suitable for manufacturing cold-resistant and shock-resisting materials.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

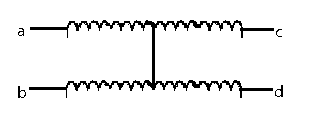

Method for determining short-circuit position of parallel-wound wires of transformer coil

InactiveCN102707189ADoes not affect costLow costElectrical testingElectrical resistance and conductanceTransformer

The invention discloses a method for determining a short-circuit position of parallel-wound wires of a transformer coil and relates to detection of the transformer coil. According to a conventional method for determining the short-circuit position of the parallel-wound wires of the transformer coil, an iron core is sleeved, current is increased, turn wires at a short-circuit point are insulated to cause carbonization, the coil is severely damaged, labor intensity is improved, and material cost is improved. The method provided by the invention comprises the following steps of: 1) measuring, and thus obtaining a resistance value RH of a normal wire; 2) searching a short-circuit wire; 3) measuring, and thus obtaining a front-section resistance value Rab of the wire; 4) subtracting a resistance value RB of a direct current resistance tester measuring line from the front-section resistance value Rab of the wire, comparing a difference value with the resistance value RH of the normal wire, and calculating to determine the position of the short-circuit point; and 5) calculating to determine the short-circuit point between the two wires, and if the quantity of the short-circuit points is more than 1, determining other short-circuit points between the two wires according to the steps 3 and 4 after repairing the short-circuit point. The method is simple, practical and high in efficiency.

Owner:WOLONG ELECTRIC GRP CO LTD +1

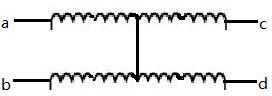

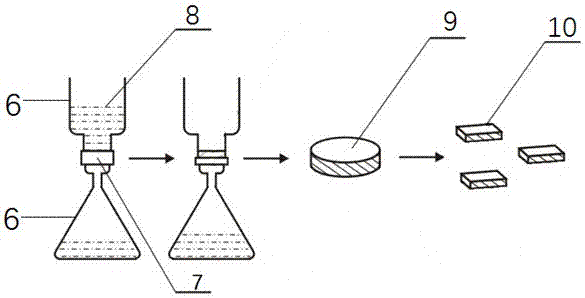

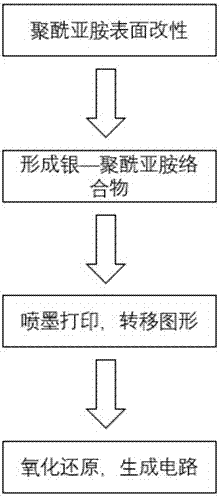

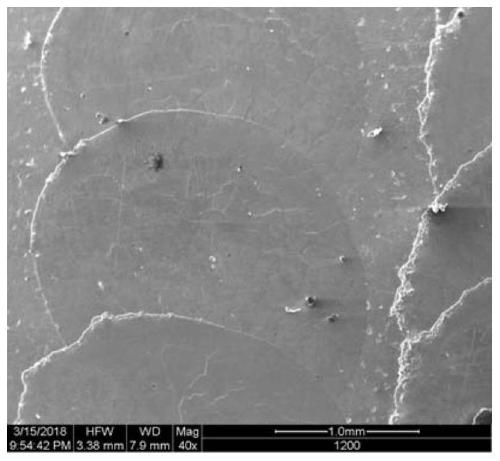

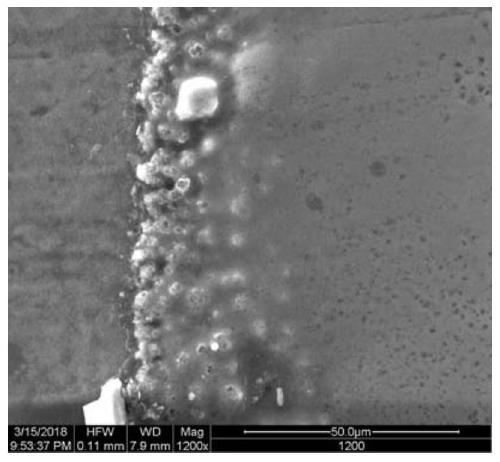

Ink-jet-printing-technology-based preparation method of flexible wireless pressure detection system

InactiveCN107219028ALow costImprove conductivityDuplicating/marking methodsPattern printingIon exchangeIon

The invention discloses an ink-jet-printing-technology-based preparation method of flexible wireless pressure detection system. The preparation method is characterized in that metal graphical processing of a flexible substrate surface is realized by ion exchange based on an all-wet chemical process; a flexible pressure sensor and a flexible antenna are prepared successively to realize signal transmitting and receiving; and then integration is carried out to form a flexible wireless pressure-sensitive sensor. Mechanical signals can be collected, transmitted and processed. During the metal graphical process, a common ink-jet printer can be used for printing with the low cost; and the obtained silver circuit is continuous and compact and the conductivity is high. The bonding force between a pressure sensing unit, the silver circuit, and the flexible substrate is strengthened; the pressure response frequency reaches 10000 hertz; and the pressure response range is from 10 pascal and 1 megapascal. During the flexible antenna signal collection and transmission, pressure response and transmission can be completed within 0.02 seconds. The flexible equipment has high stability; and the bending fatigue test demonstrates that the stability of the circuit characteristic of the system is kept after repeated 10000-times testing.

Owner:EAST CHINA NORMAL UNIVERSITY

Valve device for throttling a pressure medium flow, and damping device for damping pressure pulsations

ActiveCN108137030AThrottling characteristics are simpleReduce loadValve members for absorbing fluid energyVehicle sub-unit featuresMechanicsThrottle

Owner:ROBERT BOSCH GMBH

Guide rail lubricating device

InactiveCN107489876ASolve the problem of no space to inject greaseSimple structureManual lubricationConduits/junctionsStructural engineeringMechanical engineering

The invention discloses a guide rail lubricating device. The guide rail lubricating device comprises an installation block, adaptors and an oil pipe. The two ends of the oil pipe are connected to the installation block and a guide rail sliding block through the adaptors correspondingly. The novel guide rail lubricating device is simple in structure, convenient to assemble and capable of achieving spatial switching, and the problem that no space is used for allowing lubricating grease to be injected is solved.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

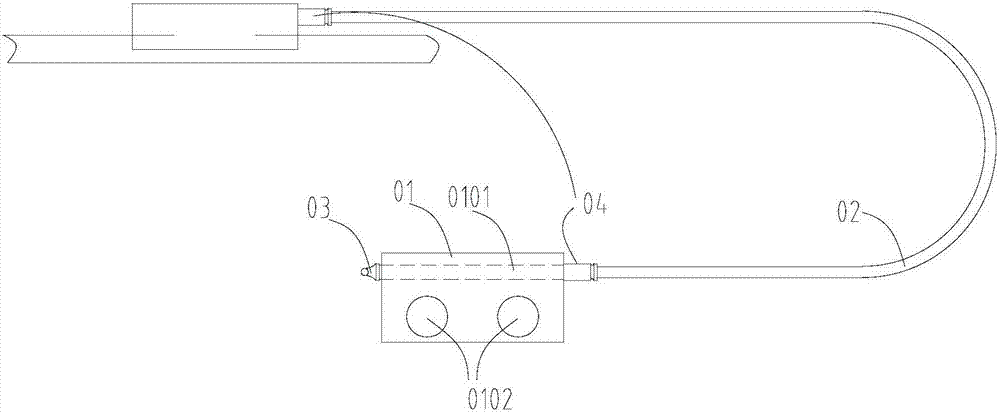

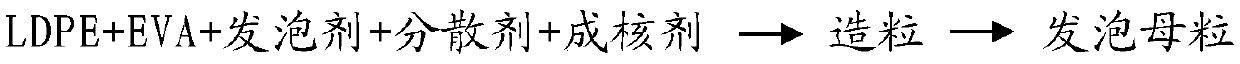

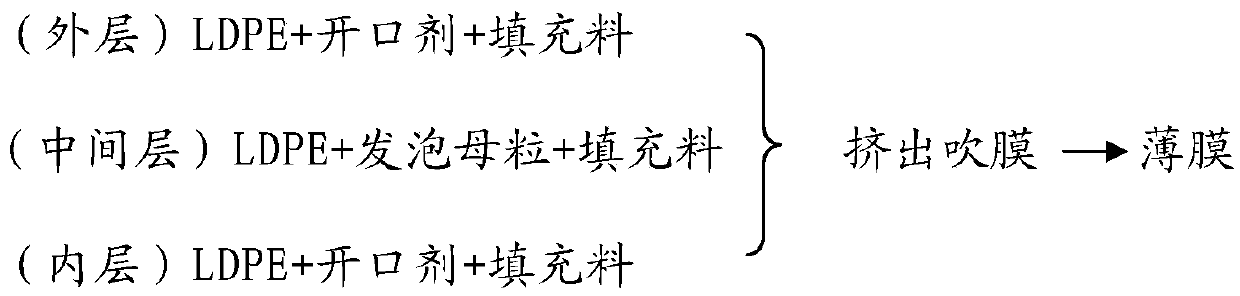

Foaming master batch and thickening type plastic film and corresponding preparation methods

ActiveCN105504446AIncreasing the thicknessDoes not affect costSynthetic resin layered productsLow-density polyethyleneFoaming agent

The invention provides a foaming master batch. The foaming master batch is prepared from, by weight, 30%-60% of low-density polyethylene, 20%-30% of EVA, 10%-20% of foaming agent and 10%-20% of dispersing agent. The invention further provides a method for preparing the foaming master batch, thickening type plastic film taking the foaming master batch as the raw material and a preparation method of the thickening type plastic film. The thickening type plastic film takes polyethylene as the main raw material, by means of three-layer co-extrusion film blowing, the foaming agent is added to an interlayer but not added to inner film and outer film, film blowing is conducted at a certain temperature and speed, foaming is conducted on the interlayer of the film but not conducted on the inner film and the outer film, the thicknesses of all the layers are controlled, and therefore the film is thickened without affecting the cost and the performance of the film. The products can be applied directly and can also be applied on multi-layer composite plastic weaved cloth. The preparation process of the products is simple, the cost performance is high, the market prospect is wide, and positive social meaning is achieved.

Owner:FSPG HI TECH

Method for improving utilization efficiency of factory rice seeding greenhouses

InactiveCN107646587AAvoid wastingIncrease profitCultivating equipmentsRoot crop cultivationAgricultural scienceGreenhouse cultivation

The invention discloses a method for improving the utilization efficiency of factory rice seeding greenhouses. Since only one crop of rice seedlings per year can be raised in many factory rice seedinggreenhouses, serious waste of resources is caused, and in order to solve the problem, a greenhouse cultivation mode of potatoes, rice seeding and peppers can be achieved through the method accordingto the growth characteristics of the potatoes, rice seedlings and autumn-and-winter peppers; the method has the advantages of good engagement of crop rotation, a good yield and a high earning, and canreduce the production cost of the potatoes by means of natural advantages and have no influence on the performance of rice seeding, so that the utilization efficiency of land is effectively improved,and after rice seeding is finished, the autumn-and-winter peppers can be cultivated by means of a cultivation technique of the method, so that a short growth period and good benefit are achieved; since the selling period of the autumn-and-winter peppers coincides with December, the off-season market demand for the peppers can be met, and the autumn-and-winter peppers are welcomed by consumers. According to the cultivation mode for improving the yield of rice seeding in the factory greenhouses, since the time period of crop rotation of agricultural products is arranged reasonably, the comprehensive benefit of rice production can be improved, the waste of the high-cost factory rice seeding greenhouses can be avoided, and therefore the method has a wide application prospect.

Owner:SHUCHENG WENHE PLANTING SPECIALIZED COOP

Rotation handrail switch alarm device

InactiveCN107520662ASimple structureEasy to assembleMaintainance and safety accessoriesSwitching signalEngineering

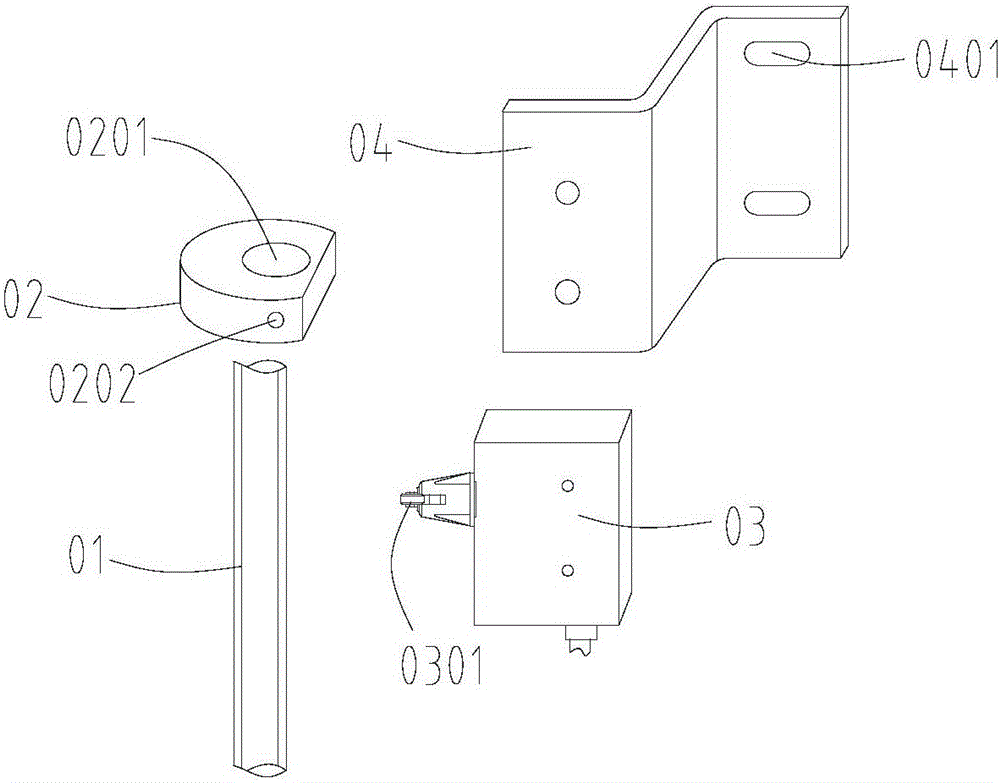

The application discloses a rotary railing switch alarm device. The rotary railing switch alarm device includes a rotary railing, a cam, a travel switch and a mounting bracket, the cam is sheathed on the rotary railing, the travel switch is installed on the mounting bracket, and the contact of the travel switch against the cam. The rotation of the rotating railing drives the rotation of the cam to press the contact of the travel switch, the travel switch signal is sent out, and the machine tool alarms. The novel rotating railing switch alarm device has simple structure, convenient assembly and simple use. When the rotating railing is opened, the device will alarm and cannot operate.

Owner:张家港市华舰五金工具有限公司

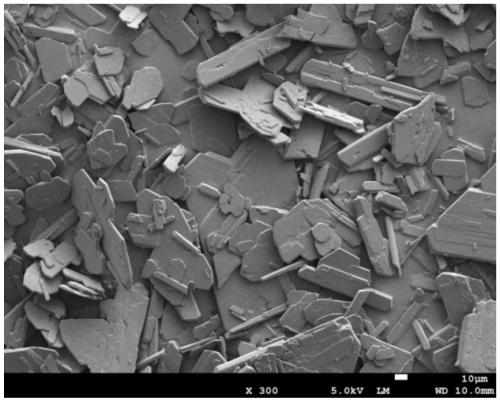

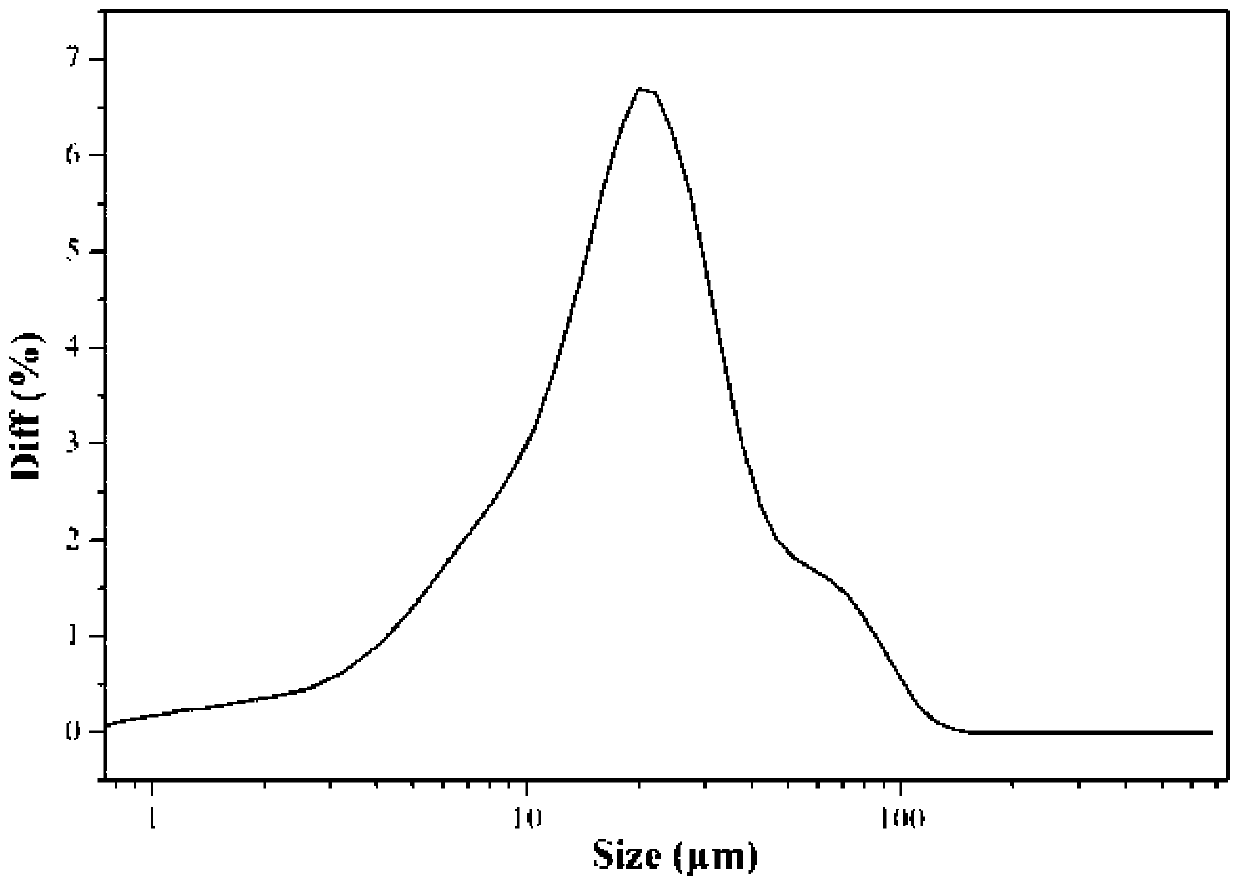

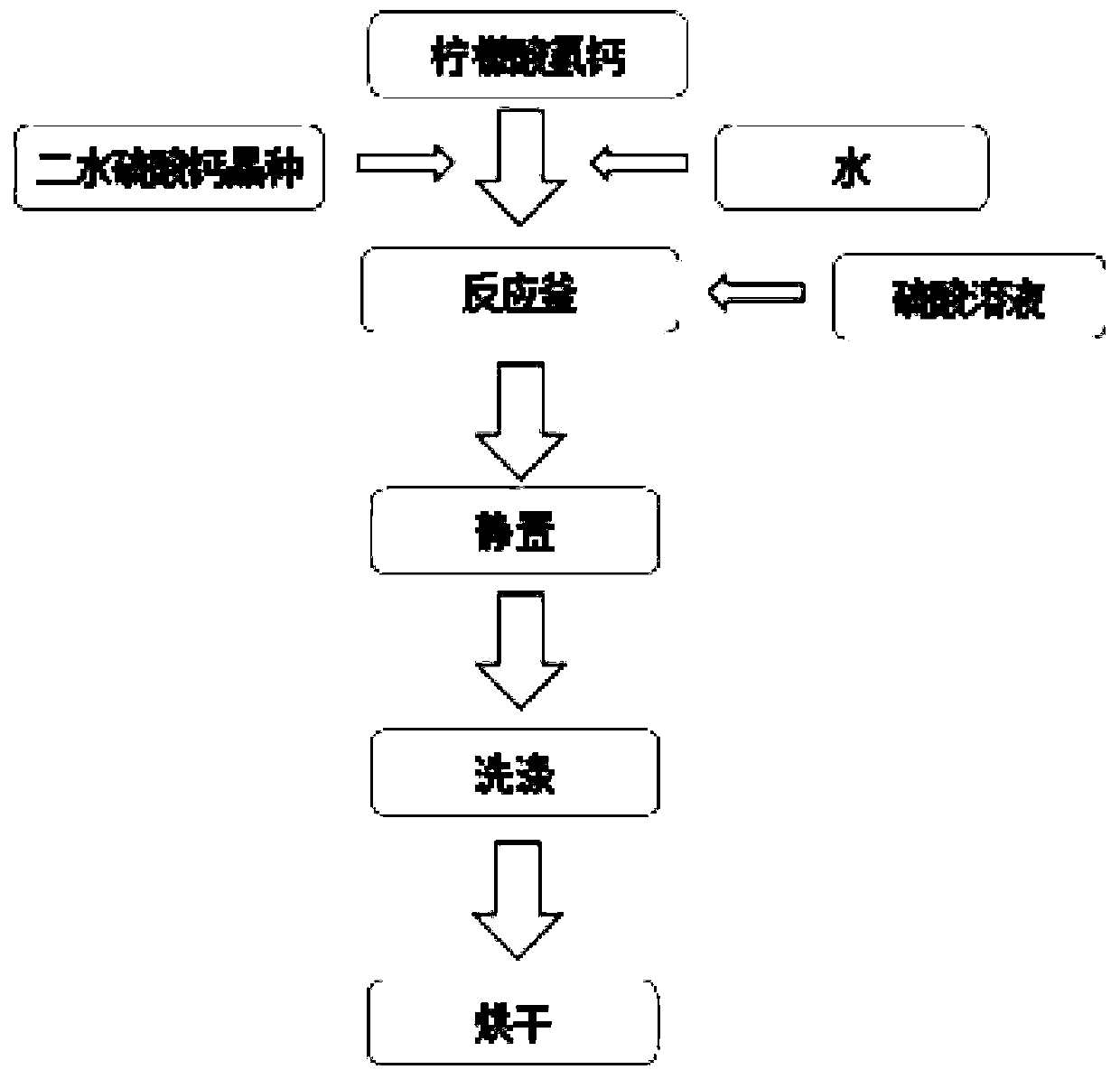

Synthetic method of citric acid gypsum

ActiveCN110282648ACoarse particlesCrystal Structure RulesCalcium/strontium/barium sulfatesGypsumSeed crystal

The invention belongs to the field of dihydrate gypsum synthesis and relates to a synthetic method of citric acid gypsum. The method comprises the following steps: preparing a suspension from calcium hydrogen citrate, calcium sulphate dihydrate seed crystal and water; heating the suspension until the temperature of the suspension is 20-80 DEG C, stirring the suspension and simultaneously adding a sulfuric acid solution into the suspension until sulfuric acid and calcium hydrogen citrate completely react; standing and taking a bottom solid after the reaction, cooling and washing and drying. By the technical scheme, the problem of low strength of building gypsum powder due to fine citric acid gypsum particles and irregular crystal structure is solved.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

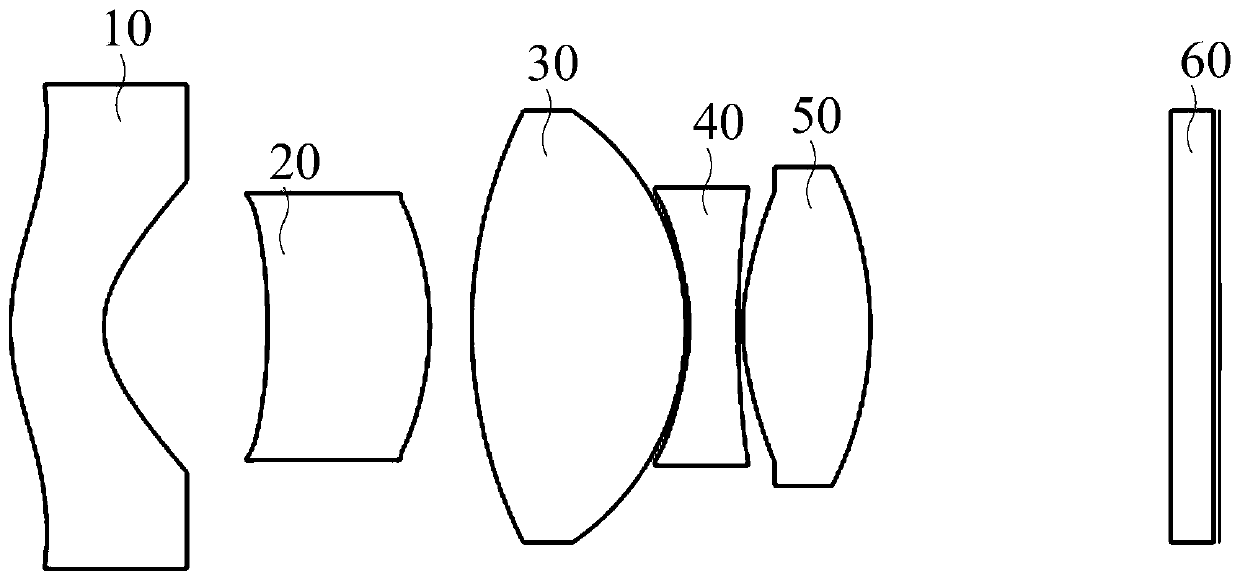

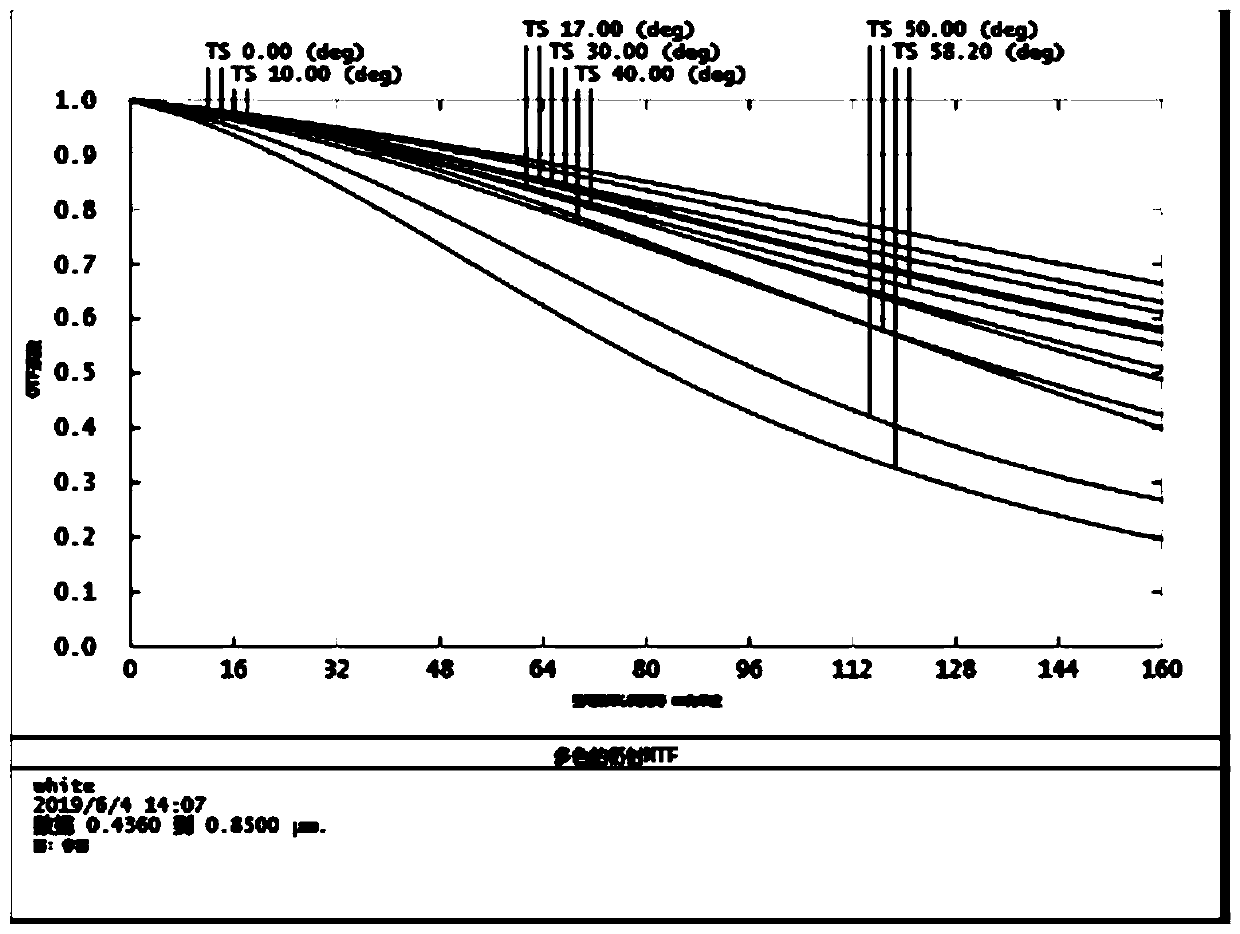

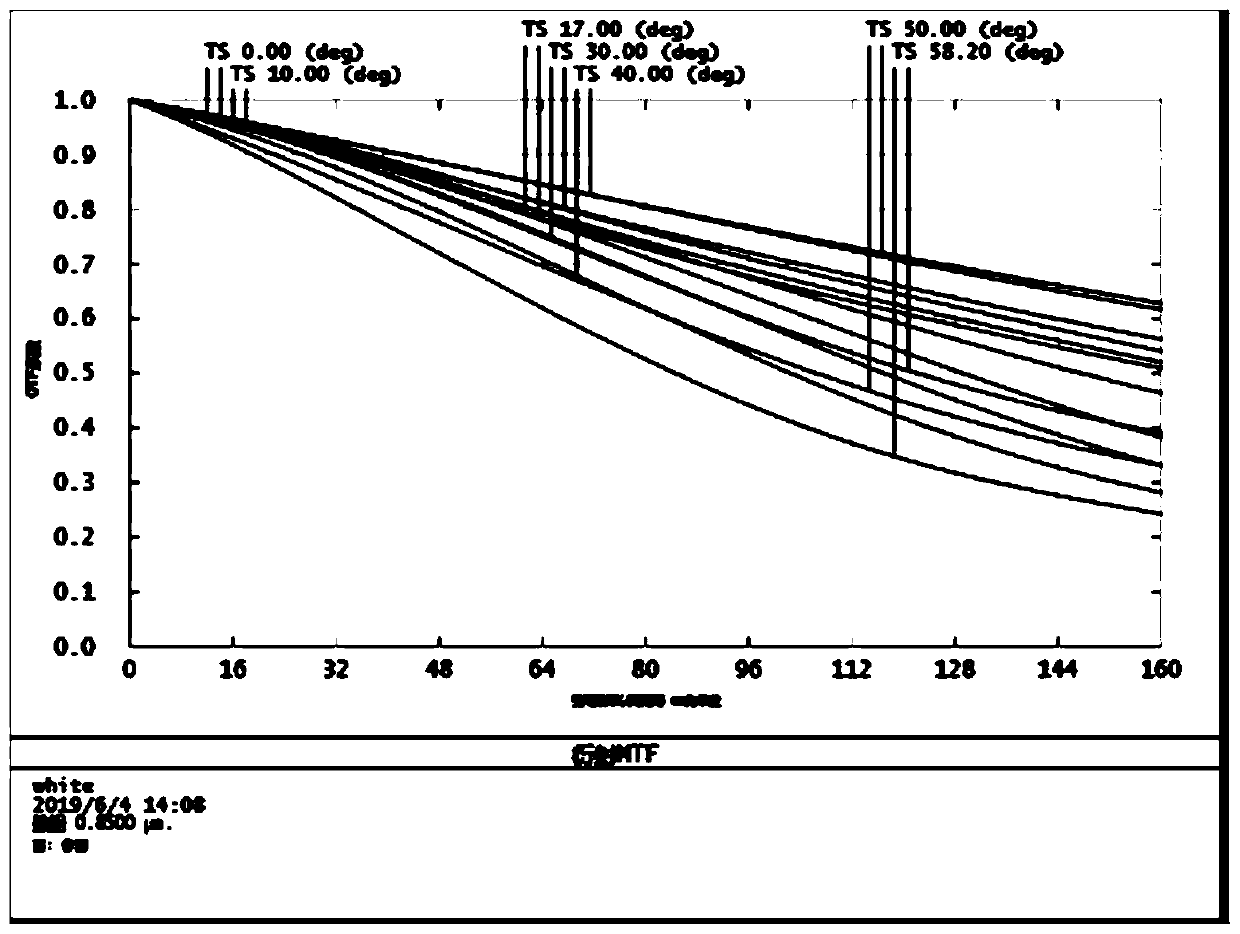

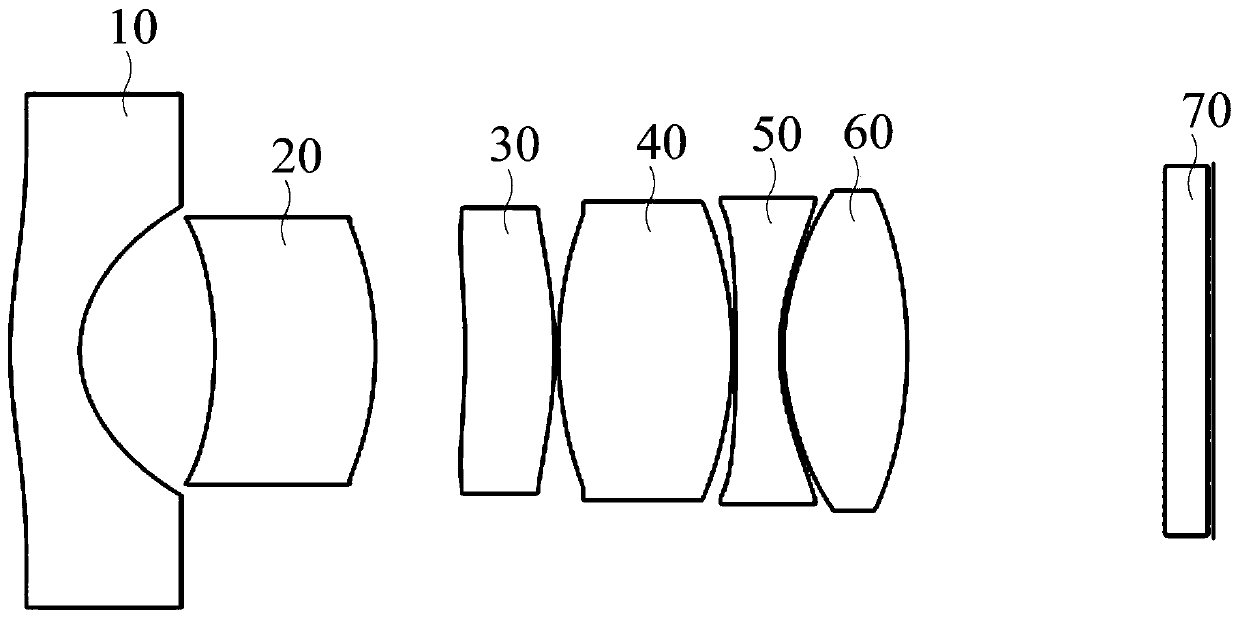

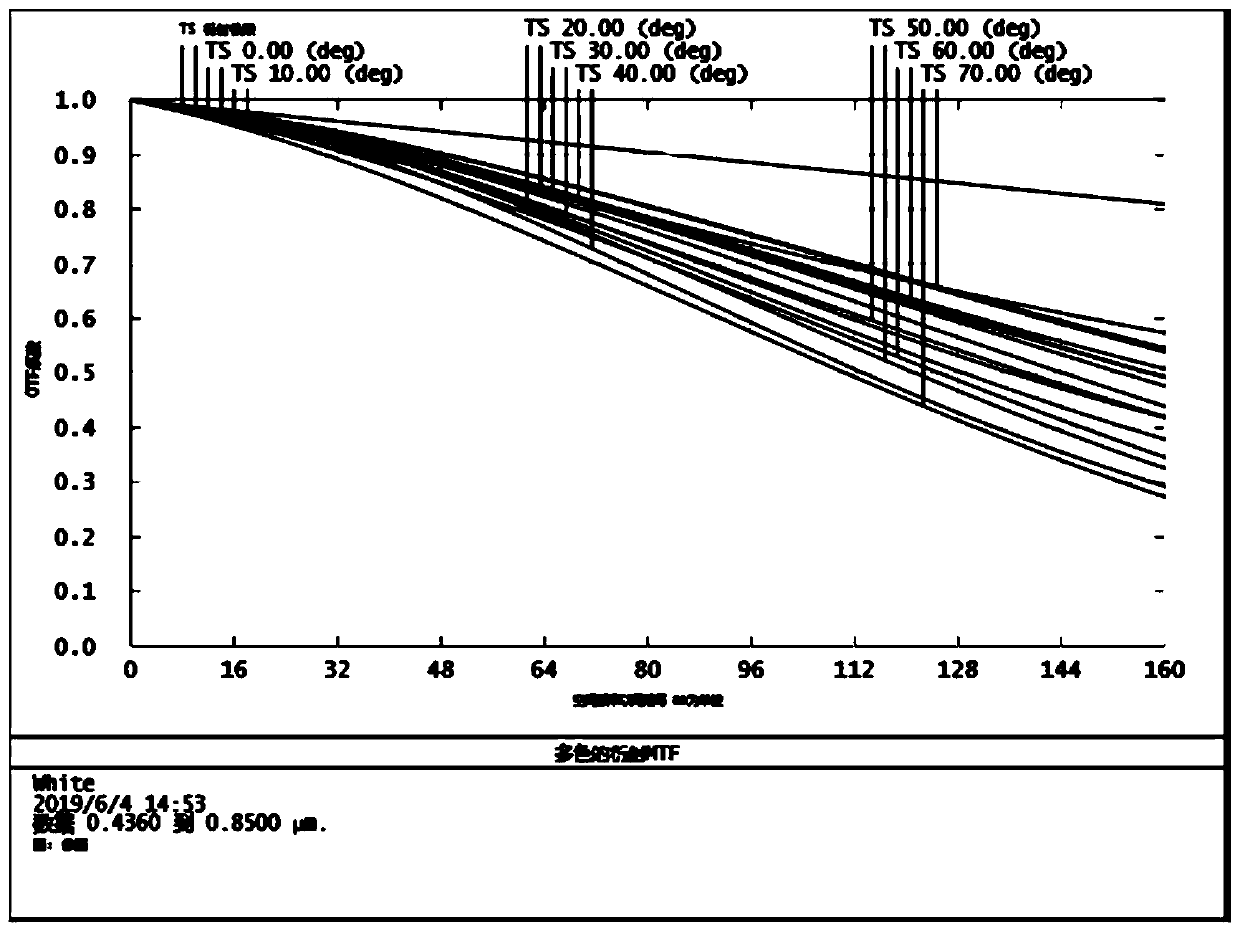

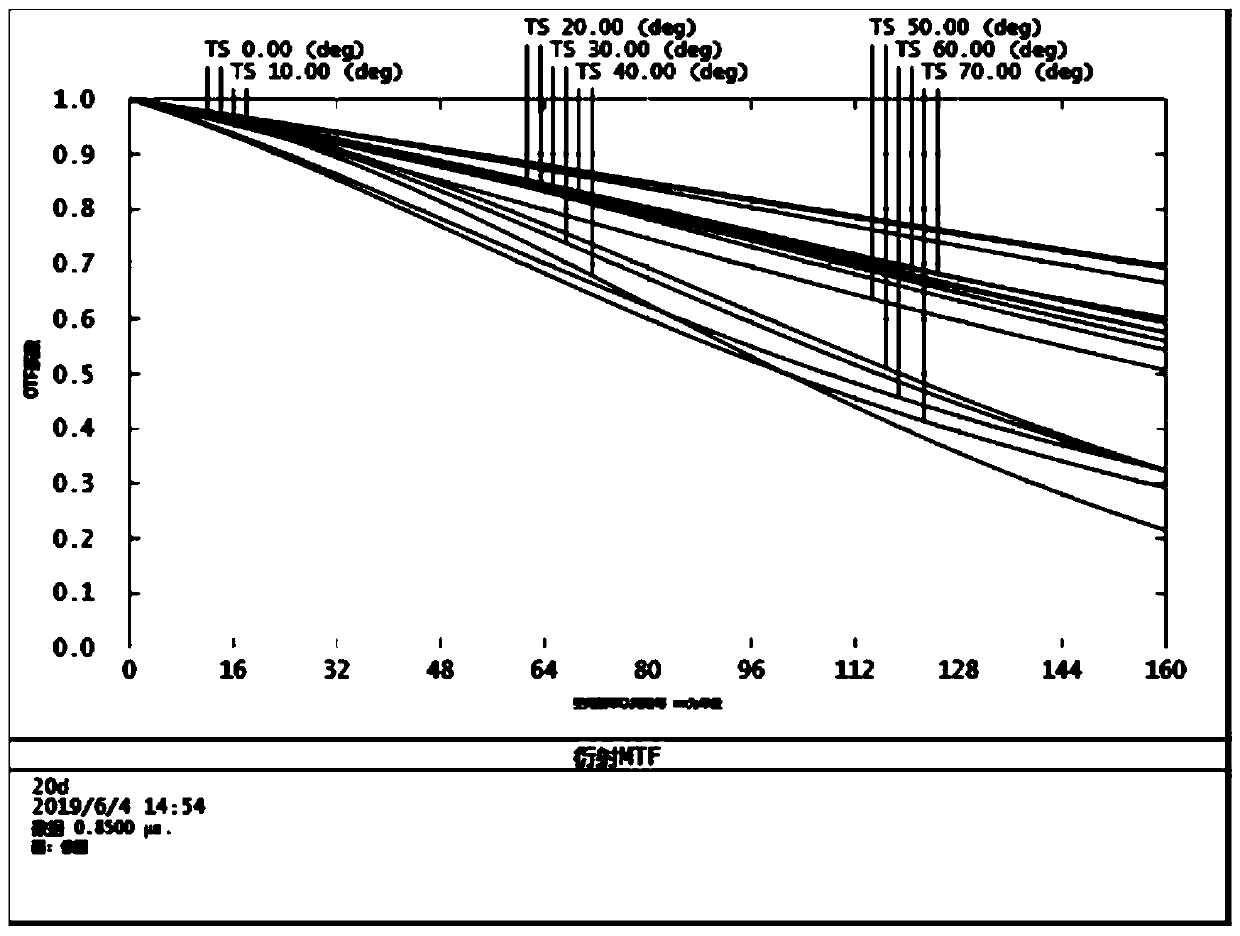

Glass-plastic mixed prime lens

The invention discloses a glass-plastic mixed prime lens. The glass-plastic mixed prime lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens, which are arranged inorder from an object side to an image side; wherein the third lens is a glass spherical lens, and the first lens, the second lens, the fourth lens and the fifth lens are all plastic aspherical lenses;the first lens is a convex-concave negative power lens, the second lens is a concave-convex positive power lens, the third lens is a biconvex positive power lens, the fourth lens is a convex-concaveor a biconcave negative power lens, and the fifth lens is a biconvex positive power lens; a ratio of focal lengths of the second lens, the third lens, the fourth lens and the fifth lens to the entirelens satisfies the following conditions: f2 / f is greater than 3 and less than 6; f3 / f is greater than 1.6 and less than 2; f5 / f is greater than 1 and less than 10; and f4 / f5 is greater than -1.1 and less than -0.65. By adopting the technical scheme provided by the embodiment of the invention, the performance of the prime lens is not affected while the cost is reduced.

Owner:DONGGUAN YUTONG OPTICAL TECH

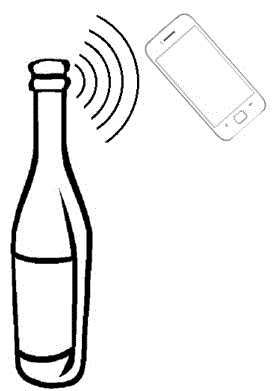

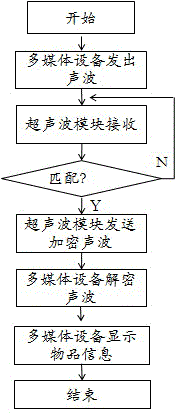

Ultrasonic wave anti-fake device and method

InactiveCN104463610AFast readingDoes not affect costSensing record carriersCommerceEngineeringAcoustic wave

The invention discloses an ultrasonic wave anti-fake device and method. The device comprises an anti-fake module and a verification module, the anti-fake module and an object needing anti-fake processing are packaged together, and the anti-fake module comprises a first acoustic wave receiver, a first acoustic wave generator and a first processing unit, wherein the first acoustic wave receiver is used for monitoring external pairing ultrasonic wave signals, the first acoustic wave generator is used for transmitting encryption signals containing object information, and the first processing unit is used for analyzing and processing the pairing ultrasonic wave signals and generating the encryption signals. The verification module comprises a second acoustic wave generator, a second acoustic wave receiver, a second processing unit and a displaying unit, wherein the second acoustic wave generator is used for generating pairing ultrasonic wave signals, the second acoustic wave receiver is used for receiving encryption signals, the second processing unit is used for generating pairing ultrasonic wave signals and decrypting the encryption signals, and the displaying unit is used for displaying the object information obtained through decrypting the encryption signals. When the information of the object needing anti-fake processing needs to be inquired, the verification module generates the pairing ultrasonic wave signals, the anti-fake module generates the encryption signals when monitoring that the pairing ultrasonic wave signals are matched with stored secrete keys, and the verification module receives and decrypts the encryption signals according to a conventional algorithm and displays the decrypted information on the displaying unit.

Owner:TOUCHAIR TECH

Glass and plastic mixed fixed-focus lens

The invention discloses a glass and plastic mixed fixed-focus lens. The glass and plastic mixed fixed-focus lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and asixth lens, which are sequentially arranged from the object side to the image side, wherein the fourth lens is a glass spherical lens; the first lens, the second lens, the third lens, the fifth lens and the sixth lens are plastic aspheric lenses; the first lens is a convex-concave negative focal lens; the second lens is a convex-concave positive focal lens; the third lens is a convex-concave lens;the fourth lens is a double-convex positive focal lens; the fifth lens is a double-concave negative focal lens; the sixth lens is a double-convex positive focal lens; and the focal length ratio of the second lens, the fourth lens, the fifth lens and the sixth lens to the whole lens satisfies the following condition: a formula as shown in the specification. According to the technical scheme provided in the embodiment of the invention, the performance of the fixed-focus lens is not influenced while the cost is reduced.

Owner:DONGGUAN YUTONG OPTICAL TECH

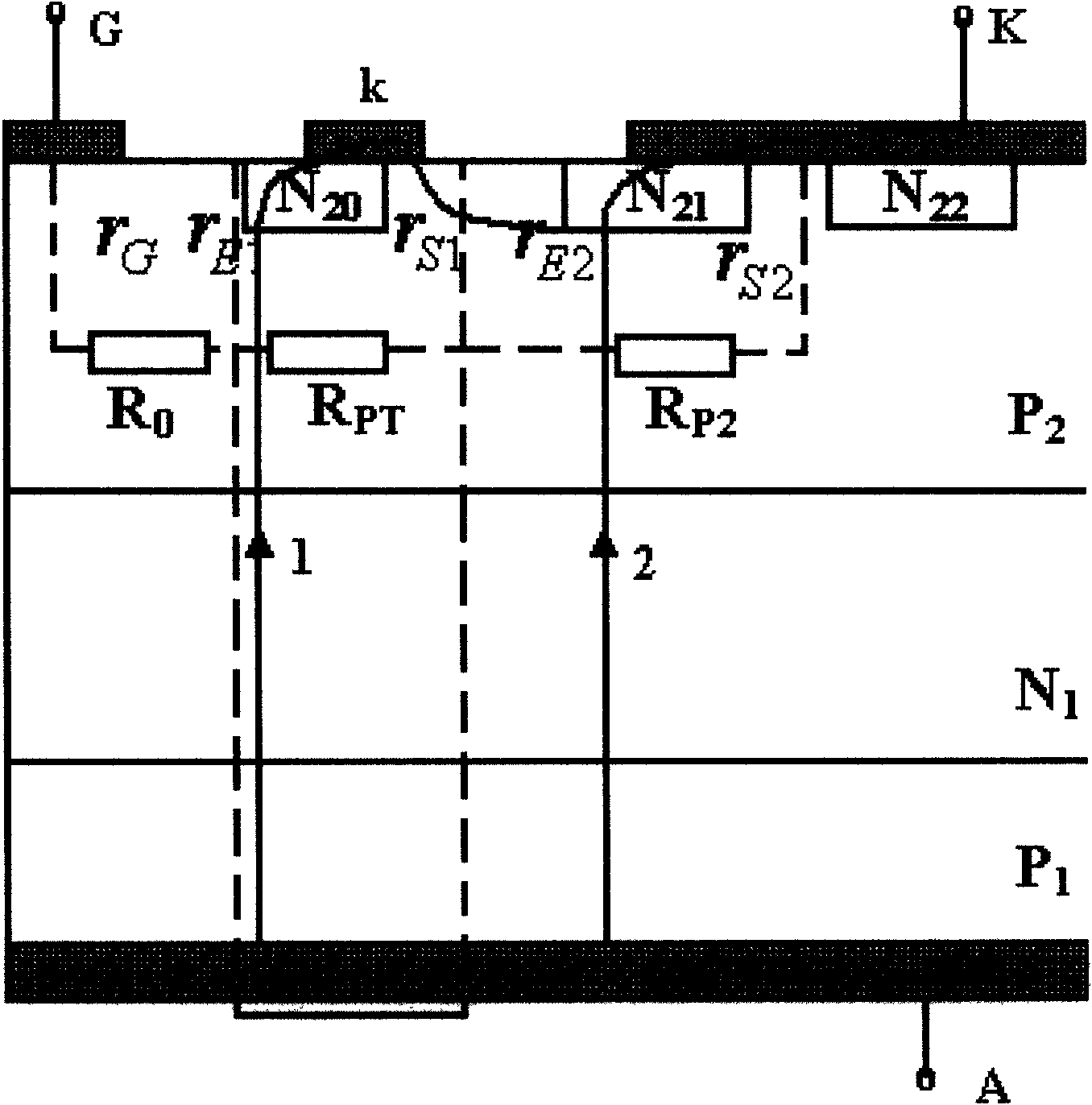

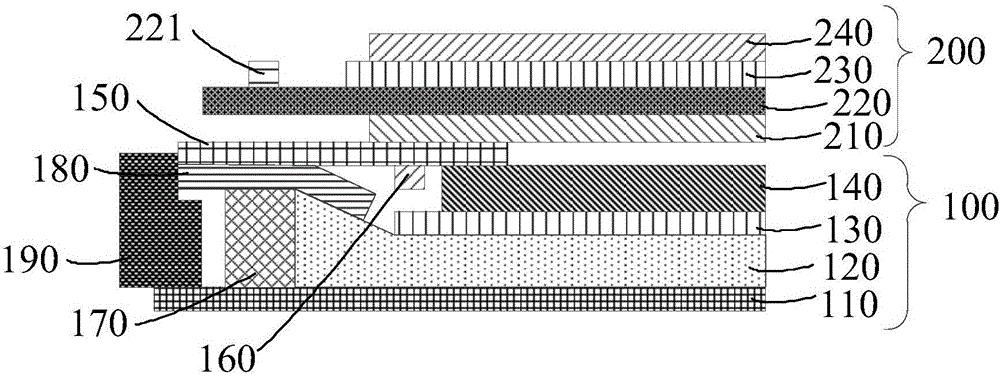

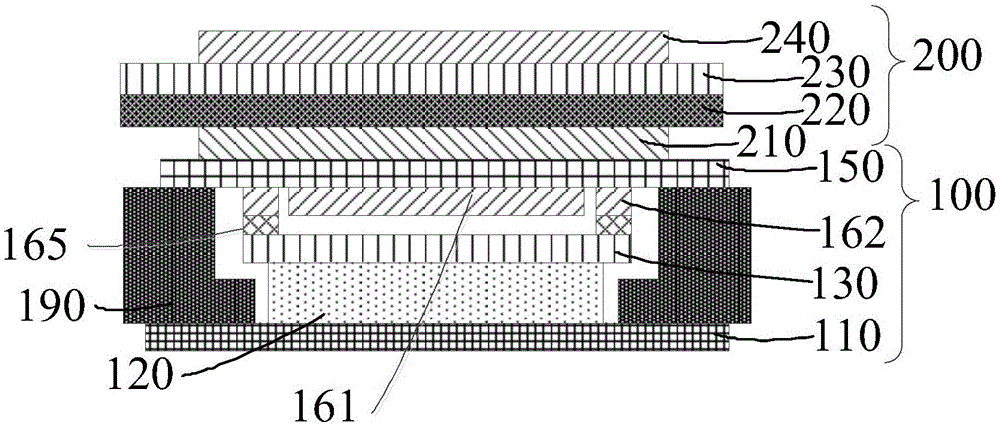

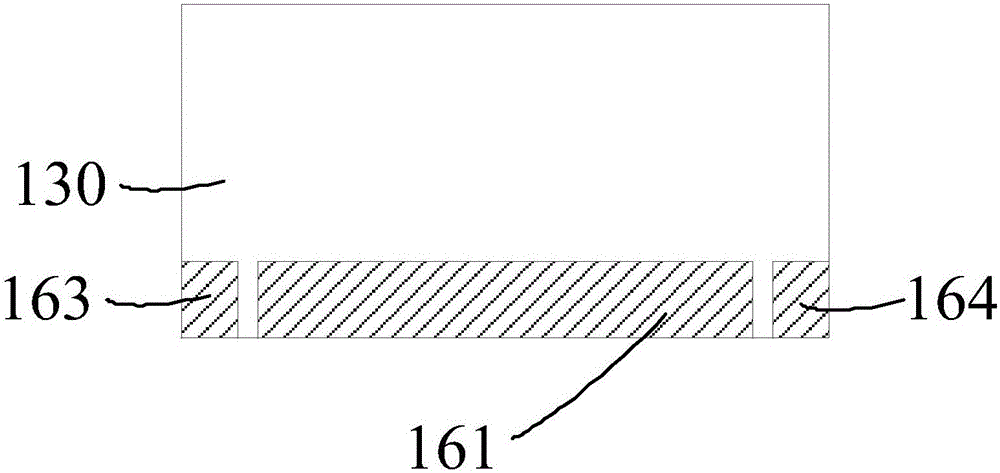

Solar cell

InactiveCN101866967BReduce manufacturing costImprove conductivityFinal product manufacturePhotovoltaic energy generationThermal expansionSolar cell

The invention relates to a silicon-based single-junction gallium indium nitride solar cell which comprises a back electrode (11), a silicon substrate (1), a seed crystal layer (2), a buffer layer (3), an n-type doped GaN buffer layer (4), an InaGal-aN layer (5), an unintentional doped InbGal-bN layer (6), a p-type doped IncGal-cN layer (7), a window layer (8), a positive electrode (9) and an anti-reflection conductive film (10) which are arranged from bottom to top, wherein the silicon substrate and the InaGal-aN layer is are an n-type doped structure, the seed crystal layer and the buffer layer are made of ZnO material, the window layer is made of p-type heavily doped GaN, and the anti-reflection conductive film covers areas of the window layer other than the positive electrode. The solar cell can quite effectively solve the problems of lattice matching, thermal expansion coefficient matching and the like encountered when a GaN film extends from the silicon substrate, and has the advantages of low manufacturing cost, high sunlight absorbability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

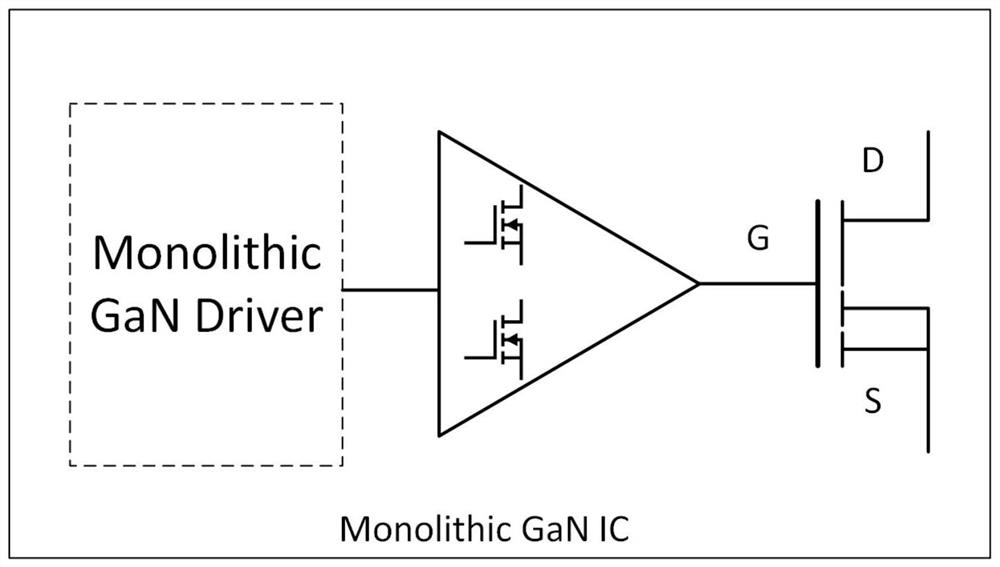

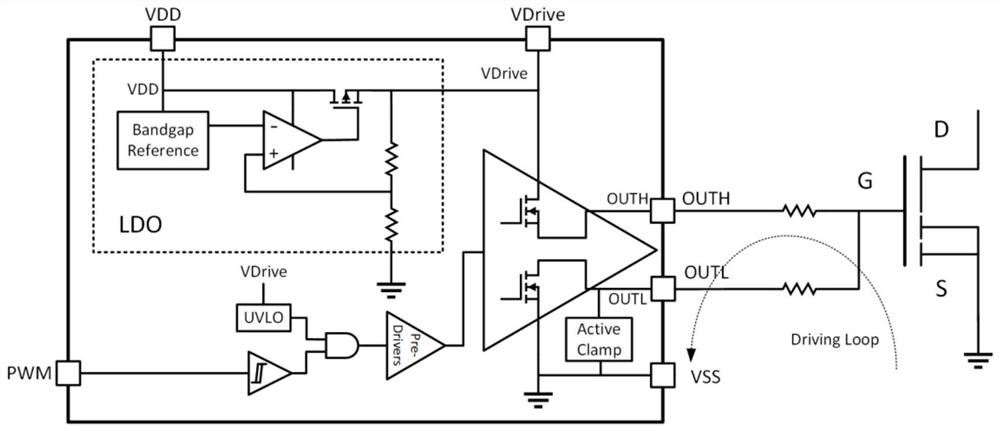

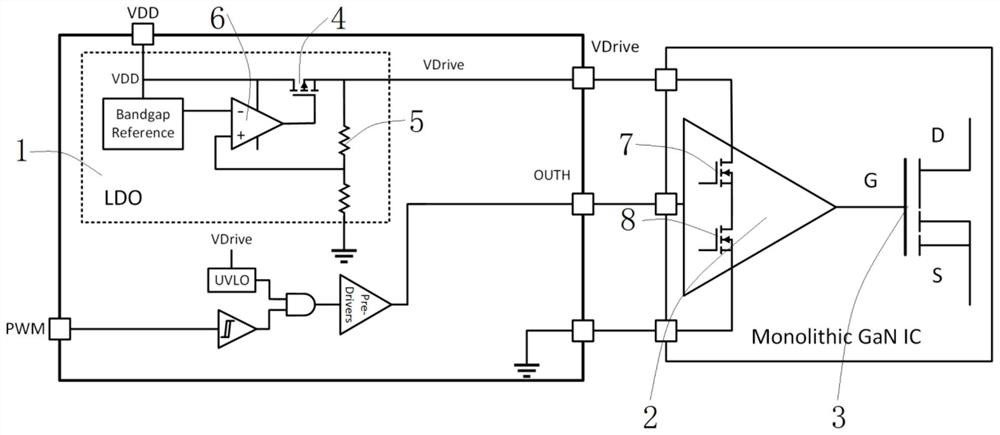

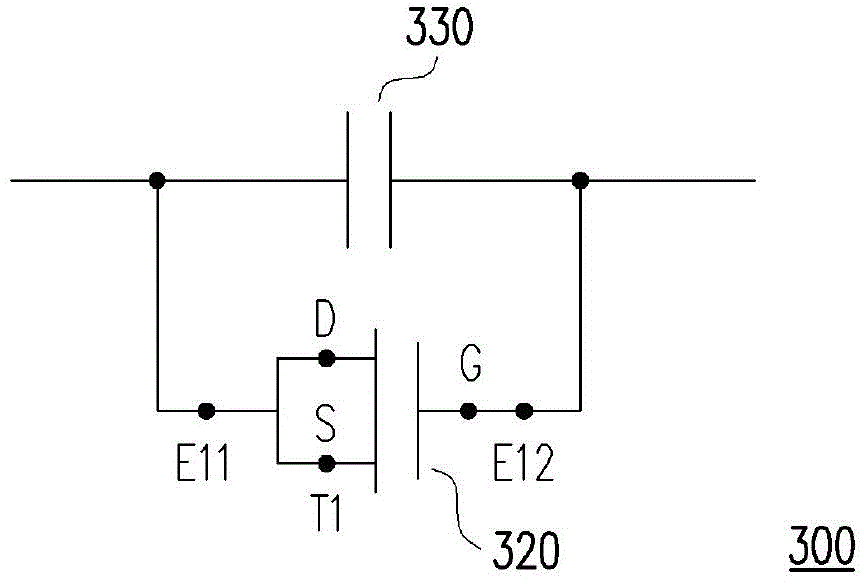

Silicon IC-gallium nitride hybrid drive system

PendingCN111800115AReduce areaLow costElectronic switchingElectric vehicle charging technologyHemt circuitsEngineering

The invention discloses a silicon IC-gallium nitride hybrid driving system. The system comprises a driving module and a gallium nitride power device. The driving module comprises a silicon IC type linear voltage reduction assembly used for outputting a preset voltage and a gallium nitride monolithic integrated type driving half-bridge assembly. The output end of the gallium nitride monolithic integrated drive half-bridge assembly is in signal connection with a gate circuit of the gallium nitride power device, so as to modulate the conductivity of the gallium nitride power device in a chargingand discharging manner. The silicon IC type linear voltage reduction assembly is connected with the gallium nitride monolithic integrated type drive half-bridge assembly through wire bonding; and thedriving module and the gallium nitride power device are matched in a common packaging mode. The system at least comprises the following advantages: the advantages of flexibility, low cost and maturityof a silicon IC integrated circuit and the advantages of a gallium nitride monolithic integrated half-bridge assembly for eliminating parasitic parameters of a drive circuit are combined.

Owner:苏州量芯微半导体有限公司

Backlight module and display device

ActiveCN107178713AMinor changesDoes not affect the original processElectric circuit arrangementsPlanar/plate-like light guidesLight guideDisplay device

The invention provides a backlight module and a display device. The backlight module comprises a light guide plate comprising the light entering surface, the light emitting surface and the reflecting surface, a reflector, a diffuser, a prismatic lens set, a rim tape, a light source and a light shield layer, wherein the reflector is arranged on the reflecting surface of the light guide plate, the diffuser is arranged on the light emitting surface of the light guide plate, the prismatic lens set is arranged on the light emitting surface of the diffuser, the rim tape is arranged around the light emitting surface of the light guide plate, the light source is arranged on one side of the light entering surface of the light guide plate, and the light shield layer is arranged between the diffuser and the rim tape and arranged on the outer side of the prismatic lens set in the mode that the light shield layer corresponds to the side of incident light of the diffuser. The light shield layer comprises a middle section and side sections which are separated, and the length of the middle section is larger than the length of each side section. The two sides of the side sections are fixedly connected with the diffuser and the rim tape correspondingly, and only one side of the middle section is fixedly connected with the rim tape. Under the condition of high temperatures or low temperatures or the like, the light shield layer and the diffuser move relatively, and warping of the light shield layer and the diffuser is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Processing method of copper-aluminum composite special-shaped parallel groove clamp

InactiveCN106329287AHigh strengthImprove securityContact member manufacturingAbnormal shapedAluminum composites

The invention discloses a processing method of a copper-aluminum composite special-shaped parallel groove clamp. According to the method, copper is continuously casted on semi-solid aluminum or aluminum alloy in an oxygen-free manner according to different proportions, and then cutting, die punching, pressing and shaping are carried out, so that the copper-aluminum composite special-shaped parallel groove clam can be formed. The copper-aluminum composite special-shaped parallel groove clamp formed by using the processing method of the invention has the advantages of no need for welding, high copper-aluminum combination strength, low resistance, little heat emission and the like. Compared with existing methods according to which a copper-aluminum combination process such as polishing welding and explosive welding is adopted to produce a special-shaped parallel groove clamp, the processing method of the invention has obvious advantages.

Owner:江苏苏源电气有限公司

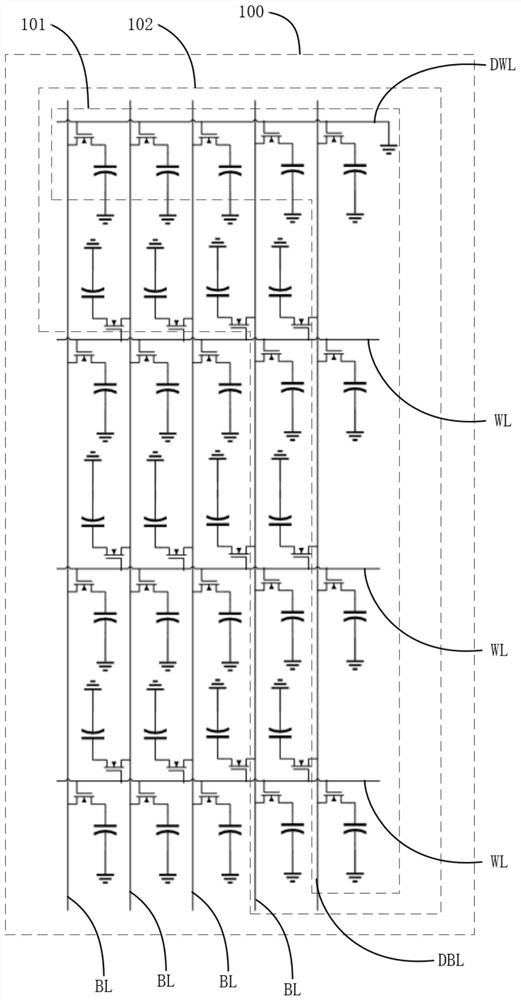

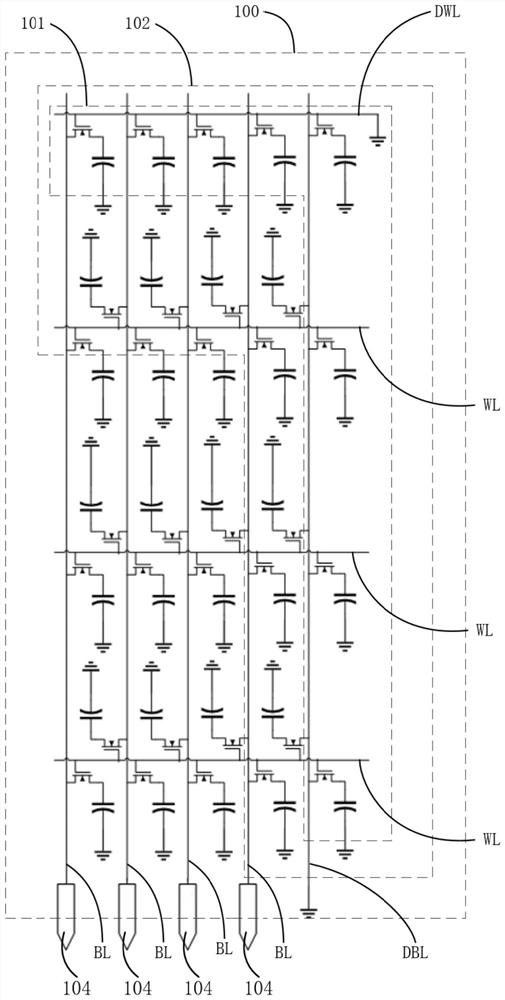

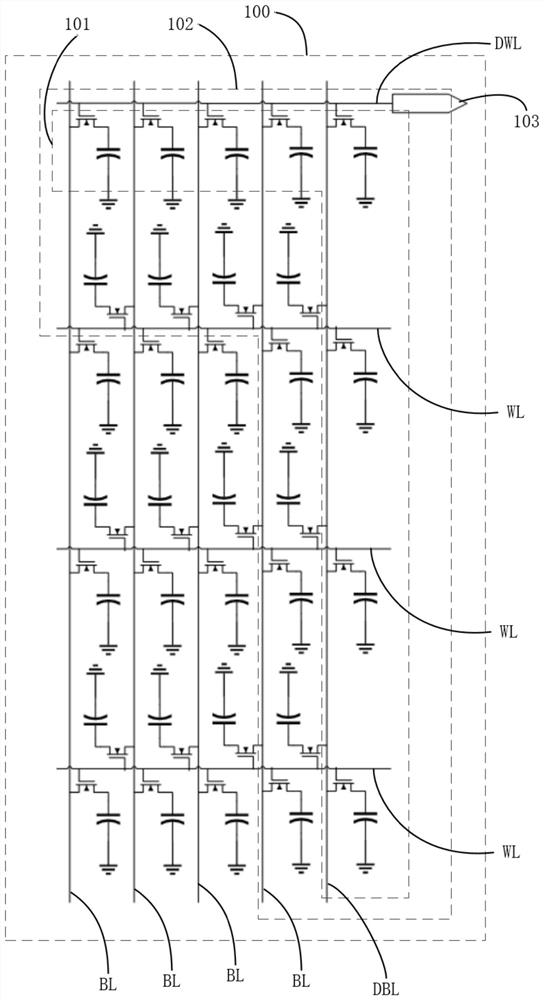

Performance detection method and detection circuit for DRAM (Dynamic Random Access Memory)

PendingCN114360618ADoes not affect performance testingYield is not affectedStatic storageBit lineHemt circuits

The invention relates to a performance detection method and detection circuit of a DRAM (Dynamic Random Access Memory). The performance detection method of the DRAM comprises the following steps: respectively connecting one end of a word line and / or one end of a bit line of a storage unit with a measurement bonding pad, wherein the storage unit is located at the edge of the DRAM; applying a measurement voltage or a measurement current to one end of the word line and / or one end of the bit line connected to the measurement pad; and outputting a measurement result through the measurement bonding pad. One end of the word line and / or one end of the bit line of the storage unit located at the edge of the DRAM are / is connected with the measurement bonding pad, the measurement voltage or the measurement current is applied, and the measurement result is output, so that the performance of the storage can be detected under the condition that the storage unit is not influenced, and the product yield and the product cost are not influenced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

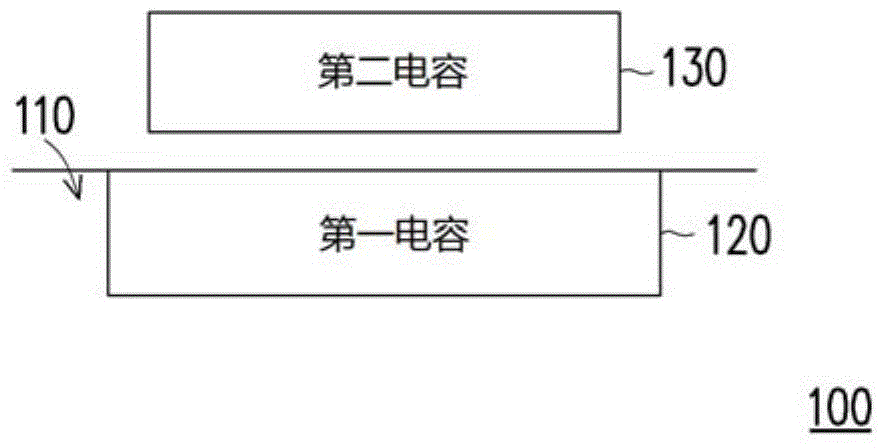

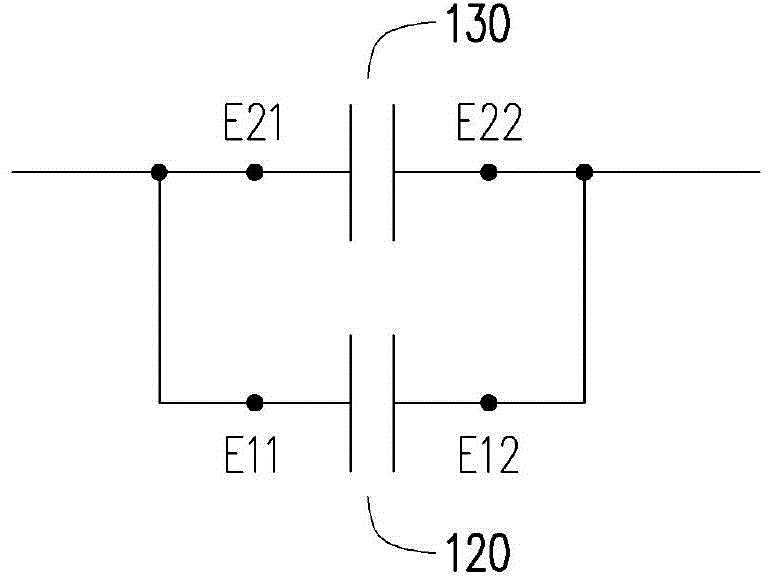

Capacitor for integrated circuits

InactiveCN104617091AIncrease capacitanceDoes not affect costSolid-state devicesSemiconductor devicesCapacitanceEngineering

The invention provides a capacitor for integrated circuits, comprising a base layer, a first capacitor, and a second capacitor. The first capacitor is configured in the base layer. The second capacitor is configured on the first capacitor, and at least partially covers the first capacitor. A first electrode of the first capacitor is coupled to a first electrode of the second capacitor, and a second electrode of the first capacitor is coupled to a second electrode of the second capacitor.

Owner:WINBOND ELECTRONICS CORP

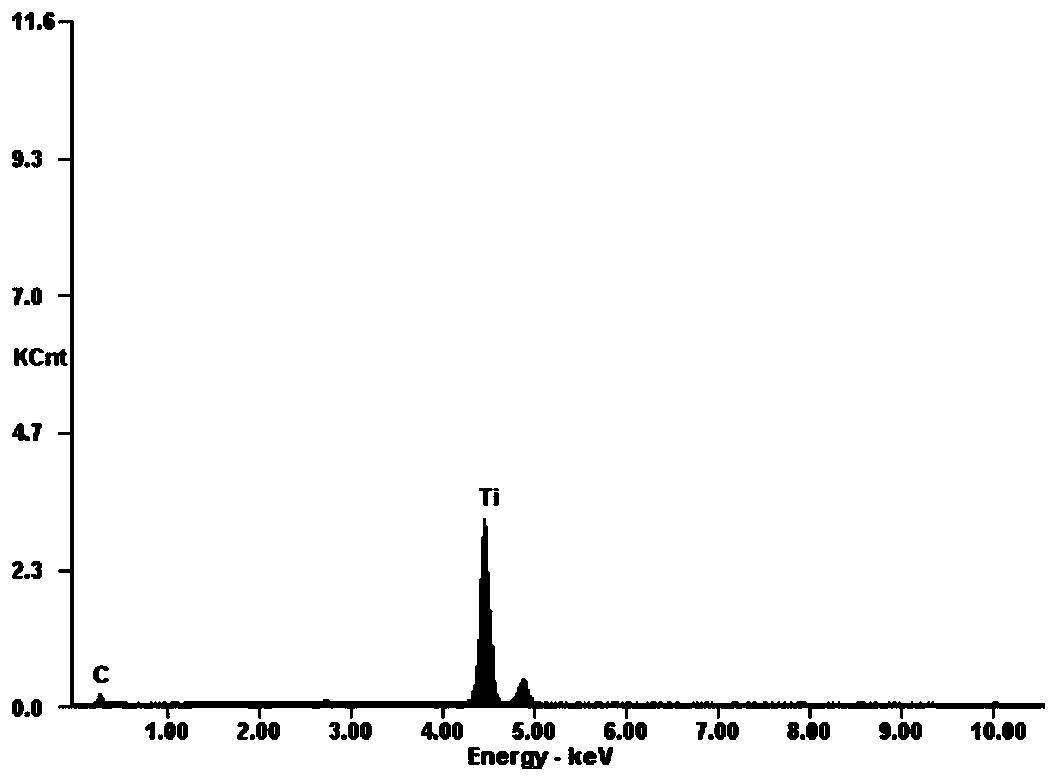

A preparation method of carburizing strengthened biomimetic structure based on pulsed arc

ActiveCN109097724BImprove wear resistanceHigh hardnessSolid state diffusion coatingMolten bathAlloy substrate

The invention discloses a preparation method of a carburization-reinforced bionic structure based on pulsed arcs. According to the preparation method, a graphite electrode is adopted as the anode, a pulsed power supply is utilized to generate the pulsed arcs, arc reinforcing is conducted on the surface of an alloy substrate, and an anode carbon source leaves from the surface of the electrode at ahigh speed and at the high temperature along the arcs and meanwhile impacts the surface of the substrate in an orientated mode along a flow field formed by the arcs; and the substrate forms small molten baths under the effect of the arcs, thus carbon enters the substrate to complete carburization, the circular pit-shaped pulsed molten baths are left, and the multiple molten baths are overlaid to form a scale-like bionic structure. According to the preparation method, the microstructure and residual stress of a reinforced bionic area are comprehensively adjusted and controlled, surface carburization is conducted to improve hardness, through the scale-like bionic structure, the contact face is reduced, friction resistance is lowered, the anti-abrasion property of a material can be improved remarkably through combination of surface carburization and the scale-like bionic structure, and particularly, as for application to the abrasive particle abrasion environment, the service life can beprolonged well.

Owner:HUAZHONG AGRI UNIV

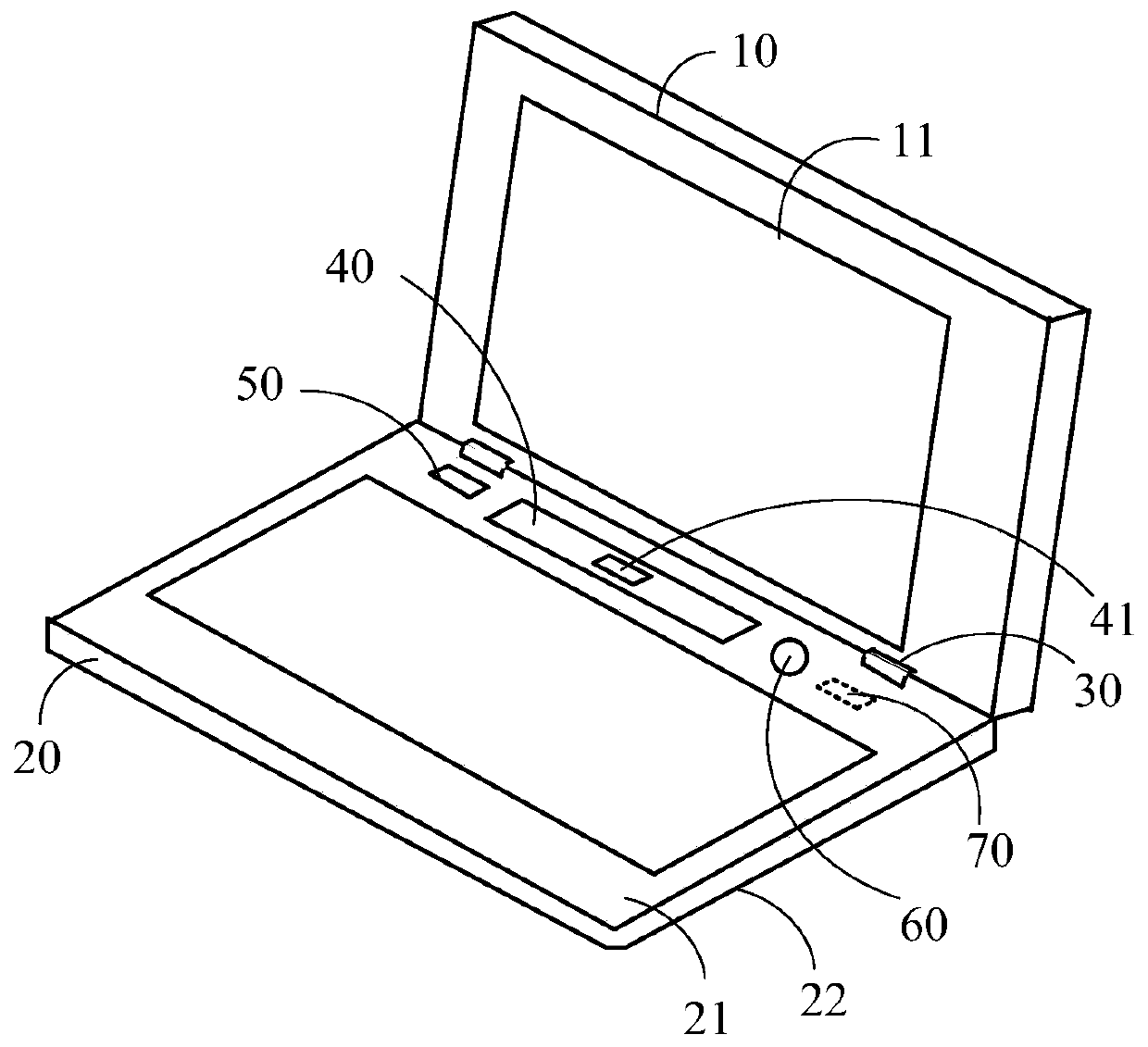

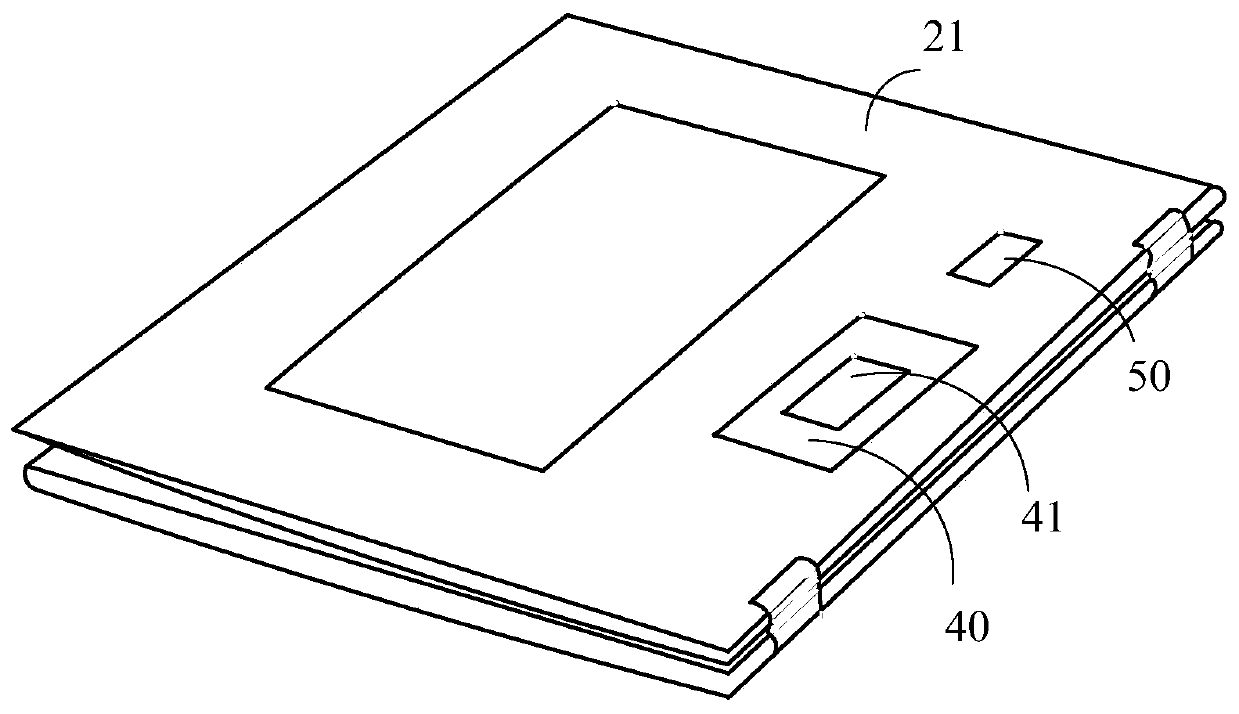

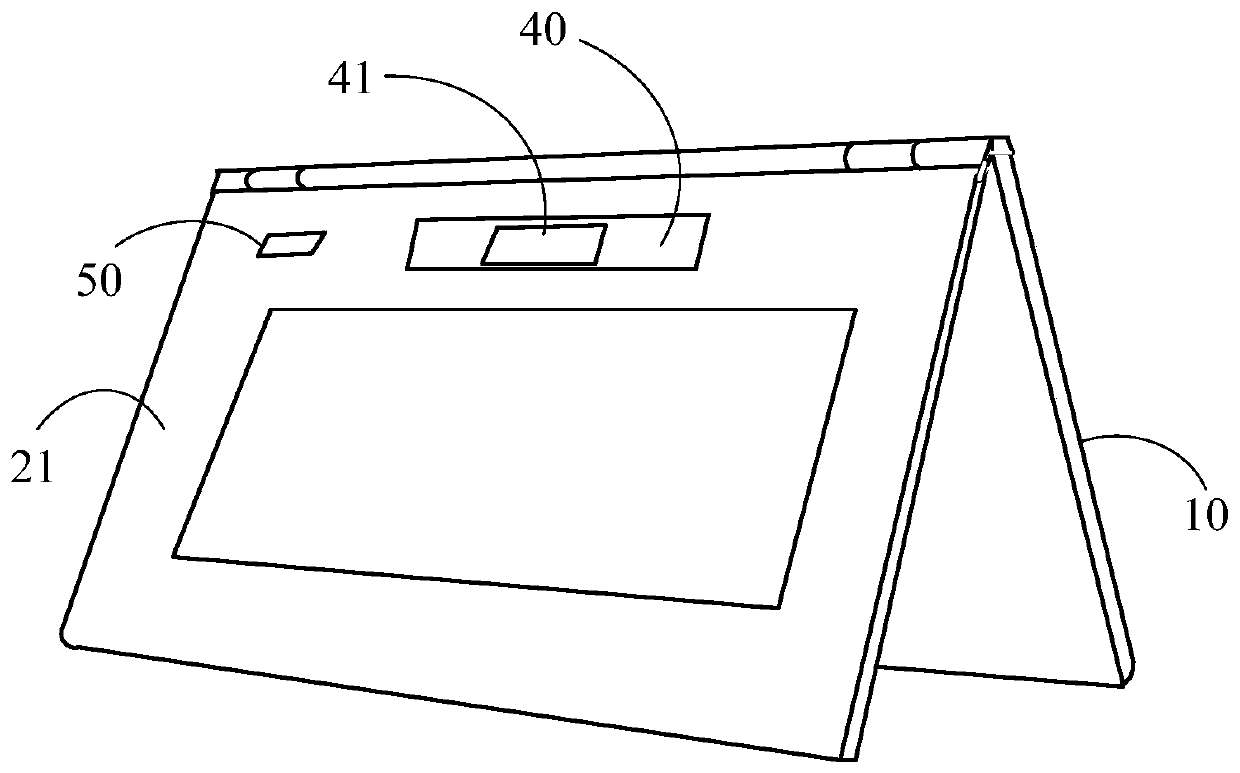

an electronic device

ActiveCN105353829BDoes not affect costEfficient use ofDigital data processing detailsCamera module3d camera

The invention discloses an electronic device. The electronic device comprises a first body, a second body, a connecting piece and a camera module, wherein the first body is provided with a first display unit; the second body comprises a first surface and a second surface opposite to the first surface, and at least one key is arranged on the first surface; the connecting piece is used for connecting the first body with the second body to ensure that the first body and the second body can rotate around the connecting piece; and the camera module is arranged on a surface region, between the at least one key and the connecting piece, of the first surface, and the camera module comprises at least one camera unit. According to the electronic device, the technical problems that the thickness of a display unit and the product cost need to be increased when a 3D camera is arranged on the frame of the display unit for an electronic device in the prior art are solved, so that the technical effect of mounting the 3D camera on the premise of not influencing the thickness and cost of a device body is achieved.

Owner:LENOVO (BEIJING) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com