Toughened regenerated modified granule manufactured through polyolefin of waste medical plastic transfusion container

A technology of toughening modification and infusion container, which is applied in the resource recycling of medical waste plastics and waste resource recycling. It can solve the problems of performance impact of modified materials, high production cost, and high price, so as to improve the impact strength. , easy to process, and realize the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

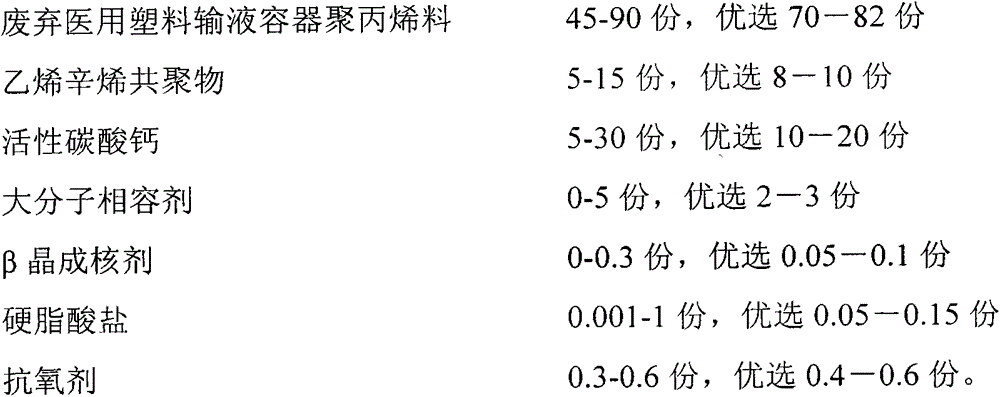

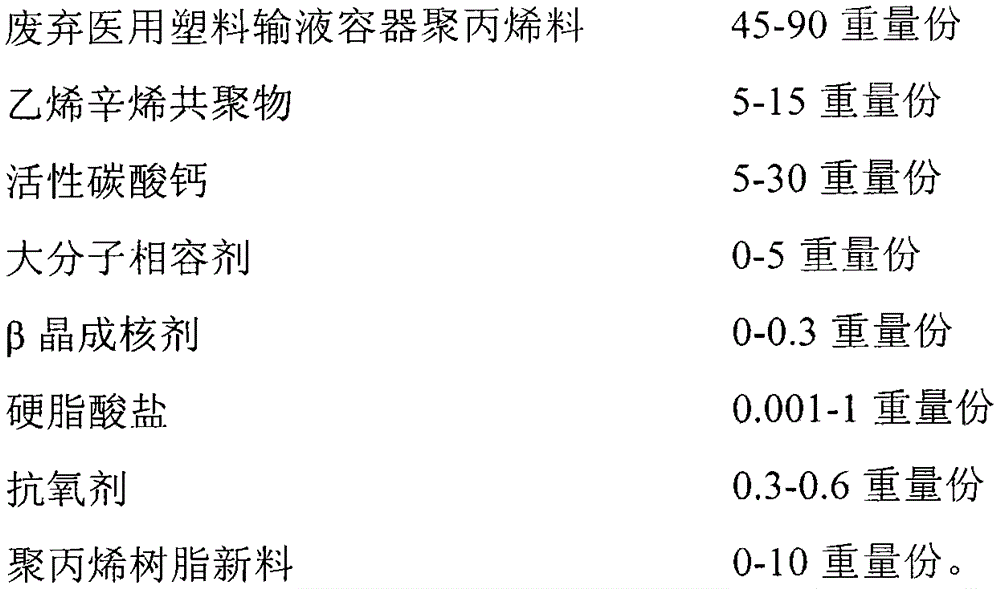

Method used

Image

Examples

Embodiment 1

[0029] (1) 75 parts by weight of discarded medical plastic infusion container polypropylene material, 15 parts by weight of ethylene octene copolymer (ENGAGE8150 Dow Plastics), 10 parts by weight of active calcium carbonate (5 microns in particle size), 0.1 part by weight of stearic acid Calcium (purchased from Gaomi Dongfang Chemical Co., Ltd.), 3 parts by weight of POE-g-MAH (CMG5805, Nantong Rizhisheng Molecular New Material Technology Co., Ltd.), 0.1 parts by weight of antioxidant 1010 (purchased from Tixiai ( Shanghai) Chemical Industry Development Co., Ltd.) and 0.2 parts by weight of antioxidant 168 (purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd.) etc. are placed in the mixer, the speed of the mixer is 30rpm, high-speed mixing 3min;

[0030] (2) Put the mixture in step (1) into a twin-screw extruder at an extrusion temperature of 180-230° C., a screw rotation speed of 180 rpm, and a feeding speed of 40 rpm for melt mixing, extrusion injection moldi...

Embodiment 2

[0034] (1) 70 parts by weight of discarded medical plastic infusion container polypropylene material, 10 parts by weight of ethylene octene copolymer (ENGAGE8150 Dow Plastics), 20 parts by weight of active calcium carbonate (5 microns in particle size), 0.2 parts by weight of stearic acid Calcium (purchased from Gaomi Dongfang Chemical Co., Ltd.), 3 parts by weight of POE-g-MAH (CMG5805, Nantong Rizhisheng Molecular New Material Technology Co., Ltd.), 0.1 parts by weight of antioxidant 1010 (purchased from Tixiai ( Shanghai) Chemical Industry Development Co., Ltd.) and 0.2 parts by weight of antioxidant 168 (purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd.) etc. were placed in a mixer.

[0035] (2) Put the neutralized mixture in step (1) into a twin-screw extruder at an extrusion temperature of 180-230° C., a screw speed of 180 rpm, and a feeding speed of 40 rpm for melt mixing, extrusion, injection molding, cutting and granulation.

[0036] Measure the te...

Embodiment 3

[0038](1) 70 parts by weight of discarded medical plastic infusion container polypropylene material, 10 parts by weight of ethylene octene copolymer (ENGAGE8150 Dow Plastics), 20 parts by weight of active calcium carbonate with a particle diameter of 5 microns, 0.2 parts by weight of calcium stearate (purchased from Gaomi Dongfang Chemical Co., Ltd.), 3 parts by weight POE-g-MAH (CMG5805, Nantong Sunrise Molecular New Material Technology Co., Ltd.), 0.1 parts by weight β-crystal rare earth nucleating agent WBG-2 (purchased From Guangdong Weilinna Materials Co., Ltd.), 0.1 parts by weight of antioxidant 1010 (purchased from Ticiai (Shanghai) Chemical Industry Development Co., Ltd.) and 0.2 parts by weight of antioxidant 168 (purchased from Ticiai (Shanghai) Chemical Industry Development Co., Ltd.) Industrial Development Co., Ltd.) etc. are placed in a mixer, the speed of the mixer is 30rpm, and the mixture is mixed at a high speed for 3min.

[0039] (2) Put the mixture in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com