Method for determining short-circuit position of parallel-wound wires of transformer coil

A technology for transformer coils and determination methods, which is applied to instruments, measuring devices, measuring electrical variables, etc., can solve problems such as hidden dangers, carbonization, coil damage, etc., to simplify the work process and time, reduce material costs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] The method for determining the short-circuit position of transformer coils and wires includes the following steps:

[0017] 1) Measure the resistance value RH of the normal wire;

[0018] 2) According to the resistance value of the normal wire, compare the multiple parallel wires in the coil to find the short-circuit wire;

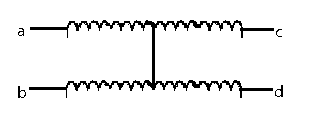

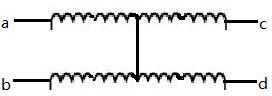

[0019] 3) Use a DC resistance tester to measure the resistance of the short-circuit wire, and connect the first ends of the two short-circuit wires to the DC resistance tester to measure the resistance value Rab of the front section of the wire;

[0020] 4) The resistance value Rab of the front section of the wire is subtracted from the resistance value RB of the wire measured by the DC resistance tester and compared with the resistance value RH of the normal wire to obtain the position of the short-circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com