Solar cell

A solar cell and electrode technology, applied in the field of solar cells, can solve problems such as thermal mismatch, lattice mismatch between gallium nitride epitaxial layer and silicon substrate, etc., achieve high absorption rate, reduce process cost and equipment depreciation cost, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

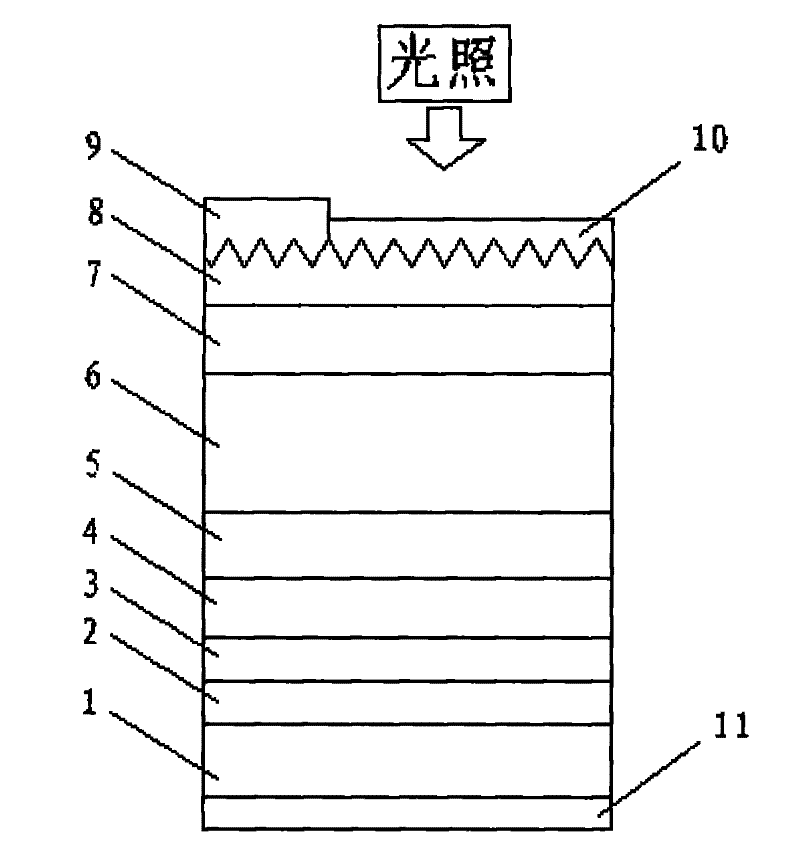

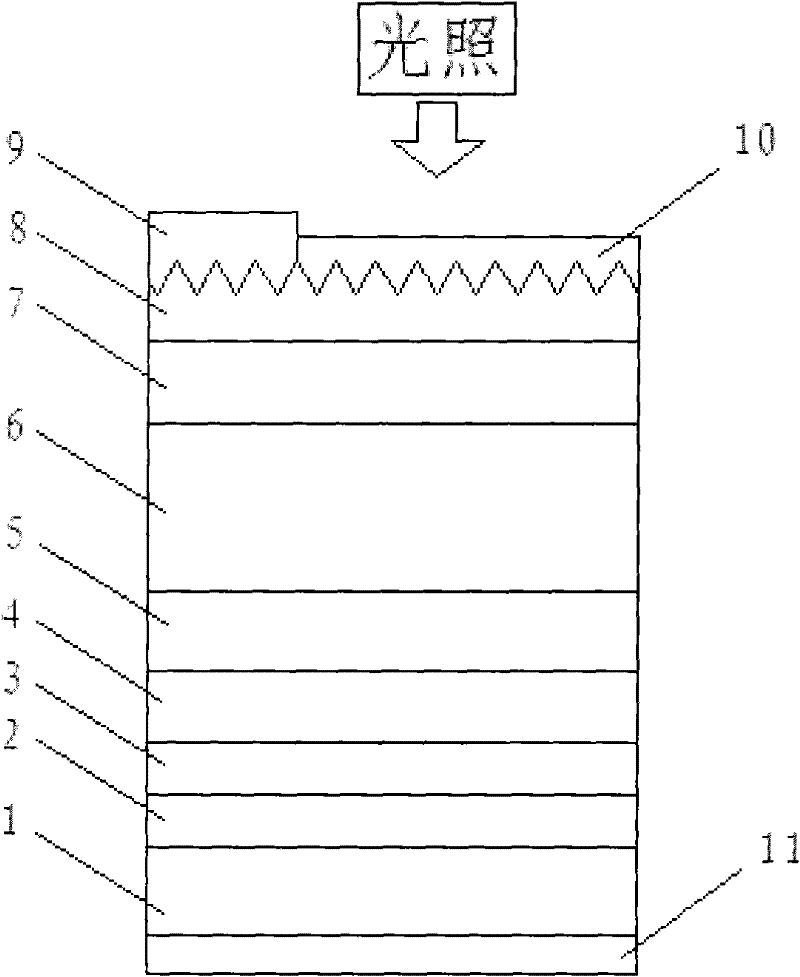

[0019] Embodiment 1: a silicon-based single-junction indium gallium nitride (InGaN) solar cell.

[0020] The structure of the solar cell is as figure 1 As shown: an n-type doped silicon substrate 1 is provided, and a layer of zinc oxide seed crystal layer 2 is formed on the silicon substrate. A zinc oxide nano-array buffer layer 3 is provided, which is fabricated on the zinc oxide seed crystal layer 2 . A layer of n-type doped gallium nitride buffer layer 4 is provided on the zinc oxide nano-array buffer layer 3 . With a layer of n-type doped In a Ga 1-a The N layer is made on the n-type doped gallium nitride buffer layer 3 . With a layer of unintentionally doped In b Ga 1-b N-layer 6, which is fabricated on n-type doped In a Ga 1-a N layer 5 above. with a layer of p-doped In c Ga 1-c N-layer 7, which is fabricated on unintentionally doped In b Ga 1-b N layer above. There is a layer of p-type heavily doped GaN window layer 8, which is fabricated on p-type doped I...

Embodiment 2

[0032] Example 2: Preparation of a silicon-based single-junction indium gallium nitride (InGaN) solar cell.

[0033] The preparation of the solar cell adopts the method comprising the following steps:

[0034] Step 1: Select an n-type doped silicon substrate 1, and obtain an n-type doped silicon wafer by doping phosphorus impurities;

[0035] Step 2: sputtering a 0.01-0.1 μm thick zinc oxide seed layer 2 on the surface of the silicon substrate, and then growing an aligned zinc oxide nano-array buffer layer 3 on the surface of the silicon wafer by wet chemical method, hydrothermal method or other methods , with a thickness of 0.2-2.5 μm.

[0036] Step 3: growing a silicon-doped n-type gallium nitride buffer layer 4 on the zinc oxide nano-array buffer layer 3 by using metal organic chemical vapor deposition technology. The growth temperature is 1000-1150°C, the growth pressure is 50-500torr, the thickness is 0.5-3μm, and the electron concentration is 1E16-1E19 / cm 3 ;

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com