Method for recycling polyhydric alcohol by degrading thermal-insulation polyurethane foam materials for buildings

A polyurethane foam and thermal insulation material technology, applied in the chemical industry, can solve problems such as high requirements for reaction conditions and equipment, restrictions on the popularization and application of phosphorus degradation methods, and complex composition of decomposition products, and achieve low cost, protection of waste disposal problems, and foam performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

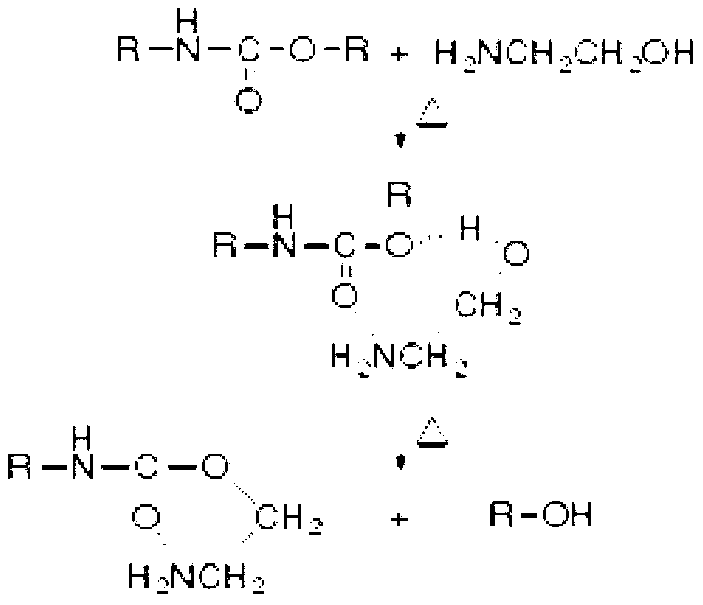

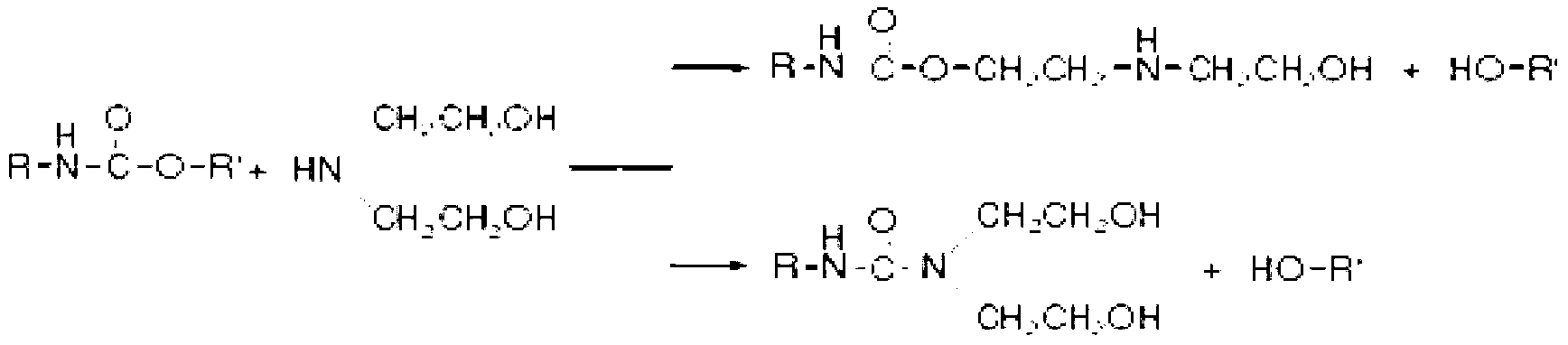

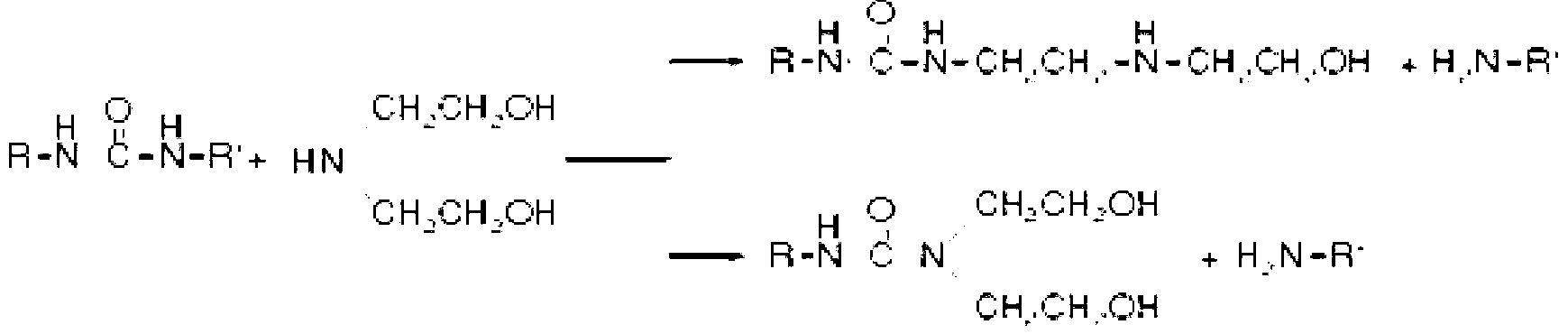

Method used

Image

Examples

Embodiment 1

[0025] A kind of method of producing recycled polyols and reproducing foaming of a kind of building insulation polyurethane foam material waste material of the present embodiment, comprises the following steps:

[0026] 1. Add diethylene glycol, monoethanolamine, calcium chloride, and BHT into the reactor, heat up until the liquid temperature in the reactor reaches 170°C, and then add waste materials into the reactor one by one. The number of additions is 3 times, the mass ratio of the addition of insulation material waste material, diethylene glycol, monoethanolamine, calcium chloride, and BHT five is 100:50:12:0.3:2, heating and stirring to heat up, and the reaction temperature is controlled at 210°C, react for 3 hours, filter out unreacted solid impurities, cool, and the obtained liquid is polyol;

[0027] The above method was used to obtain a polyhydric alcohol with a hydroxyl value of 508 mgKOH / g and an acid value of 1.56 gKOH / g.

[0028] 2. Use the above-mentioned degra...

Embodiment 2

[0030] A kind of method of producing recycled polyols and reproducing foaming of a kind of building insulation polyurethane foam material waste material of the present embodiment, comprises the following steps:

[0031] 1. Add dipropylene glycol, triethanolamine, zinc acetate, and BHA into the reactor, heat up until the liquid temperature in the reactor reaches 140°C, then add waste materials into the reactor one by one, the number of additions is 10 times, The amount of insulation material waste added, the mass ratio of dipropylene glycol, triethanolamine, zinc acetate, and BHA is 100:150:10:0.5:0.5, heating and stirring to raise the temperature, and the reaction temperature is controlled at 175 ° C. React for 5 hours and filter Unreacted solid impurities are removed, cooled, and the obtained liquid is polyol;

[0032] The above method was used to obtain a polyhydric alcohol with a hydroxyl value of 498 mgKOH / g and an acid value of 1.29 gKOH / g.

[0033] 2. Replace 50% of pol...

Embodiment 3

[0035] A kind of method of producing recycled polyols and reproducing foaming of a kind of building insulation polyurethane foam material waste material of the present embodiment, comprises the following steps:

[0036] 1. Add propylene glycol, diethylene glycol, sodium hydroxide, and TBHQ into the reactor, heat up until the liquid temperature in the reactor reaches 150°C, then add waste materials into the reactor one by one, the number of additions is 5 times, The amount of insulation material waste added, the mass ratio of propylene glycol, diethylene glycol, sodium hydroxide, and TBHQ is 100:100:2.5:0.2:1, heating and stirring to raise the temperature, the reaction temperature is controlled at 160 ° C, and the reaction is 8 hours. Filter out unreacted solid impurities, cool, and the obtained liquid is polyol;

[0037] The above method was used to obtain a polyhydric alcohol with a hydroxyl value of 482 mgKOH / g and an acid value of 0.98 gKOH / g.

[0038] 2. Use the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com