Colored flexible face brick for internal wall and external wall decoration

A technology for flexible finishing, interior and exterior walls, applied in the field of building decoration materials, can solve the problems of whitening, high price, poor water resistance, etc., and achieve the effect of prolonging service life, improving flexibility, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

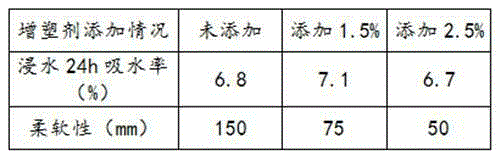

Image

Examples

Embodiment 1

[0018] 1. Formula

[0019] Pure acrylic emulsion 12%

[0020] Silane emulsion water repellent 0.5%

[0021] Curing agent 1%

[0022] (WANNATE of Wanhua Chemical Group MDI-50)

[0023] Aluminum oxide 5%

[0024] Tributyl Citrate 1.8%

[0025] 2,4-Dihydroxybenzophenone 1.2%

[0026] Hydroxyethyl Cellulose 0.25%

[0027] Fineness 120-40 mesh colored quartz sand 65.25%

[0028] Polydimethylsiloxane Dispersion 1%

[0029] water 12%

[0030] 2. Preparation

[0031] Weigh raw materials according to the above ratio, stir in a mixer for 15 minutes until uniform, spread the material on a molding machine, cut and dry in an oven at 85°C for 4 hours.

[0032] 3. Performance test

[0033] According to the JG / T 311-2011 "Flexible Decorative Brick" standard, the performance of the above products was tested, and the results are as follows:

[0034] water absorption flexibility Alkali resistance Temperature denaturation Artificial aging resistance 1000h Combus...

Embodiment 2

[0036] 1. Formula

[0037] Silicone acrylic emulsion 13%

[0038] Silane emulsion water repellent 0.7%

[0039] Curing agent 1%

[0040] (WANNATE of Wanhua Chemical Group HT-100)

[0042] Phthalic acid 1.5%

[0043] 2-Hydroxy-4-n-octyloxybenzophenone 1.5%

[0044] Polyurethane thickener 0.4%

[0045] Fineness 120-40 mesh colored quartz sand 63.1%

[0046] Dimethicone dispersion 0.8%

[0047] water 13%

[0048] 2. Preparation

[0049] Weigh raw materials according to the above ratio, stir in a mixer for 15 minutes until uniform, spread the material on a molding machine, cut and dry in an oven at 90°C for 4 hours.

[0050] 3. Performance test

[0051] According to the JG / T 311-2011 "Flexible Decorative Brick" standard, the performance of the above products was tested, and the results are as follows:

[0052] water absorption flexibility Alkali resistance Temperature denaturation Artificial aging resistance 1000h C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com