Connection device for use with a blast-resistant container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

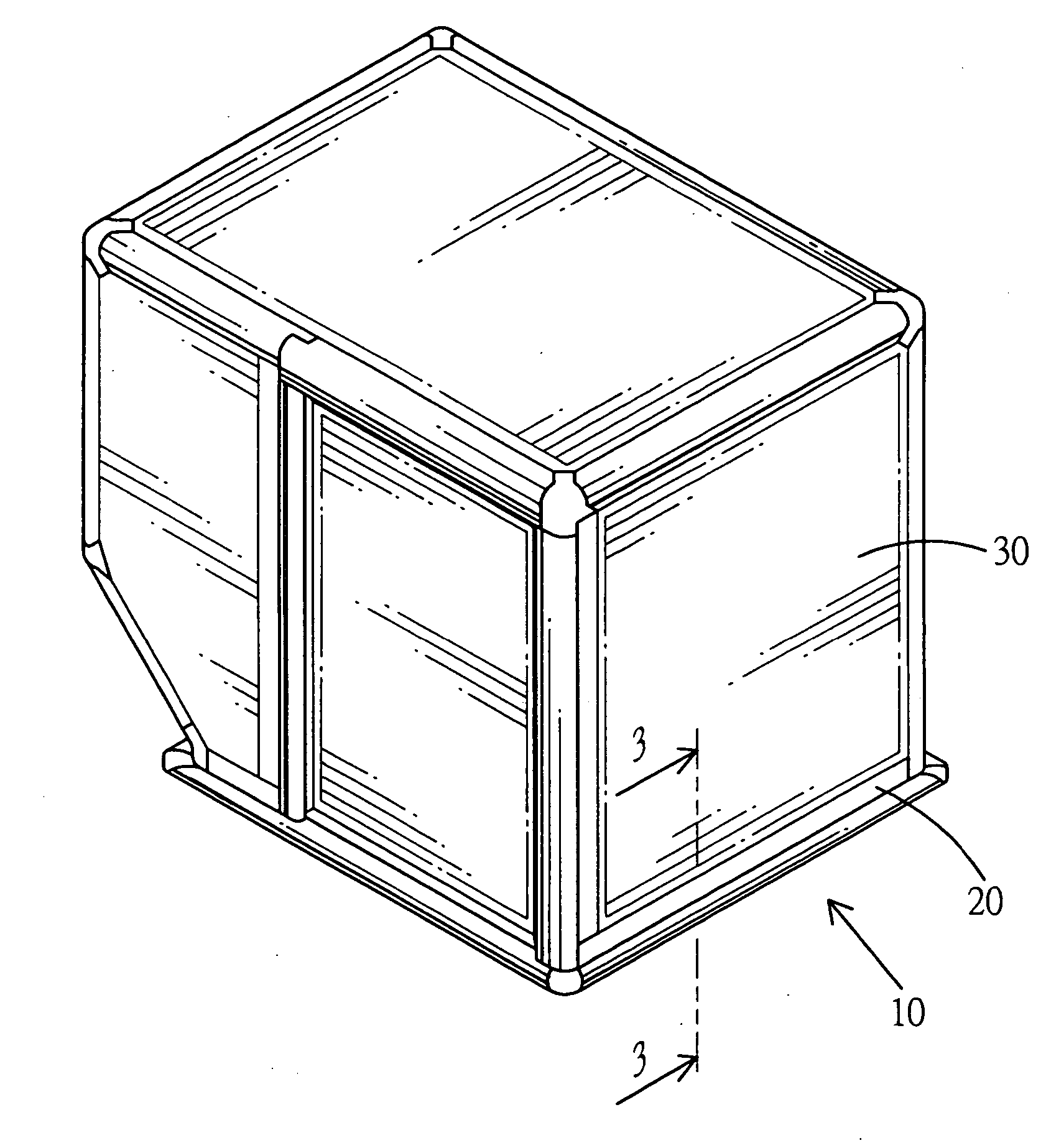

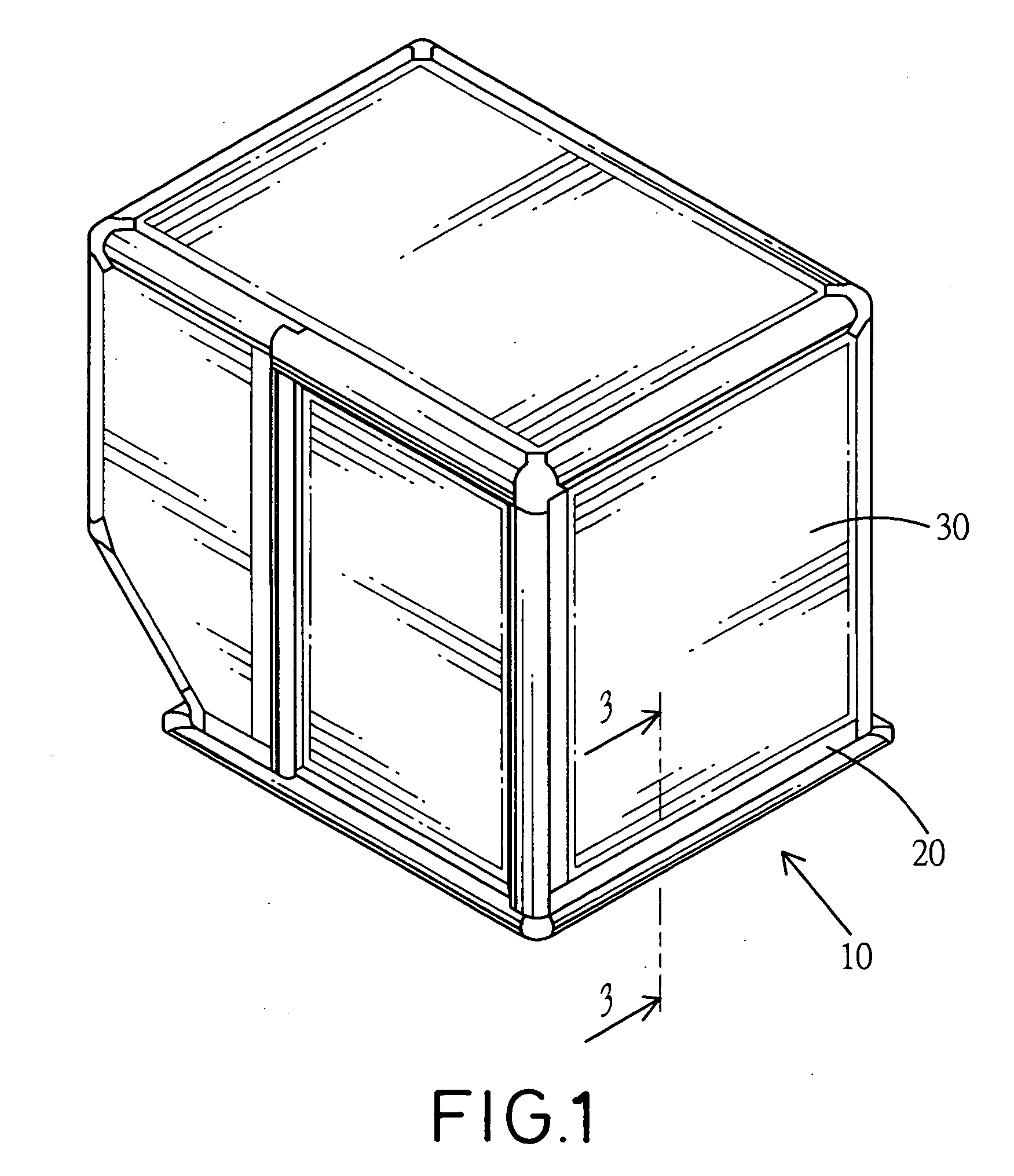

[0026] With reference to FIG. 1, an air cargo blast-resistant container includes bottom perimeter frames (10) formed on a peripheral edge of a bottom panel (not shown) of the blast-resistant container. The bottom perimeter frames (10) are used to connect the bottom panel to side panels (30). Each of the side panels (30) has a connecting member (20) formed on a lower portion of the side panel (30) to connect with the bottom perimeter frame (10).

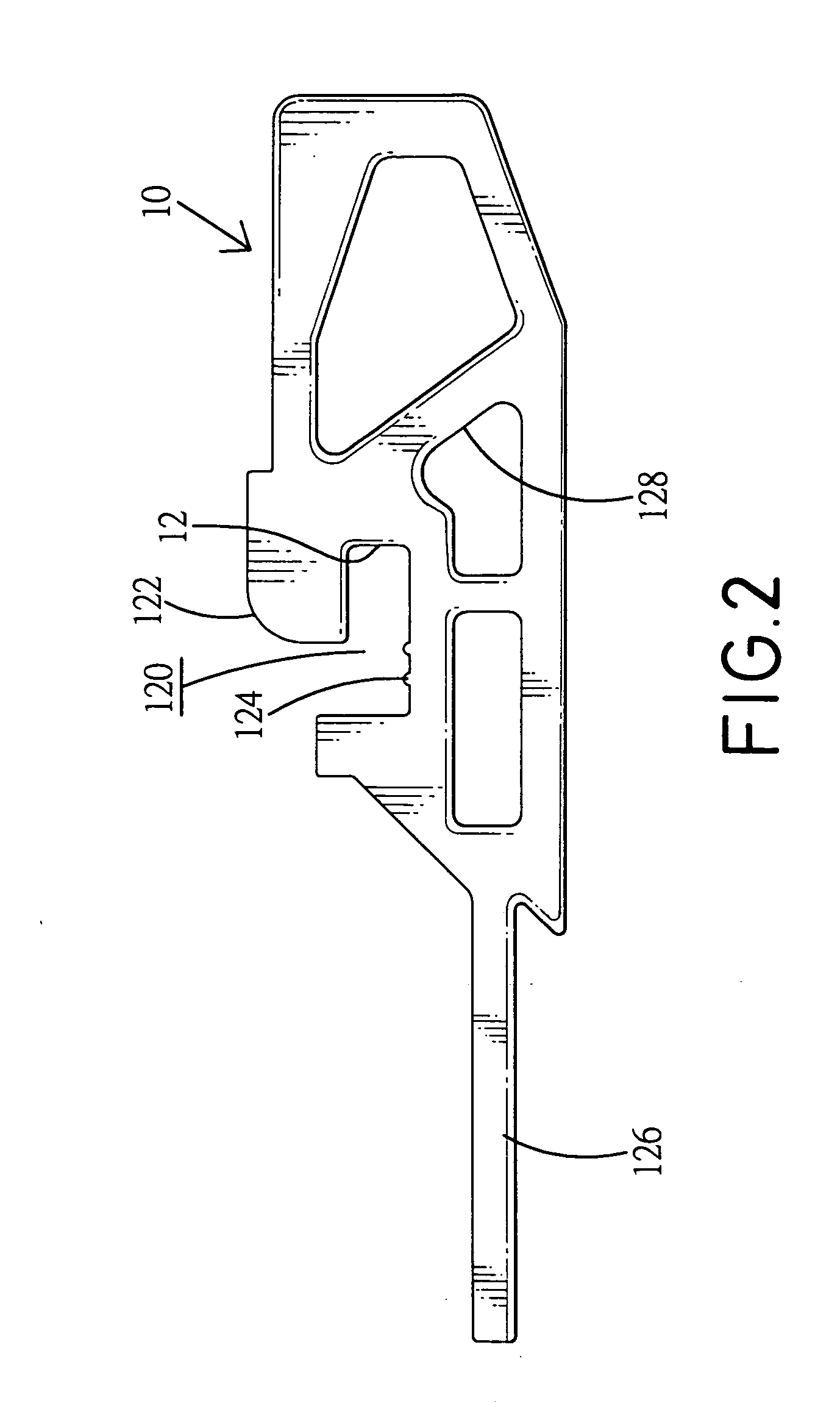

[0027] With reference to FIGS. 2 and 2A, the bottom perimeter frame (10) has a recess (12). An arcuate surface (122) is formed the outside of the opening (120) of the recess (12). Besides, the bottom perimeter frame (10) has an engaging portion (126) extending from a side of the bottom perimeter frame (10) to connect with the bottom panel of the blast-resistant container. In order to keep the same stiffness and reduce the weight of the connection device, multiple reinforced ribs (128) are formed inside the bottom perimeter frame (10) instead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com